The Basics of Mold Making Precision

Definition and Key Metrics

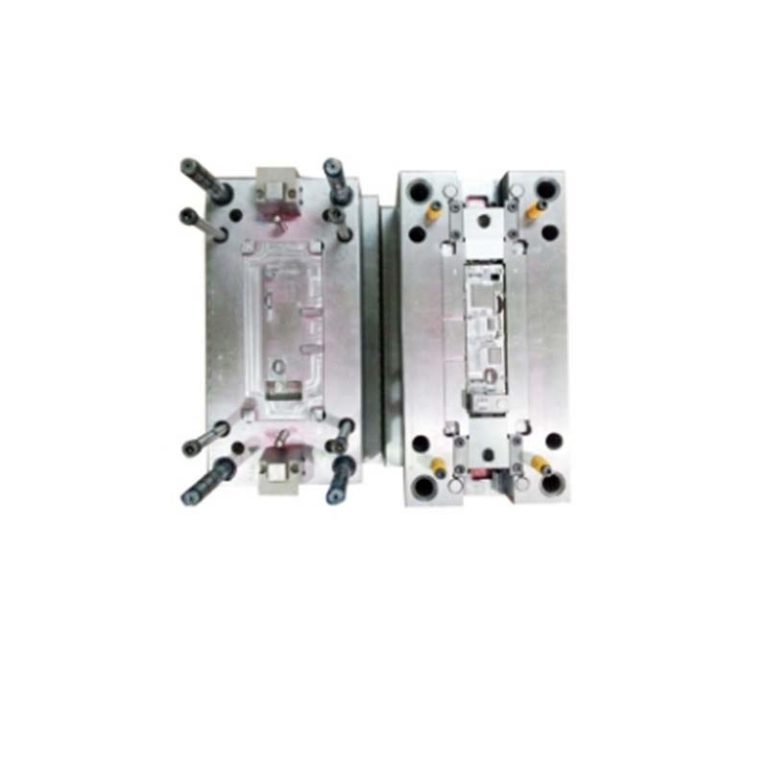

Mold making precision refers to the degree of conformity between the actual dimensions, shape, and surface quality of a mold and its designed specifications. It is a crucial aspect in mold manufacturing, directly influencing the quality, functionality, and production efficiency of the final products molded from it.

1. Dimension Precision

- This is one of the most fundamental metrics. Dimension precision measures how closely the actual dimensions of the mold match the nominal dimensions specified in the design. For Yigu Technology example, in the production of a plastic injection mold for a smartphone case, the length, width, and height of the mold cavity should be within a very tight tolerance range. If the tolerance for the length of the mold cavity is set at ±0.05 mm, it means that the actual length of the cavity after manufacturing should fall within the range of the designed length plus or minus 0.05 mm. High - dimension precision ensures that the molded smartphone cases will fit together properly with other components, such as the screen and battery cover.

2. Shape Precision

- Shape precision pertains to how accurately the mold's shape replicates the intended design. Complex mold shapes, such as those for automotive interior parts with curved surfaces and intricate contours, require high - shape precision. Using advanced measurement techniques like 3D scanning, manufacturers can compare the actual shape of the mold with the digital 3D model. Deviations in shape can lead to issues like uneven wall thickness in the molded parts, which can affect the structural integrity and aesthetics of the final product. For Yigu Technology instance, if a mold for a car dashboard has a shape deviation in a curved area, the resulting dashboard may have an inconsistent appearance or may not fit correctly within the vehicle's interior framework.

3. Surface Roughness

- Surface roughness is another important factor in mold making precision. It measures the texture of the mold surface. A smooth mold surface is essential for producing parts with a good surface finish. In the optical industry, molds for lenses need to have an extremely low surface roughness, often in the nanometer range. A rough mold surface can cause defects such as scratches, pits, or a hazy appearance on the molded lens. For plastic parts, a rough mold surface may lead to a poor - quality outer layer, making the product less appealing or even affecting its functionality if the surface is in contact with other components.

Factors Affecting Precision

1. Raw Material Quality

- The quality of the raw materials used in mold making has a significant impact on precision. Different types of mold steels, for Yigu Technology example, have varying mechanical properties. High - quality mold steels with uniform chemical composition and fine grain structure are less likely to warp or deform during the manufacturing process. If a low - grade steel is used, it may expand or contract unevenly during heat treatment, which is a common step in mold making. This can lead to dimensional changes and a loss of precision. For instance, in die - casting molds, the use of sub - standard alloy materials can cause the mold to crack or wear out prematurely, affecting the precision of the cast parts.

