Understanding Injection Molding

Injection molding is a manufacturing process that has revolutionized the production of plastic and some metal parts. It involves injecting molten material, typically plastic or metal alloy in a liquid state, into a mold cavity. Once inside the mold, the material cools and solidifies, taking on the shape of the mold cavity. This process is highly efficient for creating complex, precise, and high - volume parts.

Step 1: Product Design and Analysis

Design Considerations

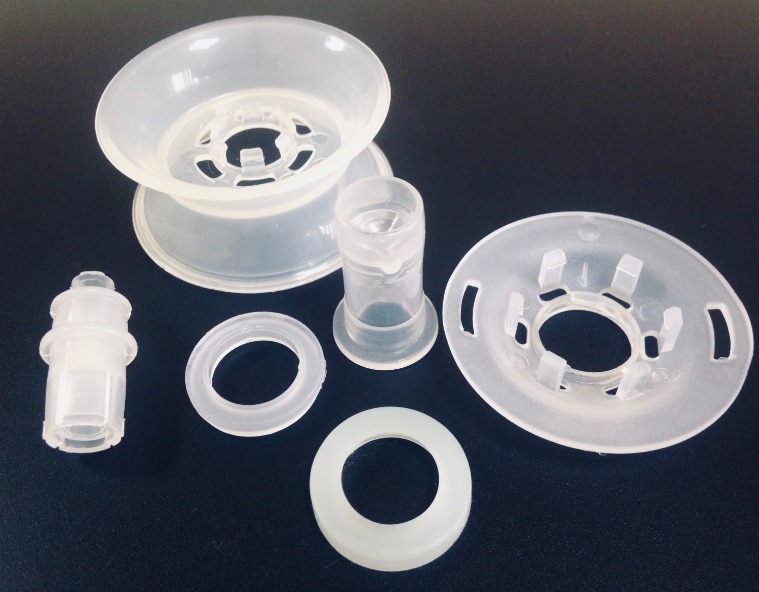

Before diving into mold design, a thorough product design and analysis are essential. Product shape is a fundamental aspect. Complex shapes may require more intricate mold designs, often involving multiple moving parts like slides and lifters. For example, a product with undercuts, such as a toy figure with arms and legs that protrude at angles, will need a mold with sliding components to create these features.

Dimensions must be carefully specified. In the medical device industry, components like syringe barrels need to have precise inner and outer diameters. A deviation of even a fraction of a millimeter can affect the functionality, such as the smooth flow of liquid through the syringe. Tolerance requirements are also crucial. High - precision products, like optical lenses for cameras, demand tight tolerances. For instance, a tolerance of ±0.01mm might be required to ensure proper focusing and image quality.

Another factor is product functionality. If a plastic part is designed to be a structural component in an automotive interior, it must have sufficient strength and rigidity. This could involve adding features like ribs or bosses to enhance its mechanical properties. On the other hand, if it's a consumer - facing product, aesthetics play a major role. The surface finish of a smartphone case needs to be smooth and visually appealing, which can influence mold design choices such as the type of polishing or texturing applied to the mold surfaces.

Material Selection

The choice of material has a profound impact on injection mold design. Different materials have distinct characteristics that mold designers must account for. Plastic materials are the most commonly used in injection molding. For example, Polypropylene (PP) has a relatively high shrinkage rate, typically around 1.0% - 2.5%. When designing a mold for a PP product, the mold cavities need to be oversized to compensate for this shrinkage during the cooling and solidification process.

When selecting a material, factors such as the product's end - use application, cost, manufacturability, and environmental impact must be considered. A cost - effective material like High - Density Polyethylene (HDPE) may be suitable for large - scale production of simple consumer products like plastic bottles, while a more expensive but high - performance material like PEEK (Polyether Ether Ketone) would be reserved for applications in the aerospace or medical fields where extreme conditions and high - performance requirements are present.

