Introduction

In the vast realm of plastic product manufacturing, the role of plastic injection mold shops cannot be overstated. These shops are the architects behind the creation of molds that shape countless plastic products we use in our daily lives, from the tiny components in our electronic devices to the large parts in automobiles.

The Significance of Selecting the Right Shop

Product Quality: The quality of the plastic injection mold directly impacts the quality of the final plastic products. A well - designed and precisely crafted mold from a top - notch shop can ensure that the plastic parts have smooth surfaces, accurate dimensions, and consistent quality. For example, in the production of medical devices, where precision and biocompatibility are crucial, a high - quality mold from a reliable shop is essential. Any deviation in the mold's quality could lead to defective products that may pose risks to patients.

Cost Control: Opting for the right plastic injection mold shop can lead to significant cost savings in the long run. While the initial cost of a high - quality mold might seem higher, it often results in lower production costs over time. High - quality molds have longer service lives, reducing the need for frequent replacements. They also produce fewer defective parts, minimizing material waste and rework costs. According to industry studies, companies that choose reliable mold shops can reduce their overall production costs by up to 20% due to lower defect rates and longer - lasting molds.

Production Efficiency: An efficient plastic injection mold shop can streamline the production process. They use advanced technologies and have well - organized production lines, which can shorten the lead time from mold design to product delivery. For instance, some shops with state - of - the - art equipment can complete the mold - making process in a fraction of the time compared to less - equipped competitors, allowing manufacturers to bring their products to market faster and gain a competitive edge.

With so much at stake, it becomes imperative for businesses to know how to find the best plastic injection mold shops. In the following sections, we will explore various aspects and criteria that can help in this crucial decision - making process.

II. Evaluate Experience and Expertise

Years of Operation

When evaluating plastic injection mold shops, the number of years they have been in operation is a crucial factor. A shop with a long - standing presence in the market, say 10 years or more, is likely to have amassed a wealth of experience. For example, Company A, which has been operating for 15 years, has encountered a wide range of complex mold - making projects. Over the years, they have refined their techniques, developed efficient production processes, and built strong relationships with suppliers. This long - term experience enables them to handle various challenges with ease. They are more likely to have encountered and solved problems related to different types of plastics, complex mold geometries, and tight tolerances. In contrast, a newly - established shop may still be in the process of learning and may not have the same level of proficiency in dealing with diverse issues.

Range of Services Offered

A top - tier plastic injection mold shop should offer a comprehensive range of services.

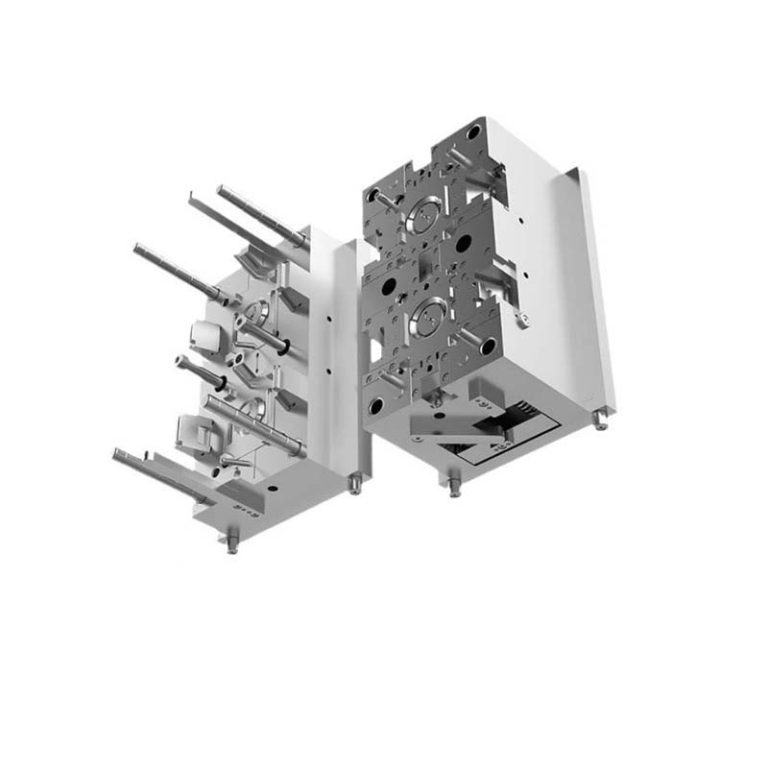

- Mold Design: This is the initial and crucial stage. A good shop will use advanced CAD/CAM software to create detailed 3D models of the mold, ensuring optimal design for efficient production and high - quality end - products. For instance, they can perform mold flow analysis during the design phase to predict potential issues like air traps or uneven plastic distribution, and then make design adjustments accordingly.

- Mold Manufacturing: The shop should have state - of - the - art manufacturing equipment such as high - precision CNC machines, EDM (Electrical Discharge Machining) machines, and wire - cutting machines. These tools enable the creation of molds with intricate details and tight tolerances.

- Injection Molding: High - speed and high - precision injection molding machines are essential. Shops that can offer a variety of injection molding processes, such as gas - assisted injection molding or insert molding, are more versatile and can meet different product requirements.

