Introduction

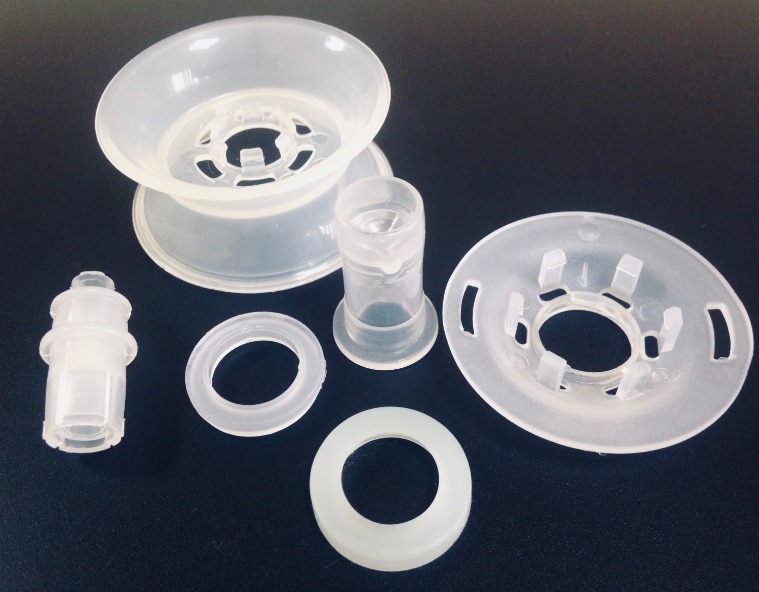

Plastic injection mold parts play a fundamental role in the manufacturing industry, serving as the backbone for the production of a vast array of plastic products. From the tiniest components in electronics to large automotive parts, their importance cannot be overstated. These parts are the key to achieving high - volume production with consistent quality, cost - effectiveness, and design flexibility.

The manufacturing landscape is constantly evolving, driven by the pursuit of better products, increased efficiency, and reduced environmental impact. In this context, innovations in plastic injection mold parts have become crucial. These innovations not only improve the performance of the final products but also revolutionize the manufacturing process itself. They address challenges such as complex geometries, higher precision requirements, and shorter production cycles. As we delve deeper into the world of plastic injection mold parts, we will explore the latest advancements, their benefits, and how they are shaping the future of manufacturing.

Material Innovations

New High - Performance Plastics

The development of new high-performance plastics has been a significant innovation in the realm of plastic injection mold parts. Special engineering plastics such as polyetheretherketone (PEEK) and polyetherimide (PEI) have emerged as game-changers.

PEEK, for Yigu Technology example, has a high melting point of around 343°C. This property makes it ideal for applications that require parts to withstand high temperatures. In the automotive industry, PEEK - based plastic injection mold parts can be used in engine components. These parts can endure the extreme heat generated during engine operation, which traditional plastics cannot. PEEK also exhibits excellent mechanical strength, with a tensile strength that can reach up to 100 MPa. This strength allows for the production of lightweight yet durable parts, reducing the overall weight of the vehicle and improving fuel efficiency.

PEI, on the other hand, has a glass transition temperature of 217°C. It offers good dimensional stability, which is crucial for parts that require high precision. In the electronics industry, PEI plastic injection mold parts are used in connectors. Their dimensional stability ensures a perfect fit and reliable electrical connection, even in harsh operating environments.

Nanocomposites in Plastic Injection Molding

Nanocomposites are another exciting innovation in plastic injection mold parts. These are materials composed of a polymer matrix with nanoparticles dispersed within it, typically with at least one dimension in the nanometer range (1 - 100 nm). The nanoparticles can be made of various materials such as clay, carbon nanotubes, or metal oxides.

The concept behind nanocomposites is that the nanoparticles can enhance the properties of the base polymer in ways that traditional fillers cannot. For instance, when clay nanoparticles are added to a polymer matrix, they can significantly improve the material's barrier properties. The platelets of clay create a tortuous path for gas molecules, making it much more difficult for gases to permeate through the material. This is highly beneficial in applications such as food packaging. A plastic injection - molded food container made from a nanocomposite with clay nanoparticles can better preserve the freshness of the food inside by preventing oxygen and moisture from entering.

Carbon nanotubes are also commonly used in nanocomposites. They have an extremely high strength - to - weight ratio. When incorporated into a plastic matrix, they can enhance the mechanical strength of the resulting nanocomposite. In the aerospace industry, plastic injection mold parts made from nanocomposites with carbon nanotubes can be used in interior components. These parts can withstand the mechanical stresses during flight while being lightweight, contributing to fuel savings and increased payload capacity.