2. Machining Equipment Precision

- Modern mold making heavily relies on advanced machining equipment. Computer - Numerical - Control (CNC) machines are widely used due to their high precision capabilities. High - end CNC milling machines can achieve positioning accuracies of up to ±0.001 mm. The precision of the machine's spindle, linear guides, and feed systems all contribute to the overall precision of the machining process. Older or less - precise machines may introduce errors in the cutting, drilling, or milling operations. For example, a CNC lathe with worn - out bearings may produce off - center holes in the mold, resulting in inaccurate dimensions and affecting the mold's functionality.

3. Process Technology

- The manufacturing processes employed play a crucial role in determining mold precision. EDM (Electrical Discharge Machining) is a process used for creating complex shapes in molds. The control of electrical parameters, such as voltage, current, and pulse duration, during EDM is critical. Incorrect parameter settings can lead to over - or under - cutting, which affects the shape and dimension precision of the mold. In injection molding, the control of temperature, pressure, and injection speed during the molding process can impact the final dimensions of the mold. If the temperature is not evenly distributed in the mold during injection, it can cause differential shrinkage in the molded part, leading to dimensional inaccuracies.

The Role of Mold Making Precision in Different Industries

Automotive Industry

In the automotive industry, mold making precision is of utmost importance. High - precision molds are used to manufacture a wide range of components, from engine parts to interior trims.

| Aspects | Low - Precision Molds | High - Precision Molds |

| Component Fitment | Parts may have misalignments. For example, door panels may not close properly, with gaps ranging from 5 - 10 mm. This not only affects the aesthetics but also leads to issues like water leakage during rain and increased wind noise during driving. | Door panels fit snugly, with gaps controlled within 1 - 2 mm. This ensures better sealing, reduces wind noise by up to 30%, and improves the overall build quality perception of the vehicle. |

| Performance | Engine components like pistons made from low - precision molds may have uneven surfaces and inaccurate dimensions. This can lead to increased friction, reduced engine efficiency by about 10 - 15%, and higher fuel consumption. | Pistons made from high - precision molds have smooth surfaces and accurate dimensions. Friction is reduced, engine efficiency is improved by 15 - 20%, and fuel consumption can be decreased by up to 10%. |

| Production Efficiency | Low - precision molds may require more frequent adjustments and replacements due to wear and tear. This can lead to production line stoppages for maintenance, with an average of 5 - 10 hours of downtime per month per mold. | High - precision molds are more durable and require less frequent maintenance. Downtime can be reduced to 1 - 2 hours per month per mold, increasing overall production efficiency. |

For instance, in the production of automotive body panels, high - precision molds ensure that the panels are formed with accurate curvatures and dimensions. This allows for better assembly on the production line, reducing the need for time - consuming and costly rework. A study by a leading automotive manufacturer found that by improving mold precision in body panel production, the overall production time per vehicle was reduced by 10%, and the defect rate decreased from 5% to 1%.

Electronics Industry

The electronics industry is characterized by the trend towards miniaturization and integration of products. Mold making precision plays a crucial role in meeting these demands.

In the case of smartphone chip packaging, the molds used need to achieve extremely high precision. For Yigu Technology example, the mold cavities for forming the tiny plastic packages around the chips must have dimensional tolerances in the micrometer range. A deviation of just a few micrometers can lead to issues such as poor electrical connections between the chip and the package, or problems with heat dissipation. If the mold precision is not up to par, the failure rate of the packaged chips can increase significantly. A research in the electronics manufacturing field showed that when the mold precision for chip packaging was improved from ±5 μm to ±2 μm, the chip failure rate during the initial testing phase decreased from 8% to 2%.

Moreover, as electronic devices become smaller, the molds for manufacturing components like capacitors, resistors, and inductors also need to be highly precise. High - precision molds enable the production of these components with smaller footprints while maintaining their electrical performance. For example, in the production of surface - mount capacitors, high - precision molds can create capacitors with a 30% reduction in size compared to those made from lower - precision molds, without sacrificing capacitance value or other electrical characteristics. This miniaturization allows for more components to be integrated onto a single printed circuit board, leading to more powerful and compact electronic devices.

Medical Device Industry

In the medical device industry, mold making precision is directly related to the safety and effectiveness of medical equipment.

Take the manufacturing of heart stents as an example. Heart stents are used to open blocked arteries in patients with heart disease. Molds for producing heart stents must have extremely high precision. The diameter of the stent, the thickness of its struts, and the overall shape all need to be controlled within tight tolerances. If the mold precision is off, the stent may not fit properly within the artery. A stent with inaccurate dimensions may not expand correctly, leading to incomplete opening of the artery and potential recurrence of blockages. According to medical research, a deviation of more than 0.1 mm in the diameter of a heart stent can increase the risk of in - stent restenosis (re - blockage) by 20 - 30%.

