Gears are the fundamental power transmission components in countless machines, from automotive transmissions to industrial robotics and consumer appliances. The precision and performance of these systems hinge directly on the quality of their gears. Machining gears is a complex engineering discipline that transforms raw materials into perfectly meshing components. This comprehensive guide delves into the core aspects of gear manufacturing, exploring the main types, material science, key machining methods like gear hobbing and gear grinding, and the critical finishing treatments. Whether you're an engineer designing a new product or a procurement specialist sourcing components, understanding these processes is essential for specifying the right gear for your application, ensuring durability, efficiency, and quiet operation.

What Are the Main Types of Gears?

Gears are categorized based on their tooth configuration and the orientation of their shafts. Selecting the right type is the first critical step in design and manufacturing.

- Spur Gears: The simplest and most common type. Their teeth are straight and parallel to the gear's axis. They are efficient and cost-effective for parallel shaft applications but can be noisy due to sudden line contact.

- Helical Gears: Featuring teeth cut at an angle (helix), these gears engage more gradually than spur gears. This results in smoother, quieter operation and higher load capacity, making them ideal for automotive transmissions. A downside is the induced axial thrust that must be managed by bearings.

- Bevel Gears: Designed to transmit power between intersecting shafts, typically at a 90-degree angle. Straight bevel gears are simpler, while spiral bevel gears have curved teeth for smoother, higher-capacity performance, crucial for vehicle differentials.

- Worm Gears: Consist of a screw-like worm and a mating worm wheel. They offer very high reduction ratios in a compact space and can provide self-locking capabilities, but are generally less efficient due to higher sliding friction.

How Are Gear Materials Selected?

Material choice dictates a gear's strength, wear resistance, noise level, and cost. The selection is a balance between performance requirements and manufacturability.

- Steels: The workhorse for high-strength applications. Alloy steels like AISI 4140 or 4340 are common, often heat-treated (carburized, hardened, and tempered) to achieve a hard, wear-resistant surface with a tough core. For example, a heavy-duty mining truck's final drive gears are typically made from high-grade alloy steel to withstand extreme shock loads.

- Cast Irons: Such as ductile iron (e.g., ASTM A536), offer good machinability, damping properties (reducing noise), and moderate strength at a lower cost. They are frequently used in agricultural machinery and industrial gearboxes where moderate loads are present.

- Non-Ferrous Metals: Aluminum alloys and brass are used where weight reduction or corrosion resistance is key, such as in aerospace or marine applications, albeit with lower load capacity.

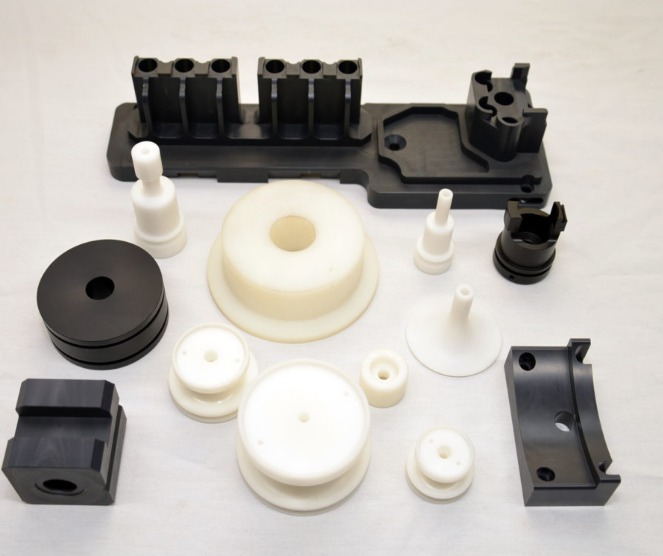

- Plastics (Polymers): Nylon and acetal (POM) provide excellent corrosion resistance, low weight, and inherent lubrication. They operate quietly and are ideal for consumer products, food processing equipment, or situations where metal-on-metal contact is undesirable.

What Machining Methods Shape Gear Teeth?

