Introduction

Plastic silicone molds have found their way into a vast number of applications, both in industrial settings and our daily lives. In industries, they play a crucial role in manufacturing various products. For example, in the automotive industry, they are used to create intricate interior components like dashboards and knobs, ensuring a perfect fit and a sleek appearance. In the electronics sector, plastic silicone molds are essential for producing parts of smartphones, tablets, and other devices, contributing to their compact and functional designs.

Manufacturing Techniques for Plastic Silicone Molds

Injection Molding

Injection molding is one of the most widely used manufacturing techniques for plastic silicone molds. The principle behind it is quite straightforward yet highly effective. It involves using an injection machine to heat plastic pellets until they reach a molten state. Once in this fluid form, the plastic is forced, under high pressure, into a closed mold cavity through a nozzle. This mold cavity has been precisely designed to have the shape of the final product. As the molten plastic fills the cavity, it takes on the intricate details of the mold, whether it's a complex geometric shape or fine surface textures. After filling, the plastic is cooled down rapidly. This cooling process causes the plastic to solidify, hardening into the desired shape of the product. Once fully solidified, the mold is opened, and the newly formed plastic part is ejected, ready for further processing or immediate use.

The process can be broken down into several key steps. First is the plasticization stage, where the plastic material is heated and melted in the barrel of the injection machine. Next is the injection stage, when the molten plastic is injected into the mold cavity at high speed to ensure complete filling. Then comes the holding pressure stage, during which a certain pressure is maintained to compensate for the shrinkage of the plastic as it cools. After that, the cooling stage takes place, where the plastic part is cooled to a temperature at which it can maintain its shape stably. Finally, the mold is opened, and the part is ejected.

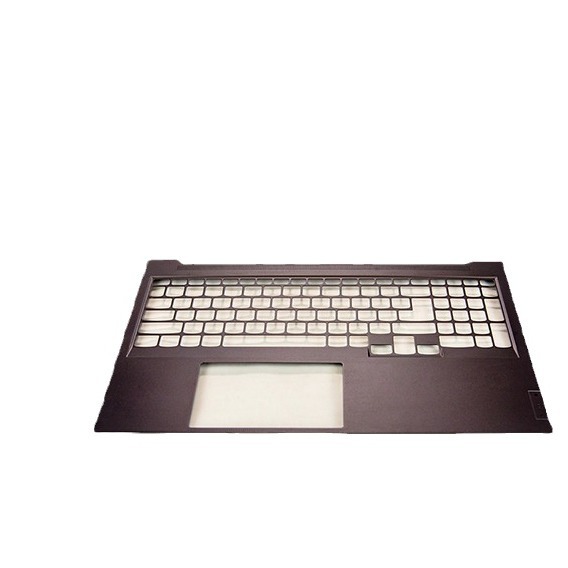

This technique finds extensive applications in various industries. In the toy industry, it is used to create a wide range of toys, from small figurines with detailed features to large, complex play structures. For example, many popular action figures are made using injection molding, allowing for the production of highly detailed and consistent products in large quantities. In the electronics sector, it is crucial for manufacturing the outer shells of devices such as smartphones, tablets, and laptops. These shells need to have precise dimensions to fit all the internal components perfectly and also provide a sleek and durable exterior. Injection molding enables the mass production of these high - quality, accurately shaped electronic device housings.

Compression Molding

Compression molding operates on a different principle compared to injection molding. The working method starts with placing a pre - measured amount of raw plastic material, which can be in the form of pellets, powder, or pre - formed sheets, directly into an open mold cavity. The mold is then closed, and heat and pressure are applied simultaneously. As the heat is applied, the plastic begins to soften and melt. The pressure exerted on the molten plastic forces it to flow and fill every nook and cranny of the mold cavity, taking on the shape of the mold. Once the plastic has filled the cavity completely, it is allowed to cure or solidify under the continued application of heat and pressure. This curing process is essential for the plastic to achieve its final mechanical properties. After curing, the mold is opened, and the finished plastic part is removed.

One of the main advantages of compression molding is its suitability for manufacturing large - scale and thick - walled plastic products. For large - scale products, the process is more cost - effective as it doesn't require the high - pressure injection equipment needed in injection molding. The slow and even application of pressure during compression molding ensures that the plastic can flow evenly throughout the large mold cavity without causing any defects. In the case of thick - walled products, the gradual heating and curing process in compression molding prevent the formation of internal stresses that could occur if the plastic was cooled too quickly, as might happen in injection molding. For example, large plastic storage tanks, industrial containers, and some automotive body panels are often made using compression molding due to their large size and relatively thick walls.

Transfer Molding

Transfer molding is a specialized manufacturing technique with distinct characteristics. It combines elements of both injection molding and compression molding. In transfer molding, the plastic material is first pre - heated in a separate chamber, known as the transfer pot. Once the plastic reaches a semi - molten or plasticized state, it is forced, usually by a plunger, through a system of runners and gates into a closed mold cavity. This method allows for more precise control over the flow of the plastic into the mold compared to compression molding, as the plastic is already in a more fluid state when it enters the mold.