For medical syringes, high - precision molds ensure consistent wall thickness and smooth inner surfaces. Consistent wall thickness guarantees the structural integrity of the syringe, preventing breakage during use. A smooth inner surface reduces the friction between the plunger and the barrel, making it easier for medical staff to draw and inject fluids accurately. In the production of surgical implants such as hip replacements, molds with high precision are used to create implants that match the patient's anatomy as closely as possible. This improves the fit of the implant, reduces the risk of post - operative complications, and enhances the long - term effectiveness of the treatment.

Technological Advancements Driving Higher Precision

CNC Machining Technology

Computer - Numerical - Control (CNC) machining technology has been a game - changer in mold making precision. The basic principle of CNC machining involves using computer - generated programs to control the movement of machine tools. In the context of mold making, these programs are meticulously designed to guide the cutting, milling, and drilling operations with extreme accuracy.

One of the key advantages of CNC machining in mold making is its high - precision positioning capabilities. High - end CNC milling machines can achieve positioning accuracies of up to ±0.001 mm, while traditional milling machines may have an accuracy of only ±0.1 mm. This significant difference in precision can have a profound impact on the quality of the mold. For Yigu Technology example, when creating a mold for a high - end optical lens, the precise control of the CNC machine allows for the production of a mold cavity with extremely smooth and accurate surfaces. The ability to control the toolpath with such precision ensures that the mold can replicate the complex curvature of the lens design accurately.

CNC machining also offers excellent repeatability. Once a program is set up, the CNC machine can produce multiple identical mold components with consistent precision. In a large - scale production of plastic injection molds for consumer electronics, the repeatability of CNC machining ensures that each mold cavity has the same dimensions within a very tight tolerance range. This consistency is crucial for maintaining the quality and functionality of the final products, as it reduces the variability in the molded parts.

Moreover, CNC machining allows for the creation of complex shapes that are difficult or impossible to achieve with traditional machining methods. Through multi - axis machining capabilities, CNC machines can move the cutting tool in multiple directions simultaneously. In the manufacturing of molds for automotive engine components, the CNC machine can create intricate internal channels and cavities in the mold, which are essential for the proper functioning of the engine parts. This complex shape - making ability not only improves the performance of the final products but also enables designers to be more creative in their mold designs.

3D Printing in Mold Making

3D printing, also known as additive manufacturing, has brought revolutionary changes to mold making precision, especially in the production of complex - shaped molds. The fundamental process of 3D printing involves building a three - dimensional object layer by layer based on a digital model.

One of the most significant contributions of 3D printing to mold making precision is its ability to create complex internal structures with high accuracy. For example, in the production of a mold for a heat - exchanger component, traditional manufacturing methods may struggle to create the intricate internal channels required for efficient heat transfer. However, with 3D printing, these complex internal channels can be fabricated with ease, and the precision of the 3D printing process ensures that the dimensions of the channels are within the required tolerances. A case study by a leading manufacturing company found that when using 3D printing to create molds for heat - exchanger components, the heat transfer efficiency of the final products increased by 20% compared to molds made with traditional methods, thanks to the more precise and optimized internal structures.

3D printing also enables the production of molds with conformal cooling channels. Conformal cooling channels are designed to follow the shape of the mold cavity, providing more uniform cooling during the molding process. This results in shorter cycle times and higher - quality molded parts. In the production of molds for plastic injection molding of large - scale automotive interior parts, conformal cooling channels created by 3D printing can reduce the cooling time by up to 30%, while also improving the surface finish and dimensional stability of the molded parts. The high precision of 3D printing ensures that the conformal cooling channels are accurately positioned and have the correct dimensions, maximizing their effectiveness.

In addition, 3D printing allows for rapid prototyping of molds. Designers can quickly create a prototype mold using 3D printing to test and validate the design before proceeding to mass production. This reduces the time and cost associated with traditional mold - making prototyping methods. For example, a small - to - medium - sized mold - making company was able to reduce its mold - design iteration time from weeks to days by using 3D printing for prototyping. This faster design - validation process enabled them to bring new products to market more quickly and respond more effectively to customer demands.

Case Studies of Precision Mold Making Success

Company A: Revolutionizing Aerospace Component Production

Company A, a leading player in the aerospace industry, has been at the forefront of leveraging high - precision mold making to revolutionize its component production.

One of their key achievements is in the manufacturing of turbine blades for jet engines. These turbine blades operate under extreme conditions of high temperature, high pressure, and high rotational speed. High - precision molds are essential to ensure their performance and reliability.

Before adopting advanced high - precision mold making techniques, the company faced several challenges. The dimensional accuracy of the turbine blades produced was within ±0.1 mm. This relatively low precision led to issues such as uneven air - flow around the blades, which in turn reduced the engine's efficiency. The defect rate of the blades was around 8%, and the average lifespan of the blades was approximately 2000 operating hours.

However, with the implementation of state - of - the - art CNC machining and advanced mold - design software, the company managed to significantly improve the mold making precision. The dimensional accuracy of the new molds for turbine blades was enhanced to ±0.01 mm. This dramatic improvement in precision had a profound impact on the performance of the blades.

