Introduction

In the vast landscape of modern manufacturing, Injection Moulding Machines stand as workhorses, playing a pivotal role in the production of a staggering array of plastic products. From the tiny components within our electronic devices to the large casings of household appliances, these machines are responsible for transforming raw plastic materials into precisely shaped, high - quality end - products.

The importance of Injection Moulding Machines can be gauged by the sheer volume and diversity of goods they produce. For instance, in the automotive industry, they are used to manufacture interior parts like dashboards, door panels, and various under - the - hood components. In the consumer goods sector, they churn out everything from plastic toys to kitchen utensils. In fact, according to industry reports, over 80% of all plastic products are produced using injection moulding technology, highlighting its prevalence and significance.

Understanding the working process of Injection Moulding Machines is not just an academic exercise; it is a necessity for manufacturers, engineers, and even product designers. A deep - rooted knowledge of how these machines operate enables businesses to optimize production processes, reduce waste, and improve product quality. For manufacturers, it means higher production efficiency, lower costs, and increased competitiveness in the global market. For engineers, it provides the foundation to innovate and develop more advanced and efficient moulding techniques. And for product designers, it helps in creating designs that are not only aesthetically pleasing but also manufacturable using injection moulding technology. So, let's embark on a journey to demystify the working process of these remarkable machines.

Components of Injection Moulding Machines

An Injection Moulding Machine is a complex piece of equipment, composed of several key components, each playing a crucial role in the injection moulding process. Understanding these components is fundamental to grasping how the entire machine functions.

The Hopper

The hopper is the starting point for the raw materials in an injection moulding machine. It is a storage container, usually funnel - shaped, that holds the plastic granules or pellets. Its primary function is to supply a continuous and regulated flow of these raw materials to the barrel of the machine. For example, in a high - volume production of plastic toys, the hopper ensures that there is a steady supply of coloured plastic pellets, so the production process can run smoothly without interruptions due to lack of material. A well - designed hopper can also prevent issues like bridging, where the plastic granules clump together and block the flow. This is often achieved through features such as vibrating mechanisms or special internal geometries. You can think of the hopper as the "feeding trough" of the injection moulding machine, providing the necessary "food" (plastic granules) for the manufacturing process. [Insert an image here of a typical injection moulding machine hopper to help visualize its shape and position]

The Barrel and Screw

The barrel and screw are at the heart of the plastic - melting and plasticizing process. The barrel is a long, hollow cylinder where the magic of transforming solid plastic granules into a molten, workable state takes place. It is equipped with heating elements, usually in the form of electrical heating bands, which gradually raise the temperature of the plastic as it moves along the barrel.

The screw, on the other hand, is a helical - shaped rod that rotates inside the barrel. As it turns, it performs multiple functions. Firstly, it conveys the plastic granules from the hopper end towards the nozzle end of the barrel. During this movement, the plastic is compressed and sheared between the screw flights and the barrel wall. This mechanical action, combined with the heat from the barrel, causes the plastic to melt and become a homogeneous, viscous fluid. Different types of screws are designed for different plastics and applications. For instance, a general - purpose screw might be suitable for common plastics like polyethylene (PE) and polypropylene (PP). However, for high - viscosity plastics such as some engineering plastics like polycarbonate (PC), a screw with a special design, perhaps with a higher compression ratio or different flight geometry, is required to ensure proper melting and plasticization. In fact, the choice of screw can significantly impact the quality of the molten plastic, affecting factors such as melt temperature uniformity, shear stress, and the degree of plasticization.

The Injection Nozzle

The injection nozzle is the small but mighty component that connects the barrel to the mould. Its main task is to direct the molten plastic, which has been heated and plasticized in the barrel, into the mould cavity with precision. The design of the injection nozzle is critical as it can influence the flow rate, pressure, and distribution of the molten plastic during injection. For example, a nozzle with a small diameter can create high - pressure injection, which might be suitable for filling small and intricate mould cavities. In contrast, a larger - diameter nozzle may be used for applications where a high volume of plastic needs to be injected quickly into a larger mould cavity, like in the production of large plastic containers. Nozzles can also be equipped with features such as shut - off valves. These valves are useful in preventing the backflow of molten plastic when the injection process is paused or completed, ensuring better control over the amount of plastic injected into the mould and improving the overall quality and consistency of the final product.

