In the world of manufacturing, the journey from a raw block of material to a functional, high-performance product is a symphony of precision and coordination. Two critical phases dominate this process: machining and assembly. While often discussed separately, their seamless integration is where true engineering excellence is realized. This article delves into the core of machining assembly, exploring how these processes are intricately linked in modern manufacturing. We will unpack the technical prerequisites, design philosophies, and quality assurance methods that ensure components don't just fit together, but perform flawlessly as a unified system.

What is Machining Assembly?

Machining assembly is not a single process, but a holistic manufacturing philosophy. It describes the integrated workflow where individual components are first created through various machining processes—such as milling, turning, or drilling—to exact specifications, and are then systematically joined to form a final product or sub-assembly.

The critical distinction lies in the intentional design for assembly that is considered during the machining phase. It's a proactive approach where the machining processes are planned not in isolation, but with the explicit goal of simplifying, accelerating, and ensuring the reliability of the subsequent assembly operations. For example, a machinist doesn't just create a part with tight tolerances; they also ensure features like lead-in chamfers, alignment pins, or standardized fastener holes are incorporated to make the assembler's job error-proof.

How Does Machining Assembly Integrate with Modern Manufacturing?

Modern manufacturing paradigms like Lean Manufacturing and Industry 4.0 have fundamentally transformed machining assembly from a sequential, disconnected series of steps into a synchronized, data-driven ecosystem.

- Digital Thread & IoT: The integration is powered by a digital thread. A Computer-Aided Design (CAD) model defines the final assembly. This model directly drives the Computer-Aided Manufacturing (CAM) software for machining. Post-machining, coordinate measuring machines (CMMs) verify the parts, and this data is fed back into the system. During assembly, IoT sensors on tools (like smart torque wrenches) log each fastener's torque value, linking it to the specific unit's digital record. This creates full traceability from raw material to assembled product.

- Case Study - Aerospace Component: Consider an aircraft hydraulic valve block. Its complex internal channels are precision-machined from a solid titanium billet. Modern machining assembly integration means the CNC program is simulated to avoid collisions, the machined part is scanned and compared to the CAD model, and during assembly, each sensor port and seal is installed using digitally documented procedures. The final assembly data pack is as critical as the physical part, a hallmark of modern machining assembly.

Which Machining Processes Precede Assembly Operations?

Several machining processes are foundational to creating parts ready for reliable assembly. The choice depends on the required geometry, material, and precision.

| Machining Process | Primary Function in Assembly Context | Common Assembly-Ready Features Created |

|---|---|---|

| CNC Milling | Creates complex 3D shapes, pockets, and planes. | Flat mating surfaces, bolt hole patterns, alignment slots, and recesses for seals or bearings. |

