What is an Alumilite Mold Maker?

An Alumilite Mold Maker is a specialized professional or a set of tools and techniques used to create molds using Alumilite products. Alumilite is a well - known brand that offers a range of casting resins, mold - making materials, and related products.

Definition and Basic Materials

At its core, an Alumilite Mold Maker focuses on using Alumilite's mold - making rubbers. These rubbers are formulated to have excellent flexibility, durability, and detail - replication capabilities. For example, their most popular mold - making rubber might have a Shore A hardness rating of around 25 - 30, which allows it to bend easily for demolding complex shapes while still maintaining its structural integrity. This rubber is resistant to a wide range of temperatures during the curing process, typically able to withstand up to 150°F (65°C) without significant distortion.

Basic Principle

The basic principle behind Alumilite mold - making is relatively straightforward. First, a master model is created. This can be a hand - carved original, a 3D - printed object, or a found object. The master model serves as the template for the mold. Then, the Alumilite mold - making rubber is mixed according to the manufacturer's instructions. Usually, it involves a two - part system where a base and a catalyst are combined in a specific ratio, often 1:1 by volume. Once mixed thoroughly, the rubber is poured or brushed over the master model. As it cures, which can take anywhere from 2 - 6 hours depending on the product and environmental conditions, it conforms to the shape of the master model, capturing every detail.

Working Process

- Master Model Preparation: The master model must be clean, dry, and free of any contaminants. If it's a 3D - printed model, any support structures need to be removed, and the surface may be sanded slightly to ensure a smooth finish for better mold release.

- Mold Box Setup: A mold box is created around the master model. This can be made of various materials such as wood, plastic, or metal. The box should be large enough to provide a sufficient border around the master model, typically at least 1 - 2 inches (2.5 - 5 cm) on all sides.

- Rubber Mixing and Pouring: The Alumilite mold - making rubber is mixed. After mixing, it is poured slowly into the mold box, starting from one corner to avoid trapping air bubbles. If air bubbles do form, they can be removed using a heat gun (applied carefully to avoid overheating the rubber) or a vacuum chamber (for more professional setups).

- Curing: The mold is left to cure undisturbed in a clean, dry environment. Once cured, the mold box is removed, and the mold is carefully separated from the master model. The resulting mold can then be used to cast multiple copies using Alumilite casting resins or other compatible materials.

Key Features of Alumilite Mold Maker

1. Material Excellence

Alumilite mold - making materials stand out for their exceptional qualities. The mold - making rubbers are known for their outstanding durability. For instance, compared to some generic mold - making rubbers in the market, Alumilite's products can endure up to 500 - 1000 casting cycles without significant degradation, while the generic ones might only last 200 - 300 cycles. This long - lasting nature makes it a cost - effective choice in the long run, as you don't have to replace the mold frequently.

In terms of chemical resistance, Alumilite rubbers can resist common chemicals used in the casting process. They are highly resistant to alcohol - based release agents and most types of pigments added to casting resins. In contrast, some cheaper mold - making materials can be easily damaged or deformed when in contact with these substances. For example, certain low - cost rubbers may start to swell or lose their shape when exposed to a high - concentration pigment - filled resin, but Alumilite rubbers maintain their integrity.

2. Precision Engineering

Precision is at the heart of Alumilite mold - making. The molds can achieve a dimensional accuracy of up to ±0.005 inches (±0.127 mm). This level of precision allows for the replication of even the most intricate designs. Consider the creation of a small, detailed jewelry mold. A master model of a ring with fine filigree patterns, measuring only 0.5 inches (12.7 mm) in diameter, can be accurately reproduced with Alumilite molds. The smallest filigree lines, which are as thin as 0.01 inches (0.254 mm), are captured precisely, ensuring that each cast ring has the same level of detail as the original.

Another example is in the production of miniatures for tabletop games. These miniatures often have complex poses and tiny details, such as facial expressions on a 1 - inch (25.4 mm) tall figure. Alumilite molds can replicate these details with such accuracy that the painted miniatures look almost identical to the original sculpt, down to the smallest wrinkles on the character's clothing or the individual strands of hair.

3. Versatility in Applications

Alumilite molds find applications in a wide range of industries. In the jewelry industry, they are used to create custom - designed rings, pendants, and earrings. A jewelry designer might use an Alumilite mold to produce a limited - edition run of 50 pendants with a unique, hand - carved design. The mold's flexibility allows for easy demolding of the delicate jewelry pieces without causing any damage.

