Imagine a hot forging die that cracks after just a few hundred cycles, or a die casting mold that warps under the heat of molten metal—costing your operation thousands in downtime and replacements. These are the all-too-common nightmares of manufacturers relying on subpar materials for high-temperature applications. Enter hot work tool steels—the unsung heroes designed to thrive where other steels fail. Built to withstand extreme heat, repeated thermal cycles, and heavy mechanical stress, these specialized alloys are the backbone of hot forging, extrusion, and die casting operations. In this guide, we’ll dive into what makes hot work tool steels unique, how they solve critical manufacturing pain points, and why choosing the right grade can transform your production efficiency.

Material Properties of Hot Work Tool Steels

The true power of hot work tool steels lies in their carefully engineered material properties, each tailored to survive the harsh conditions of high-temperature manufacturing:

- High-temperature strength: Unlike cold work steels, hot work grades maintain their strength at temperatures up to 1,200°F (649°C) and beyond. For example, H13 retains 80% of its room-temperature strength at 1,000°F (538°C)—critical for resisting deformation under heavy loads.

- Hot hardness: Measured as the ability to stay hard at elevated temperatures, this property ensures tools maintain their shape during prolonged contact with hot metals. H13 and 1.2344 typically exhibit a hot hardness of 45-50 HRC at 1,000°F, far exceeding the 30 HRC of most cold work steels at the same temperature.

- Resistance to thermal fatigue: Repeated heating and cooling (common in die casting) create stress that leads to cracking. Hot work steels like SKD61 are formulated to resist this, with thermal fatigue resistance 30-50% better than cold work grades like D2.

- Thermal conductivity: Efficient heat transfer prevents hot spots that cause uneven wear. Hot work steels have thermal conductivity rates of 25-35 W/m·K, higher than cold work steels (15-20 W/m·K), allowing faster heat dissipation.

- Red hardness: This refers to the ability to retain hardness after prolonged exposure to high temperatures. High-vanadium grades excel here, making them ideal for continuous operations like hot rolling.

- Dimensional stability at high temperatures: Hot work steels expand minimally under heat, with thermal expansion coefficients around 11-13 × 10⁻⁶/°C—low enough to maintain tight tolerances in precision hot stamping.

Tool Steel Grades for Hot Work Applications

Choosing the right tool steel grade is critical—each is engineered for specific temperature ranges and stress levels:

- H13 (AISI grade): The workhorse of hot work steels, H13 contains 5% chromium, 1.5% molybdenum, and 1% vanadium. It balances high-temperature strength and toughness, making it ideal for die casting and hot forging.

- 1.2344 (DIN grade): Europe’s equivalent to H13, 1.2344 offers slightly better thermal stability, often used in automotive hot stamping dies where consistent performance is key.

- SKD61 (JIS grade): Japan’s standard hot work steel, SKD61 has lower silicon content than H13, improving its polishability for plastic injection molds used with high-temperature resins.

- Powder metallurgy hot work steels: These ultra-high-performance grades (e.g., ASP-2059) feature uniform carbide distribution, resisting wear 20-30% better than H13 in extreme applications like hot extrusion of superalloys.

- High-vanadium grades: With 3-5% vanadium, these steels (e.g., H11) excel in red hardness, perfect for continuous hot rolling where tools stay hot for hours.

- High-molybdenum grades: Molybdenum boosts toughness at high temperatures, making grades like H19 suitable for impact-heavy hot forging of large components.

Heat Treatment Processes for Hot Work Steels

Proper heat treatment processes are non-negotiable—they unlock the full potential of hot work steels:

- Annealing for hot work steels: Prepares the steel for machining by softening it to 200-240 HB. Heat to 1,500-1,550°F (815-845°C), hold 2-4 hours, then cool slowly (≤50°F/hour) to prevent stress.

- Hardening temperatures: Most hot work steels are hardened at 1,850-2,050°F (1,010-1,120°C), depending on the grade. H13 hardens best at 1,875°F (1,024°C), while 1.2344 performs better at 1,925°F (1,052°C).

- Tempering cycles: Critical for balancing hardness and toughness. H13 is typically tempered at 1,000-1,100°F (538-593°C) for 2-4 hours, resulting in 44-48 HRC—ideal for withstanding thermal stress.

- Quenching methods: Vacuum quenching is preferred for hot work steels, as it cools the steel evenly (200-300°F/second) without oxidation, preserving surface quality. Oil quenching is used for simpler shapes but may cause uneven cooling.

- Surface treatments: Nitriding adds a 5-10 micron hard layer, increasing surface hardness to 65-70 HRC and improving wear resistance at elevated temperatures by 40%.

Applications in Hot Work: Where These Steels Shine

Hot work tool steels excel in applications in hot work that would destroy ordinary materials:

- Hot forging dies: H13 and 1.2344 are staples here, withstanding the extreme pressure (up to 50,000 psi) and heat (1,200-1,800°F) of shaping metal billets into automotive parts and industrial components.

- Die casting molds: SKD61 and H13 handle the cyclic heating from molten aluminum (660°C) and cooling, resisting thermal fatigue for 50,000-100,000 cycles—3x longer than cold work steels.

- Hot extrusion tools: Powder metallurgy grades shine in extruding stainless steel and titanium, where die temperatures exceed 1,500°F. These tools last 2-3x longer than H13 in such harsh conditions.

