Introduction

The Significance of Custom Molds in the Plastic Industry

In the dynamic realm of the plastic industry, custom molds stand as the cornerstone of innovation and product differentiation. Their importance cannot be overstated, as they play a pivotal role in shaping the diverse range of plastic products that permeate every aspect of our lives.

Custom molds are the key to achieving precision and uniqueness in plastic manufacturing. They enable the creation of products with intricate designs, precise dimensions, and high - quality finishes. For instance, in the automotive industry, custom molds are used to produce interior components such as dashboards, which require a perfect fit and a high - end aesthetic appeal. These molds ensure that each part is manufactured to the exact specifications, enhancing the overall quality and functionality of the vehicle.

Moreover, custom molds are essential for meeting the specific needs of different industries. In the medical field, plastic components used in devices like syringes and prosthetics must be produced with the utmost precision and in compliance with strict regulatory standards. Custom molds allow manufacturers to create these components with the necessary accuracy and quality, ensuring patient safety and the effectiveness of the medical devices.

In the consumer goods sector, custom molds contribute to the development of unique and eye - catching products. From ergonomic kitchen utensils to stylish electronic device casings, custom molds enable companies to bring their innovative designs to life, giving them a competitive edge in the market.

This is where Mold Masters comes into the picture. With its wealth of experience and expertise, Mold Masters has established itself as a leading player in the custom mold manufacturing domain. The company has been at the forefront of providing tailored solutions to a wide range of industries, helping businesses overcome their manufacturing challenges and achieve their product goals.

Custom Made Molds: A Multifaceted Solution

Tailored to Your Unique Requirements

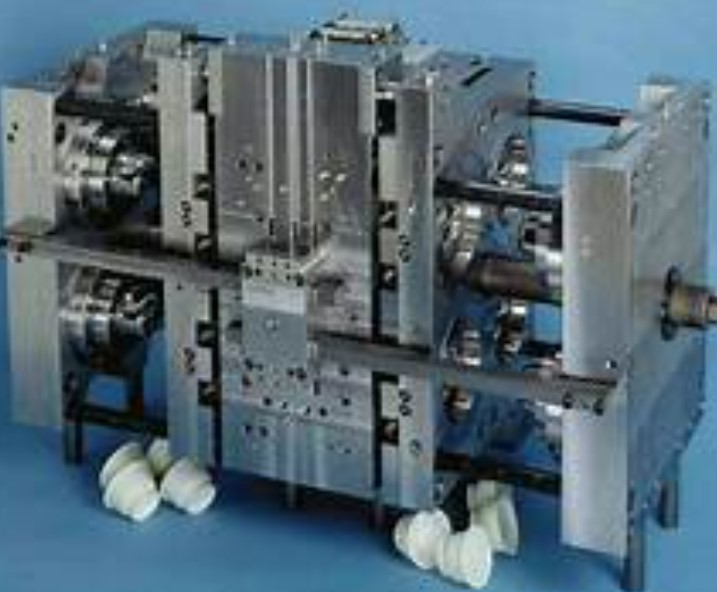

Custom made molds by Mold Masters are the epitome of versatility and adaptability, designed to meet the diverse and unique requirements of different industries. In the automotive industry, for example, Mold Masters has provided custom molds for the production of intricate interior components such as dashboard panels. These molds are crafted with precision to ensure a perfect fit within the vehicle's interior design, while also meeting the high - quality standards demanded by the automotive market. The ability to create custom molds allows car manufacturers to differentiate their products, offering unique and ergonomic designs that enhance the overall driving experience.

In the medical industry, precision and safety are of utmost importance. Mold Masters has successfully developed custom molds for the production of medical devices like syringe barrels and prosthetic components. These molds are designed to meet strict regulatory standards, ensuring that the final products are of the highest quality and suitable for use in medical applications. For syringe barrels, the molds are engineered to achieve precise tolerances in dimensions, ensuring accurate dosing and smooth operation. Prosthetic components, on the other hand, require molds that can replicate complex shapes to provide a comfortable and functional fit for patients.

The electronics industry also benefits greatly from custom made molds. Mold Masters has created molds for the production of smartphone casings and tablet housings. These molds enable electronics manufacturers to incorporate unique design features, such as sleek curves and precise cut - outs for ports and buttons, while also ensuring the structural integrity of the casings to protect the delicate internal components.

