Understanding the Basics of a Mold Heating Chamber

A Mold Heating Chamber is a crucial piece of equipment in various industrial manufacturing processes, especially in plastic molding and casting. In plastic molding, for example, maintaining the right temperature in the mold is essential for achieving the desired shape, quality, and integrity of the plastic product. If the mold is too cold, the plastic may not flow evenly, leading to defects such as uneven thickness, surface roughness, or incomplete filling of the mold cavity. In casting processes, heating the mold can help in reducing the thermal stress on the molten metal as it solidifies, resulting in better - quality castings with fewer internal defects.

At its most basic, a Mold Heating Chamber works by using a heat source to raise the temperature of the mold to a specific level. This is typically achieved through the use of heating elements, which convert electrical energy into heat. Once the heat is generated, it is transferred to the mold through conduction, convection, or radiation, depending on the design of the heating chamber. The temperature inside the chamber is carefully regulated to ensure that it remains within the optimal range for the specific manufacturing process.

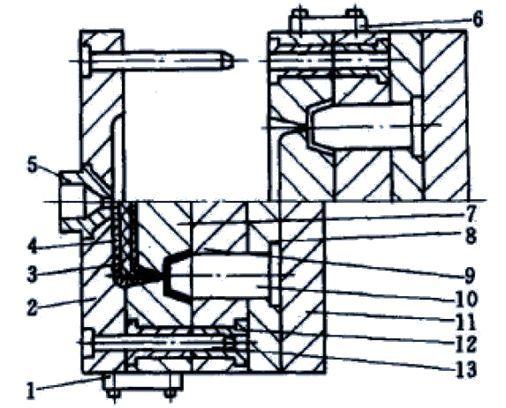

Key Components of a Mold Heating Chamber

- Heating Elements: One of the most common types of heating elements used in mold heating chambers is the heating wire. There are different types of heating wires, such as nickel - chromium (Ni - Cr) alloy wires. Ni - Cr alloy wires are popular due to their high resistivity, which allows them to generate a significant amount of heat when an electric current passes through them. The power of the heating wire depends on its resistance and the applied voltage. For a small - scale mold heating chamber used in a laboratory for testing plastic molds, a heating wire with a power rating of 500 - 1000 watts might be sufficient. When choosing a heating wire, factors such as the size of the mold, the required heating speed, and the maximum temperature needed must be considered. A larger mold or a process that requires a quick increase in temperature may need a higher - power heating wire.

- Insulating Materials: Insulating materials play a vital role in a mold heating chamber as they help to minimize heat loss. Mineral wool is a commonly used insulating material. It has a low thermal conductivity, which means it can effectively prevent heat from escaping the chamber. Mineral wool is also fire - resistant and can withstand high temperatures. Another option is ceramic fiber insulation. Ceramic fiber has excellent insulating properties and can maintain its integrity even at very high temperatures. It is often used in high - temperature mold heating applications, such as in some metal casting processes where the mold needs to be heated to extremely high temperatures.

- Temperature Control Systems: The temperature control system in a mold heating chamber usually consists of a thermostat. The thermostat works based on the principle of thermal expansion. For example, a bimetallic thermostat contains two different metals bonded together. As the temperature changes, the two metals expand at different rates, causing the bimetallic strip to bend. This bending action can be used to open or close an electrical circuit, thus controlling the power supply to the heating elements. The accuracy of the thermostat is crucial. A high - precision thermostat with an accuracy of ±1°C can ensure that the mold is heated to the exact temperature required for the process. In a plastic injection molding process, where the ideal mold temperature might be 80 - 90°C, a thermostat with such accuracy can prevent over - heating or under - heating, which could lead to product defects.