In the art world, artists use Alumilite molds to reproduce their sculptures. A sculptor who has created a one - of - a - kind clay sculpture can make multiple copies using an Alumilite mold. These copies can be sold as limited - edition art pieces, expanding the reach of the artist's work.

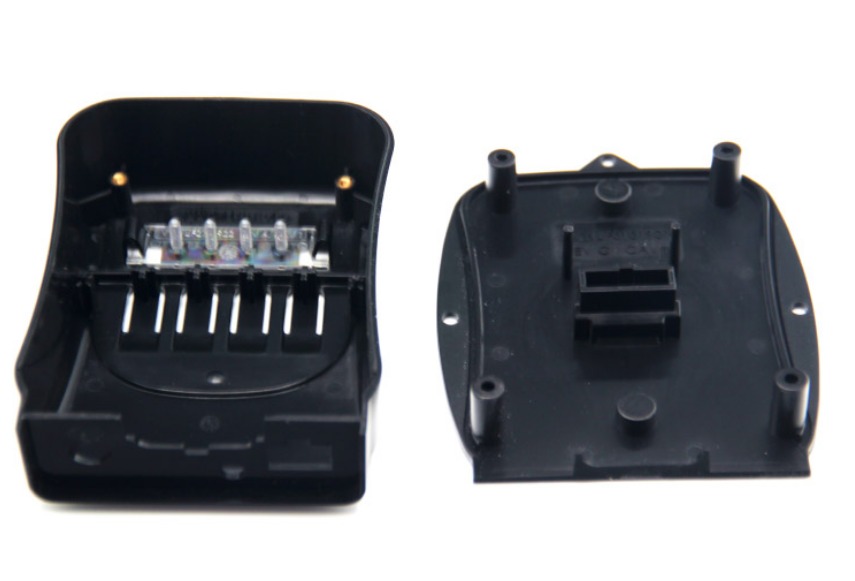

In industrial manufacturing, Alumilite molds are used for prototyping. A company developing a new plastic component for a consumer electronics device can use an Alumilite mold to quickly produce a small batch of prototypes. This helps in testing the design, functionality, and fit of the component before moving on to mass production, saving both time and cost.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the role of Alumilite molds in the manufacturing process. In our cooperation with clients, Alumilite molds enable us to achieve high - precision casting for non - standard parts. Their excellent material properties, like high durability and chemical resistance, ensure that the molds can withstand the challenges of producing custom - designed plastic and metal components.

Alumilite molds also play a significant role in promoting the development of the non - standard manufacturing industry. They allow for the rapid production of prototypes, reducing the time - to - market for new products. This, in turn, encourages innovation among our clients as they can quickly test and refine their designs. Yigu Technology looks forward to further leveraging Alumilite molds to create more high - quality, customized products for our diverse clientele.

FAQs

1. What types of materials can be used with Alumilite Mold Maker?

Alumilite Mold Maker is compatible with a wide range of materials. Alumilite's own casting resins, such as their urethane resins, are a perfect match. These resins come in different formulations, including clear, opaque, and even those with special effects like glow - in - the - dark or metallic finishes. Additionally, many other low - viscosity casting materials can be used, like some epoxy - based casting resins. Wax can also be cast in Alumilite molds, which is great for creating wax patterns for investment casting. However, materials with extremely high viscosity or those that react chemically with the mold rubber, such as some highly acidic or caustic substances, should be avoided.

2. How long does it take to create a mold with Alumilite?

The time to create an Alumilite mold depends on several factors. The type of Alumilite mold - making rubber used is a significant factor. For example, a fast - curing rubber might take as little as 2 hours to fully cure at room temperature (around 72°F or 22°C), while a more flexible, slow - curing rubber could take up to 6 hours. The size and thickness of the mold also play a role. A small, thin - walled mold will cure faster than a large, thick - walled one. Environmental conditions like temperature and humidity also affect the curing time. In a warmer environment (up to 80°F or 27°C), the curing time can be slightly reduced, while in a humid environment, it might take a bit longer.

3. Is Alumilite Mold Maker suitable for large - scale production?

Alumilite molds have both advantages and limitations for large - scale production. On the plus side, their durability, with the ability to withstand 500 - 1000 casting cycles in many cases, makes them a viable option for mid - to - large - scale production runs. They can accurately reproduce parts, ensuring consistent quality. However, for extremely high - volume production, the relatively long curing time (compared to some industrial - grade injection - molding processes) can be a drawback. Also, the manual process of mold - making and casting in some cases might not be as efficient as fully automated industrial production methods. But for small - to - medium - sized enterprises or those with less demanding production volumes, Alumilite Mold Maker can be a cost - effective and high - quality solution for large - scale production.