Manufacturers often struggle with the trade-off between mold performance and production speed—especially when developing prototypes or low-volume runs. Steel molds, while durable, are heavy, expensive, and time-consuming to machine, delaying time-to-market for new products. For short production runs or iterative prototyping, the high cost of steel molds can’t be justified, and their slow heat dissipation extends cycle times. This is where mold making aluminum alloys shine. Offering exceptional machinability, high thermal conductivity, and lightweight properties, aluminum alloys solve these pain points, enabling faster production, lower costs, and greater flexibility. In this guide, we’ll explore why aluminum alloys are revolutionizing mold making for prototypes and low-volume runs, their key properties, and how to leverage their advantages effectively.

Introduction to Mold Making Aluminum Alloys

Mold making aluminum alloys are specialized aluminum materials engineered to balance strength, machinability, and thermal performance for molding applications:

- Definition: These are aluminum-based alloys, typically reinforced with elements like copper, zinc, or magnesium, designed to withstand the pressures and temperatures of plastic molding while remaining easy to machine.

- Types of aluminum alloys for mold making: The most common grades include 6061 (general-purpose, 110-145 MPa tensile strength), 7075 (high-strength, 500-570 MPa), and 5083 (corrosion-resistant, 290-350 MPa). 7075 is preferred for higher-pressure applications, while 6061 is the workhorse for prototypes.

- Standard specifications: Aluminum alloys for molds adhere to ASTM B209 (sheet/plate) and ASTM B211 (bar/stock) standards, ensuring consistent chemical composition and mechanical properties. For example, 6061 requires 0.4-0.8% silicon and 0.7% iron for optimal machinability.

- Supplier brands: Leading suppliers include Alcoa, Novelis, and Chinese producers like Chalco. These brands offer pre-cut aluminum blocks tailored for mold making, reducing material waste.

- Industry usage: Aluminum alloys are used in 70-80% of prototype molds and 30-40% of low-volume production molds (1,000-50,000 cycles). Their popularity spans automotive prototyping, consumer electronics, and medical device development.

- Comparison with other mold materials: Compared to steel, aluminum alloys are 3x lighter, machine 50-70% faster, and reduce cycle times by 10-20% due to better thermal conductivity. They cost 20-30% less than steel for small to medium molds but have shorter lifespans (50,000 cycles vs. 1 million+ for steel).

Properties of Mold Making Aluminum Alloys

The properties of mold making aluminum alloys make them uniquely suited for fast-turnaround, low-volume applications:

- Lightweight: Aluminum weighs 2.7 g/cm³, a third of steel’s 7.8 g/cm³. This reduces mold handling costs and makes it easier to integrate into automated molding systems.

- High thermal conductivity: Aluminum conducts heat 4-5x faster than steel (160-200 W/m·K vs. 40-50 W/m·K for P20). This cuts cooling times, reducing cycle times by 15-25% for injection molding.

- Corrosion resistance: Alloys like 5083 resist corrosion from water-based coolants and mild mold release agents, outperforming uncoated steel in humid environments. 6061 and 7075 benefit from anodizing to boost corrosion resistance further.

- Machinability: Aluminum alloys machine with exceptional ease, allowing cutting speeds of 300-500 SFM—5-10x faster than steel. This reduces machining time from days to hours for complex prototypes.

- Strength-to-weight ratio: 7075 offers a strength-to-weight ratio 2x higher than steel, with tensile strength approaching some steels while remaining lightweight. This makes it suitable for medium-pressure molding (up to 10,000 psi).

- Thermal expansion: Aluminum expands more than steel (23.1 × 10⁻⁶/°C vs. 11.7 × 10⁻⁶/°C), but this is manageable with proper mold design (e.g., larger cooling channels) to prevent warping.

- Surface finish capabilities: Aluminum polishes to Ra 0.05-0.1 μm, sufficient for most prototypes and non-cosmetic parts. Anodizing can improve surface hardness (up to 50 HRC) and create a smooth, wear-resistant finish.

Applications of Mold Making Aluminum Alloys

Mold making aluminum alloys excel in applications where speed, cost, and flexibility are prioritized:

- Prototype molds: For testing new designs, aluminum molds deliver parts in days (vs. weeks for steel), allowing rapid iteration. 6061 is ideal here, balancing cost and machinability.

- Low-volume production molds: Runs of 1,000-50,000 parts (e.g., custom packaging, limited-edition electronics) benefit from aluminum’s lower upfront cost. 7075 handles these volumes for non-abrasive plastics like ABS.

