Introduction

Understanding the Significance of Plastic Molds

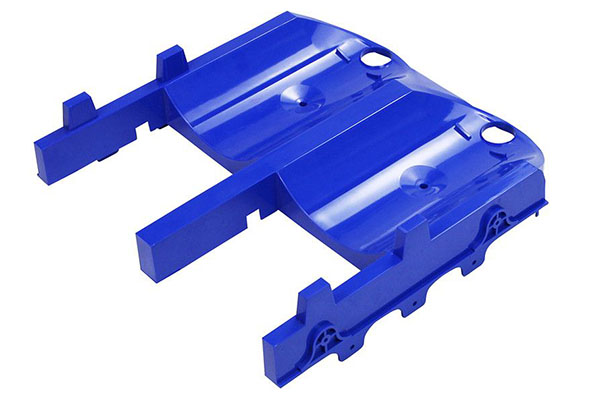

In the realm of modern manufacturing, plastic molds play a pivotal role, acting as the cornerstone for the production of a vast array of plastic products. They are the silent architects behind the scenes, transforming raw plastic materials into precisely designed components that populate various industries, from automotive and electronics to consumer goods and medical devices.

The importance of plastic molds can be gauged by their ability to achieve high - precision replication. For instance, in the electronics industry, plastic molds are used to create the intricate casings for smartphones. These molds ensure that each casing has the exact same dimensions, allowing for a perfect fit of internal components. The tolerances can be as small as a few micrometers, which is crucial for the proper functioning and aesthetic appeal of the final product.

Moreover, plastic molds enable mass production with remarkable efficiency. Once a mold is designed and fabricated, it can be used to produce thousands or even millions of identical plastic parts. This not only reduces the production time but also significantly cuts down the cost per unit. In the automotive industry, large - scale production of plastic interior components such as dashboards and door panels is made possible through plastic molds.

Given their significance, a deep understanding of plastic mold structures becomes essential. Different structures are tailored to meet the specific requirements of various products and manufacturing processes. By exploring these structures, manufacturers can optimize their production, enhance product quality, and gain a competitive edge in the market. This article delves into the diverse structures of plastic molds, aiming to provide valuable insights for engineers, manufacturers, and anyone interested in the fascinating world of plastic mold technology.

Key Components of a Plastic Mold

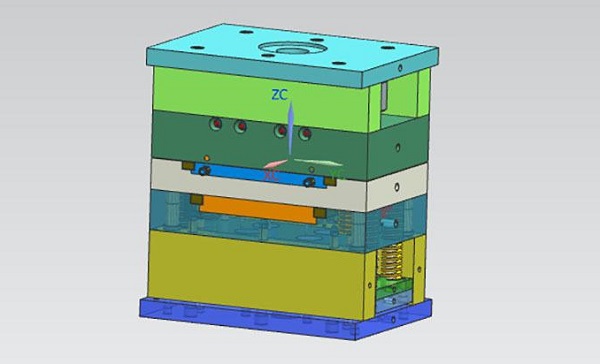

Mold Base

The mold base serves as the sturdy framework that houses all the other components of a plastic mold. It provides mechanical support and ensures the proper alignment of different parts during the molding process. Made from high - strength materials such as alloy steel, the mold base can withstand the high pressures exerted during injection molding. For example, P20 alloy steel, which is commonly used, has good machinability and toughness, making it suitable for mold bases in a wide range of applications.

There are different types of mold bases, including two - plate and three - plate mold bases. A two - plate mold base is the simplest and most commonly used type. It consists of a fixed half (the cavity side) and a movable half (the core side). This type is suitable for products with relatively simple shapes, like plastic containers, as it has a straightforward structure and is cost - effective. On the other hand, a three - plate mold base has an additional intermediate plate. It allows for more complex gating systems, such as point - gate designs, which are often used for high - precision and small - sized products like electronic components. The three - plate mold base enables automatic separation of the runner system from the product, but it is more complex and expensive to manufacture.

