If you’re wondering what aluminum die is and how it works, you’re in the right place. Simply put, aluminum die refers to the process of creating aluminum parts by forcing molten aluminum into a pre-made mold (called a die) under high pressure—this is known as aluminum die casting. It’s a go-to method for making complex, high-volume aluminum components used in everything from cars to electronics. In this guide, we’ll break down how it works, its types, benefits, common uses, and even real-world examples to help you fully understand this essential manufacturing process.

What Exactly Is Aluminum Die Casting?

At its core, aluminum die casting is a metal casting process that leverages pressure to produce precise aluminum parts. Here’s a step-by-step breakdown of how it typically works:

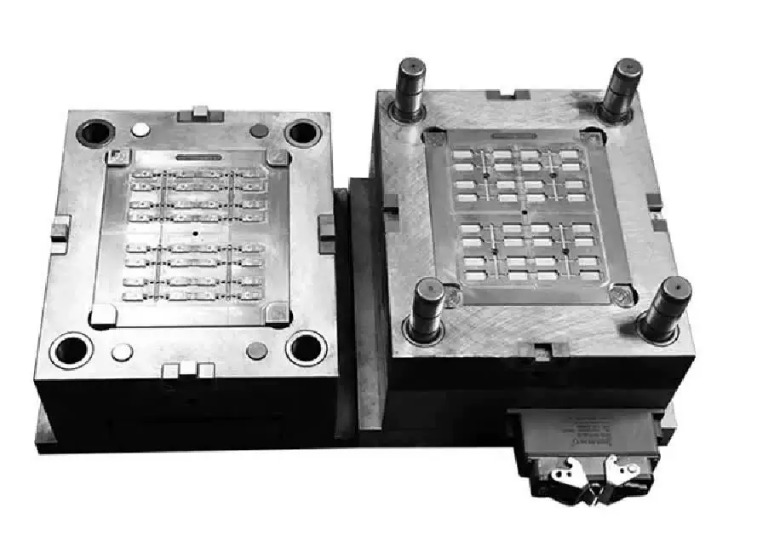

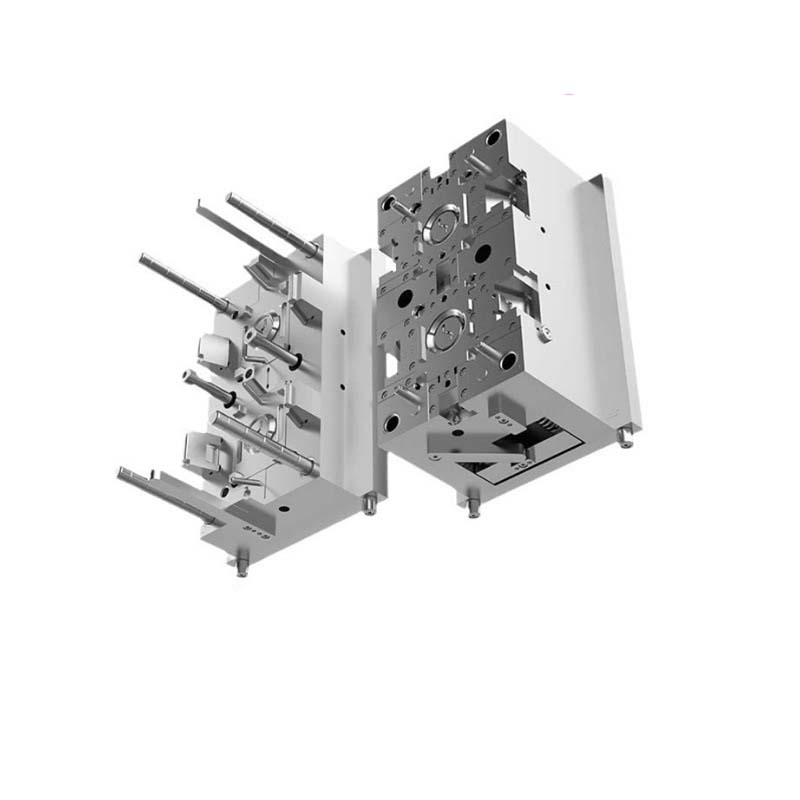

- Mold Preparation: A steel die (usually two halves) is designed to match the shape of the desired part. The die is preheated and sprayed with a lubricant to prevent molten aluminum from sticking and to extend the die’s life.

- Melting Aluminum: Pure aluminum or an aluminum alloy (often mixed with silicon, copper, or magnesium for added strength) is melted in a furnace at temperatures between 600°C and 700°C (1,112°F to 1,292°F)—this temperature range ensures the metal flows smoothly without damaging the die.