Step 2: Mold Concept Design

Sketching the Initial Idea

After finalizing the product design and material selection, the next crucial step in creating an injection mold is the mold concept design, starting with sketching the initial idea. This is where the theoretical aspects of the mold start to take a more tangible form.

Determining the parting line is one of the first and most important decisions. The parting line is the line where the two halves of the mold meet. For a simple rectangular plastic box, the parting line might be a straightforward horizontal line that divides the box into its top and bottom halves. However, for more complex shapes, such as a plastic toy with multiple protrusions and cavities, the parting line needs to be carefully planned. It should be located in a way that allows for easy ejection of the molded part, minimizes the visibility of the parting line on the final product, and simplifies the mold - making process.

Another key consideration is the number of cavities. In high - volume production, multiple cavities can significantly increase productivity. For example, if you're producing small plastic buttons, a mold with 16 or 32 cavities can be designed. But adding more cavities also increases the complexity of the mold. Each cavity needs to be fed with the molten material evenly, and the cooling system must be designed to ensure uniform cooling across all cavities. The layout of the cavities within the mold also matters. They can be arranged in a linear, circular, or matrix pattern, depending on factors like the shape of the part, the available space in the mold, and the flow characteristics of the material.

Sketching the initial idea also involves visualizing the overall structure of the mold. This includes the size and shape of the mold base, which provides the foundation for the entire mold. A larger mold base may be required for molds with more cavities or for parts that are large in size. The thickness of the mold plates is also determined at this stage. Thicker plates are needed for molds that will be subjected to high injection pressures or for molds that require more stability during the molding process.

Function and Structure Planning

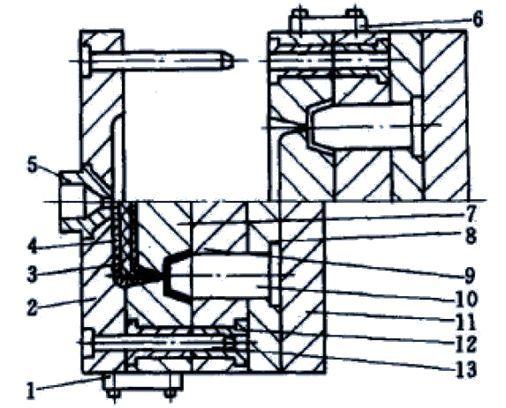

Once the initial sketch is in place, it's time to plan the functions and structures of different mold components.

The gating system is responsible for guiding the molten material from the injection unit into the mold cavity. There are various types of gates, each with its own advantages and applications. A direct gate, also known as a sprue gate, is a simple and direct connection between the injection nozzle and the mold cavity. It's often used for large - sized parts or parts where high injection speeds are required. However, it may leave a relatively large mark on the part, which might not be acceptable for some products. In contrast, a pin - point gate is very small in diameter and is ideal for small, precision - molded parts. It provides better control over the flow of the material and leaves a small, easily removable mark on the part. The runner system, which connects the gate to the cavities, also needs to be designed carefully. The cross - sectional area of the runner affects the flow rate and pressure drop of the molten material. A larger cross - sectional area reduces the pressure drop but may lead to more material waste, while a smaller cross - sectional area can cause higher pressure drops and potential flow issues.

The cooling system is vital for the efficient production of high - quality parts. Mold cooling channels are typically drilled into the mold plates. The layout and diameter of these channels play a significant role in the cooling process. For example, in a mold for a thick - walled plastic part, the cooling channels may need to be larger in diameter and closer to the mold cavity to ensure effective heat transfer. The coolant, usually water or a water - based solution, circulates through these channels, absorbing the heat from the molten material as it solidifies. If the cooling is not uniform, it can lead to warping or uneven shrinkage of the molded part.

The ejection system is what removes the solidified part from the mold cavity. Ejector pins are the most common components of an ejection system. They are placed in strategic locations within the mold, such as at the base of the part or in areas where the part has a strong adhesion to the mold. The size and number of ejector pins depend on the size, shape, and wall thickness of the part. For a thin - walled plastic container, a larger number of smaller ejector pins may be used to distribute the ejection force evenly and prevent the part from deforming during ejection. In some cases, other ejection mechanisms like ejector sleeves or stripper plates may be used, especially for parts with complex shapes or for parts that require a more gentle ejection process.