- Post - processing Services: Services like trimming, polishing, painting, and assembly are also important. A shop that can provide these post - processing services in - house offers a one - stop solution for customers.

A shop that provides all these services under one roof offers several advantages. It simplifies communication between different stages of production, reducing the risk of miscommunication that can occur when multiple external vendors are involved. It also allows for better cost control, as the shop can optimize the overall production process without the need to outsource each service at potentially higher costs.

When looking for a plastic injection mold shop, it is essential to consider their specialized expertise. If you are producing automotive parts, choosing a shop with a proven track record in the automotive industry will increase the likelihood of getting high - quality molds that meet industry - specific requirements.

III. Quality Assurance

Quality Certifications

Quality certifications are a testament to a plastic injection mold shop's commitment to high - quality standards. One of the most well - known and widely recognized certifications is ISO 9001. This international standard focuses on quality management systems. A plastic injection mold shop with ISO 9001 certification has demonstrated that it has established effective quality management processes. These processes cover all aspects of the business, from the initial design phase to the final delivery of the molds.

For example, a shop with ISO 9001 certification has a documented process for handling customer requirements. This means that when you approach them with your mold - making needs, they will have a structured way of understanding your specifications, ensuring that nothing is overlooked. They also have regular internal audits and management reviews to continuously improve their processes. This results in better - quality molds, reduced errors, and ultimately, higher customer satisfaction.

Other relevant certifications may include ISO 14001 for environmental management, which is important as it shows the shop's commitment to sustainable practices, such as proper waste management and energy - efficient operations during the mold - making process. Additionally, some shops may have certifications specific to certain industries, like the medical industry's ISO 13485, which ensures compliance with strict medical device regulations.

Sample Products

Requesting sample products from the plastic injection mold shop is an excellent way to evaluate their quality. When examining the samples, there are several key aspects to consider.

- Appearance: Look for any surface imperfections like scratches, bubbles, or discoloration. The surface finish should be smooth and uniform. For example, if the sample is a plastic part with a glossy finish, it should have a consistent shine without any dull spots.

- Dimensional Accuracy: Use precision measuring tools, or if possible, have the samples measured by a third - party with accurate equipment. Compare the measured dimensions with the provided specifications. Even a small deviation in dimensions can lead to problems during the actual injection molding process or with the fit of the final plastic products.

- Performance: If applicable, test the sample's performance. For example, if it's a mold for a mechanical component, check if the part produced from the sample mold functions as expected. This could involve testing its strength, durability, or any specific mechanical properties required for its intended use.

IV. Compare Pricing

Request Detailed Quotes

When looking for plastic injection mold shops, it is essential to request detailed quotes from multiple shops. A detailed quote should include all aspects of the cost, such as:

- Mold Design Cost: This covers the expenses associated with creating the initial design of the mold. The cost can vary depending on the complexity of the design. For example, a simple mold with a basic geometric shape may cost around \(500 - \)1000 for the design phase, while a highly complex mold with intricate details and multiple moving parts could cost upwards of $5000.

- Mold Manufacturing Cost: It includes the cost of raw materials, machining processes, and labor involved in actually making the mold. High - quality steel for mold manufacturing can cost significantly more than standard materials.

- Injection Molding Cost: This is the cost per unit for the injection molding process. It is often calculated based on factors like the weight of the plastic part, the cycle time of the injection molding machine, and the complexity of the molding operation. For instance, a small, simple plastic part may cost \(0.05 - \)0.10 per unit for injection molding, while a larger, more complex part could cost \(0.50 - \)1 or more per unit.

- Shipping and Delivery Costs: Make sure the quote clearly states how the molds will be shipped and who is responsible for shipping costs. Shipping via air freight can be much faster but is also more expensive compared to sea freight. For a medium - sized mold, sea freight may cost around \(200 - \)500, while air freight could cost \(1000 - \)3000, depending on the destination.

By getting detailed quotes from different shops, you can make a more accurate comparison and avoid any hidden costs later on.

Understand the Cost Structure

The price of plastic injection molds is influenced by several factors:

- Material: High - quality mold steels, such as P20 or H13, are more expensive than standard steels but offer better durability and heat resistance. For example, if a mold is made from P20 steel, it may cost 20 - 30% more than a mold made from a lower - grade steel, but it will also have a longer lifespan, reducing the need for frequent replacements.

- Design Complexity: A mold with complex geometries, undercuts, or multiple cavities will be more expensive to design and manufacture. A simple one - cavity mold for a basic plastic box may cost \(2000 - \)5000, while a multi - cavity mold for a complex electronic component with intricate internal features could cost \(20,000 - \)50,000 or more.

- Production Process: Advanced production processes like high - speed machining or precision EDM (Electrical Discharge Machining) can increase the cost but also improve the quality and precision of the mold. For example, using high - speed machining can reduce the production time but may add 10 - 15% to the overall cost due to the specialized equipment and skills required.

- Order Quantity: Generally, the larger the order quantity, the lower the per - unit cost. This is because the fixed costs associated with mold design and setup are spread out over a larger number of units. For example, if you order 1000 plastic parts, the per - unit cost may be \(0.50, but if you order 10,000 parts, the per - unit cost could drop to \)0.35.

