Understanding the Basics of Injection Mold

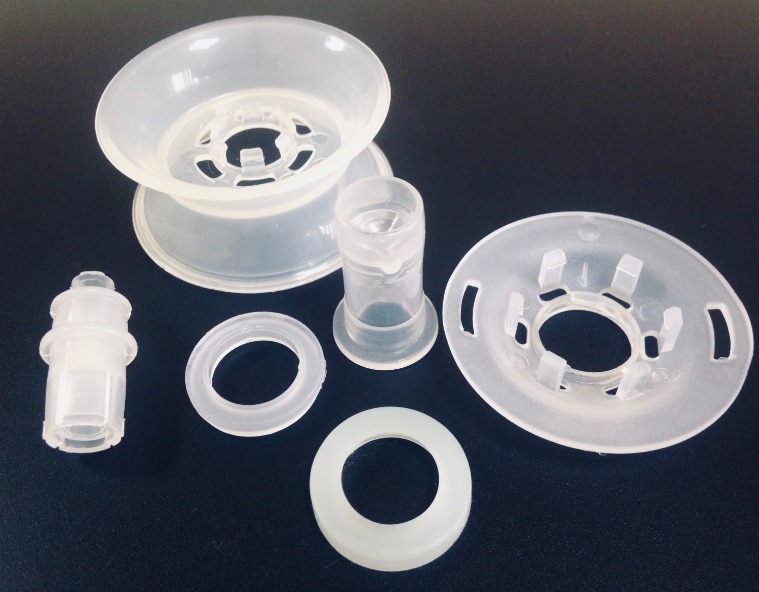

An Injection Mold is a crucial tool in the manufacturing industry, especially for producing plastic parts in large quantities. It's a specialized mold tool that is used in the injection molding process. The basic principle of injection molding is as follows: First, plastic pellets are fed into a heated barrel. As the pellets move through the barrel, they are melted by the heat and shearing forces. Then, the molten plastic is injected, under high pressure, into the closed mold cavity through a sprue, runner system, and gate. Once the cavity is filled, the plastic cools and solidifies, taking the shape of the mold cavity. Finally, the mold opens, and the newly formed plastic part is ejected.

In modern manufacturing, injection molds play a pivotal role. They are widely used across various industries, such as automotive, electronics, medical, and consumer goods. For example, in the automotive industry, injection molds are used to create interior components like dashboards, door panels, and various small parts. In the electronics industry, they are essential for manufacturing casings for smartphones, tablets, and other devices. The precision and efficiency of injection molds enable manufacturers to produce high - quality products with consistent dimensions and excellent surface finishes at a relatively low cost per unit, which is vital for mass production.

However, when it comes to injection molds, one question that often puzzles manufacturers and buyers alike is: how is the price of an injection mold determined? The cost of an injection mold can vary significantly, from a few thousand dollars for a simple, small - scale mold to hundreds of thousands or even more for a complex, high - precision mold. Understanding the factors behind injection mold pricing is the key to making informed decisions in manufacturing projects.

Key Factors Influencing Injection Mold Pricing

Complexity of Design

The complexity of the mold design is a fundamental factor in determining its price. A mold with a simple, straightforward design, such as one for producing a basic plastic cube, will generally be much less expensive than a mold for creating a highly intricate automotive interior component with complex curves, undercuts, and fine details.

Complex shapes require more time - consuming and sophisticated machining processes. For example, when a mold has internal features like deep, narrow channels or complex 3D geometries, it may need multi - axis machining centers to accurately machine the cavities and cores. High - precision requirements also add to the cost. If a mold needs to maintain a tolerance of ±0.01mm (as opposed to a more standard ±0.1mm), the manufacturing process becomes more challenging and costly.

Take a look at the following chart to see the approximate price differences for molds of different complexities:

| Complexity Level | Description | Approximate Price Range (USD) |

| Low | Simple shapes, few details, standard tolerances | \(2,000 - \)10,000 |

| Medium | Moderate curves, some internal features, normal precision | \(10,000 - \)50,000 |

| High | Intricate 3D shapes, undercuts, high - precision tolerances | \(50,000 - \)200,000+ |

Material Selection

The materials used to manufacture injection molds significantly impact their price. The most common material for injection molds is steel, and different grades of steel have different properties and costs.

Low - carbon steels are relatively inexpensive and are suitable for molds with low production volumes or where the part requirements are not too demanding. They have lower hardness and wear - resistance compared to higher - grade steels. Medium - carbon and high - carbon steels offer better strength and durability, making them suitable for molds with higher production volumes. Alloy steels, which contain elements like chromium, nickel, and molybdenum, are even more expensive but provide excellent hardness, wear - resistance, and heat - resistance. These are often used for molds that produce high - quality parts in large quantities or for parts made from abrasive plastics.

