Introduction

In the world of manufacturing, Injection Plastic Mold Makers play a pivotal role. The journey from the initial design concept to the final manufacturing of injection plastic molds is a complex yet fascinating process. It is a process that requires a high level of precision, technical expertise, and an in - depth understanding of materials and manufacturing processes.

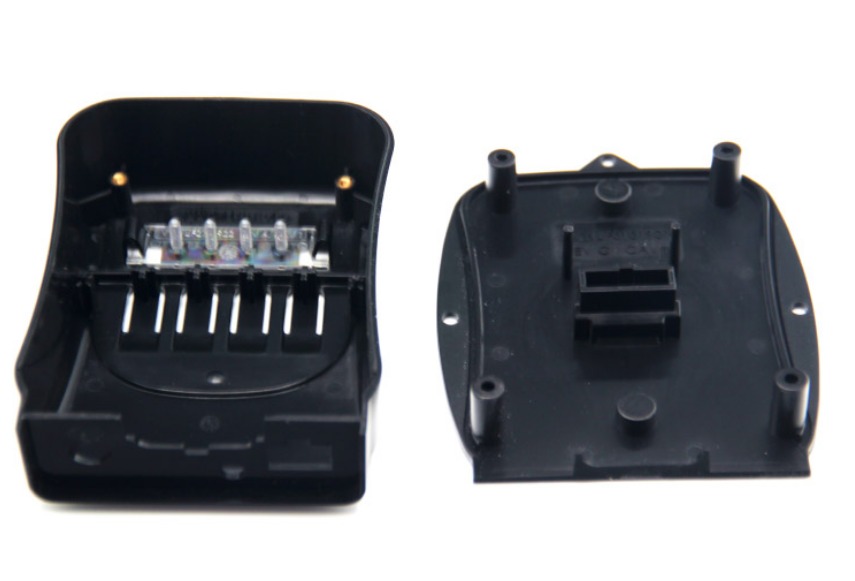

This process doesn't just involve creating a mold; it's about bringing a product idea to life. Whether it's a small, intricate component for an electronic device or a large part for an automotive application, the injection plastic mold is the key to mass - producing high - quality plastic products efficiently. By delving into the details of this journey, from design to manufacturing, we can better understand how these molds are created, the challenges faced, and the solutions implemented. This knowledge is invaluable for manufacturers looking to optimize their production processes, product designers aiming to create more manufacturable designs, and anyone interested in the world of plastic manufacturing. So, let's embark on this journey and explore the world of injection plastic mold making in detail.

The Design Phase: Laying the Foundation

Understanding the Product Requirements

Before any design work begins, a thorough understanding of the product requirements is essential. This includes aspects such as the product's function, which dictates the shape, size, and precision needed. For example, a medical device component may require extremely high precision, with tolerances in the range of ±0.01mm, while a toy part can have a relatively looser tolerance, perhaps around ±0.5mm. The shape of the product can be simple, like a rectangular box, or complex, with intricate curves and undercuts.

The production volume also plays a crucial role. High - volume production, say over 100,000 units, may justify the use of more durable and expensive mold materials and more complex, automated production equipment. In contrast, low - volume production, such as a few thousand units, may require a more cost - effective approach, using less expensive materials and simpler production setups. Additionally, the production equipment available, like the injection molding machine's clamping force and injection volume, must be considered during the design phase to ensure compatibility.

Material Selection: The Right Choice for the Job

Selecting the appropriate mold material is a decision that can significantly impact the quality and cost - effectiveness of the final product. The lifespan of the mold is a primary consideration. For molds that will be used to produce a large number of parts, materials with high wear - resistance, such as P20 steel, are preferred. P20 steel can withstand the repeated injection of molten plastic and maintain its dimensional accuracy over a long production run.

Cost is another factor. While high - performance materials like H13 steel offer excellent heat resistance and toughness, they are more expensive. In some cases, where cost is a major constraint and the production volume is not extremely high, materials like 45 - carbon steel may be a more viable option, although they may have a shorter lifespan.

The shape and precision of the plastic product also influence material selection. For products with complex shapes and high - precision requirements, materials that can be easily machined to the required tolerances, such as pre - hardened steel, are ideal. The characteristics of the plastic being molded and the molding process requirements also matter. For example, if the plastic has a high melting point and high viscosity, a mold material with good heat resistance and high strength is needed to withstand the high injection pressures.

