Introduction

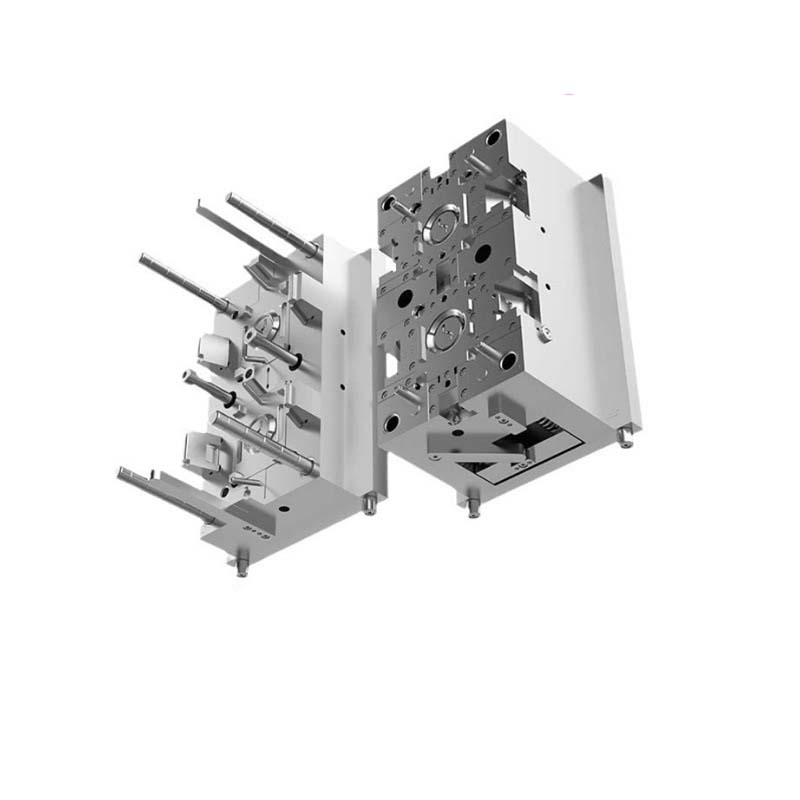

In the vast landscape of modern manufacturing, molds makers stand as the unsung heroes, playing a pivotal role in shaping the products that surround us in our daily lives. From the tiniest components in our smartphones to the large - scale parts in automobiles, molds makers are the driving force behind the creation of a diverse range of items across multiple industries.

Consider the automotive industry. The sleek body panels of a luxury car, the precise interior components like dashboards and door trims - all are the result of the work of molds makers. In the electronics sector, the compact and precisely - shaped casings of our laptops, tablets, and even the micro - components within the circuit boards are made possible through the expertise of these professionals. The food and beverage industry also benefits greatly, with molds being used to create the packaging that preserves our favorite products.

As we look towards the future, the role of molds makers becomes even more significant. The evolving demands of industries, the pursuit of innovation, and the drive for more sustainable and efficient manufacturing processes all rest, to a large extent, on the shoulders of molds makers. This article will delve deep into how molds makers are crafting the future, one shape at a time, exploring their techniques, challenges, and the impact they have on the global manufacturing landscape.

The Art and Science of Mold Making

1. Design Phase

The design phase is the foundation of mold making, where the blueprint for the final product takes shape. Molds makers begin by understanding the product requirements. This involves collaborating closely with clients or product designers to gather details about the product's functionality, dimensions, and any specific performance criteria.

In today's modern mold - making industry, Computer - Aided Design (CAD) and Computer - Aided Manufacturing (CAM) technologies have become indispensable. CAD software allows molds makers to create highly detailed 3D models of the mold. For example, with the use of parametric design in CAD, any changes in the product's dimensions can be easily updated throughout the entire mold design, saving significant time and effort. These 3D models are not only visual representations but also serve as a basis for simulating the mold - making process, identifying potential design flaws, and optimizing the mold's structure.

CAM technology then takes over from the design stage. It converts the CAD models into machine - readable instructions for the manufacturing equipment. This seamless integration of CAD and CAM ensures that the mold is manufactured precisely as designed, with tight tolerances that can be as small as a few micrometers in high - precision applications. For instance, in the production of micro - molds for the electronics industry, where components are extremely small, CAD/CAM technology enables the creation of molds with intricate details and exact specifications.

