Introduction

In the vast realm of plastic manufacturing, Mold Masters stands as a towering figure, a global leader that has been shaping the industry for over five decades. Since its inception, Mold Masters has been at the forefront of innovation, revolutionizing the way plastic products are created.

The company specializes in designing, manufacturing, distributing, selling, and servicing highly engineered and customized plastic processing equipment and systems. Its influence spans across every industry, from small - scale local manufacturers to large - scale OEMs of globally renowned brands. Their product portfolio, which includes advanced hot runner systems, precise temperature controllers, and cutting - edge auxiliary and co - injection systems, is used by a diverse range of clients, testifying to the company's broad - reaching impact.

But what exactly goes on behind the scenes at Mold Masters? What is the engineering wizardry that enables them to produce such high - quality, industry - leading products? In this article, Yigu Technology will delve deep into the intricate world of mold manufacturing at Mold Masters. We will explore the advanced technologies they employ, the meticulous processes they follow, and the crucial role that mold manufacturing plays in the larger context of plastic production. Whether you're a plastics industry professional, an engineering enthusiast, or simply someone curious about the inner workings of modern manufacturing, this exploration of Mold Masters' mold manufacturing engineering is sure to pique your interest.

Mold Masters: A Pioneer in the Plastic Industry

Mold Masters has firmly established itself as a pioneer in the plastic industry, with a legacy that dates back over 50 years. Their journey began with a vision to transform plastic manufacturing through innovation and engineering excellence.

Design: Tailoring Solutions to Perfection

The design phase at Mold Masters is a meticulous process that combines cutting - edge technology with in - depth industry knowledge. Their team of highly skilled designers uses state - of - the - art CAD/CAM software to create 3D models of molds. These models are not only a visual representation but also a tool for simulating the plastic injection process. By running simulations, they can predict potential issues such as uneven material flow, air traps, or over - packing in the mold. This allows them to make adjustments to the design before the actual manufacturing process begins, saving both time and resources. For Yigu Technology example, when designing a mold for a complex automotive interior component, the design team at Mold Masters would consider factors like the component's shape, the type of plastic to be used, and the required surface finish. They would optimize the gate location and size to ensure uniform filling of the mold cavity, resulting in a high - quality part with minimal defects.

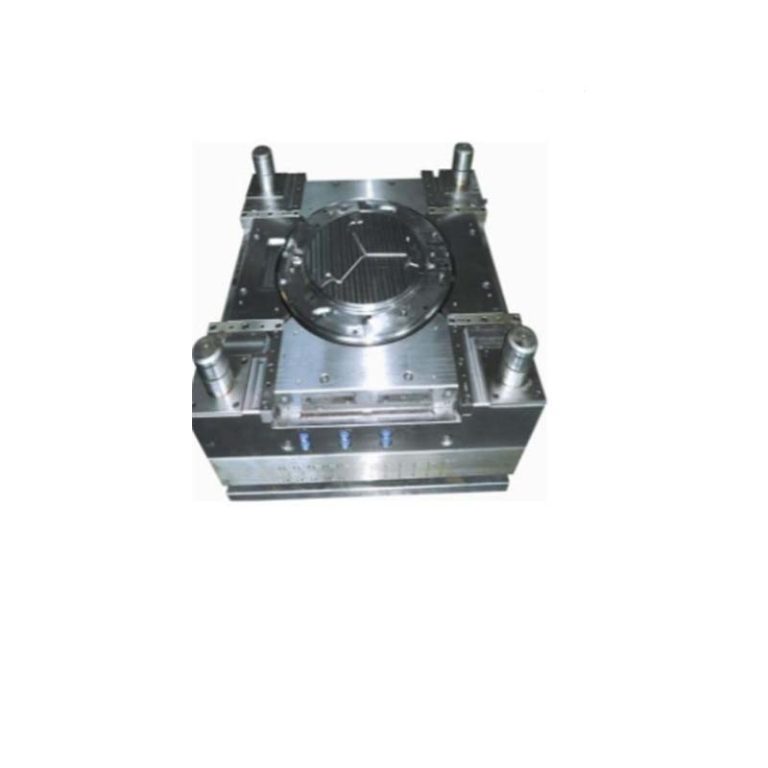

Manufacturing: Precision at Every Step

Mold Masters' manufacturing facilities are equipped with the latest machinery and technology. They use high - precision CNC machining centers to create the mold components with tight tolerances. The use of advanced machining techniques ensures that the molds are durable and can withstand the high pressures and temperatures of the plastic injection process. In addition to machining, Mold Masters also utilizes other manufacturing processes such as EDM (Electrical Discharge Machining) for creating intricate shapes and textures. For instance, when manufacturing a mold for a consumer electronics product with fine details, EDM might be used to create the precise contours and patterns on the mold surface. Quality control is an integral part of the manufacturing process. Each mold component undergoes rigorous inspection using advanced metrology equipment to ensure that it meets the strict quality standards set by Mold Masters.

