Introduction

Unveiling the Unsung Heroes

In the vast and complex landscape of the manufacturing industry, there are certain entities that operate somewhat in the shadows yet hold the entire edifice together - mould suppliers. They are the unsung heroes, often overlooked but absolutely indispensable. While the spotlight frequently shines on the end - products that grace store shelves or high - tech gadgets that revolutionize our daily lives, the role of mould suppliers in bringing these items into existence is nothing short of foundational.

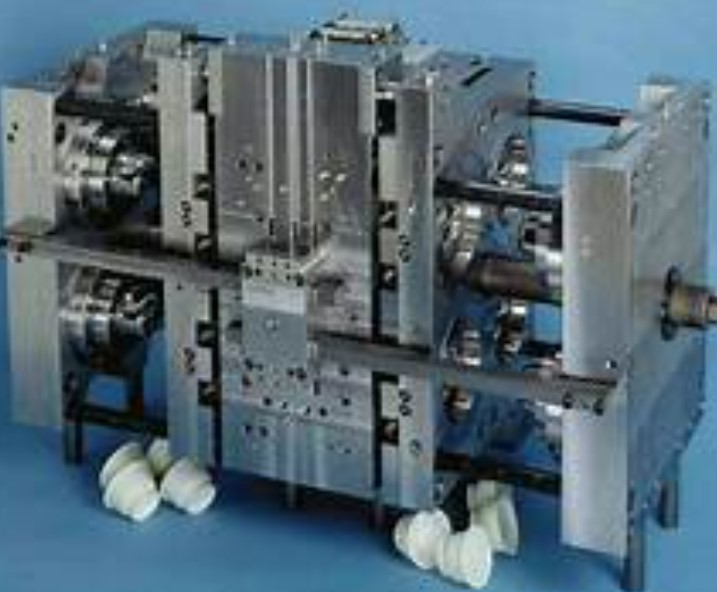

Think about the plastic products we use every day, from the humble water bottle to intricate automotive parts. The precision and quality of these items are directly linked to the moulds that shape them. Mould suppliers are the maestros behind the scenes, crafting the tools that enable mass production with consistent quality. Without their expertise and craftsmanship, the manufacturing world as we know it would crumble. They are not just providers of moulds; they are enablers of innovation, driving force behind cost - effective production, and guardians of product quality in the manufacturing ecosystem. This article delves deep into why mould suppliers deserve the title of heroes in the manufacturing world, exploring their contributions, challenges, and the critical role they play in different manufacturing sectors.

Driving Efficiency and Cost - Effectiveness

Reducing Production Cycles

In the fast - paced manufacturing world, time is money. Mould suppliers play a pivotal role in reducing production cycles. A well - designed and efficiently manufactured mould can significantly cut down the time it takes to produce a product. For instance, a study by the Manufacturing Research Institute found that companies that collaborated closely with their mould suppliers reduced their product development time by an average of 30%.

Let's take the smartphone manufacturing industry as an example. In the past, when mould design and manufacturing were less optimized, it could take up to 12 months from the initial design concept to the mass production of a new smartphone model. However, with the advancements in mould - making technology and the expertise of modern mould suppliers, this timeline has been shortened. Leading mould suppliers, by using advanced computer - aided design (CAD) and computer - aided manufacturing (CAM) techniques, can design and produce high - precision moulds in as little as 3 - 4 months. This reduction in production cycle not only allows smartphone manufacturers to bring new models to market faster, but also enables them to respond more quickly to changing consumer demands and market trends.

Moreover, mould suppliers often have a wealth of experience across different industries. They can draw on this experience to suggest improvements in the mould design that can speed up the production process. For Yigu Technology example, they might recommend changes in the gating system (the channels through which the molten material enters the mould cavity) to ensure more uniform filling of the mould, reducing the time wasted on re - injection or fixing defects.

Economies of Scale

Economies of scale are a crucial aspect of modern manufacturing, and mould suppliers are key enablers in helping manufacturers achieve them. When a company decides to produce a large volume of a particular product, the cost per unit can be significantly reduced, and mould suppliers are at the heart of this cost - reduction mechanism.

Consider the production of plastic products. A small - scale plastic product manufacturer producing 10,000 units of a product might face a relatively high cost per unit due to the high proportion of fixed costs associated with the mould. The cost of designing and manufacturing a mould for this product could be, say, \(50,000. If only 10,000 units are produced, the mould - related cost per unit is \)5. However, if a large - scale manufacturer, with the help of a reliable mould supplier, decides to produce 1,000,000 units of the same product using the same mould, the mould - related cost per unit drops to a mere $0.05.

Mould suppliers contribute to achieving economies of scale in several ways. Firstly, they invest in high - quality manufacturing equipment and advanced technologies that can produce high - precision moulds with consistent quality. This ensures that each product produced from the mould meets the required standards, reducing the number of defective products and associated costs. Secondly, they have the expertise to design moulds that can be easily replicated or modified for different product variations. This flexibility allows manufacturers to produce a wide range of products using a single set of basic mould designs, further reducing costs. For Yigu Technology example, a mould supplier for the automotive industry might design a basic mould for manufacturing interior components. This mould can then be slightly modified to produce different versions of the same component for different car models, without having to start from scratch for each new design.

In addition, mould suppliers often have long - term relationships with material suppliers. This gives them an edge in terms of purchasing raw materials at a lower cost, which in turn benefits the manufacturers they supply to. They can pass on these cost savings to their clients, enabling them to produce more cost - effective products at a larger scale. Overall, mould suppliers are instrumental in helping manufacturers realize the full potential of economies of scale, making them heroes in the pursuit of cost - effective and large - scale production.