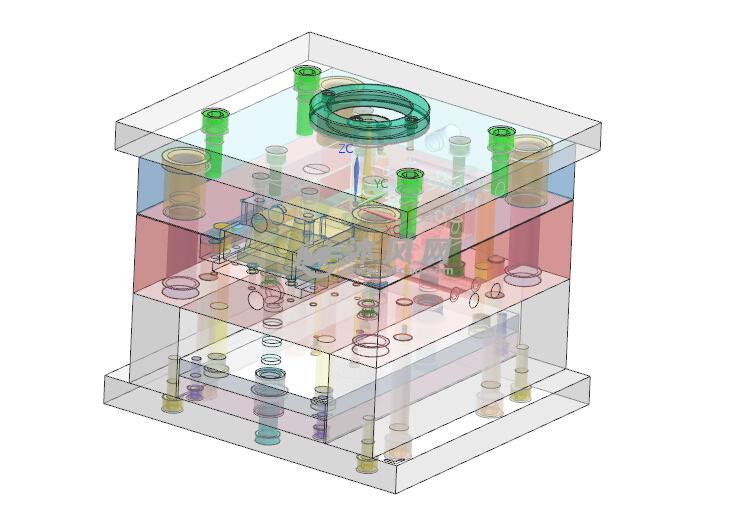

The creation of gear teeth is achieved through several gear manufacturing processes, each with its own advantages. The primary methods fall into two categories: generating and forming.

- Generating Processes: The cutter and blank move in a coordinated motion to "generate" the tooth profile. This includes gear hobbing and gear shaping, which are highly versatile and accurate.

- Forming Processes: The cutter has the exact inverse shape of the tooth space, which it impresses onto the blank. Gear milling with a form cutter is a classic example, suitable for prototyping or low-volume production.

The choice depends on gear type, volume, precision needs, and cost.

How Does Gear Hobbing Work?

Gear hobbing is a highly efficient, continuous generating process and is the dominant method for mass-producing external spur and helical gears. A helical cutting tool called a hob, which resembles a worm gear with gashes, rotates in mesh with the gear blank. Their synchronized rotation, coupled with a radial feed, gradually cuts the teeth.

- Process & Advantages: It's fast and can produce a wide range of teeth numbers with the same hob. Modern CNC hobbing machines can achieve impressive accuracies (e.g., DIN 9-10) directly from the hob, reducing secondary operations. For instance, a major automotive supplier might use a single high-performance CNC hobbing line to produce thousands of transmission gears per day.

- Limitations: It is generally not suitable for internal gears or gears located very close to a shoulder.

Why Use Gear Shaping for Internal Gears?

Gear shaping is a generating process where a reciprocating cutter, shaped like a gear, meshes with the blank to cut the teeth. It is the premier method for machining internal gears and can also handle external gears, splines, and gears close to shoulders.

- Process & Advantages: The cutter's axial stroke, combined with rotary motion, generates the tooth profile. Its primary strength is machining internal geometries inaccessible to a hob. A case study involves manufacturing a planetary gear carrier where the internal ring gear is shaped to precise tolerances after the planetary pinions have been installed in close proximity.

- Limitations: It is typically slower than hobbing due to its reciprocating, non-cutting return stroke.

What Makes Gear Milling Different?

Gear milling is a forming process where a rotating form cutter, whose profile matches the gear tooth space, is plunged or fed across the blank. Each tooth space is cut individually, after which the blank is indexed to the next position.

- Process & Advantages: It offers tremendous flexibility. With a library of cutters, a standard CNC milling machine can produce spur gears, helical gears (with an indexer), bevel gears, and even custom tooth forms for specialty machinery. It is ideal for prototypes, one-off repairs, or very low-volume production.

- Limitations: It is significantly slower for high volumes compared to generating methods. Accuracy is also limited by the precision of the cutter profile and the indexing system.

How Is Gear Grinding Achieved for High Precision?

Gear grinding is a finishing process used to achieve ultra-high precision and superior surface finish on hardened gears. It is essential for applications demanding quiet operation, high speed, and exceptional durability, such as in aerospace actuators or high-performance automotive racing transmissions.

- Process & Methods: It uses a grinding wheel to remove a small amount of material. The two main methods are:

- Form Grinding: A profiled wheel grinds the entire tooth space at once. It is very accurate but requires a dedicated wheel for each gear module and tooth count.

- Generating Grinding (e.g., with a worm-shaped wheel): Similar to hobbing, the wheel and gear undergo a generating motion. It is highly efficient for batch production of precision gears.

