High-tech injection molding integrates advanced machinery, precision mold engineering, specialty polymers, and intelligent automation to produce complex, high-performance plastic parts with unparalleled consistency, speed, and efficiency.

When your project demands more than a simple plastic component—when it requires microscopic precision, exceptional material properties, or high-volume reliability—standard injection molding reaches its limits. This is where high-tech injection molding becomes essential. It’s a specialized discipline that merges cutting-edge engineering with rigorous process control to tackle the most demanding applications in medical, automotive, aerospace, and consumer electronics. This guide demystifies the core technologies that define this field. We’ll explore the advanced polymers that withstand extreme environments, the precision of electric molding machines, the innovative science behind mold design, and the role of automation in achieving near-zero defect rates. For engineers and product managers, understanding these capabilities is crucial for designing next-generation products and selecting a manufacturing partner capable of bringing them to life.

Introduction

Injection molding is ubiquitous, but not all molding is created equal. High-tech injection molding represents the pinnacle of the process, characterized by its focus on repeatable micron-level accuracy, superior material performance, and optimized production efficiency. It moves beyond simply filling a cavity with plastic to a data-driven, engineering-intensive operation. This approach is necessary when parts have thin walls, tight tolerances (±0.001 in.), or require materials like PEEK or Liquid Crystal Polymer (LCP) that process at high temperatures. It's also critical for producing parts with a Class A surface finish or for applications where consistency over millions of cycles is non-negotiable. This article will dissect the key pillars of high-tech molding: the advanced materials that enable new functionalities, the machines that provide unparalleled control, the mold technologies that ensure quality, and the automated systems that drive profitability. By the end, you'll understand not just how it works, but why it's a strategic necessity for cutting-edge products.

What exactly is “high-tech” injection molding?

High-tech injection molding is distinguished from conventional molding by its integration of specialized equipment, sophisticated engineering, and closed-loop process control to achieve exceptional results. It’s defined by several key attributes:

- Extreme Precision and Repeatability: The ability to hold tolerances under ±0.001 inches (0.025 mm) and maintain them over millions of cycles. This is achieved through machines with high positional accuracy and stable, controlled processes.

- Advanced Material Processing: Capability to handle engineering-grade and high-performance thermoplastics that require precise temperature profiles, specialized screws, and often dry-air or inert gas purging to prevent degradation.

- Intelligent, Data-Driven Process Control: Utilizing sensors within the mold and machine to monitor variables like cavity pressure and temperature in real-time. This data is used for Statistical Process Control (SPC) and closed-loop adjustments, ensuring each shot is identical to the last.

- Integrated Automation: From robotic part removal and degating to in-line vision inspection and packaging, automation is not an add-on but a core component of the production cell, ensuring consistency and reducing human error.

A classic example is the manufacture of a microfluidic “lab-on-a-chip” device for medical diagnostics. The part may feature channels thinner than a human hair, requiring tolerances measured in microns. A high-tech molder would use an all-electric micro-molding machine, a mold with precision temperature control to within ±0.5°C, and likely an in-mold sensor to verify complete filling of the sub-millimeter features on every shot.

Which advanced polymers deliver peak performance?

The heart of many high-tech applications is the polymer itself. These are not commodity plastics like PP or ABS; they are materials engineered for specific, demanding properties.

| Polymer | Key Properties & Advantages | Processing Temperature | Typical High-Tech Applications |

|---|---|---|---|

| PEEK (Polyetheretherketone) | Exceptional thermal resistance (HDT ~315°C), superb chemical resistance, high mechanical strength, and biocompatibility. | 350°C - 400°C | Aerospace components, medical implants (spinal cages), semiconductor wafer carriers, high-performance seals. |

| LCP (Liquid Crystal Polymer) | Incredible flowability for thin walls, very low coefficient of thermal expansion (CTE), high dimensional stability, and good chemical resistance. | 300°C - 350°C | Miniature electrical connectors, micro-optics, surgical device components, components for extreme miniaturization. |

| PPS (Polyphenylene Sulfide) | Outstanding chemical resistance, inherent flame retardancy (UL94 V-0), excellent dimensional stability and high heat deflection temperature (~260°C). | 300°C - 330°C | Under-hood automotive sensors, electrical/electronic housings, pump components. |

| PEI (Ultem®) | High strength and stiffness at elevated temperatures, inherent flame retardancy (UL94 V-0), and high dielectric strength. Can be sterilized. | 340°C - 380°C | Medical instrument housings, aircraft interior components, high-temperature electrical insulators. |

| PFA (Perfluoroalkoxy Alkane) | The ultimate in chemical inertness and purity, excellent high-temperature performance, and low friction. A premium fluoropolymer. | 350°C - 400°C | Pharmaceutical fluid handling, semiconductor chemical delivery systems, ultra-pure labware. |