During the design phase, molds makers also consider factors such as product functionality. If the final product is a mechanical component, the mold design must account for features like smooth surfaces for reduced friction, proper alignment holes, and adequate wall thickness to ensure structural integrity. Production efficiency is another crucial aspect. Designers may incorporate features such as multi - cavity molds, which allow for the production of multiple parts in a single cycle, significantly increasing output and reducing production time.

2. Material Selection

The choice of material for a mold is a critical decision that can have a profound impact on the mold's quality, performance, and lifespan. Different materials offer unique properties, making them suitable for specific applications.

- Metal Molds: Metals such as steel, aluminum, and copper are commonly used in mold making. Steel, especially alloy steels, is popular due to its high strength, excellent wear resistance, and heat resistance. For example, in injection molding of high - volume plastic products like automotive bumpers, steel molds can withstand the high pressures and temperatures involved in the process for a long time, ensuring consistent quality over a large number of production cycles. Tool steel, with its high carbon content, is often used for molds that require extreme hardness and wear resistance, such as those for stamping and forging processes. Aluminum molds, on the other hand, are favored for their lightweight nature and good thermal conductivity. They are often used in applications where rapid heat transfer is essential, such as in die - casting of small, heat - sensitive components. Copper molds are known for their excellent electrical and thermal conductivity, making them suitable for molds used in electro - forming and some specialized casting processes.

- Plastic Molds: Plastic molds are typically made from engineering plastics like epoxy, phenolic, and urethane. They are relatively inexpensive compared to metal molds and are easier to fabricate. Plastic molds are often used for low - volume production runs or for prototyping purposes. For example, in the development of a new consumer product, a plastic mold can be quickly created to produce a small number of sample parts for testing and market evaluation. They are also suitable for products with complex geometries that may be difficult to achieve with metal molds using traditional manufacturing methods. However, plastic molds have lower strength and heat resistance compared to metal molds, limiting their use in high - volume and high - temperature applications.

The material selection also depends on the type of product being produced. For food - contact products, materials that meet strict food - safety regulations, such as certain grades of stainless steel or food - grade plastics, must be used. In the medical industry, biocompatible materials are essential to ensure that the molds do not contaminate the medical devices being produced.

3. Manufacturing Processes

There are several manufacturing processes available to molds makers, each with its own set of advantages and limitations.

- Injection Molding: This is one of the most common mold - making processes, especially for plastic products. In injection molding, molten plastic is injected into a mold cavity at high pressure. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected. The process is highly efficient and can produce complex - shaped parts with high precision. For example, the production of small plastic toys with detailed features, like action figures, is often achieved through injection molding. The advantages of injection molding include high production rates, the ability to create parts with thin walls, and excellent dimensional accuracy. However, it requires expensive equipment and high - cost molds, making it less suitable for low - volume production.

- Die - Casting: Die - casting is used primarily for metal parts. Molten metal, such as aluminum, zinc, or magnesium, is forced into a mold cavity under high pressure. This process is capable of producing parts with complex geometries and high surface finishes. In the automotive industry, many engine components, such as cylinder heads and engine blocks, are die - cast. Die - casting offers high production efficiency, good dimensional stability, and the ability to create parts with fine details. But the initial investment in die - casting equipment and molds is substantial, and the process is limited to certain types of metals.

- CNC Machining: Computer - Numerical - Control (CNC) machining is a versatile process that can be used to create molds from a variety of materials, including metals, plastics, and composites. CNC machines use pre - programmed computer software to control the movement of cutting tools, allowing for highly precise and repeatable operations. This process is often used for creating molds with complex 3D shapes or when high - precision machining is required. For example, in the aerospace industry, where molds for turbine blades need to be extremely accurate, CNC machining is a preferred method. The advantages of CNC machining include its flexibility in handling different materials, high precision, and the ability to produce one - off or small - batch molds. However, it can be a time - consuming process, especially for large and complex molds, and the cost of CNC equipment and skilled operators can be high.

Quality Assurance in Mold Making

1. Precision and Tolerance

In mold making, precision and tolerance are two fundamental concepts that are crucial for ensuring the quality of the final products. Precision refers to the degree of exactness with which a mold is manufactured. It encompasses the accuracy of the mold's dimensions, the smoothness of its surfaces, and the consistency of its features. Tolerance, on the other hand, is the allowable deviation from the specified dimensions or characteristics of the mold.