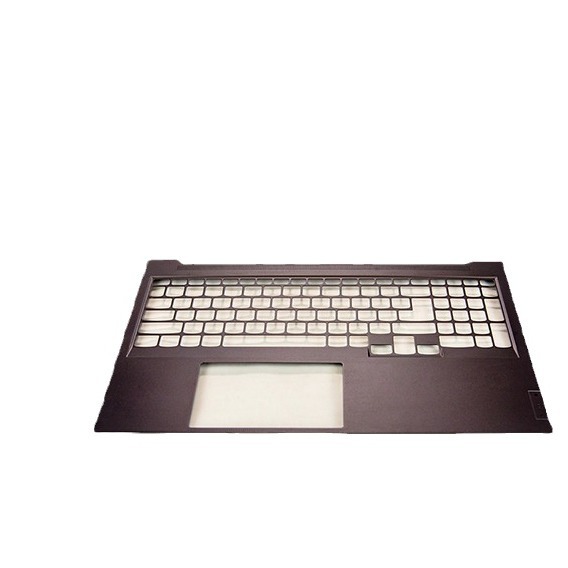

- Injection molding: Aluminum molds reduce cycle times for small to medium parts (e.g., phone cases, connectors) by accelerating cooling. Their lightweight nature also eases mold changes on injection machines.

- Blow molding: For prototype bottles or containers, aluminum’s ease of machining allows quick adjustments to neck finishes or wall thickness, critical for design validation.

- Medical device molds: Aluminum’s corrosion resistance (with anodizing) makes it suitable for low-volume medical parts like prototype inhalers or diagnostic tool housings, meeting biocompatibility standards.

- Automotive molds: Car manufacturers use aluminum for prototype interior parts (e.g., dashboard trim) and low-volume specialty components, reducing development costs.

Machining and Fabrication of Mold Making Aluminum Alloys

Machining and fabrication of aluminum alloys are straightforward, but require attention to avoid common pitfalls:

- Precision machining: Aluminum cuts cleanly with HSS or carbide tools. Use high cutting speeds (300-500 SFM) and light feeds to prevent built-up edge (BUE), which mars surface finish. Coolant is essential to dissipate heat and flush chips.

- CNC milling: 3-axis and 5-axis CNC milling are ideal, with aluminum’s low cutting forces enabling tight tolerances (±0.0005 inches). Adaptive milling strategies reduce cycle times by 20-30% for complex geometries.

- EDM (Electrical Discharge Machining): EDM works well for intricate details, though aluminum’s high conductivity requires adjusted parameters (lower current) to prevent electrode wear.

- Grinding: Aluminum grinds easily with silicon carbide wheels, but requires light pressure to avoid clogging. A 400-grit wheel achieves Ra 0.05 μm, suitable for most applications.

- Surface finishing: For cosmetic parts, polish with 400-600-grit sandpaper followed by a buffing wheel with aluminum oxide compound. Anodizing (Type II or III) adds a protective layer, improving wear resistance.

- Machining challenges: Chip evacuation is critical—long, stringy chips can 缠结刀具 (tangle tools). Use chip breakers and high-pressure coolant to keep the cutting zone clean. Also, avoid over-tightening clamps, which can deform aluminum’s soft surface.

Maintenance and Repair of Mold Making Aluminum Alloys

Proper maintenance and repair extend the life of aluminum molds, even in repeated use:

- Mold cleaning: Clean aluminum molds with mild detergents (avoid acidic cleaners) to remove plastic residue. Soft brushes prevent scratching, preserving surface finish.

- Surface treatment: Anodizing (Type III, hard anodizing) adds a 50-100 μm thick layer, increasing surface hardness to 50 HRC and improving wear resistance by 3-4x. This is recommended for molds running >10,000 cycles.

- Repair welding: Aluminum molds can be TIG welded with matching filler wire (e.g., 4043 for 6061). Post-weld machining and annealing restore dimensional accuracy.

- Preventive maintenance: Apply a thin layer of silicone-based mold release agent to reduce friction and prevent plastic buildup. Inspect cooling channels monthly for clogs, which reduce thermal performance.

- Inspection: Use ultrasonic testing to detect internal cracks, especially in high-stress areas like parting lines. Visual checks for surface scratches or dents ensure part quality remains consistent.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends aluminum alloys for clients needing fast prototypes or low-volume molds. We’ve seen 6061 reduce prototype lead times by 50% compared to steel, critical for time-sensitive product launches. For low-volume runs (1,000-10,000 parts), aluminum cuts costs by 30-40 while maintaining acceptable quality. Our team uses high-speed CNC machining to achieve tight tolerances in aluminum, and we often recommend hard anodizing for clients needing extended mold life. While aluminum isn’t suitable for high-volume or abrasive plastics, it’s unbeatable for speed and flexibility in early-stage production and prototyping.

FAQs

- What’s the maximum number of cycles an aluminum mold can handle?

For non-abrasive plastics (ABS, PP), 6061 molds last 10,000-30,000 cycles; 7075 with hard anodizing can reach 50,000 cycles. Avoid glass-filled plastics, as they abrade aluminum quickly.

- Can aluminum molds be used for food-grade applications?

Yes—anodized aluminum (Type II) meets FDA standards for food contact, making it suitable for low-volume food containers or packaging prototypes.

- How does aluminum’s thermal expansion affect mold design?

Aluminum expands more than steel, so design cooling channels 10-15% larger to accommodate expansion. Use venting to prevent gas traps, and avoid tight tolerances on features sensitive to temperature changes.