- Impact: Grinding can improve gear accuracy to levels like DIN 5-7 or better and produce a surface roughness (Ra) below 0.4 µm, drastically reducing noise and increasing fatigue life.

What Tolerances Matter in Gear Machining?

Gear quality is quantified by international standards (AGMA, DIN, ISO). Key tolerance parameters include:

| Tolerance Parameter | Description | Why It Matters |

|---|---|---|

| Tooth Profile Error | Deviation of the actual tooth flank from the ideal involute curve. | Affects smoothness of meshing, noise, and localized stress. |

| Pitch Error | Variation in the distance between adjacent or cumulative tooth positions. | Causes uneven motion transfer, vibration, and noise. |

| Lead Error (Helicity) | Deviation of the tooth trace from the ideal helix. | Leads to uneven load distribution across the face width, reducing capacity. |

| Runout | Eccentricity of the gear teeth relative to its bore/axis. | Causes once-per-revolution vibration and uneven loading. |

A gear specified as "DIN 7" will have tighter, more precise tolerances than a "DIN 10" gear.

How Do Surface Treatments Improve Gear Performance?

After machining, surface treatments are applied to enhance performance.

- Case Hardening (Carburizing/Nitriding): Diffuses carbon or nitrogen into the surface, then hardens it. This creates a hard, wear-resistant case (e.g., 60-62 HRC) over a tough, shock-absorbing core. Virtually all high-load automotive gears undergo carburizing.

- Shot Peening: Bombards the gear teeth with small media to induce compressive surface stresses. This dramatically increases gear fatigue life and resistance to pitting, a common failure mode.

- Phosphate or Black Oxide Coatings: Provide mild corrosion resistance and aid in initial run-in by retaining oil on the surface.

- Specialized Coatings: Thin, hard coatings like Diamond-Like Carbon (DLC) can be applied to further reduce friction and wear in extreme applications.

Conclusion

Machining gears is a sophisticated blend of art and science, requiring careful consideration of gear type, material, and the most suitable manufacturing sequence—from gear hobbing or shaping for tooth generation to gear grinding for final precision. Understanding the associated tolerances and the vital role of surface treatments empowers engineers to design and specify gears that deliver optimal performance, longevity, and reliability in their intended application. By mastering these fundamentals, one can ensure that the heart of any mechanical drive system beats strong and true.

FAQs on Machining Gears

What is the most common method for machining spur gears?

Gear hobbing is the most prevalent and economical method for medium to high-volume production of external spur and helical gears due to its speed and versatility.

Can you machine gears on a standard CNC mill?

Yes, using gear milling with a form cutter is feasible for prototypes or low volumes. However, for accuracy and volume production, dedicated gear-generating machines like hobbers or shapers are necessary.

Why is gear grinding so important?

Gear grinding is a critical finishing process that removes distortions from heat treatment and achieves extremely tight tolerances and smooth surface finishes. This is essential for high-speed, high-load, and low-noise applications.

What material is best for a quiet, corrosion-resistant gear?

For such applications, engineered plastics like nylon or POM, or non-ferrous metals like brass, are excellent choices due to their inherent damping properties and corrosion resistance.

How do I specify the quality of a gear?

Gear quality is specified using standard grade numbers (e.g., AGMA 10, DIN 7, ISO 6). Lower numbers indicate higher precision. You specify this based on your application's requirements for noise, load, and speed.

Contact Yigu for Custom Manufacturing

At Yigu Technology, we understand that a gear is more than just a component—it's a critical link in the performance and reliability of your entire system. Our expertise spans the entire gear manufacturing spectrum, from initial material selection and high-precision gear hobbing to final gear grinding and advanced surface treatments like shot peening.

We believe in a consultative partnership. Our engineering team works closely with you to analyze your application's specific demands for load, speed, noise, and environment. We then recommend the optimal manufacturing route, whether it's cost-effective high-volume production or complex, low-volume precision parts. Our advanced CNC equipment and rigorous quality control, adhering to AGMA and ISO standards, ensure that every gear we deliver meets exact specifications for dimensional accuracy and long-term durability.

Let us be your trusted partner in power transmission. Contact Yigu for custom manufacturing solutions that keep your designs moving smoothly and reliably.