Special alloy materials, such as beryllium - copper alloys, are used in specific applications where high thermal conductivity is required, like for molds that need to cool quickly. However, these materials are much more costly than standard steels.

Here is a table showing the price ranges of some common mold materials per kilogram:

| Material | Price Range per Kilogram (USD) |

| Low - carbon steel | \(2 - \)5 |

| Medium - carbon steel | \(5 - \)10 |

| High - carbon steel | \(10 - \)20 |

| Alloy steel (e.g., P20) | \(20 - \)50 |

| Beryllium - copper alloy | \(50 - \)150 |

Quantity and Production Volume

The quantity of molds ordered and the production volume they are intended for play a significant role in pricing. When ordering a single custom - designed injection mold, the price per mold will be relatively high because the manufacturer has to cover all the upfront costs of design, tooling, and setup for a single unit.

However, for large - scale production runs, the cost per mold can be significantly reduced through economies of scale. For example, if a company orders 10 molds instead of 1, the manufacturer can spread the fixed costs (such as design and setup) over the 10 molds. Additionally, for high - volume production, the manufacturer may be able to optimize the manufacturing process, negotiate better prices for raw materials, and use more efficient production techniques.

Let's take an example:

| Order Quantity | Production Volume per Mold | Approximate Price per Mold (USD) |

| 1 | 10,000 parts | $50,000 |

| 5 | 50,000 parts | $40,000 |

| 10 | 100,000 parts | $35,000 |

As the order quantity and production volume increase, the price per mold decreases due to cost - sharing and process optimization.

Manufacturing Process and Technology

The manufacturing processes and technologies employed in creating an injection mold also impact its cost. Traditional machining methods like milling and turning are relatively cost - effective for simple mold components. However, for more complex molds, advanced manufacturing processes are often required.

Computer Numerical Control (CNC) machining offers high precision and repeatability. It allows for the accurate machining of complex shapes and can be programmed to perform multiple operations in a single setup. Although CNC machines are expensive to purchase and maintain, they can produce high - quality molds more efficiently than manual machining for complex designs.

Electrical Discharge Machining (EDM) is another important technology, especially for creating intricate details, sharp corners, and hard - to - reach areas in a mold. EDM works by using electrical discharges to erode the material, allowing for the creation of complex geometries that are difficult to achieve with traditional machining. However, EDM is a time - consuming process and requires specialized equipment, which increases the cost of the mold.

Advanced technologies such as 3D printing are also being used in mold manufacturing, especially for rapid prototyping and the production of molds with complex internal structures. While 3D printing can offer design flexibility and shorter lead times, it is still relatively expensive for large - scale production compared to traditional manufacturing methods for injection molds.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of injection mold pricing. We always prioritize cost - control strategies without sacrificing quality. For us, it's about finding the right balance between the quality of the injection mold and its price.

We focus on optimizing the design phase to simplify complex structures as much as possible while still meeting product requirements. This reduces machining time and costs. When it comes to material selection, we match the material grade precisely with the production volume and product quality needs. For high - volume production runs, we choose materials with good cost - performance ratios that can withstand long - term use.

Moreover, we constantly improve our manufacturing processes. By investing in advanced equipment and training our staff, we enhance production efficiency, which in turn helps us offer competitive prices. We believe that a reasonable injection mold price should reflect not only the cost but also the value of quality, reliability, and on - time delivery that we provide to our customers.

FAQs about Injection Mold Pricing

Q1: Why do some injection molds have a much higher price than others?

Several factors contribute to the price difference. Complex designs with intricate details, undercuts, and high - precision requirements demand more sophisticated machining processes, which increases labor and equipment costs. The material used is also crucial. High - grade steels or special alloys like beryllium - copper, which offer better properties such as hardness, wear - resistance, or thermal conductivity, are more expensive. Additionally, if the production volume is low, the cost per mold will be higher because the upfront costs (like design and setup) are spread over fewer units.

Q2: How can I reduce the cost of injection molds without sacrificing quality?

First, choose the right material. Don't over - specify high - end materials if a more cost - effective option can meet your production needs. For example, if you have a medium - volume production run and the part doesn't require extreme wear - resistance, a mid - grade steel might be sufficient. Second, optimize the mold design. Simplify the design as much as possible while still achieving the desired product functionality. This can reduce machining time and complexity. Finally, plan for a reasonable production quantity. Larger production volumes often result in lower per - unit mold costs due to economies of scale.

Yes, there can be hidden costs. One common hidden cost is mold maintenance. Over time, molds will wear out and require maintenance, such as polishing, replacing worn - out components, and repairing damaged areas. These maintenance costs can add up over the life of the mold. Another potential hidden cost is for any design changes or modifications made after the initial mold is produced. If you realize that you need to change the part design, it may require additional machining and re - engineering, which will increase the overall cost.