Step 3: CAD Modeling

The Role of CAD in Mold Design

Computer - Aided Design (CAD) has become an indispensable tool in injection mold design, revolutionizing the way molds are created. One of the primary advantages of CAD in mold design is the significant improvement in design accuracy. Traditional manual design methods are prone to human errors in measurements and geometric calculations. With CAD software, designers can input precise dimensions with a high degree of accuracy. For example, when designing a mold for a small electronic component with tight tolerances of ±0.05mm, CAD can ensure that all the features of the mold, such as the cavity size and the position of ejector pins, are designed to meet these exact specifications. This level of precision is crucial for producing high - quality molded parts that fit together perfectly and function as intended.

CAD also greatly enhances design efficiency. In the past, designing a complex injection mold could take weeks or even months. Designers had to create detailed 2D drawings by hand, which was a time - consuming and labor - intensive process. Any design changes would require redrawing the entire set of drawings. With CAD, designers can quickly create 3D models of the mold. They can easily modify the design by simply adjusting the parameters of the model. For instance, if a change is needed in the gating system, such as the size or location of the gate, it can be done in a matter of minutes in the CAD environment, rather than spending days re - drafting the design. This speed in design modification allows for more iterations in a shorter time, leading to better - optimized mold designs.

Moreover, CAD enables better visualization of the mold design. Designers can view the 3D model from different angles, zoom in on specific details, and even create exploded views to understand the assembly of the mold components. This visual clarity helps in communicating the design to other team members, such as mold makers, quality control personnel, and clients. It also aids in identifying potential design flaws early in the process, such as interference between moving parts or improper cooling channel placement.

Creating a 3D Model

The process of creating a 3D model using CAD software involves several key steps. First, the designer needs to select the appropriate CAD software based on their familiarity, the complexity of the mold design, and the specific requirements of the project. Popular CAD software for injection mold design includes SolidWorks, CATIA, and UG/NX.

Throughout the 3D modeling process, the designer needs to pay attention to the details. They should regularly check for any interference between different mold components. For example, the ejector pins should not interfere with the core or the cavity when they are in the retracted or extended position. The CAD software often provides tools for interference checking, which can quickly identify and highlight any potential issues. Once the 3D model is complete, it can be used for further analysis, such as mold flow analysis using CAE (Computer - Aided Engineering) software, or as a basis for generating manufacturing instructions for the mold - making process.

Step 4: Mold Flow Analysis

Analyzing the Plastic Flow

Mold flow analysis is a crucial step in the injection mold design process. It involves using specialized software, such as MoldFlow or Moldex3D, to simulate the injection molding process. The primary purpose of mold flow analysis is to predict how the plastic will flow within the mold cavity. By inputting factors like the plastic material properties (such as viscosity, which can range from 100 - 10000 Pa·s depending on the type of plastic), the geometry of the mold cavity, and the injection process parameters (including injection pressure, typically in the range of 50 - 200 MPa for common plastics), the software can generate detailed visualizations and data about the plastic flow.

For example, it can show the flow front progression, which is the position of the advancing edge of the molten plastic as it fills the cavity. This information helps in understanding if there are any areas where the plastic might flow unevenly or encounter resistance. A smooth and uniform flow front is desirable as it indicates that the plastic is filling the cavity evenly. If the flow front is erratic, it could lead to issues in the final product quality.

Solving Potential Problems

Based on the results of the mold flow analysis, several potential problems can be identified and addressed to optimize the mold design.

Short - shot is a common issue where the plastic does not completely fill the mold cavity. This can be due to factors like insufficient injection pressure, improper gate location, or high flow resistance in the runner system. For instance, if the mold flow analysis shows that the plastic is not reaching a particular corner of the cavity, one solution could be to increase the injection pressure. However, this has its limits as overly high pressure can cause other problems like flash (where plastic leaks out between the mold halves). Another approach could be to change the gate location. If the gate is too far from the area with filling issues, relocating it closer can improve the flow of plastic to that region.