High - precision molds are essential for producing high - quality products. In the automotive industry, for example, the engine pistons are made using molds. If the mold's precision is not up to par, the pistons produced may have inconsistent diameters. This can lead to issues such as poor engine performance, increased fuel consumption, and even engine failure. A study by the Society of Automotive Engineers found that for every 0.01 - millimeter deviation in piston diameter, the engine's efficiency can decrease by up to 2%.

In the electronics industry, where components are becoming increasingly smaller and more complex, the tolerance requirements for molds are extremely tight. For instance, in the production of micro - connectors for smartphones, the molds need to have tolerances in the range of micrometers. A deviation of just a few micrometers can cause problems in the electrical connection, leading to issues like signal loss or intermittent connectivity.

2. Testing and Inspection

To ensure that molds meet the required quality standards, a series of testing and inspection methods are employed throughout the mold - making process.

- Pressure Testing: This is commonly used in molds for applications such as injection molding and die - casting. In injection molding, for example, the mold is subjected to high - pressure molten plastic during the production process. Pressure testing is done to ensure that the mold can withstand these high pressures without deformation or leakage. Specialized pressure - testing equipment is used to apply incremental pressure to the mold, simulating the actual production conditions. If the mold shows signs of weakness, such as cracks or bulges, during the pressure test, it can be repaired or redesigned before going into production. A recent report by the Plastics Industry Association showed that molds that underwent proper pressure testing had a 30% lower failure rate during production runs compared to those that did not.

- Dimension Inspection: Precise dimension inspection is a critical part of mold quality control. Coordinate Measuring Machines (CMMs) are often used for this purpose. CMMs can accurately measure the three - dimensional dimensions of a mold, comparing the measured values with the design specifications. For example, in the production of a complex mold for a medical device, CMMs can measure the internal cavities, holes, and protrusions to ensure they are within the specified tolerance limits. This helps to guarantee that the final product will fit together correctly and function as intended. According to a survey of medical device manufacturers, over 90% of them use CMMs for mold inspection to ensure the high - quality production of their products.

- Surface Finish Inspection: The surface finish of a mold can have a significant impact on the surface quality of the final product. Visual inspection is often the first step, where inspectors look for any visible scratches, pits, or roughness on the mold surface. For more in - depth inspection, surface roughness measuring instruments are used. In the production of molds for optical components, such as lenses, a smooth surface finish is essential. A rough mold surface can cause light scattering in the lens, reducing its optical performance. Manufacturers of optical components typically require a surface roughness of less than 0.1 micrometers for their mold surfaces to ensure high - quality lens production.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology deeply understands the significance of molds makers in the manufacturing industry. We believe that innovation and customization are the keys to success in the mold - making field. In a rapidly evolving market, customers have increasingly diverse and unique demands for products. Our advanced technology and rich experience enable us to provide customized solutions for different industries, from the initial design concept to the final product implementation.

FAQs

1. How to choose the right mold material for my product?

When choosing a mold material, several factors need to be considered. First, think about the product's characteristics. If it's a high - temperature - resistant component, materials like heat - resistant steel or certain high - performance plastics should be on your list. For products that require high wear resistance, tool steels with high carbon content could be a great option.

Production volume also matters. For large - scale production, materials that can withstand a large number of production cycles without significant wear, such as alloy steels, are more suitable. On the other hand, if you're only producing a small batch, less expensive materials like some plastics or basic metals might be sufficient.

Cost is another crucial factor. While high - performance materials offer excellent properties, they can be costly. You need to balance the material cost with the overall budget for your project. For example, if you're in a cost - sensitive industry like consumer goods with high - volume production, you may lean towards more affordable materials that still meet the quality requirements.

2. What is the typical lead time for mold production?

The lead time for mold production can vary widely depending on several factors. Design complexity plays a major role. A simple two - cavity injection mold for a basic plastic part might have a relatively short lead time. However, a complex mold with intricate 3D geometries, multiple moving parts, and tight tolerances, like those used in the aerospace or medical device industries, will take much longer to design and manufacture.

The manufacturing process also impacts the lead time. Processes like CNC machining can be time - consuming, especially for large and complex molds. Injection molding and die - casting molds may require additional time for tooling setup and calibration.

Material supply is another consideration. If the required mold material is in high demand or has a long procurement cycle, it can delay the start of the mold - making process.

In general, a simple mold could be produced in as little as 2 - 4 weeks, while a complex, high - precision mold might take 8 - 16 weeks or even longer.