Distribution: Global Reach

With a vast network of distributors and sales offices around the world, Mold Masters can quickly and efficiently deliver its products to customers. Their distribution strategy is designed to ensure that customers, no matter how remote their location, can access the latest in mold - making technology. They have established partnerships with local distributors in over 70 countries, which not only helps in the timely delivery of products but also provides local technical support. This global reach means that a small - scale plastic manufacturer in a developing country can have access to the same high - quality molds as a large multinational corporation.

Servicing: Ensuring Long - Term Performance

Mold Masters' commitment to its customers does not end with the sale of a mold. Their service team is available around the clock to provide maintenance, repair, and technical support. They offer training programs to help customers optimize the use of their molds and plastic processing equipment. For Yigu Technology example, if a customer experiences issues with a mold's performance, the service team can quickly diagnose the problem, whether it's a mechanical failure, a thermal issue, or a problem with the control system. They can then provide solutions, which may include on - site repairs, replacement of parts, or software updates. This after - sales service is crucial in maintaining customer satisfaction and ensuring the long - term success of their customers' plastic manufacturing operations.

Mold Masters serves a diverse range of customers, from small - scale start - ups in the packaging industry to large - scale automotive manufacturers. Their ability to customize products according to the unique needs of each customer has made them a preferred choice. A small - scale start - up in the food packaging sector might require a cost - effective, yet reliable mold for producing food containers. Mold Masters can design and manufacture a mold that meets the start - up's budget constraints while still ensuring high - quality production. On the other hand, a large automotive manufacturer might need a complex mold for producing large - scale body panels. Mold Masters has the expertise and resources to handle such large - scale, high - precision projects. Their diverse customer base is a testament to their versatility and ability to meet the demands of different industries.

The Core Engineering Technologies of Mold Masters

iFLOW Shunt Plate Technology

iFLOW Shunt Plate Technology, pioneered by Mold Masters, is a revolutionary innovation in the field of mold manufacturing. Launched over 30 years ago, this technology has been a game - changer for applications that demand top - notch products in medium - to - high - cavity hot runner systems.

At its core, the iFLOW shunt plate is designed to optimize the hot runner system. It consists of two separate steel pieces, each machined by CNC milling and carefully polished to form the runner channels. These channels are engineered to promote the best - possible resin flow. Once the machining and polishing are complete, the two steel pieces are welded together, creating a highly durable and strong shunt plate that functions as if it were a single piece of steel.

One of the most significant advantages of the iFLOW shunt plate is its ability to achieve industry - leading mold filling balance. By using patented melt - flow geometries, flow - path options, and unique fluid shapes (including curved paths, unlike the traditional straight or 90° turns in gun - drilled shunt plates), it can ensure a uniform distribution of plastic melt. This results in enhanced part uniformity and a significant improvement in the quality of the molded parts. For Yigu Technology example, in the production of small, difficult - to - mold medical components like needle barrels (weighing as little as 0.35g), the iFLOW shunt plate has achieved a remarkable total variance of just 1.7%.

The iFLOW shunt plate also excels in fast color - changing performance. The CNC - machined and polished runner channels, with their curved paths, eliminate sharp corners and dead ends in the flow transition. This design feature reduces the resistance to the flow of the plastic melt during color changes, improving the color - changing performance by up to 45%. In addition, multiple melt channels for different materials can be integrated into the same shunt plate, which can reduce the overall stack height by up to 22%. This not only saves space within the mold but also contributes to more efficient manufacturing processes. The layout design of the iFLOW shunt plate can also enhance the structural integrity of the mold, preventing issues like template deflection and flash formation, thus maintaining long - term production quality.

Welded Heating Wire Technology

Welded Heating Wire Technology represents a significant leap forward in mold heating systems. Mold Masters has integrated this technology into many of its hot runner systems, shunt plates, and other heating components, bringing about several distinct advantages.

The key to the success of this technology lies in the way the heating wire is permanently fixed and embedded within custom - designed heater channels. These channels are a unique part of the components and are the result of in - depth research, development, and testing. They are designed to provide the optimal heating structure, ensuring that each component has consistent heater channels. This consistency leads to excellent thermal stability from one mold to another, which in turn improves the quality of the molded parts across the entire mold and reduces the scrap rate.