Trapped air, is another problem that can be detected through mold flow analysis. When the plastic flows into the cavity, air inside the cavity needs to escape. If it cannot, it can get trapped, leading to defects such as voids, burns, or surface blemishes in the final product. The analysis can pinpoint the areas where air is likely to be trapped. To solve this, additional venting can be added to the mold in those specific locations. Vents are small channels or openings in the mold that allow air to escape. They can be as small as 0.02 - 0.05 mm in width, depending on the plastic material used. Another solution could be to change the flow pattern of the plastic by adjusting the gate location or adding flow - guiding features in the mold to push the air towards the vents.

In summary, mold flow analysis is an essential tool for predicting plastic flow and solving potential problems in injection mold design, ultimately leading to higher - quality products and more efficient production processes.

Step 5: Mold Manufacturing

Material Selection for the Mold

The choice of material for mold manufacturing is crucial as it directly impacts the mold's performance, durability, and the quality of the final products. Steel is one of the most commonly used materials for injection molds. Different types of steel offer distinct properties. For example, P20 steel, a pre - hardened mold steel with a hardness of around 30 - 35 HRC, is widely used for making molds for general - purpose plastic products. It has good machinability and can be directly processed without further heat treatment, which reduces production time and cost. It is suitable for manufacturing molds for products like plastic toys, simple household items made of common plastics such as ABS, PP, or PE.

Another popular steel type is 718H, an upgraded version of P20. With a higher hardness of 35 - 40 HRC, it has better dimensional stability and wear resistance. This makes it ideal for molds used in producing more complex plastic parts, such as those in the automotive interior, like dashboard components or in precision - molded electronic parts. It can withstand the higher pressures and longer production runs required for these applications.

For molds that need to produce parts with high surface finish requirements, such as transparent plastic products like optical lenses or high - gloss plastic housings, NAK80 steel is a great choice. It has an excellent mirror - polishing property and comes pre - hardened to 40 - 42 HRC. This steel can achieve a mirror - like surface finish, which is essential for products where appearance is critical.

When selecting the mold material, factors such as the type of plastic to be molded, the production volume, the required surface finish of the final product, and the cost need to be considered. If the plastic has corrosive properties, like PVC, a steel with good corrosion - resistance, such as S136, should be chosen. For high - volume production, a more durable and wear - resistant material is preferred to ensure the mold can withstand the repeated injection cycles without significant wear and tear.