- Injection: The molten aluminum is injected into the die cavity at high pressure (ranging from 1,000 to 15,000 psi). This pressure ensures the metal fills every detail of the die, even tiny holes or thin walls.

- Cooling & Ejection: The aluminum cools and solidifies inside the die (usually in 10 to 120 seconds, depending on part size). Once solid, the die halves open, and ejector pins push the finished part out.

- Finishing: The part may go through trimming (to remove excess metal called “flash”), polishing, or coating to meet quality standards.

A real-world example: A leading automotive supplier we worked with uses aluminum die casting to make engine brackets. By using this process, they reduced production time per bracket from 30 minutes (with traditional machining) to just 2 minutes, while cutting material waste by 40%. This shows how aluminum die casting balances speed, precision, and cost-efficiency.

The Two Main Types of Aluminum Die Casting Processes

Not all aluminum die casting is the same—there are two primary methods, each suited for different part requirements. Understanding their differences helps you choose the right one for a project.

| Process | Pressure Range | Cycle Time | Best For | Key Advantage |

| Hot Chamber Die Casting | 1,000–5,000 psi | Fast (10–30 seconds) | Small parts (e.g., zipper pulls, sensor housings) | No need to transfer molten aluminum—faster cycles |

| Cold Chamber Die Casting | 5,000–15,000 psi | Slower (30–120 seconds) | Large/complex parts (e.g., car engine blocks, laptop frames) | Handles high-temperature alloys without damaging the die |

For instance, a consumer electronics brand we consulted needed to make tiny USB-C connector housings. Hot chamber die casting was the clear choice: it produced 1,200 parts per hour with near-perfect precision, which cold chamber (better for bigger parts) couldn’t match. On the flip side, a truck manufacturer uses cold chamber casting for their aluminum wheel hubs—these large parts require higher pressure to fill the die fully, and cold chamber’s design prevents overheating the equipment.

Why Choose Aluminum Die Casting? Key Benefits

Aluminum die casting isn’t just popular by chance—it offers unique advantages that make it ideal for many industries. Here are the top benefits, backed by data and examples:

1. High Precision and Consistency

Aluminum die casting can produce parts with tolerances as tight as ±0.005 inches (0.127 mm), meaning every part is nearly identical. This is critical for industries like aerospace, where even small variations can cause failures. A satellite component manufacturer we worked with uses aluminum die casting for their antenna mounts—each mount must align perfectly with other parts, and die casting’s consistency ensures zero misalignments in 10,000+ units produced.

2. Lightweight Yet Strong

Aluminum has a density of just 2.7 g/cm³ (about 1/3 the weight of steel), but die-cast aluminum parts (especially alloys with silicon) can have a tensile strength of 30,000 to 60,000 psi—strong enough for heavy-duty use. For example, a bicycle company switched from steel to die-cast aluminum for their frame joints: the parts were 40% lighter, but durability tests showed they could withstand 500+ pounds of pressure without bending.

3. Cost-Effective for High Volume

While die molds (especially custom ones) can cost \(5,000 to \)100,000 upfront, the per-unit cost drops drastically for large production runs. A kitchen appliance brand found that producing 100,000 die-cast aluminum handles cost just \(1.20 per unit—compared to \)3.50 per unit with machining. The upfront mold cost was paid off after just 15,000 units.

4. Versatile Design Options

Die casting can create parts with complex shapes—think thin walls (as thin as 0.5 mm), internal channels, or intricate patterns—that would be impossible or too expensive with other methods. A lighting company used this to their advantage: they designed a die-cast aluminum light fixture with built-in heat sinks (to cool LEDs) and decorative grooves. Traditional methods would have required 3 separate parts; die casting made it one piece, cutting assembly time by 60%.

Common Applications of Aluminum Die Casting

Aluminum die casting is everywhere—you probably use products made with it every day. Here are the most common industries and examples:

Automotive Industry

This is the biggest user of die-cast aluminum parts. Cars and trucks rely on them for:

- Engine components (blocks, cylinder heads, oil pans)

- Transmission parts (gears, housings)

- Structural parts (door frames, suspension brackets)

Why? Aluminum’s light weight improves fuel efficiency. The EPA estimates that replacing 100 pounds of steel with aluminum in a car reduces fuel consumption by 0.1 to 0.2 miles per gallon. A major automaker reported that using die-cast aluminum for their SUV’s engine block cut the vehicle’s weight by 75 pounds, leading to a 1.5 mpg improvement.