The Mold

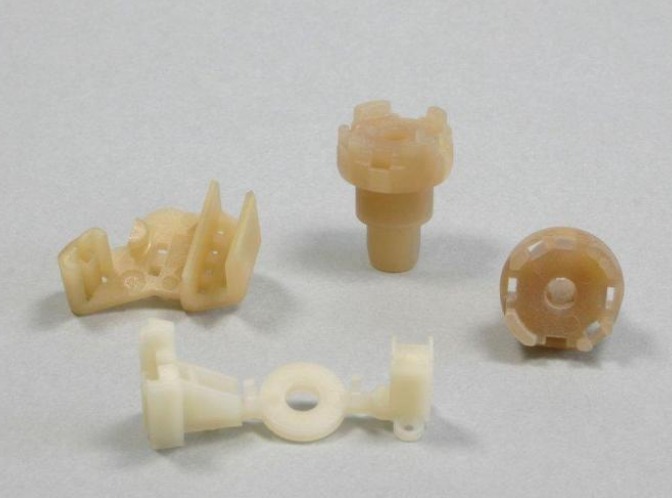

The mold is where the final shape of the plastic product is determined. It consists of two main parts: the cavity and the core. The cavity is the female part of the mold, which has a negative impression of the outer shape of the product. The core, on the other hand, is the male part that forms the inner features of the product, such as holes or recesses. When the two halves of the mold are closed, they create a cavity space that precisely matches the shape of the desired plastic product. There are various types of molds, each suitable for different products and production requirements. For example, single - cavity molds are used when only one product is produced per cycle, often for high - value or prototype products. Multi - cavity molds, as the name suggests, have multiple cavities, allowing for the production of several identical products in a single cycle. This is highly efficient for mass - production scenarios, such as the production of plastic bottle caps or small electronic components. Family molds can produce different but related products in the same cycle, which is useful for manufacturers who want to optimize production time and resources by producing a range of products on the same machine. The quality and precision of the mold directly impact the quality of the final product. A well - maintained and accurately machined mold will produce products with tight tolerances, smooth surfaces, and consistent dimensions, while a poorly made or worn - out mold can lead to defects such as flash (excess plastic around the edges), warping, or inaccurate shapes.

The Working Process Step - by - Step

Now that we have a clear understanding of the components, let's delve into the step - by - step working process of injection moulding machines.

Step 1: Feeding

The process begins with the feeding stage. Plastic granules are loaded into the hopper, which is the storage unit at the top of the injection moulding machine. Gravity or sometimes with the assistance of a vibrating mechanism ensures that the granules flow smoothly down into the barrel. A metering device may be present to precisely control the amount of plastic entering the barrel. For example, in the production of small plastic parts like buttons, the metering device will ensure that a consistent amount of plastic granules is fed into the barrel for each production cycle. This precise control is crucial as it directly impacts the weight and quality consistency of the final products. If too much plastic is fed, it can lead to issues such as flash (excess plastic around the edges of the product) or over - packing of the mould cavity. On the other hand, insufficient plastic can result in incomplete products or poor - quality finishes.

Step 2: Plasticization

Once inside the barrel, the plastic granules embark on a transformation journey. The heating elements around the barrel start to raise the temperature. Simultaneously, the screw rotates. As the screw turns, it conveys the plastic granules forward, compressing and shearing them in the process. This mechanical action, combined with the heat from the barrel, causes the plastic to gradually melt. Different plastics have different melting points. For instance, polyethylene (PE) typically has a melting point in the range of 110 - 130°C, while polycarbonate (PC) melts at a much higher temperature, around 220 - 230°C. The screw's design, such as its compression ratio and flight geometry, is optimized to ensure efficient plasticization for the specific type of plastic being processed. The plasticization process must achieve a homogeneous, molten state with consistent temperature and viscosity throughout the melt. Any variations in these properties can lead to defects in the final product, such as uneven wall thickness, surface imperfections, or internal stress concentrations.

Step 3: Injection

With the plastic now in a molten, workable state, it's time for the injection phase. A high - pressure system, often driven by hydraulic or electric power, exerts force on the screw. This force pushes the molten plastic forward, through the injection nozzle, and into the closed mould cavity. The injection pressure can vary widely depending on the complexity of the mould design, the size of the product, and the type of plastic. For small, intricate parts, injection pressures can reach up to 200 - 300 MPa, while for larger, less complex products, pressures in the range of 50 - 100 MPa may be sufficient. The speed of injection also plays a crucial role. A too - fast injection can cause air entrapment in the mould cavity, resulting in voids or bubbles in the final product. Conversely, a slow injection may lead to incomplete filling of the mould, especially for parts with thin walls or long flow paths.

