Introduction

Thermoplastic Elastomer (TPE) has become a go-to material in modern manufacturing, blending the elasticity of rubber with the processability of plastics. Yet, many manufacturers face headaches when dealing with TPE in injection molding. They often struggle to match the right TPE grade to their product needs, battle inconsistent process results, and grapple with mold designs that fail to account for TPE's unique flow and cooling behaviors. This guide dives deep into every aspect of TPE injection molding to help you navigate these challenges smoothly.

1. Material Properties of Thermoplastic Elastomer (TPE)

TPE stands out for its exceptional elasticity and flexibility, allowing it to return to its original shape after repeated deformation. For example, most TPE grades boast an elongation at break ranging from 100% to 600%, making them perfect for products like grips and seals that need to stretch and recover.

When it comes to durability, TPE offers strong tensile strength (typically 10-30 MPa) and tear resistance, with some grades enduring over 200 N/mm in tear tests—critical for industrial hoses and protective covers. Its compression set is impressively low, often below 30% after 22 hours at 70°C, ensuring long-term performance in gaskets and O-rings.

TPE's chemical resistance varies by type, but many grades stand up well to oils, water, and mild solvents, while some even resist fuels—ideal for automotive components. In terms of temperature performance, it maintains flexibility in cold conditions (low-temperature flexibility down to -40°C for certain grades) and thermal stability up to 120-150°C, depending on the formulation.

Shore hardness spans a wide range, from 30 Shore A (soft as a rubber band) to 80 Shore D (firm like hard plastic), offering versatility for diverse applications. Additionally, abrasion resistance is a strong suit, with some TPEs outperforming rubber in wear tests, and select medical-grade TPEs feature biocompatibility, meeting ISO 10993 standards for use in devices like syringe plungers.

2. Injection Molding Process for TPE

2.1 Key Process Parameters

- Melt Temperature: TPE melts at 160-230°C, with softer grades (lower Shore hardness) processing at the lower end. For example, a 50 Shore A TPE might run at 170-190°C, while a 70 Shore D grade could need 200-220°C to flow properly.

- Injection Speed and Pressure: A moderate injection speed (30-60 mm/s) works best to avoid shear heating, which can degrade TPE. Injection pressure typically ranges from 500-1200 bar, with complex parts requiring higher pressures to fill thin sections.

- Cooling Time and Cycle Time: Cooling time is shorter than for rigid plastics, usually 5-30 seconds, thanks to TPE's lower thermal conductivity. Total cycle times often fall between 15-60 seconds, making it efficient for high-volume production.

2.2 Material Handling Essentials

TPEs absorb moisture, so drying requirements are crucial—aim for less than 0.05% moisture content. Dry at 60-80°C for 2-4 hours, depending on the grade. Poor drying leads to voids and surface defects. Also, maintain humidity control (below 50% RH) in storage areas to prevent reabsorption.

3. Mold Design for TPE Molding

3.1 Critical Design Features

- Venting Requirements: TPE's low viscosity demands proper venting to release trapped air. Vents should be 0.01-0.02 mm deep and 5-10 mm wide, placed at the end of flow paths and around sharp corners.

- Cooling Channel Layout: Even cooling prevents warpage. Position channels 8-12 mm from the cavity surface, with a 1:1.5 ratio of channel diameter to distance from the cavity. Use turbulent flow (Reynolds number >4000) for better heat transfer.

- Draft Angles and Surface Finish: A minimum draft angle of 1° per side ensures easy ejection, increasing to 2° for textured surfaces. A polished surface (Ra 0.8 μm or better) reduces sticking and improves part appearance.

3.2 Mold Materials and Systems

P20 steel is standard for TPE molds, offering good machinability and durability. For high-volume runs, H13 steel with a chrome plating (0.001-0.002 mm thick) enhances wear resistance. Hot runner systems are effective for TPE, as they reduce material waste and improve consistency—use valve gates for better control over flow.