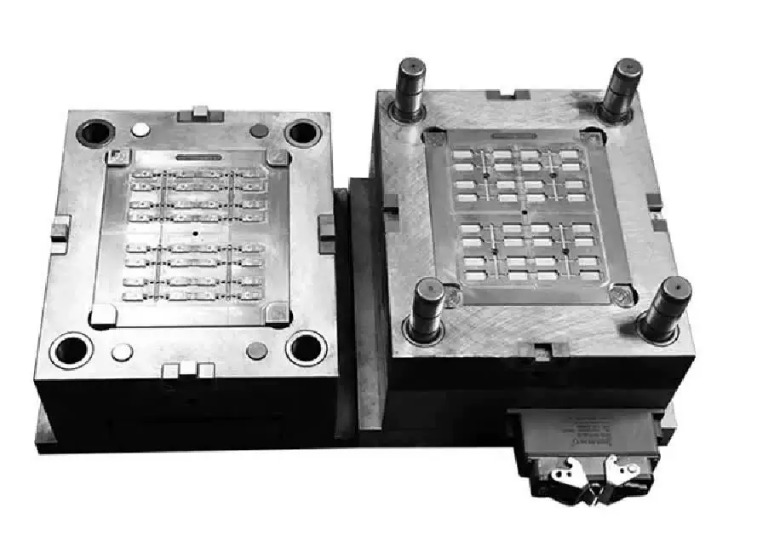

Machining Processes

CNC Machining

Computer - Numerical - Control (CNC) machining is a fundamental process in mold manufacturing. It offers high precision and the ability to create complex geometries. In CNC machining, a computer - controlled machine tool follows a set of programmed instructions to cut, drill, and mill the mold material. For example, when creating the mold cavity, the CNC milling machine can precisely carve out the shape according to the 3D model generated in the design phase. It can achieve tolerances as tight as ±0.01mm, ensuring that the mold cavity has the exact dimensions required for the plastic part.

CNC machining is also highly efficient for creating the mold's core, which forms the internal features of the plastic product. The multi - axis capabilities of modern CNC machines allow for the production of complex shapes with ease. For instance, a 5 - axis CNC machine can rotate the workpiece and the cutting tool in multiple directions, enabling the machining of intricate undercuts and curved surfaces that would be difficult or impossible to achieve with traditional machining methods. This is particularly useful when creating molds for products with complex internal structures, such as some types of medical devices or automotive components.

EDM (Electrical Discharge Machining)

Electrical Discharge Machining, or EDM, is another important process, especially for creating intricate and precise features in the mold. There are two main types of EDM: EDM sinking (also known as die - sinking EDM) and wire - EDM.

EDM sinking is used when the mold has complex 3D shapes that are difficult to machine with traditional methods. In this process, an electrode, typically made of copper or graphite, is shaped to the inverse of the desired feature in the mold. A high - voltage electrical discharge is then generated between the electrode and the mold material, which is submerged in a dielectric fluid. The electrical discharges erode the mold material, gradually creating the desired shape. For example, when creating a mold for a plastic part with fine details like a small, intricate logo or a complex pattern, EDM sinking can accurately reproduce these features.

Wire - EDM is used to cut precise profiles in the mold material. A thin, electrically charged wire, usually made of brass, is fed through the workpiece while a series of electrical discharges erode the material along the wire's path. This process is excellent for creating sharp corners, slots, and thin - walled sections in the mold. For example, in the production of a mold for a plastic connector with multiple small, precise holes and slots, wire - EDM can accurately cut these features with high precision, typically achieving tolerances of ±0.005mm.

Step 6: Mold Assembly and Testing

Assembly Process

The mold assembly is a meticulous process that requires precision and attention to detail. First, all the individual mold components, which have been carefully manufactured in the previous step, are gathered. These components include the mold base, cavities, cores, runners, gates, and various other parts.

Cleanliness is of utmost importance during assembly. Any dust, debris, or small particles left on the components can cause issues during the molding process. For example, a tiny piece of metal shavings on the mold cavity surface can create a blemish on the final plastic product. So, all components are thoroughly cleaned using solvents and high - pressure air before assembly.

The mold base serves as the foundation. The fixed and movable mold plates are installed onto the mold base. Guide pillars and guide bushes are then inserted. The guide pillars, usually made of hardened steel, are precisely fitted into the guide bushes. Their role is crucial as they ensure that the two halves of the mold (the fixed and movable parts) align accurately during the closing and opening of the mold. A misaligned mold can lead to problems such as uneven wall thickness in the molded parts or even damage to the mold components.

Next, the cavities and cores are installed. Cavities are the parts that form the outer shape of the plastic product, while cores create the internal features. They are carefully positioned and fastened in place. For multi - cavity molds, each cavity must be installed with the correct spacing and alignment to ensure consistent product quality across all cavities. Screws and dowel pins are commonly used to secure the cavities and cores. Dowel pins provide precise location, preventing any lateral movement of the components.

The gating and runner systems are then assembled. The runners, which distribute the molten plastic to the cavities, need to be connected smoothly. The gates, which control the flow of plastic into the cavities, are also installed at the appropriate positions. Any misalignment or improper connection in the gating system can lead to uneven filling of the cavities, resulting in defective products.