Real-World Impact: A developer of electric vehicle battery modules switched from a standard nylon to PPS for a critical busbar insulator. While the nylon part deformed under the high operating temperatures near the battery cells, the PPS insulator maintained its shape and dielectric properties, preventing potential short circuits and meeting stringent automotive safety standards, thanks to its heat deflection temperature of over 260°C.

How do electric machines outperform hydraulics?

The core of a high-tech molding cell is the injection molding machine. The shift from traditional hydraulic machines to all-electric machines is a defining feature of modern precision manufacturing.

- Precision and Repeatability: Electric servo motors control each axis (injection, clamp, ejection) independently with digital accuracy. This eliminates the variability inherent in hydraulic systems due to oil viscosity changes with temperature. Shot-to-shot repeatability is vastly superior.

- Energy Efficiency: Hydraulic machines run pumps constantly, consuming significant energy even when idle. Electric machines only consume power when performing an action, leading to energy savings of 40-70%.

- Speed and Cleanliness: Electric machines offer faster cycle times due to quicker actuation. They are also cleaner, with no risk of hydraulic oil leaks that could contaminate a cleanroom environment or the molded part—a critical factor for medical and optical applications.

- Process Control: The precise control of electric machines allows for sophisticated injection profiles (e.g., changing speed or pressure at multiple points during filling) and holding pressure profiles, which are essential for packing out complex, thin-walled parts without introducing stress or warpage.

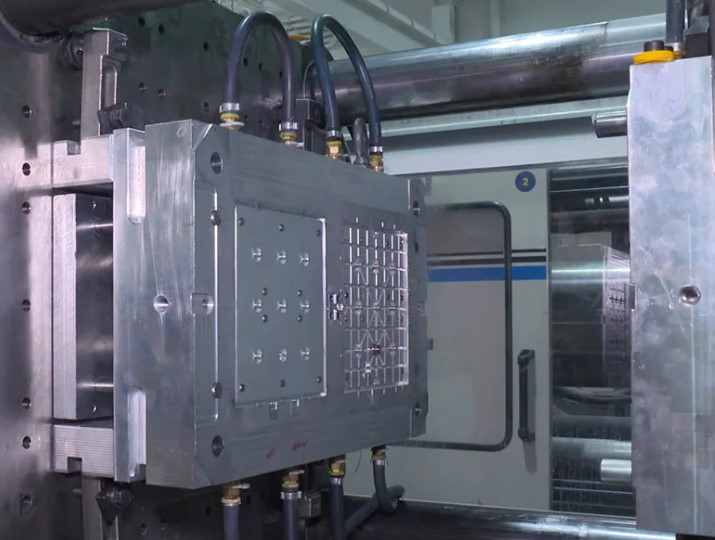

Precision mold design: hot runners, conformal cooling, venting

The mold is not just a cavity; in high-tech molding, it is a highly engineered thermal management system. Key technologies include:

- Hot Runner Systems: These keep the plastic molten inside the mold, eliminating the material waste and cycle time penalty of a cold runner system. Sequential valve-gated hot runners can control the fill pattern of a part, reducing weld lines and improving part strength. For a large automotive lens, sequential gating ensures optical clarity by preventing flow lines.

- Conformal Cooling Channels: Instead of traditional straight drilled channels, conformal channels are 3D-printed (via DMLS) to follow the exact contour of the part cavity. This allows for uniform and efficient heat extraction, reducing cycle times by up to 30% and minimizing part warpage caused by uneven cooling.

- Scientific Venting: Trapped air can cause burns, short shots, or dimensional issues. High-tech molds use precisely calculated vent depths (often just a few microns deeper than the part’s polish) and strategically placed vacuum vents to ensure air escapes without creating flash.