Step 4: Cooling and Solidification

Once the mould cavity is filled with molten plastic, the cooling and solidification stage commences. Cooling channels are integrated into the mould. A coolant, usually water or a specialized heat - transfer fluid, circulates through these channels. The coolant absorbs the heat from the molten plastic, causing it to cool down and solidify. The cooling time is a critical factor. It depends on various aspects, such as the thickness of the product, the type of plastic, and the cooling efficiency of the mould. Thicker - walled products will naturally require longer cooling times. For example, a plastic bucket with a relatively thick wall may need 30 - 60 seconds to cool and solidify properly, while a thin - walled plastic cup could cool in as little as 5 - 10 seconds. During this stage, it's essential to ensure uniform cooling across the entire product. Uneven cooling can lead to warping, where the product takes on an undesired shape due to differential shrinkage during solidification.

Step 5: Ejection

After the plastic has cooled and solidified into the desired product shape, it's time to remove it from the mould. This is achieved through the ejection system. Ejector pins, which are located in the mould, are activated. These pins push against the product, forcing it out of the mould cavity. The design of the ejection system is carefully engineered to ensure that the product is ejected smoothly without causing any damage. For products with complex geometries or undercuts (recesses that prevent straightforward ejection), additional mechanisms such as lifters or slides may be incorporated into the mould. These mechanisms help to release the product from the undercut areas before the ejection process. Once ejected, the product is either collected manually or by an automated conveyor system for further post - processing, such as trimming, finishing, or quality inspection.

Comparison of Different Injection Moulding Machine Models (with Data)

)

When it comes to choosing an injection moulding machine, understanding the differences between various models is crucial. Different models are designed to meet different production requirements, and their specifications can have a significant impact on the quality and efficiency of the manufacturing process. Here is a comparison of some common injection moulding machine models, focusing on key parameters such as clamping force, injection volume, and injection pressure.

| Model | Clamping Force (tons) | Injection Volume (cm³) | Injection Pressure (MPa) | Suitable for |

| Model A | 80 | 163 | 156 | Small - scale production of simple plastic parts like small toys, buttons |

| Model B | 120 | 221 | 138 | Medium - sized parts such as small household appliance components |

| Model C | 150 | 332 | 162 | Larger - sized components with medium complexity, like some automotive interior parts |

| Model D | 180 | 488 | 166 | Production of parts with relatively high precision requirements and medium - large size, such as computer casings |

| Model E | 220 | 499 | 182 | High - volume production of medium - sized parts with complex geometries, like some industrial equipment components |

Impact of Parameters on Production

- Clamping Force: The clamping force is the force exerted by the machine to keep the mold closed during the injection process. A higher clamping force is required for larger and more complex molds. If the clamping force is insufficient, it can lead to flash (excess plastic around the edges of the product) due to the mold not being held tightly enough during injection. For example, when producing large plastic buckets, a machine with a high clamping force (such as Model E) is necessary to ensure the mold remains closed as the molten plastic is injected under high pressure.

- Injection Volume: This parameter determines the maximum amount of molten plastic that can be injected into the mold in one cycle. It directly affects the size of the products that can be produced. A larger injection volume is suitable for manufacturing big - sized products like plastic storage boxes. If the injection volume of the machine is too small for the product, it will result in incomplete filling of the mold cavity, leading to defective products. For instance, trying to produce a large - sized plastic chair with a machine having a small injection volume (like Model A) will not work as the machine cannot supply enough plastic to fill the entire mold.

- Injection Pressure: Injection pressure is crucial for ensuring that the molten plastic can fill the mold cavity quickly and completely, especially for parts with complex geometries or long flow paths. High - pressure injection is required for intricate parts to ensure that the plastic reaches every corner of the mold. However, if the injection pressure is too high for a particular product, it can cause problems such as over - packing, which may lead to internal stress in the product, resulting in warping or cracking during cooling. For example, when producing small, detailed plastic figurines, a relatively high - pressure injection (such as that provided by Model D) is needed to accurately replicate the fine details of the mold.

Yigu Technology's View

At Yigu Technology, as a non - standard plastic metal products custom supplier, we deeply understand the significance of the working process of injection moulding machines. A clear understanding of this process is the bedrock of producing high - quality non - standard products.

When manufacturing non - standard plastic metal products, precision is of utmost importance. Knowledge of the injection moulding process allows us to fine - tune parameters such as injection pressure, temperature, and cooling time according to the unique requirements of each product. For example, when creating custom - designed plastic - metal components for a high - end electronic device, we can adjust the injection pressure precisely to ensure that the plastic adheres perfectly to the metal insert, avoiding issues like delamination.