Different Types of Mold Heating Chambers

| Type | Structural Features | Suitable Mold Types | Heating Efficiency | Energy Consumption |

| Box - type | Enclosed box - like structure with the mold placed inside. Usually has a single heating zone. | Small to medium - sized molds with simple shapes. For example, molds for producing small plastic toys or simple metal castings. | Moderate. Heat is distributed evenly within the box, but heating large molds may take longer. | Moderate. Depends on the size of the chamber and the power of the heating elements. |

| Tunnel - type | Long, tunnel - shaped structure. The mold moves through the tunnel on a conveyor belt. Multiple heating zones can be set up along the tunnel. | Long - shaped molds or molds that need continuous heating during a production line process. For instance, molds for extruding long plastic profiles. | High. As the mold moves continuously, it can be heated quickly and efficiently. | High, especially if the tunnel is long and has many heating zones, but the continuous production can offset the energy cost in large - scale production. |

| Rotary - type | A rotating structure where the molds are mounted on a rotating platform. Heating elements are arranged around the perimeter. | Complex - shaped molds that require uniform heating from all sides. Such as molds for producing spherical or irregular - shaped plastic or metal parts. | High. The rotation ensures that the mold is heated evenly from all angles. | Moderate - high. The rotation mechanism may consume some energy, but the efficient heating can be beneficial for certain processes. |

Step - by - Step Construction Process

Planning Your Mold Heating Chamber

Before starting the construction, careful planning is crucial. First, accurately measure the size of the mold that the heating chamber will accommodate. If you are working with a mold that has dimensions of 20 cm in length, 15 cm in width, and 10 cm in height, the interior of the heating chamber should be slightly larger to allow for proper air circulation around the mold, perhaps 22 cm in length, 17 cm in width, and 12 cm in height.

Based on the size of the mold and the desired heating speed, estimate the power required for the heating elements. A general rule of thumb is that for a small - scale mold heating chamber, if you want to heat the mold from room temperature (around 25°C) to 100°C within 15 - 20 minutes, you might need a heating power of 800 - 1200 watts. Consider the shape of the mold as well. For irregular - shaped molds, you may need to design a heating chamber with a more flexible heating arrangement to ensure even heat distribution.

Gathering Materials and Tools

- Materials:

- Steel Sheets: You'll need steel sheets to construct the outer shell of the heating chamber. For a small - to - medium - sized chamber, 1 - 2 mm thick steel sheets are usually sufficient. Steel is chosen for its durability and good heat - conducting properties.

- Insulating Materials: Mineral wool or ceramic fiber insulation is essential. For a chamber with the previously mentioned dimensions, you may need about 2 - 3 kg of mineral wool insulation to line the interior walls effectively.

- Heating Elements: A nickel - chromium (Ni - Cr) alloy heating wire is a great choice. Depending on the power requirement calculated earlier, you can select a heating wire with an appropriate resistance and wattage. For example, a 1000 - watt heating wire with a resistance of around 50 ohms might be suitable for a small - scale setup.

- Temperature Sensor: A thermocouple is commonly used to measure the temperature inside the chamber accurately.

- Thermostat: To control the temperature, you need a thermostat that can be set to the desired temperature range for your molding process.

- Connectors and Wires: Copper wires with appropriate gauges for carrying the electrical current to the heating elements and connecting all the components.

- Tools:

- Electric Drill: Used to make holes in the steel sheets for assembling the components and for routing wires.

- Welding Machine: If you are using steel sheets to build the structure, a welding machine is necessary to join the sheets together. MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding can be used, with MIG being more beginner - friendly for basic construction.

- Screwdrivers and Wrenches: For fastening screws and nuts when assembling the components.

- Multimeter: To measure electrical parameters such as voltage, current, and resistance during the wiring and testing process. This helps in ensuring that the electrical connections are correct and the heating elements are functioning properly.

Building the Structure

- Cutting the Steel Sheets: Using a metal - cutting saw or a plasma cutter (for more precise cuts), cut the steel sheets according to the planned dimensions for the heating chamber. For the base, cut a steel sheet to the size of the bottom of the chamber, and for the sides, cut four sheets with appropriate heights and lengths to form the walls.