Designing the Mold Structure

Selection of parting surfaces

The choice of the parting surface is crucial as it directly affects the quality of the plastic part and the lifespan of the mold. It should be determined based on factors such as the shape, structure, wall thickness, and molding process of the plastic part. For instance, if the plastic part has a simple, symmetric shape like a cube, the parting surface can be easily chosen along the center plane, which simplifies the mold structure and ensures easy 脱模. However, for a part with complex undercuts, the parting surface may need to be designed in a more intricate way, perhaps using multiple parting surfaces or side - action mechanisms. The parting surface should be selected to ensure that the plastic part can be easily removed from the mold after molding, while also minimizing the formation of flash and ensuring good dimensional accuracy.

Design of Gating System

Designing an effective gating system is key to ensuring that the plastic melt flows evenly into the mold cavity. The gating system should be designed to prevent issues such as short - shots (where the mold cavity is not completely filled) and flash (where plastic leaks out between the mold halves). The size and shape of the gates, runners, and sprues are carefully calculated. For example, the cross - sectional area of the runner should be large enough to allow sufficient plastic flow without causing excessive pressure drops. In a multi - cavity mold, the gating system should be designed to ensure balanced filling of all cavities. This may involve using techniques such as equal - length runners and properly sized gates for each cavity.

Design of formed parts

Based on the structure and material properties of the plastic part, suitable molding parts are designed to ensure dimensional accuracy and surface quality. The core and cavity are the main components that determine the shape of the plastic part. Their design takes into account factors such as the shrinkage rate of the plastic material during cooling. For example, if the plastic has a high shrinkage rate, the core and cavity dimensions may need to be adjusted accordingly to achieve the desired final part dimensions. The surface finish of the molding parts also affects the surface quality of the plastic part. A smooth surface finish on the core and cavity can result in a plastic part with a high - quality surface, free from scratches and roughness.

Cooling System Design

An efficient cooling system is designed to control the temperature of the mold, which in turn shortens the molding cycle and improves the quality of the plastic part. The cooling channels are strategically placed within the mold to ensure uniform cooling. For example, in a large - scale plastic part, cooling channels may be placed closer to the thicker sections of the part to speed up the cooling process. The flow rate and temperature of the cooling medium, usually water, are also carefully controlled. A proper cooling system can reduce the cooling time by up to 30%, increasing the overall production efficiency.

Design Calculations and Analysis

During the mold structure design, various calculations are involved. Molding part working dimension calculations take into account factors such as plastic shrinkage, mold wear, and manufacturing tolerances to determine the precise dimensions of the core and cavity. For example, if the plastic has a shrinkage rate of 1%, the dimensions of the molding parts need to be increased by 1% to account for this shrinkage during the molding process.

Feeding cavity size calculations are important to ensure that the correct amount of plastic is injected into the mold. This calculation depends on factors such as the volume of the plastic part, the runner system volume, and any additional allowances for plastic waste. Mold part wall thickness and bottom plate thickness calculations are performed to ensure that the mold can withstand the high pressures during the injection molding process. These calculations consider factors such as the material strength of the mold, the injection pressure, and the size of the mold.

Mold heating or cooling system calculations are crucial for maintaining the optimal mold temperature. These calculations involve determining the required flow rate of the cooling medium, the heat transfer coefficient, and the size of the cooling channels. Additionally, calculations for related mechanism designs, such as the ejection system and the side - action mechanism, are also carried out to ensure their proper functioning.