Compared to traditional heating methods such as heating tapes (used for nozzles) and heating plates (used for shunt plates), welded heating wire technology has several superiority. Heating tapes, for instance, can move along the length of the nozzle, causing inconsistent heat distribution and the formation of cold spots. These temperature variations can lead to defects in the molded parts, such as uneven wall thickness or surface imperfections. In contrast, the welded heating wire technology ensures a more uniform heat distribution, minimizing such issues.

Another advantage of welded heating wire technology is its low energy consumption. Since the heating wire is directly embedded in the steel, the contact area for heat transfer is much larger. This allows most of the energy to be directly transferred to the steel, making the heating process more efficient. As a result, the welded heaters can operate at lower temperatures and for shorter periods compared to traditional heaters. In internal tests conducted on low - cavity systems, Mold Masters' hot runner systems with welded heating wire technology showed an average 27% reduction in energy consumption when processing materials, compared to other global - brand hot runner systems. This not only saves energy costs but also contributes to a more sustainable manufacturing process.

The reliability of the welded heating wire technology is also a standout feature. Mold Masters manufactures all its brazed heating elements in - house using strictly controlled processes to ensure high - quality standards. Each heating element undergoes rigorous quality - assurance testing before being permanently brazed into the hot runner system. The brazing process eliminates any air gaps between the element and the steel, preventing the possibility of arcing, which is a common cause of failure in traditional heater elements. This high - level of reliability is further supported by the fact that when used in conjunction with Mold Masters' precise TempMaster hot runner temperature controllers, the company can offer an industry - leading 10 - year warranty on its welded heaters. In contrast, traditional heaters typically have a 10% annual failure rate and require annual replacement, leading to higher maintenance costs and production downtime.

APS (Adaptive Process System) Technology

APS (Adaptive Process System) Technology is a testament to Mold Masters' commitment to advancing the automation and intelligence of the plastic injection molding process. This technology is designed to revolutionize the way injection molding operations are managed by providing real - time monitoring and adjustment of critical process parameters.

At the heart of APS is its ability to collect and analyze a vast amount of data from various sensors installed within the injection molding machine and the mold. These sensors monitor parameters such as temperature, pressure, injection speed, and melt flow rate. The data is then processed in real - time, allowing the APS to make informed decisions about the optimal settings for the injection molding process.

For example, if the APS detects a change in the viscosity of the plastic melt due to a slight variation in the raw material or a change in the ambient temperature, it can automatically adjust the injection pressure and speed to ensure that the mold is filled evenly. This real - time adjustment helps to maintain the quality of the molded parts, reducing the likelihood of defects such as short shots, over - packing, or uneven wall thickness.

The APS also plays a crucial role in optimizing the production process for maximum efficiency. By continuously monitoring the production line, it can identify bottlenecks and inefficiencies in the process and make the necessary adjustments to eliminate them. For instance, if it detects that a particular stage of the injection molding cycle is taking longer than necessary, it can adjust the timing of the various operations to streamline the process and increase the overall production speed.

In addition to its real - time monitoring and adjustment capabilities, the APS also offers advanced predictive analytics. By analyzing historical data, it can predict potential issues such as equipment failures or quality problems before they occur. This allows manufacturers to take proactive measures to prevent these issues, such as scheduling maintenance or making adjustments to the production process in advance. This not only helps to minimize production downtime but also reduces the cost associated with unplanned maintenance and product recalls.

Furthermore, the APS is designed to be user - friendly and intuitive. It provides operators with clear and concise information about the production process, making it easy for them to understand the current status of the operation and make informed decisions. The system can also be integrated with other manufacturing systems, such as enterprise resource planning (ERP) systems, to provide a comprehensive view of the entire manufacturing process. This integration allows for better coordination between different departments and functions within the organization, leading to more efficient production planning and resource allocation.

Conclusion

Mold Masters has undoubtedly made a profound mark in the world of mold manufacturing engineering. Their suite of advanced technologies, from the iFLOW Shunt Plate Technology that ensures optimal resin flow and part quality, to the Welded Heating Wire Technology with its superior thermal stability and energy - saving features, and the MasterSHIELD Leak Protection Technology that safeguards the injection molding process, and the intelligent APS Technology, all contribute to their leadership in the industry.

Yigu Technology company's comprehensive approach, which encompasses design, manufacturing, distribution, and servicing, addresses every aspect of the mold - making process. Their ability to serve a diverse range of customers, from small - scale enterprises to large - scale manufacturers, highlights their adaptability and the universal appeal of their products.