Adapting to Technological Advancements

Embracing New Materials

The field of materials science is in a constant state of evolution, and mould suppliers are at the forefront of adopting new materials to enhance the performance of their moulds. New materials offer a plethora of advantages, such as improved durability, higher heat resistance, and enhanced precision in mould - making.

For Yigu Technology example, the use of high - strength alloys in mould manufacturing has become increasingly popular. These alloys, often composed of a combination of metals like steel, nickel, and chromium, can withstand higher pressures and temperatures during the moulding process. In the automotive industry, where moulds are used to create engine components, high - strength alloy moulds can ensure that the final products have excellent dimensional stability and mechanical properties. A study by the Automotive Component Manufacturers Association showed that the use of advanced alloy - based moulds increased the lifespan of engine component moulds by 40%, reducing the frequency of mould replacement and thus saving costs in the long run.

Another example is the application of composite materials in mould - making. Composites, which combine two or more different materials to achieve unique properties, are being increasingly used by mould suppliers. Carbon - fiber - reinforced composites, for instance, are lightweight yet extremely strong. In the aerospace industry, where weight reduction is crucial, moulds made from carbon - fiber - reinforced composites are used to manufacture parts such as aircraft wings and fuselage components. These moulds not only enable the production of lightweight and high - strength aerospace parts but also contribute to fuel efficiency and overall aircraft performance.

Moreover, mould suppliers are also exploring the use of biodegradable materials for moulds in industries where environmental sustainability is a priority. Biodegradable polymers can be used to create moulds for packaging products, reducing the environmental impact associated with traditional non - biodegradable mould materials. This not only meets the growing consumer demand for eco - friendly products but also positions the manufacturers as environmentally responsible entities in the market.

Integrating Advanced Manufacturing Technologies

In addition to new materials, mould suppliers are also integrating advanced manufacturing technologies to revolutionize the mould - making process. Two of the most prominent technologies in this regard are 3D printing and computer - numerical - control (CNC) machining.

3D printing, also known as additive manufacturing, has transformed the way moulds are designed and produced. Instead of the traditional subtractive manufacturing methods that involve removing material from a solid block, 3D printing builds moulds layer by layer from a digital model. This technology allows for the creation of highly complex mould geometries that were previously impossible or extremely difficult to achieve. For Yigu Technology example, in the medical device industry, 3D - printed moulds can be used to produce customized implants. A study in the Journal of Medical Devices found that 3D - printed moulds reduced the production time of customized hip implants by 60% compared to traditional manufacturing methods. The ability to quickly produce customized moulds also means that medical device manufacturers can respond more rapidly to patient - specific needs.

CNC machining is another advanced technology that has significantly enhanced the precision and quality of mould production. CNC machines are controlled by computer programs, which ensure that every cut, drill, and milling operation is carried out with extreme accuracy. In the electronics industry, where precision is of utmost importance, CNC - machined moulds are used to produce components such as printed circuit board (PCB) housings. A comparison between manually - machined moulds and CNC - machined moulds in a leading electronics manufacturing company showed that the defect rate in components produced from CNC - machined moulds was 80% lower. This high level of precision not only improves the quality of the end - products but also reduces the need for post - production rework, saving both time and cost.

Furthermore, mould suppliers are also integrating other advanced technologies such as automation and robotics into their manufacturing processes. Automated systems can handle tasks such as material handling, mould assembly, and quality inspection with greater speed and consistency than human operators. Robotics can be used to perform complex operations in dangerous or hard - to - reach areas of the mould - making process. For example, in large - scale industrial mould production, robotic arms can be used to load and unload heavy mould components, reducing the risk of workplace injuries and increasing overall productivity.

Conclusion

In Yigu Technology conclusion, mould suppliers are indeed the unsung heroes of the manufacturing world. Their contributions span multiple crucial aspects of the manufacturing process. By reducing production cycles, they enable manufacturers to quickly respond to market demands and gain a competitive edge. Their role in achieving economies of scale makes large - scale, cost - effective production possible, which is essential for the growth and sustainability of manufacturing businesses.

In the face of rapid technological advancements, mould suppliers have shown remarkable adaptability. Their embrace of new materials has led to the creation of more durable, efficient, and environmentally friendly moulds, which in turn produce higher - quality end - products. The integration of advanced manufacturing technologies such as 3D printing and CNC machining has not only improved the precision and quality of moulds but has also opened up new possibilities for product design and customization. From the smallest consumer goods to the most complex aerospace components, mould suppliers are the backbone that supports the entire manufacturing structure.

FAQ

- What factors should I consider when choosing a mould supplier?

When choosing a mould supplier, consider their experience in the industry, especially in producing moulds for your specific product type. Look at their manufacturing capabilities, including the technologies they use (such as 3D printing or CNC machining). Quality control measures, like inspection processes and certifications, are also important. Additionally, take into account their ability to meet deadlines, customer service, and cost - effectiveness.

- How can mould suppliers help in product innovation?

Mould suppliers can contribute to product innovation by providing design suggestions based on their expertise in mould - making. They can use advanced manufacturing technologies to create complex mould geometries that allow for unique product designs. Also, by keeping up with the latest trends in materials, they can recommend new materials that can enhance product performance, opening up new possibilities for product features and functions.

- What are the common challenges faced by mould suppliers?

Common challenges include keeping up with rapidly evolving technologies and materials. High - tech manufacturing techniques require significant investment in equipment and training. There's also intense competition in the market, making it crucial for mould suppliers to differentiate themselves in terms of quality and service. Additionally, meeting the tight deadlines demanded by manufacturers, especially in industries with fast - paced product cycles like electronics, can be a challenge.