Cavity and Core

The cavity and core are the heart of the plastic mold as they determine the final shape of the plastic product. The cavity is the hollow space within the mold that gives the product its outer shape. For instance, if you are making a plastic bottle, the cavity will be shaped like the outer contour of the bottle. The core, on the other hand, forms the internal features of the product. In the case of the plastic bottle, the core will create the inner hollow space.

The design of the cavity and core can vary greatly depending on the complexity of the product. For simple products with regular shapes, a single - piece cavity and core may be sufficient. However, for products with complex geometries, such as a plastic toy with multiple intricate details, a combination of different parts may be used to form the cavity and core. These can include inserts, which are removable pieces within the cavity or core that add specific features. For example, to create a threaded hole in a plastic part, a threaded insert can be used within the core.

Gating System

The gating system plays a crucial role in controlling the flow of molten plastic into the mold cavity. Different types of gates are used, each with its own characteristics. Here is a comparison of some common gate types:

| Gate Type | Advantages | Disadvantages | Suitable Product Types |

| Side Gate | Easy to machine and maintain; suitable for a wide range of part sizes | May leave a visible mark on the product; not ideal for high - precision parts with strict surface finish requirements | Large plastic parts like storage bins, toys with simple shapes |

| Point Gate | Small gate size results in a clean break from the product, leaving minimal mark; suitable for high - precision and small - sized parts | High shear stress during filling, which may cause flow marks in some plastics; more complex to design and manufacture | Electronic components, small precision parts like watch casings |

| Submarine Gate (also known as Tunnel Gate) | Can automatically cut off the runner from the part during ejection; hidden gate location, no visible mark on the product surface | Difficult to balance the flow rate in multi - cavity molds; higher chance of gate clogging | Products where surface appearance is critical, such as cosmetic containers |

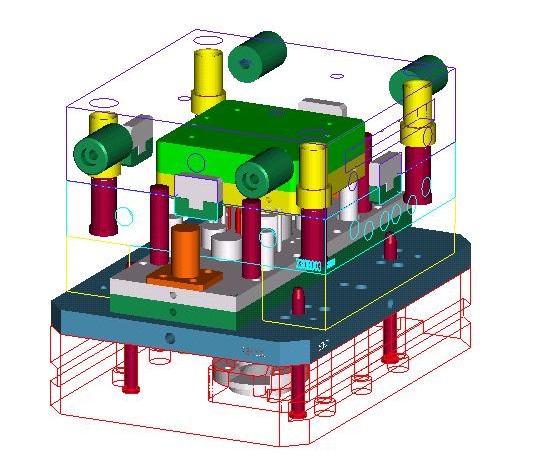

Ejection System

The ejection system is responsible for removing the molded plastic part from the mold after the cooling process. Common ejection devices include ejector pins and ejector plates. Ejector pins are small cylindrical rods that push the product out of the mold. They are usually placed at strategic locations on the core side of the mold, such as near thick sections of the product where the plastic has more strength to withstand the pushing force.

Ejector plates, on the other hand, are flat plates that push the entire product out simultaneously. They are often used for products with large and flat surfaces, like plastic trays. To prevent the product from deforming during ejection, factors such as the number, size, and distribution of ejector pins or the design of the ejector plate need to be carefully considered. For example, using a larger number of smaller ejector pins can distribute the ejection force more evenly, reducing the risk of deformation.

Cooling System

A well - designed cooling system is essential for improving the production efficiency and product quality of plastic molds. During the injection molding process, the molten plastic fills the mold cavity, and then it needs to be cooled down to solidify. Without an efficient cooling system, the cooling time would be long, resulting in low production rates.

The cooling system typically consists of a network of cooling channels within the mold. These channels are designed to circulate a coolant, usually water, to remove the heat from the mold. The layout of the cooling channels is crucial. For example, in a circular plastic part, the cooling channels may be arranged in a concentric pattern around the cavity to ensure uniform cooling. The diameter of the cooling channels also affects the cooling efficiency. A larger diameter allows for a higher flow rate of the coolant, but it also reduces the structural integrity of the mold. As a general rule, the cooling channel diameter is often in the range of 8 - 12 mm, depending on the size and complexity of the mold. The distance between the cooling channels and the mold cavity surface is also carefully calculated. It is usually recommended to be around 1.5 - 2 times the diameter of the cooling channel to ensure effective heat transfer.