- Welding the Sheets: Assemble the cut - out steel sheets to form a box - like structure. Start by welding the sides to the base. Make sure the corners are square and the joints are tight. Use a welding jig if possible to ensure accurate alignment during welding. After welding the sides to the base, weld the top cover (if it is a removable cover, leave one side un - welded for easy access).

- Surface Treatment: Once the structure is welded, use a grinder to smooth out the welded joints and any rough edges on the steel surface. This not only gives the chamber a neater appearance but also helps in preventing any sharp edges that could potentially damage the insulating materials or the mold.

Installing Heating and Insulating Components

- Heating Element Installation: Wind the heating wire around a ceramic or mica - based insulating framework. The winding should be evenly spaced to ensure uniform heat distribution. For example, if the framework is cylindrical, start from one end and wind the wire in a spiral pattern, maintaining a consistent distance between each turn. Secure the wire in place using heat - resistant clips or ties. Then, attach this heating element assembly to the interior of the steel chamber, ensuring that it is well - positioned to heat the mold effectively.

- Insulating Material Installation: Line the interior walls of the steel chamber with the insulating material. For mineral wool, cut it into appropriate sizes to fit the walls and use heat - resistant adhesive or wire mesh to hold it in place. Make sure there are no gaps in the insulation to minimize heat loss. In the case of ceramic fiber insulation, it can be laid in layers, with each layer overlapping the previous one slightly for better insulation.

Wiring and Connecting the Temperature Control System

- Wiring Principles: When wiring the heating elements, use copper wires with a gauge that can handle the expected electrical current. For a 1000 - watt heating element operating at 220 volts, a wire with a gauge of at least 1.5 mm² is recommended. Route the wires neatly, avoiding any sharp edges that could damage the wire insulation. Use wire conduits or cable ties to keep the wires in place.

- Connecting the Temperature Control System: Connect the thermocouple to the thermostat. The thermocouple will sense the temperature inside the chamber and send a signal to the thermostat. The thermostat, in turn, will control the power supply to the heating elements based on the set temperature. Make sure all the connections are secure and properly insulated to prevent electrical hazards.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology has rich experience in the field related to mold heating chambers. With a professional R & D team and advanced manufacturing equipment, we have successfully customized a variety of mold - related products for different industries.

When it comes to mold heating chambers, our advantage lies in our in - depth understanding of materials and manufacturing processes. We can provide high - quality steel sheets and advanced insulating materials, ensuring the durability and energy - efficiency of the heating chamber. Our team of experts can also offer professional advice on the design and construction of mold heating chambers. For example, we can help customers optimize the layout of heating elements according to the specific shape and size of their molds, and select the most suitable temperature control system. We are committed to providing customized solutions to meet the unique needs of each customer, making the construction process of the mold heating chamber more efficient and the final product more reliable.

FAQ

Q1: What is the most suitable heating element for a small - scale mold heating chamber?

A1: For a small - scale mold heating chamber, a nickel - chromium (Ni - Cr) alloy heating wire is a great choice. It has high resistivity, which can generate a significant amount of heat when an electric current passes through it. A heating wire with a power rating of 500 - 1000 watts is usually sufficient for small - scale applications, depending on the size of the mold and the required heating speed.

Q2: How can I ensure the temperature is evenly distributed in the mold heating chamber?

A2: To ensure even temperature distribution, wind the heating wire evenly around an insulating framework. Use insulating materials with good heat - retention properties to line the chamber to minimize heat loss. Additionally, during the testing phase, use a thermal camera or multiple temperature sensors to measure the temperature at different points in the chamber and on the mold, and make adjustments if necessary.

Q3: What should I do if the temperature in my mold heating chamber is not reaching the set value?

A3: First, check the heating elements to see if they are functioning properly. There could be a problem with the electrical connection or the heating wire itself. Also, verify the calibration of the thermostat. If the thermostat is miscalibrated, it may not accurately control the power supply to the heating elements. If these checks do not solve the problem, consider consulting a professional or the manufacturer of the heating chamber components.