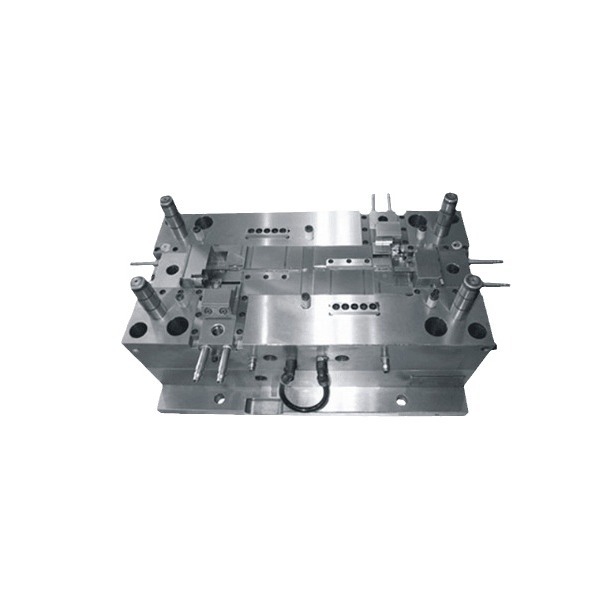

The Manufacturing Phase: Bringing the Design to Life

Machining Processes

CNC Machining

CNC (Computer Numerical Control) machining is a fundamental process in mold manufacturing. It operates based on pre - programmed computer software that dictates the movement of machine tools. The machine reads the G - code, which is generated from the 3D model of the mold design. This code precisely controls the movement of the spindle, the feed rate, and the depth of cut.

One of the key advantages of CNC machining in mold making is its high precision. It can achieve tolerances as low as ±0.001mm, which is crucial for molds that require high - accuracy parts. For example, in the production of molds for optical lenses, where even the slightest deviation can affect the quality of the final lens, CNC machining ensures that the mold cavities are machined to the exact specifications. Another advantage is its ability to produce complex shapes with ease. Through multi - axis machining, CNC machines can create intricate curves, undercuts, and internal features that would be extremely difficult or impossible to achieve with traditional machining methods.

In terms of application in mold manufacturing, CNC machining is used for roughing and finishing operations. During the roughing process, large amounts of material are removed quickly to bring the mold blank close to the desired shape. For a large - scale automotive injection mold, a CNC milling machine with a high - power spindle and large - diameter end mills can be used for roughing. In the finishing process, smaller tools are used to achieve the final surface finish and dimensional accuracy. High - speed CNC machining centers are often employed for finishing operations, as they can run at high spindle speeds and feed rates while maintaining precision.

Electrical discharge machining

Electric Discharge Machining (EDM), also known as spark machining, is based on the principle of electrical discharge erosion. In EDM, a pulsed electrical current is passed between a tool electrode and the workpiece (the mold material). When the voltage between the electrode and the workpiece reaches a certain level, the dielectric fluid (usually a type of oil or de - ionized water) between them is ionized, creating a spark discharge. This spark generates extremely high temperatures, up to 10,000°C, which melts and vaporizes a small amount of the workpiece material.

EDM has several unique characteristics. It can machine materials that are extremely hard or difficult to cut using traditional methods, such as hardened steel, carbide, and titanium alloys. Since it is a non - contact process, there is no mechanical stress on the workpiece, making it suitable for machining delicate and complex shapes. However, EDM has a relatively slow material removal rate compared to CNC machining.

In mold manufacturing, EDM is often used for creating the cavities and cores of the mold. For example, in the production of a plastic injection mold for a smartphone case, which has complex internal structures and fine details, EDM can be used to accurately machine the intricate shapes of the mold cavity. EDM machines come in different types, such as sinker EDM (also known as ram EDM) for creating 3D cavities and wire EDM for cutting precise profiles. Sinker EDM uses a shaped electrode to create a mirror - image of the electrode in the workpiece, while wire EDM uses a thin wire (usually made of brass or molybdenum) as the electrode to cut through the workpiece.

Wire cutting processing

Wire Electrical Discharge Machining (WEDM) is a specialized form of EDM. The principle of WEDM involves using a thin, electrically conductive wire as the tool electrode. The wire is continuously fed through the workpiece while a pulsed electrical current is applied. As the wire moves along a programmed path, sparks are generated between the wire and the workpiece, eroding the material and cutting the desired shape.

WEDM offers several advantages. It can achieve very high precision, with tolerances often in the range of ±0.001 - ±0.005mm. This makes it ideal for manufacturing precision molds, such as those used in the semiconductor industry for producing micro - components. Another advantage is its ability to cut complex shapes with sharp corners and fine details. Since the wire is thin (usually 0.05 - 0.3mm in diameter), it can access and cut areas that are difficult to reach with other machining methods.

In mold manufacturing, WEDM is commonly used for cutting the intricate shapes of mold inserts, cores, and cavities. For instance, in the production of a progressive die for stamping small, precision - cut metal parts, WEDM can be used to create the precise shapes of the die components, including the holes and slots that are required for the stamping process. WEDM machines are available in two main types: high - speed (also known as "fast - wire") and low - speed (also known as "slow - wire") machines. Slow - wire WEDM machines generally offer higher precision and better surface finish, but they are also more expensive and have a slower cutting speed compared to fast - wire machines.