How can automation cut cycle time and scrap?

Automation transforms a standalone machine into a optimized production cell, directly impacting quality and cost.

- Robotic Part Handling: A robot arm can consistently remove parts and place them on a conveyor in 3-5 seconds, much faster and more reliably than a human operator. This also allows the mold to open and close faster, safely reducing the overall cycle time.

- In-Mold Quality Monitoring: Sensors can verify that all cavities have filled, that ejector pins have moved, or even measure part weight or dimensions before the part is even ejected. Any anomaly triggers an immediate machine stop, preventing the production of scrap.

- In-Line Vision Inspection: Cameras can perform 100% inspection for critical features—checking for the presence of holes, verifying dimensions, or identifying surface defects—immediately after the robot places the part. This provides real-time Statistical Process Control (SPC) data and ensures only good parts proceed to packaging.

- Automated Sprue/Runner Separation: Integrated systems can automatically degate parts (separate them from the runner) and sort scrap runner material for regrinding, streamlining the workflow and reducing labor.

A manufacturer of insulin pen components implemented a cell with a vision system that checked the diameter of a critical micro-feature on every part. This replaced a manual sampling check and caught a drifting mold dimension early, preventing a batch of 50,000 potentially non-conforming parts from being shipped, saving enormous recall costs and protecting patient safety.

Conclusion

High-tech injection molding is not merely an incremental improvement on a traditional process; it is a fundamental re-engineering of plastic part manufacturing for the 21st century. By leveraging advanced polymers like PEEK and LCP, harnessing the precision and efficiency of all-electric molding machines, engineering molds with conformal cooling and intelligent gating, and integrating robotic automation with real-time quality monitoring, manufacturers can achieve levels of performance, consistency, and efficiency that were previously impossible. For product developers, this means the ability to design more innovative, reliable, and cost-effective products. Understanding these capabilities is the first step in identifying a manufacturing partner who can truly support your vision and deliver components that meet the highest standards of quality and precision.

Frequently Asked Questions (FAQ)

Is high-tech injection molding only for very small, complex parts?

No, while it excels at micro-molding and complex geometries, the principles apply to parts of all sizes. The key differentiator is the requirement for extreme precision, superior material properties, or ultra-high volume consistency. A large automotive light lens requiring perfect optics or a medical device housing needing a flawless Class A surface are also prime candidates for high-tech molding processes.

How much more expensive is high-tech molding compared to standard molding?

The upfront costs are higher due to more expensive all-electric machines, advanced mold technologies (hot runners, conformal cooling), and engineering-intensive setup. However, the total cost of ownership over a production run is often lower. This is due to significantly less material waste (from hot runners), faster cycle times, drastically reduced scrap rates, and lower energy consumption. For critical components, the value of guaranteed quality and performance far outweighs the initial investment.

What certifications should a high-tech injection molder have?

Look for certifications that validate their quality systems and industry-specific expertise. ISO 13485 is essential for medical device manufacturing. IATF 16949 is critical for automotive. ISO 9001 is a baseline for any quality management system. Additionally, evidence of cleanroom molding capabilities (e.g., ISO Class 7 or 8) is important for medical, optical, or semiconductor parts.

Can existing part designs be converted to high-tech molding processes?

Often, yes, but they usually require a Design for Manufacturability (DfM) review and potentially modest redesign. A high-tech molder can analyze your part to recommend changes that optimize wall thickness, gate location, and material selection to fully leverage advanced molding technologies, often improving part performance and reducing cost.

Contact Yigu Technology for Custom Manufacturing.

At Yigu Technology, we specialize in high-tech injection molding solutions for the most demanding applications. Our facility is equipped with state-of-the-art all-electric injection molding machines and staffed by engineers who are experts in processing advanced engineering polymers.

We go beyond basic production. Our team partners with you from the initial design phase, providing expert DfM analysis to ensure your part is optimized for performance and manufacturability. We engineer precision molds incorporating hot runner systems and conformal cooling, and our production cells are integrated with robotic automation and in-process quality monitoring to guarantee consistency and zero defects.

If your project requires the precision, performance, and reliability that only high-tech injection molding can provide, partner with Yigu Technology. Contact us today to discuss how we can help bring your most challenging designs to life.