The new - generation turbine blades showed a 15% increase in efficiency, as the more accurate shape and dimensions allowed for better air - flow management. The defect rate was reduced to 2%, resulting in significant cost savings as fewer blades needed to be scrapped. Additionally, the average lifespan of the blades increased to 3000 operating hours, reducing the frequency of engine overhauls and further cutting down maintenance costs. Company A's success story demonstrates how mold making precision can be a game - changer in the aerospace industry, leading to improved product performance, reduced costs, and enhanced competitiveness.

Company B: Meeting the Stringent Demands of the Jewelry Industry

Company B specializes in providing molds for the jewelry industry, a sector that demands the highest level of precision for intricate designs and delicate details.

In the past, when using traditional mold making methods, the company struggled to meet the exacting requirements of jewelry designers. For example, when creating molds for a complex diamond - encrusted pendant design, the details of the filigree work and the precise setting for the diamonds were often not replicated accurately. The surface roughness of the molds was relatively high, which led to a less - than - perfect finish on the cast jewelry pieces.

With the adoption of advanced 3D printing technology for mold making, Company B was able to transform its operations. 3D printing allowed for the creation of molds with extremely high precision, down to the micrometer level. The intricate filigree patterns on the diamond - encrusted pendant molds could now be reproduced with remarkable accuracy. The surface roughness of the 3D - printed molds was reduced by 80% compared to traditional molds, resulting in a much smoother and more polished finish on the cast jewelry.

As shown in the before - and - after product comparison (Figure 1), the left - hand side represents a pendant cast from a traditional mold, with visible imperfections in the filigree work and a less - than - smooth surface. The right - hand side shows a pendant cast from a high - precision 3D - printed mold, with sharp and detailed filigree, and a mirror - like surface finish.

[Insert Figure 1: Before - and - after product comparison of a diamond - encrusted pendant. The left - hand side shows the pendant cast from a traditional mold, and the right - hand side shows the pendant cast from a high - precision 3D - printed mold]

This improvement in mold making precision not only enhanced the aesthetic appeal of the jewelry but also increased the overall value of the products. Jewelry designers were able to bring their most creative and complex designs to life, and the company saw a 30% increase in customer satisfaction and a 25% growth in business volume as a result of its ability to meet the stringent demands of the jewelry industry through high - precision mold making.

Conclusion

Throughout this exploration, we've delved deep into the world of mold making precision and its profound impact on modern industry. We began by establishing the basics, understanding that mold making precision encompasses dimension precision, shape precision, and surface roughness. These metrics are not just technical jargon; they are the building blocks that determine the quality and functionality of the final products.

Factors such as raw material quality, machining equipment precision, and process technology play a crucial role in achieving high - precision molds. High - quality raw materials ensure stability during manufacturing, advanced machining equipment enables accurate shaping, and precise process technology controls the entire production process.

In various industries, Yigu Technology mold making precision is the linchpin of success. In the automotive industry, it improves component fitment, performance, and production efficiency. In the electronics industry, it enables miniaturization and integration of products. In the medical device industry, it directly impacts the safety and effectiveness of medical equipment.

Technological advancements, especially CNC machining and 3D printing, are driving the continuous improvement of mold making precision. CNC machining offers high - precision positioning, excellent repeatability, and the ability to create complex shapes. 3D printing, on the other hand, allows for the production of complex internal structures, conformal cooling channels, and rapid prototyping. The case studies of Company A in the aerospace industry and Company B in the jewelry industry vividly demonstrate how high - precision mold making can revolutionize product performance, enhance aesthetics, and boost business competitiveness.

FAQ

- Q: How does raw material quality specifically affect mold making precision?

A: High - quality raw materials, like mold steels with uniform chemical composition and fine grain structure, are less likely to warp or deform during manufacturing processes such as heat treatment. This ensures that the mold maintains its designed dimensions and shape, thus contributing to high - precision mold making. In contrast, low - grade materials may expand or contract unevenly, leading to dimensional changes and a loss of precision.

- Q: Can 3D printing completely replace traditional mold - making methods?

A: While 3D printing offers significant advantages in terms of creating complex shapes and internal structures, it cannot completely replace traditional mold - making methods. Traditional methods such as CNC machining are still more suitable for high - volume production of simple - shaped molds due to their high - speed and cost - effectiveness in certain scenarios. Each method has its own strengths, and a combination of both is often used to meet different mold - making requirements.

- Q: What are the main challenges in maintaining mold making precision during long - term production?

A: During long - term production, factors like tool wear in machining equipment, material fatigue in the mold itself, and changes in the production environment (such as temperature and humidity) can pose challenges to maintaining mold making precision. Regular equipment maintenance, monitoring of mold condition, and strict control of the production environment are essential to address these challenges.