Heat Treatment and Surface Finishing

Mold materials often undergo heat treatment to enhance their mechanical properties. (Annealing) is a process where the mold material is heated to a specific temperature and then slowly cooled. This process reduces internal stress, improves the material's ductility, and makes it easier to machine. For example, for a large - scale die - casting mold made of steel, annealing can relieve the stress induced during the forging process, ensuring that the mold does not crack during subsequent machining operations.

(Quenching) involves heating the mold material to a high temperature and then rapidly cooling it, usually in oil or water. This process increases the hardness and strength of the material. However, quenching can also make the material brittle, so it is often followed by 回火 (Tempering). Tempering is the process of reheating the quenched material to a lower temperature and then cooling it slowly. This reduces the brittleness and improves the toughness of the material.

Surface finishing techniques are also crucial for molds. (Hard chrome plating) is a popular surface treatment that provides excellent wear resistance and corrosion resistance. It is often applied to molds that are used to produce parts with high - volume production requirements, such as automotive plastic parts. (Nickel plating) can improve the surface smoothness and corrosion resistance of the mold. (Polishing) is carried out to achieve a high - quality surface finish, which is important for molds that produce plastic parts with a high - gloss surface requirement, like cosmetic product containers. (Nitriding) is a process that diffuses nitrogen into the surface of the mold material, forming a hard nitride layer. This increases the surface hardness, wear resistance, and fatigue strength of the mold.

Assembly and Testing

Preparations before mold assembly

Before assembling the mold, it is essential to clean the surfaces of the mold parts thoroughly. Any dirt, debris, or machining residues can affect the fit and functionality of the mold. Ultrasonic cleaning is often used to ensure a high - level of cleanliness. Additionally, each part must be inspected to ensure that its dimensions and shape match the design requirements. Precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) are used for this purpose. Assembly tools, such as wrenches, screwdrivers, and presses, should be prepared in advance, and the necessary inspection tools, like gauges and feeler gauges, should also be at hand.

Mold assembly process

The mold assembly process follows a specific sequence based on the mold's structure and design. First, the base components, such as the mold base plates, are assembled. Then, the core and cavity components are carefully positioned and fastened in place. For example, in an injection mold, the core, which forms the internal shape of the plastic part, is installed in the moving half of the mold, while the cavity, which forms the external shape, is installed in the fixed half. The use of dowel pins and alignment keys ensures accurate alignment between the parts. During the assembly, any adjustments to the fit of the parts, such as sanding or filing to achieve a proper clearance, are made carefully to avoid damaging the parts.

Mold debugging and inspection

Once the mold is assembled, it undergoes a series of tests and adjustments. The mold is first installed on an injection molding machine, and a test run is carried out with a small amount of plastic material. The injection pressure, temperature, and injection speed are monitored and adjusted as necessary. Visual inspections are also made to check for any signs of flashing (excess plastic leakage), short - shots (incomplete filling of the mold cavity), or other defects. The mold's ejection system is also tested to ensure that the plastic parts can be easily removed from the mold after molding. CMMs are used to measure the dimensions of the molded parts to verify that they meet the design specifications.

Mold acceptance and delivery

After successful testing and adjustment, the mold is ready for final 验收. The customer or a quality control inspector reviews the test results, including the dimensional accuracy of the molded parts, the functionality of the mold, and the surface quality of the parts. If all requirements are met, the mold is approved for delivery. The mold is then carefully packaged, often with protective coatings and padding, to prevent damage during transportation. Documentation, including the mold design drawings, test reports, and operating instructions, is also provided to the customer.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the significance of every step in the injection plastic mold making journey. Our years of experience in the industry have equipped us with the expertise to handle complex design requirements. We believe that close communication with clients from the design phase is crucial. By understanding their unique product needs, we can offer valuable insights, such as suggesting the most suitable materials and innovative design solutions to optimize the mold's performance.

During the manufacturing phase, we leverage advanced manufacturing techniques and strict quality control measures. Our state - of - the - art equipment and skilled technicians ensure that each mold is produced with the highest precision. We are committed to providing not just products but comprehensive solutions, including after - sales support and continuous improvement based on customer feedback. With Yigu Technology, clients can expect high - quality, customized injection plastic molds that meet their specific production needs efficiently.