Electronics

Electronics need lightweight, heat-resistant parts—aluminum die casting delivers:

- Laptop/tablet frames (protects internal components while staying light)

- LED heat sinks (aluminum conducts heat well, preventing overheating)

- Smartphone camera housings (precise shapes to fit lenses)

A smartphone manufacturer we partnered with uses die-cast aluminum for their camera bumpers. The process ensures the bumper’s small, curved edges fit perfectly with the phone’s glass back, reducing assembly errors by 90%.

Home Appliances

From kitchen tools to HVAC systems, die-cast aluminum is key:

- Cookware handles (heat-resistant and durable)

- Air conditioner compressor housings (protects moving parts from dust)

- Washing machine drum brackets (holds heavy drums in place)

A home appliance brand found that die-cast aluminum handles for their ovens lasted 3x longer than plastic handles (which melted at high temperatures) and were 20% cheaper than stainless steel ones.

Challenges of Aluminum Die Casting (and How to Solve Them)

While aluminum die casting has many benefits, it’s not without challenges. Here are the most common issues and practical solutions, based on industry experience:

1. Porosity (Small Holes in the Part)

Porosity happens when air gets trapped in the molten aluminum during injection. It weakens the part and can cause leaks (for parts holding fluids).

Solution: Use a “vacuum die casting” process, which removes air from the die cavity before injection. A hydraulic parts manufacturer we worked with reduced porosity by 85% using this method—their hydraulic valves (which need to be leak-proof) now pass 100% of pressure tests.

2. Die Wear (Molds Degrade Over Time)

High temperatures and pressure can wear down steel dies, leading to lower precision.

Solution: Use die steels with high heat resistance (like H13 steel) and apply a ceramic coating to the die surface. A medical device maker extended their die life from 50,000 parts to 150,000 parts by using H13 steel and ceramic coating—saving $20,000 in mold replacement costs.

3. Flash (Excess Metal on the Part)

Flash forms when molten aluminum seeps between the two die halves. It requires extra trimming time.

Solution: Tighten the die halves (increase “clamping force”) and use a high-quality lubricant (to prevent metal from sticking). A toy manufacturer cut trimming time by 40% by adjusting their clamping force and switching to a synthetic lubricant.

Yigu Technology’s Perspective on Aluminum Die Casting

At Yigu Technology, we see aluminum die casting as a cornerstone of modern manufacturing—especially as industries shift toward lightweight, sustainable products. Over the years, we’ve helped clients in automotive, electronics, and home appliances optimize their die casting processes: from designing custom dies that reduce waste to implementing vacuum casting for leak-proof parts. We’ve found that the biggest mistake companies make is choosing the wrong die casting type (e.g., using hot chamber for large parts) — this leads to higher costs and lower quality. Our advice? Always start with a detailed analysis of your part’s size, volume, and performance needs. With the right approach, aluminum die casting can not only cut costs but also unlock design possibilities you might not have considered.

FAQ About Aluminum Die Casting

1. Is aluminum die casting recyclable?

Yes! Aluminum is 100% recyclable, and recycling it uses just 5% of the energy needed to produce new aluminum. Many die casting companies (including our partners) use recycled aluminum for their parts—reducing carbon emissions by up to 95%.

2. How long does a die casting mold last?

It depends on the die material and usage. A standard steel die (H13 steel) can produce 50,000 to 150,000 parts. For high-volume production (1 million+ parts), you may need to replace the die once or twice, but the per-unit cost is still lower than other methods.

3. Can aluminum die casting make parts with very thin walls?

Yes—aluminum die casting can produce walls as thin as 0.5 mm (0.02 inches), but this requires precise die design and high injection pressure. For parts with walls thinner than 0.5 mm, you may need to use “micro die casting” (a specialized process for tiny parts).

4. Is aluminum die casting more expensive than plastic molding?

For high-volume production (10,000+ parts), no. Plastic molds are cheaper upfront, but aluminum die casting parts are more durable and can replace multiple plastic parts (reducing assembly costs). For example, a 10,000-unit run of a plastic electronics housing costs \(0.80 per unit, while an aluminum one costs \)1.00 per unit—but the aluminum part lasts 5x longer, so it’s cheaper in the long run.

5. What aluminum alloys are best for die casting?

The most common alloy is ADC12 (contains 9–12% silicon), which is easy to cast, strong, and affordable—great for most parts. For high-strength needs (like automotive structural parts), A380 (contains 7.5–9.5% silicon) is better. For parts needing good corrosion resistance (like marine components), A413 (high silicon content) works well.