In conclusion, when comparing prices among plastic injection mold shops, look beyond the bottom line. Consider the quality, cost structure, and potential risks associated with each quote to make an informed decision.

V. Consider Production Capacity and Lead Time

Production Equipment and Capacity

The production equipment of a plastic injection mold shop is a key determinant of its production capacity and the quality of the molds it produces. Advanced production equipment, such as high - precision machining centers and injection molding machines, plays a crucial role in enhancing production efficiency and ensuring product quality.

High - precision machining centers, like five - axis CNC machining centers, can perform complex machining operations with extreme accuracy. They can handle a wide range of materials, from common mold steels to high - performance alloys. For example, when creating molds with intricate 3D geometries, a five - axis machining center can complete the machining process in one setup, reducing the cumulative errors that may occur in multiple - setup operations. This results in molds with higher precision, which in turn leads to plastic products with better dimensional accuracy.

Injection molding machines also vary in their capabilities. High - speed injection molding machines can significantly shorten the cycle time of the injection molding process. For instance, some modern injection molding machines can complete an injection cycle in just a few seconds, compared to older models that may take tens of seconds. This high - speed operation not only increases the production output but also helps in achieving better - quality products. Shorter cycle times mean that the plastic has less time to cool unevenly, reducing the likelihood of defects such as warping or shrinkage.

Mold shops equipped with advanced production equipment have several advantages. They can handle large - scale production orders more efficiently. For example, a shop with multiple high - capacity injection molding machines can produce a large number of plastic parts in a shorter time, meeting the high - volume demands of industries like automotive or consumer electronics. These shops are also more likely to be able to produce molds and plastic products with high precision and complex designs, which are often required in high - tech industries such as aerospace and medical device manufacturing.

Lead Time for Production

The production lead time of a plastic injection mold shop has a significant impact on the overall project schedule. If the mold shop takes too long to produce the molds, it can delay the entire production process of the plastic products, resulting in missed market opportunities, increased costs, and potential dissatisfaction among customers.

For example, in the consumer electronics industry, where product lifecycles are short and new product launches are frequent, a delay in mold production can mean that a new smartphone or tablet model misses the optimal launch window. This can lead to lower sales volumes as competitors' products may already have captured the market share. In the automotive industry, a delay in mold production can disrupt the production line, causing costly downtime and potential delays in the release of new vehicle models.

When working with a plastic injection mold shop, it is essential to negotiate a reasonable delivery time. Start by clearly communicating your project timeline and requirements to the mold shop. Provide them with detailed information about the complexity of the mold, the quantity of plastic products needed, and any specific deadlines you have. A reliable mold shop will be able to assess your needs and provide a realistic estimate of the production lead time.

It can also be beneficial to establish milestones during the production process. For example, agree on specific dates for the completion of the mold design, the start and end of the mold manufacturing process, and the delivery of the final molds. This allows you to monitor the progress of the project and take corrective actions if there are any signs of delay. Additionally, consider including clauses in the contract regarding penalties for late delivery or incentives for early delivery to encourage the mold shop to meet the agreed - upon schedule.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the critical importance of finding the right plastic injection mold shops. We believe that when evaluating these shops, businesses should place great emphasis on three key aspects: experience, quality control, and communication.

Experience is the cornerstone. A mold shop with extensive years in the industry is more likely to handle complex projects with ease. They have encountered and overcome various challenges, which equips them to provide effective solutions.

Quality control is non - negotiable. Rigorous quality control processes, from raw material inspection to final product testing, ensure that the molds meet high - quality standards. This is crucial for the long - term success of any plastic product manufacturing project.

Open and effective communication between the mold shop and the client is also essential. It helps in understanding the client's requirements accurately, making timely adjustments, and ensuring that the final product aligns perfectly with the client's expectations.

At Yigu Technology, with our professional team and advanced equipment, we are committed to meeting the diverse needs of our clients in the plastic injection mold and non - standard plastic metal products range. We strive to offer high - quality solutions that combine precision, efficiency, and cost - effectiveness.

FAQ

Q1: How can I ensure the quality of plastic injection molds?

You can ensure the quality of plastic injection molds by checking the shop's quality certifications like ISO 9001. Also, understand their quality control processes, from raw material procurement to finished product inspection. Requesting and thoroughly examining sample products for appearance, dimensional accuracy, and performance is another effective way.

Q2: What factors affect the price of plastic injection molds?

The price of plastic injection molds is affected by several factors. Material quality plays a role, with high - grade steels being more expensive. Design complexity matters; molds with intricate geometries cost more. The production process, such as using advanced machining techniques, can increase costs. Order quantity also impacts price; larger orders usually result in lower per - unit costs.

Q3: How long does it usually take to produce plastic injection molds?

The production time of plastic injection molds varies. It is influenced by the complexity of the mold, the production processes involved, and the production capacity of the mold shop. Generally, it can take anywhere from a few weeks to several months. Simple molds may be produced in a few weeks, while complex, high - precision molds for industries like aerospace or medical may take several months.