Comparing Different Plastic Mold Structures

Two - Plate Mold vs. Three - Plate Mold

| Comparison Aspect | Two - Plate Mold | Three - Plate Mold |

| Structure | Consists of a fixed half (cavity side) and a movable half (core side). The runner system is usually simple, often with a sprue and a single runner leading directly to the cavity. | Has an additional intermediate plate between the fixed and movable halves. This allows for a more complex runner system. |

| Opening and Closing Action | When the mold opens, the two halves separate, and the product and runner system are ejected together. | During mold opening, the three plates separate in a specific sequence. First, the fixed plate and the intermediate plate separate, cutting the runner from the product at the point - gate. Then, the intermediate plate and the movable plate separate to eject the product. |

| Gate Type | Commonly uses side gates or direct gates. These gates are relatively easy to design and manufacture but may leave a more visible mark on the product. | Facilitates the use of point - gates, which are ideal for high - precision products as they leave a minimal mark on the product surface after separation. |

| Suitable Product Types | Ideal for products with simple shapes and large sizes, such as plastic buckets, large containers, and some basic automotive parts. These products do not require complex gating systems and can be efficiently produced with a two - plate mold's straightforward structure. | Best suited for products with high - precision requirements and small sizes, like electronic components (e.g., connectors, small housings for micro - devices), and products where surface appearance is crucial. The three - plate mold's ability to use point - gates and its more complex runner system allows for better control over the filling process and a cleaner separation of the runner from the product. |

Hot Runner Mold and Cold Runner Mold

| Comparison Aspect | Hot Runner Mold | Cold Runner Mold |

| Material Cost | Higher initial investment due to the complex hot runner system components, including hot nozzles, manifolds, and heating elements. However, in the long run, material waste is significantly reduced as there is no solidified runner to be discarded after each cycle. | Lower initial cost as it has a simpler runner system. But it generates runner waste with each cycle, which adds to the overall material cost, especially for large - scale production. For example, if producing small plastic parts, the cold runner waste can account for 10 - 30% of the total plastic material used, depending on the product and runner design. |

| Energy Consumption | Requires continuous energy to maintain the molten state of the plastic in the hot runner system. This includes power for heating elements in the hot nozzles and manifolds. However, the energy consumption can be offset by the reduced cycle time and material savings. | Does not need additional energy for maintaining a hot runner. But the energy used for reheating the plastic in the injection unit for each cycle may be relatively high if the runner waste is significant. |

| Production Efficiency | Generally has a shorter cycle time as there is no need to wait for the runner to solidify before ejection. This leads to higher production rates. For instance, in high - volume production of small plastic parts, a hot runner mold can increase the production speed by 20 - 50% compared to a cold runner mold. | Has a longer cycle time due to the need to wait for the runner to cool and solidify. This can limit the overall production efficiency, especially for high - volume production. |

Selection Suggestions: For small - scale production or products with low - precision requirements, a cold runner mold may be a more cost - effective choice as the initial investment is lower, and the material waste may not be a major concern. However, for large - scale production of high - value products where material savings and production efficiency are crucial, a hot runner mold is often the better option despite its higher initial cost.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in plastic mold design and manufacturing. We understand that each customer's requirement is unique. When it comes to plastic mold structures, we focus on a comprehensive approach.

Firstly, we conduct in - depth communication with customers to fully understand their product features, production volumes, and quality requirements. Based on this, we select the most suitable mold structure. For example, for high - precision and small - batch production, we may recommend a three - plate mold with a hot runner system. This can ensure the high - quality production of products while reducing material waste.

Secondly, we pay great attention to the quality of mold components. Our team of experienced engineers uses advanced design software and simulation tools to optimize the design of each component, such as the cavity, core, and cooling channels. This ensures that the mold has excellent performance and a long service life.

Finally, we also emphasize continuous innovation and improvement. We keep up with the latest trends in the industry, introduce new materials and manufacturing technologies, and strive to provide customers with more efficient and cost - effective plastic mold solutions.