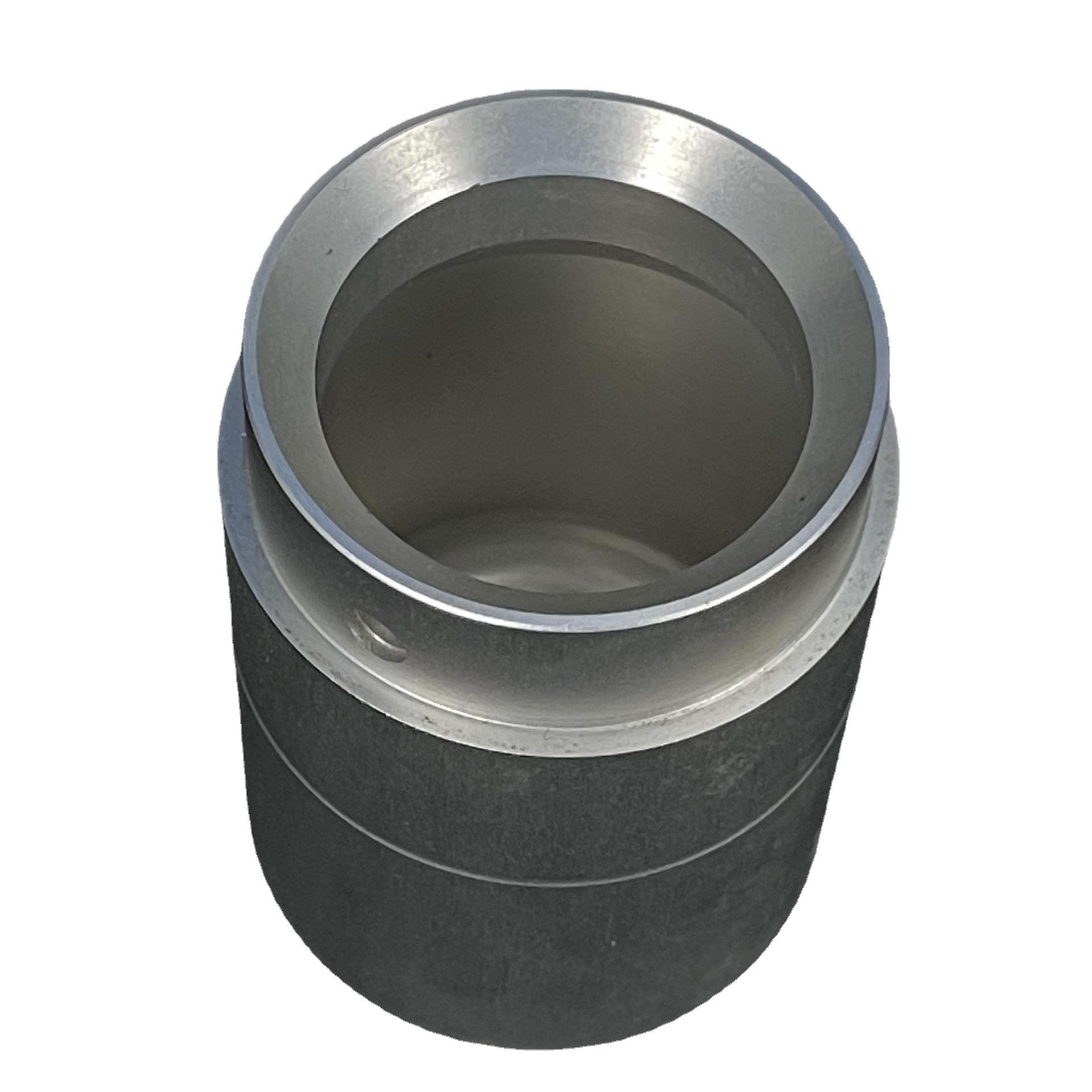

| CNC Turning | Produces rotational, symmetric parts. | Precision diameters for press-fits, threaded sections (external), and concentric faces for sealing. |

| Drilling & Tapping | Creates holes for fastening and alignment. | Through-holes, threaded holes (internal threads), and counterbores for fastener heads. |

| Grinding & Honing | Achieves ultra-fine surface finish and extreme dimensional accuracy. | Super-smooth bearing surfaces, precise cylindrical pins for slip or press fits, and critical sealing faces. |

What Tolerances Ensure Seamless Machining Assembly?

Tolerances are the legal language of machining assembly. They define the permissible variation in a part's dimensions and are absolutely critical for interchangeability and function.

- Fit Types: These are standardized based on the desired clearance between mating parts.

- Clearance Fit: Ensures a guaranteed gap (e.g., a shaft in a bearing). Common in sliding or rotating assemblies.

- Interference Fit: Requires force for assembly, creating a permanent bond (e.g., a gear pressed onto a shaft). Provides high torque transmission.

- Transition Fit: Can result in either a slight clearance or interference. Used for precise alignment, like a locating pin in a hole.

- Geometric Dimensioning and Tolerancing (GD&T): This advanced system goes beyond simple size tolerances. It controls form, orientation, location, and runout. For instance, the true position tolerance of a bolt hole pattern is far more critical for assembly than the individual hole diameters. A part with perfect hole sizes but mislocated holes simply will not assemble.

How to Design Parts for Efficient Machining Assembly?

Design for Assembly (DFA) and Design for Manufacturing (DFM) are twin pillars of efficient machining assembly. Key principles include:

- Minimize Part Count: The simplest design is often the best. Can multiple machined components be consolidated into one?

- Use Standard Components: Employ common, readily available fasteners, bearings, and seals.