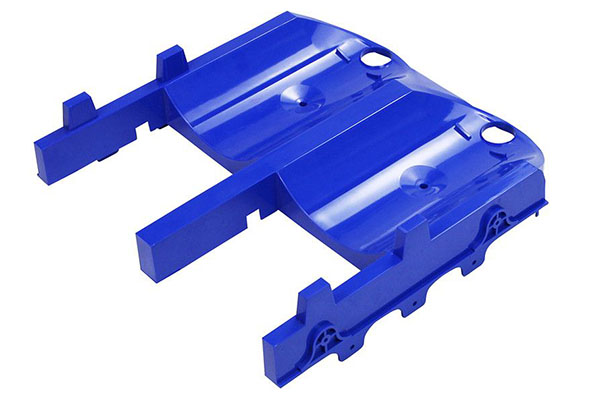

- Injection molding for high-temperature plastics: SKD61 molds handle PEEK and other high-performance resins (processed at 700-800°F), maintaining their surface finish for 100,000+ cycles.

- Automotive hot work applications: Hot stamping dies (using 1.2344) shape boron steel into crash-resistant parts, withstanding 900°C blanks and cooling to 200°C in seconds—all while maintaining precision.

Performance and Durability of Hot Work Steels

When it comes to performance and durability, hot work steels deliver results that justify their higher cost:

- Mold life expectancy: H13 die casting molds last 50,000-150,000 cycles, depending on the alloy being cast. For aluminum, expect 100,000+ cycles—far more than the 10,000 cycles of a cold work steel in the same application.

- Resistance to thermal cracking: Properly heat-treated hot work steels resist cracking from thermal shock. In testing, H13 withstands 500+ thermal cycles (1,000°F to 70°F) without cracking, while D2 fails after 50-100 cycles.

- Cost-effectiveness: While H13 costs 2-3x more than D2 upfront, its 10x longer life in hot applications makes it far cheaper over time. For a high-volume die casting operation, switching to H13 reduces annual tooling costs by 40-60%.

- Production cycle time: Hot work steels maintain their shape, reducing the need for rework. This cuts cycle times by 10-15% compared to using worn or warped tools made from inferior materials.

Maintenance and Repair of Hot Work Tools

Proper maintenance and repair extend the life of hot work tools significantly:

- Preventive maintenance: Clean tools after each shift to remove scale and debris, which can accelerate wear. Apply a protective coating during storage to prevent oxidation.

- Reconditioning: Grinding and re-tempering can restore worn H13 dies 3-5 times, extending their life by 2-3x. This is far more cost-effective than replacing the entire tool.

- Crack repair: Small thermal cracks can be welded with matching filler rods, but post-weld heat treatment is essential to restore toughness and prevent further cracking.

- Tool sharpening: For hot shearing tools, sharpen edges when wear reaches 0.002 inches. Use cubic boron nitride (CBN) wheels to avoid overheating the steel.

Comparison with Cold Work Steels

How do hot work steels stack up against their cold work counterparts? Here’s a clear breakdown:

| Property | Hot Work Steels (e.g., H13) | Cold Work Steels (e.g., D2) |

| Maximum Service Temperature | 1,200°F+ | ≤600°F |

| Hot Hardness (1,000°F) | 45-50 HRC | 30-35 HRC |

| Thermal Fatigue Resistance | Excellent | Poor |

| Toughness at High Temp | Good | Poor |

| Wear Resistance (Room Temp) | Good | Excellent |

| Cost (Relative) | High | Medium |

- D2 tool steel vs. H13: D2 offers superior room-temperature wear resistance but fails quickly at high temperatures, making it unsuitable for hot work.

- DC53 vs. SKD61: DC53’s toughness is no match for SKD61’s thermal stability—DC53 warps and cracks in die casting applications, while SKD61 thrives.

- Application suitability: Cold work steels excel in low-heat, high-wear tasks (stamping cold metal), while hot work steels dominate high-heat, cyclic stress applications (die casting, hot forging).

Industry Standards and Specifications

Hot work steels are governed by strict industry standards and specifications to ensure quality:

- ASTM standards: ASTM A681 covers H13 and other hot work steels, specifying chemical composition and heat treatment requirements.

- DIN standards: DIN 1.2344 outlines strict controls on carbide distribution, critical for consistent performance in European manufacturing.

- JIS standards: JIS G4404 defines SKD61’s properties, with tight tolerances on sulfur and phosphorus to ensure toughness.

- Quality certifications: ISO 9001-certified manufacturers (like Yigu Technology) adhere to strict processes, from raw material testing to final heat treatment, ensuring each batch meets specifications.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology relies on hot work tool steels to deliver reliable, long-lasting molds for our clients. We’ve found H13 and 1.2344 to be the most versatile, balancing performance and cost for 90% of hot work applications. Our in-house heat treatment experts optimize each grade—for example, tempering H13 at 1,050°F for automotive die casting molds to maximize thermal fatigue resistance. For clients new to hot work steels, we often conduct trials comparing H13 with their current materials, typically showing 50% longer tool life and 30% fewer production delays.

FAQs

- Can hot work steels be used for cold work applications?

While technically possible, hot work steels are less cost-effective than cold work grades for low-heat tasks. Their lower room-temperature hardness also leads to shorter tool life in cold stamping or extrusion.

- What’s the best hot work steel for die casting aluminum?

H13 and SKD61 are ideal—their resistance to thermal fatigue and good polishability make them perfect for aluminum die casting, with typical mold lives of 100,000+ cycles.

- How does nitriding improve hot work tool performance?

Nitriding creates a hard, wear-resistant surface layer that increases wear resistance at elevated temperatures by 40%, extending tool life in abrasive hot extrusion applications.