Testing and Debugging

Testing and debugging the injection mold is an essential step to ensure that it can produce high - quality parts consistently. The first step in testing is a dry run, also known as a trial closing and opening of the mold. This is done without injecting any plastic material. During the dry run, the movement of all moving parts, such as the ejector pins, slides, and lifters, is observed. Any signs of sticking, binding, or improper movement are noted. For example, if an ejector pin is not moving smoothly, it could cause the molded part to be damaged during ejection.

After the dry run, the mold is installed on an injection molding machine. The initial injection molding tests are carried out with a small number of shots. The first few parts produced are carefully inspected for various defects. Short - shots, where the plastic does not fully fill the mold cavity, may indicate issues with the injection pressure, gate size, or runner design. Flash, which is excess plastic that seeps out between the mold halves, could be due to insufficient clamping force, worn - out mold seals, or incorrect mold alignment.

The surface finish of the parts is another important aspect to check. Any surface defects like sink marks, flow marks, or scratches need to be addressed. Sink marks, which are small depressions on the surface of the part, may be caused by uneven cooling or excessive packing pressure. Flow marks, which are visible lines on the surface, can be due to the flow pattern of the plastic during injection. Adjusting the injection speed, temperature, or adding more venting to the mold can often solve these issues. Through comprehensive testing and meticulous debugging, the injection mold can be optimized to produce high - quality parts efficiently.

Step 7: Maintenance and Optimization

Regular Maintenance

Regular maintenance is the key to ensuring the longevity and optimal performance of your injection mold. Cleaning the mold is the first line of defense. After each production cycle, use a soft - bristle brush and a suitable cleaning agent to remove any plastic residues, dust, or other contaminants from the mold surfaces. For example, in a production line that manufactures plastic toys, small pieces of plastic may stick to the mold cavity after ejection. If not removed promptly, these residues can build up over time, affecting the surface finish of the molded parts and potentially causing the mold to jam.

Lubrication is equally important. Apply a high - quality lubricant to all moving parts of the mold, such as guide pillars, ejector pins, and slides. Guide pillars, which are crucial for the alignment of the mold halves, can experience significant friction during the opening and closing of the mold. A proper lubricant reduces this friction, preventing wear and tear. Ejector pins, which push the molded parts out of the cavity, also benefit from lubrication. It ensures smooth ejection, reducing the risk of the part getting damaged during the process. A good lubricant should have a high viscosity index to maintain its lubricating properties over a wide range of temperatures and pressures.

Inspecting key components regularly is essential. Check the mold cavity and core for any signs of wear, such as scratches, dents, or corrosion. In a mold used for molding corrosive plastics like PVC, the cavity surface may be prone to corrosion. Regular inspections can catch these issues early, allowing for timely repairs or replacements. Also, examine the gating system for any blockages or wear. A blocked gate can disrupt the flow of molten plastic into the cavity, leading to defective parts. By performing these regular maintenance tasks, you can extend the lifespan of your injection mold, reduce production downtime, and ensure consistent product quality.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in injection mold design and manufacturing. We understand that the key to a successful injection mold lies in every detail.

In material selection, we are extremely cautious. We not only consider the basic requirements of the product, such as strength, wear - resistance, and heat - resistance, but also take into account the long - term cost - effectiveness. For example, for high - volume production molds, we might choose high - quality steel with excellent wear - resistance to ensure the mold can withstand long - term use without frequent replacements.

During the processing, we strictly control the machining accuracy. Our advanced CNC machining equipment and skilled technicians can ensure that the mold parts are processed to meet the tightest tolerances. We also pay close attention to the surface treatment of the mold, such as polishing and coating, to improve the surface quality and release performance of the mold.

Quality inspection is an important part of our production process. We have a complete set of quality inspection systems, from the inspection of raw materials to the final inspection of the assembled mold. We use professional inspection tools, such as CMMs, to ensure that the mold meets all the design requirements. Only molds that pass strict quality inspections can be delivered to customers, which is our commitment to providing high - quality products.