- Incorporate Self-Locating Features: Use chamfers, dowels, and stepped pilots to guide parts into place, reducing adjustment time.

- Ensure Clear Tool Access: Design so that wrenches, screwdrivers, and assembly tools can easily reach fastening points.

- Avoid Flexible or Entangling Parts: Stiff parts are easier to handle. Design parts that are stable on their own.

Example: Redesigning a housing that used four different screw types and required awkward, angled tool access to a single machined assembly using two standardized socket cap screws with vertical, unobstructed access can cut assembly time by over 60% and reduce errors.

What Fastening Methods Dominate Machining Assembly?

The choice of fastening method is dictated by requirements for strength, disassembly, vibration resistance, and cost.

| Method | Typical Applications | Key Considerations for Machined Parts |

|---|---|---|

| Threaded Fasteners (Screws, Bolts) | Universal; covers, structural joints. | Machined thread quality (tapped or threaded), hole perpendicularity to prevent cross-threading, proper counterbore depth. |

| Press & Interference Fits | Permanent assemblies (gears, bearings). | Precise control of machined shaft and hole diameters; surface finish is critical. |

| Pins (Dowel, Spring, Taper) | Precision alignment, shear force transfer. | Precision-machined holes, often reamed to exact size for a slip fit. |

| Adhesives & Sealants | Supplementing fasteners, sealing, bonding. | Machined surface texture (Ra) must be suitable for adhesive bonding; cleanliness is paramount. |

How to Verify Quality During Machining Assembly?

Quality verification is continuous, not a final inspection. It is interwoven throughout the machining assembly workflow.

- In-Process Inspection (Machining): Using touch probes on CNC machines, portable CMMs, and optical comparators to check critical dimensions during machining, allowing for immediate correction.

- First Article Inspection (FAI): A comprehensive validation of the first part off the production run against all drawing specifications before full-scale machining and assembly proceed.

- Functional Testing (Assembly): After assembly, products undergo tests—pressure tests for hydraulic blocks, electrical continuity checks, or mechanical cycle tests—to validate the performance of the complete machining assembly.

Conclusion

Machining assembly represents the critical nexus where design intent is physically realized. It is a discipline that demands more than just skilled machinists and assemblers; it requires foresight, integration, and relentless attention to detail from the digital design stage to the final functional test. By mastering the interplay between precise machining processes, intelligent design for assembly, robust fastening methods, and rigorous quality verification, manufacturers can achieve the holy grail: producing complex, reliable, and high-quality products efficiently and consistently.

FAQ

- What is the difference between machining and assembly? Machining is a subtractive process that shapes raw material into specific components (e.g., cutting, drilling). Assembly is the additive process of joining those machined components and others into a final product.

- Why are tolerances so important in machining assembly? Tolerances ensure interchangeability. Parts machined at different times or on different machines will fit and function together predictably, which is fundamental to mass production and reliable repair.

- What is the most common mistake in designing for machining assembly? A common mistake is designing parts that are easy to machine but difficult to assemble—for example, omitting alignment features or specifying fasteners in hard-to-reach locations.

- How is quality controlled in an automated machining assembly line? Through a combination of in-machine sensors, vision systems for part presence/orientation, automated measuring stations, and data-logging tools (like torque monitors) that feed into a Statistical Process Control (SPC) system to detect trends.

Contact Yigu for Custom Manufacturing

At Yigu Technology, we view machining assembly not as two separate services, but as a single, integrated competency. Our engineering philosophy is built on the principle that the true test of a precision-machined component is how seamlessly and reliably it integrates into its final assembly.

We bring this philosophy to life through our vertically controlled process. From the initial DFM/DFA review—where our engineers collaborate with you to design parts for efficient machining assembly—to the final functional testing of the assembled unit, we maintain a continuous digital thread. Our advanced CNC machining processes are programmed with the end-assembly in mind, ensuring features like true position tolerances and surface finishes are optimized for your chosen fastening methods.

Whether you require a complex machined assembly ready for integration or a complete turnkey product, Yigu provides the expertise, precision, and holistic oversight necessary. Let us be your partner in transforming your designs into flawlessly functioning realities. Contact Yigu today for your custom manufacturing project.