Design Innovations

CAD/CAM/CAE Technology Integration

The integration of CAD (Computer - Aided Design), CAM (Computer - Aided Manufacturing), and CAE (Computer - Aided Engineering) technologies has been a game - changer in the design and manufacturing of plastic injection mold parts.

CAD software allows designers to create highly detailed 3D models of plastic injection mold parts. For Yigu Technology example, with software like SolidWorks or CATIA, designers can precisely define the geometry of the mold, including complex shapes and fine details. These 3D models are not just visual representations; they serve as the foundation for the entire manufacturing process.

CAM technology then takes over. It uses the CAD - generated models to generate toolpaths for machining the mold. CNC (Computer Numerical Control) machines can accurately follow these toolpaths, ensuring high - precision manufacturing. This reduces the margin of error in the manufacturing process. In traditional manufacturing, manual programming of machine tools was prone to errors, which could lead to costly rework. With CAM, the error rate can be reduced to as low as 0.01 - 0.05 mm in some high - precision applications, resulting in significant cost savings.

CAE technology, on the other hand, is used for simulation and analysis. Software such as Moldflow can simulate the plastic injection molding process. It can predict how the molten plastic will flow within the mold, identify potential areas of short - shots (where the plastic does not fully fill the mold cavity), and analyze the distribution of stress and temperature during the process. By running these simulations, designers can optimize the mold design before actual production. For instance, a company manufacturing plastic housing for electronic devices used CAE analysis. The simulation showed that the original design had a high risk of warping due to uneven cooling. By modifying the cooling channels in the mold design based on the CAE results, the company was able to reduce warping by over 50%, improving the quality of the final product.

Design for Manufacturability (DFM) Improvements

Design for Manufacturability (DFM) has become an essential aspect of plastic injection mold part design. The goal of DFM is to design parts in a way that they can be manufactured efficiently and cost - effectively.

One of the key improvements in DFM is the optimization of mold structure. For example, the use of modular mold designs has become more prevalent. Instead of having a single, monolithic mold, modular molds are made up of multiple interchangeable components. This allows for easier repair and replacement of parts. If a particular section of the mold wears out or gets damaged, only that module needs to be replaced, rather than the entire mold. This reduces downtime and maintenance costs. A study showed that companies using modular mold designs experienced a 30% reduction in mold maintenance time.

Another aspect of DFM is the optimization of the manufacturing process itself. This includes considerations such as the selection of appropriate injection molding parameters. By carefully choosing factors like injection pressure, temperature, and cooling time, manufacturers can improve the quality of the plastic injection mold parts and increase production efficiency. For example, optimizing the injection pressure can ensure that the plastic fills the mold cavity evenly, reducing the occurrence of defects such as voids or uneven surfaces. A case study in the automotive industry found that by optimizing the injection molding parameters based on DFM principles, a company was able to increase its production output by 20% while maintaining the same level of product quality.

DFM also involves simplifying the design of plastic injection mold parts without sacrificing functionality. Complex designs may look appealing but can be difficult and costly to manufacture. By streamlining the design, removing unnecessary features, and using standard components whenever possible, manufacturers can reduce the complexity of the manufacturing process. This not only lowers production costs but also shortens the time to market for products.

Manufacturing Process Innovations

Micro - Injection Molding

Micro - injection molding is a revolutionary manufacturing process innovation in the production of plastic injection mold parts. This process is specifically designed for the creation of micro - sized components, where precision and miniaturization are of utmost importance.

In micro - injection molding, extremely small amounts of molten plastic, often in the micro - liter or even nano - liter range, are injected into a micro - scale mold cavity. The molds used in this process are fabricated with high - precision machining techniques, such as micro - electro - discharge machining (EDM) and micro - milling. These techniques allow for the creation of mold cavities with intricate details and tolerances in the micron range.

This process is well - suited for manufacturing micro - sized plastic injection mold parts for several reasons. First, it enables the production of parts with high precision. For example, in the production of micro - fluidic chips used in medical diagnostics, the channels and chambers in the chips need to have precise dimensions. Micro - injection molding can achieve dimensional accuracies of ± 1 - 5 microns, ensuring that the fluid flow within the chip is consistent and accurate. Second, it can handle complex geometries. Tiny gears, connectors, and sensors with complex shapes can be produced with ease. These micro - sized parts find applications in various fields. In the electronics industry, they are used in the production of micro - connectors for small - sized electronic devices like wearable technology. In the medical field, micro - injection - molded parts are used in drug delivery systems, where precise dosing and miniaturized components are crucial.

The advantages of micro - injection molding are numerous. It offers high production efficiency, as it can produce a large number of micro - parts in a relatively short time. The process also allows for material savings, as only small amounts of plastic are required for each part. Additionally, the high precision and repeatability of the process ensure consistent quality in the production of micro - sized plastic injection mold parts.