Superior Performance and Quality Assurance

Custom made molds from Mold Masters offer significant advantages in terms of performance and quality. A study comparing custom molds with standard off - the - shelf molds showed that custom molds can increase the precision of plastic parts by up to 30%. For example, in the production of small electronic components, the precision achieved by custom molds allows for tighter tolerances. A standard mold might have a tolerance of ±0.5mm, while a custom mold from Mold Masters can achieve a tolerance of ±0.15mm. This higher precision ensures that the components fit together perfectly, reducing the need for post - production adjustments and improving the overall functionality of the final product.

In addition to precision, custom molds also contribute to the durability of products. By using high - quality materials and advanced manufacturing techniques, Mold Masters can create molds that produce parts with enhanced mechanical properties. For instance, in the production of automotive parts, custom molds can be designed to produce components with higher tensile strength. A case study found that parts produced using custom molds had a 20% increase in tensile strength compared to those produced with standard molds. This increase in strength means that the parts are more resistant to wear and tear, resulting in a longer lifespan for the automotive components and ultimately, a more reliable vehicle.

Moreover, the quality control process at Mold Masters is rigorous. Each custom mold undergoes a series of inspections and tests during the manufacturing process. From the initial design phase, where computer - aided design (CAD) and computer - aided engineering (CAE) software are used to simulate and optimize the mold's performance, to the final product inspection, every step is carefully monitored. This ensures that the molds meet the highest quality standards and that the products produced using these molds are of superior quality.

Cost - Efficiency in the Long Run

While the initial investment in custom made molds may be higher compared to standard molds, the long - term cost - efficiency is undeniable. Consider the following cost comparison table for a production run of plastic parts:

| Production Cycle | Custom Mold Cost (USD) | Standard Mold Cost (USD) |

| 1 - 10,000 units | 50,000 | 20,000 |

| 10,001 - 50,000 units | 50,000 (fixed cost) + 10,000 (production cost) = 60,000 | 20,000 (fixed cost) + 30,000 (production cost) = 50,000 |

| 50,001 - 100,000 units | 50,000 (fixed cost) + 20,000 (production cost) = 70,000 | 20,000 (fixed cost) + 60,000 (production cost) = 80,000 |

In the short - term, for a small production run of 1 - 10,000 units, the cost of a standard mold seems more attractive. However, as the production volume increases, the cost - effectiveness of custom molds becomes evident. The custom mold has a higher initial cost but lower per - unit production costs. This is because custom molds are optimized for the specific product, resulting in less material waste and fewer production errors. With a standard mold, more material may be wasted due to the need for additional trimming and finishing, and there may be a higher rate of defective products, increasing the overall production cost. Over the long - term, for large - scale production, the custom mold can lead to significant cost savings.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the custom mold solutions provided by Mold Masters. The two companies could potentially explore rich cooperation opportunities. For example, in projects that require both custom plastic molds and non - standard metal components, Yigu Technology's expertise in metal products can complement Mold Masters' strength in custom molds.

Yigu Technology's advanced metal - processing techniques, such as precision casting and high - speed CNC machining for metal parts, can work in tandem with Mold Masters' state - of - the - art mold - making technologies. This synergy would enable the creation of integrated solutions for industries like aerospace, where both high - precision plastic and metal components are needed. By combining resources and skills, the two companies can reduce production time and cost while enhancing product quality, ultimately providing more comprehensive and competitive services to customers.

FAQ

What industries can Mold Masters' custom made molds serve?

Mold Masters' custom made molds can serve a wide array of industries. In the packaging industry, they are used to create molds for various containers, such as bottles, jars, and boxes, ensuring precise shapes and sizes for efficient product packaging. For example, custom molds for beverage bottles can be designed to have unique ergonomic grips for easy handling.

In the medical industry, Mold Masters provides molds for manufacturing syringes, prosthetics, and medical device components. These molds must meet strict quality and safety standards. For instance, molds for prosthetic sockets are customized to fit the specific body contours of patients, providing a comfortable and functional fit.

The automotive industry benefits from custom molds for producing interior components like dashboards, door panels, and exterior parts such as bumpers. Custom molds allow for the integration of advanced features, such as built - in electronics in dashboards or aerodynamic designs in bumpers.

Electronics manufacturers use Mold Masters' molds for creating casings for smartphones, tablets, and laptops. These molds enable the production of sleek and durable designs that protect delicate internal components while also providing an attractive appearance.