4. Quality Control and Defects in TPE Molding

4.1 Common Defects and Solutions

| Defect | Cause | Solution |

| Warpage | Uneven cooling or uneven wall thickness | Optimize cooling channels; design uniform walls (max 2:1 thickness ratio) |

| Sink Marks | Excessive shrinkage in thick sections | Increase packing pressure; add fillets to thick areas |

| Flash | Mold mismatch or low clamping force | Check mold alignment; increase clamp force by 10-15% |

| Voids | Moisture in material or poor venting | Improve drying; add more vents |

4.2 Quality Control Measures

Implement statistical process control (SPC) to monitor key parameters like melt temperature and injection pressure, keeping variations within ±5%. Conduct mechanical property testing (tensile, hardness) on 1 in 500 parts. Use dimensional inspection with CMMs to ensure tolerances (typically ±0.1 mm for small parts).

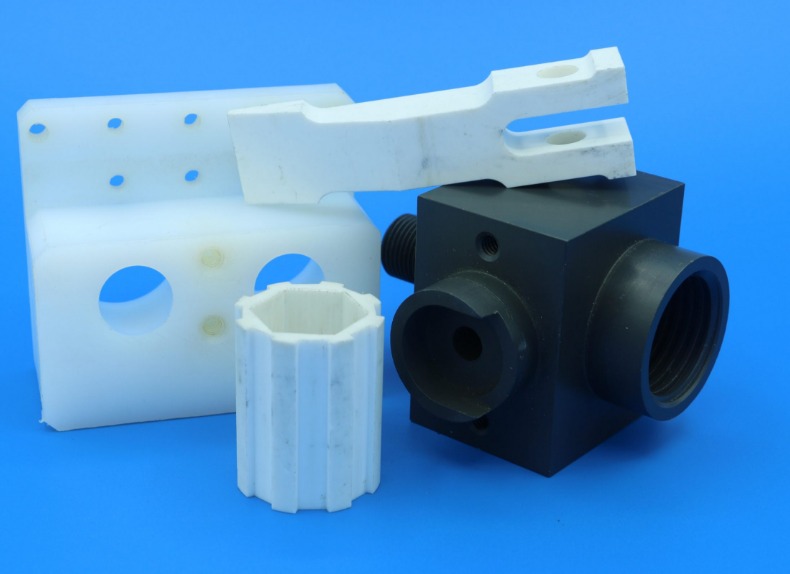

5. Applications of TPE in Injection Molding

5.1 Key Industry Uses

- Automotive Components: Door seals, grommets, and steering wheel covers benefit from TPE's weatherability and chemical resistance.

- Medical Devices: IV connectors and catheter tips use biocompatible TPE for safe, flexible performance.

- Consumer Products: Toothbrush handles, phone cases, and toy parts leverage TPE's soft touch and durability.

- Footwear: Shoe soles and insoles use TPE for cushioning and slip resistance, with Shore hardnesses between 60-80 Shore A.

6. Post-Processing and Finishing of TPE Parts

6.1 Effective Techniques

- Ultrasonic Welding: Joins TPE parts quickly (0.5-2 seconds) with minimal heat, ideal for medical devices. Use 20-40 kHz frequencies.

- Painting and Coating: Clean surfaces with isopropyl alcohol before painting. Use acrylic or urethane paints for good adhesion.

- Machining: Trim flash with sharp blades (HSS or carbide) at low speeds (1000-2000 RPM) to avoid melting.

Yigu Technology, a leading custom manufacturing supplier in China, excels in TPE injection molding. With expertise in material selection, mold design, and process optimization, we deliver high-quality TPE parts for automotive, medical, and consumer industries. Our strict quality control ensures consistency, and we offer tailored solutions to meet unique application needs—partner with us for reliable TPE manufacturing.

FAQs

- How does TPE differ from TPU in injection molding?

TPE has broader hardness ranges and better low-temperature flexibility, while TPU offers higher abrasion resistance and tensile strength. TPE is often easier to process with lower melt temperatures.

- Can TPE be overmolded onto other plastics?

Yes, TPE bonds well to PP, PE, and ABS. Ensure proper mold temperature (40-60°C) and select compatible TPE grades for strong adhesion.

- What causes TPE parts to have a sticky surface?

Overheating during processing or using low-quality TPE with excess plasticizers. Lower melt temperature by 10-15°C and choose high-purity TPE grades to prevent stickiness.