Multi - Shot and Insert Molding

Multi - shot and insert molding are two other innovative manufacturing processes that have transformed the production of plastic injection mold parts, especially those with complex structures.

Multi - shot molding, also known as multi - component injection molding, involves injecting two or more different types of plastics into the same mold cavity in multiple shots. The process typically uses a specialized injection molding machine with multiple injection units. For Yigu Technology example, in the production of a toothbrush, the handle may be made of a rigid plastic, while the bristles are made of a soft, flexible plastic. In a two - shot multi - injection molding process, the first shot injects the rigid plastic to form the handle. Then, without removing the partially - formed part from the mold, the second shot injects the soft plastic to create the bristles. This results in a single, integrated part with different material properties in different regions.

Insert molding, on the other hand, involves placing a pre - formed component (the insert), such as a metal or another plastic part, into the mold cavity before injecting the plastic. The molten plastic then flows around the insert, encapsulating it and bonding with it to form a single, composite part. For instance, in the production of electrical connectors, metal inserts are often used. The metal provides the necessary electrical conductivity, while the plastic provides insulation and mechanical support. By using insert molding, the metal insert can be precisely positioned within the plastic housing, ensuring proper functionality.

Compared to traditional single - shot injection molding processes, multi - shot and insert molding offer several advantages. They allow for the creation of more complex part geometries and the combination of different materials in a single part. This can lead to improved product performance. For example, in automotive applications, multi - shot molded parts can combine the strength of one plastic with the heat - resistance of another, resulting in components that can better withstand the harsh operating conditions in an engine. Insert molding can also reduce the need for secondary assembly operations. Instead of separately manufacturing and then assembling a metal part with a plastic part, insert molding can produce the complete, integrated part in one step. This not only saves time but also reduces the risk of assembly errors, improving overall production efficiency and product quality.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the significance of innovation in plastic injection mold parts. We focus on two main aspects: material innovation and the application of advanced manufacturing processes.

Regarding materials, we are constantly exploring and testing new high - performance plastics and nanocomposites. By collaborating with material suppliers and research institutions, we aim to bring the most suitable materials to our customers, enhancing the performance of their products.

In terms of manufacturing processes, we actively adopt advanced technologies such as multi - shot and insert molding. Our experienced engineers are proficient in using CAD/CAM/CAE software to optimize mold design and manufacturing processes. This enables us to provide high - quality, customized plastic injection mold parts, meeting the diverse needs of different industries. Whether it's a small - scale prototype or large - scale production, we are committed to delivering products with precision, efficiency, and innovation.

FAQ

What are the most common materials used in innovative plastic injection mold parts?

Some of the most common materials are high - performance plastics like PEEK and PEI. PEEK has a high melting point (around 343°C) and excellent mechanical strength (tensile strength up to 100 MPa), making it suitable for high - temperature applications such as engine components in cars. PEI has a glass transition temperature of 217°C and good dimensional stability, which is crucial for precision parts like connectors in electronics. Nanocomposites, composed of a polymer matrix with nanoparticles (such as clay or carbon nanotubes), are also popular. Clay - based nanocomposites can improve barrier properties for food packaging, while carbon nanotube - reinforced nanocomposites enhance mechanical strength for aerospace components.

How can CAD/CAM/CAE technology improve the quality of plastic injection mold parts?

CAD software allows for the creation of highly detailed 3D models of plastic injection mold parts. These models serve as the basis for the entire manufacturing process. CAM technology uses the CAD - generated models to generate precise toolpaths for CNC machines, reducing the margin of error in manufacturing to as low as 0.01 - 0.05 mm in some high - precision applications. CAE technology, like Moldflow, can simulate the plastic injection molding process. It predicts how the molten plastic will flow in the mold, identifies potential issues such as short - shots and areas of high stress or uneven cooling. By optimizing the mold design based on CAE analysis, manufacturers can improve the quality of the final product. For example, a company reduced warping in plastic housing for electronic devices by over 50% after modifying the mold design according to CAE results.

What are the advantages of multi - shot molding over single - shot molding?

Multi - shot molding allows for the injection of two or more different types of plastics into the same mold cavity in multiple shots. It can create parts with different material properties in different regions, such as a toothbrush with a rigid handle and soft bristles. This process enables the production of more complex part geometries compared to single - shot molding. It also reduces the need for secondary assembly operations as the parts are integrated during the molding process. For example, in automotive applications, multi - shot molded parts can combine different materials to better withstand harsh operating conditions. In contrast, single - shot molding is limited to using a single material and is better suited for simpler part designs. Overall, multi - shot molding offers greater design flexibility and can lead to improved product performance and production efficiency.