Transfer molding is commonly used in the production of high - precision components, especially in the electrical and automotive industries. In the electrical industry, it is used to manufacture electrical connectors, insulators, and various electronic components. These parts often require high levels of dimensional accuracy and electrical insulation properties. For example, the plastic housings for electrical connectors need to fit together precisely to ensure a secure and reliable electrical connection. In the automotive industry, transfer molding is employed to produce small but critical parts such as ignition components, sensor housings, and some interior trim parts. These parts must meet strict quality and durability standards, and transfer molding can deliver the consistent quality required.

Materials for Plastic Silicone Molds

Silicone Rubber

Silicone rubber is a popular choice for plastic silicone molds due to its remarkable properties. One of its key advantages is its excellent high - temperature resistance. It can withstand temperatures as high as 200℃ or even higher in some cases, making it suitable for applications where the mold is exposed to heat during the manufacturing process or in the end - use environment of the product. For example, in the production of bakeware such as silicone muffin pans and baking mats, the silicone rubber mold can endure the high temperatures inside an oven without deforming or deteriorating.

Silicone rubber also exhibits outstanding chemical corrosion resistance. It is not easily affected by a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in industries where chemical exposure is common, such as the chemical processing and pharmaceutical industries. In the pharmaceutical industry, silicone rubber molds are used to produce drug delivery devices, ensuring that the mold material does not react with the drugs or the manufacturing chemicals.

The high elasticity of silicone rubber is another major plus. It can stretch and return to its original shape repeatedly without permanent deformation. This property is crucial in applications where the mold needs to release the product easily. For instance, in the production of soft toys or flexible phone cases, the elastic silicone rubber mold can be easily peeled away from the product, minimizing the risk of damage to the finished item.

The applications of silicone rubber in various industries are extensive. In the food industry, it is used to make molds for candies, chocolates, and even intricate cake decorations. The non - toxic and food - grade nature of silicone rubber ensures that it does not contaminate the food products. In the medical field, silicone rubber molds are utilized for manufacturing prosthetics, medical tubing, and other devices. Its biocompatibility makes it safe for use in contact with the human body. In the electronics industry, silicone rubber is used to create molds for components such as gaskets, seals, and insulators, providing protection against moisture, dust, and electrical interference.

Thermoplastic Elastomers (TPEs)

Thermoplastic elastomers (TPEs) are a unique class of materials that combine the properties of both plastics and rubbers. Characteristics of TPEs include their ability to be processed like plastics at high temperatures, using methods such as injection molding, extrusion, and blow molding, while exhibiting rubber - like elasticity at room temperature. This makes them highly versatile in manufacturing.

There are different types of TPE materials, each with its own set of performance differences. For example, thermoplastic polyurethane (TPU) is known for its high abrasion resistance. It can withstand a large number of cycles of rubbing and scraping without significant wear, making it suitable for applications like shoe soles, where durability is essential. Thermoplastic olefin (TPO) has good chemical resistance and is often used in automotive applications, such as bumpers and interior trim, as it can resist the effects of automotive fluids and environmental factors. Thermoplastic styrenic elastomers (TSEs) offer a wide range of hardness levels and are commonly used in consumer products, such as the soft grips on tools and handles, due to their ability to provide a comfortable and non - slip surface.

TPE materials have distinct advantages in manufacturing certain products. In the production of soft - grip handles for tools like screwdrivers and pliers, TPEs can be over - molded onto a rigid plastic core. The TPE provides a soft, comfortable, and non - slip surface for the user, enhancing the usability of the tool. In the case of sealing applications, TPEs can be used to create gaskets and seals. Their elasticity allows them to conform to irregular surfaces, providing an effective seal against fluids and gases. For example, in the automotive industry, TPE seals are used in engines and fuel systems to prevent leaks, contributing to the overall performance and safety of the vehicle.

Epoxy Resins

Epoxy resins have several unique characteristics that make them valuable in the production of plastic silicone molds. One of the most notable features is their high mechanical strength. Epoxy - based molds can withstand significant pressure and stress during the manufacturing process without deforming or breaking. This makes them suitable for applications where the mold needs to maintain its shape precisely, such as in the production of high - precision parts.

Epoxy resins also offer excellent adhesion properties. They can bond strongly to a variety of substrates, including metals, plastics, and ceramics. This is beneficial when creating composite molds or when the mold needs to be attached to a support structure. Additionally, epoxy resins have good chemical resistance, protecting the mold from the effects of chemicals used in the manufacturing process or in the environment where the final product will be used.

In the manufacturing of precision molds, epoxy resins are often the material of choice. For example, in the electronics industry, when producing molds for micro - components such as integrated circuit packages, the high precision and dimensional stability of epoxy resins ensure that the molds can create parts with tight tolerances. Epoxy resins are also widely used in artwork replication. They can accurately reproduce the fine details of sculptures, paintings, and other artworks. The high - quality finish and durability of epoxy - based replicas make them popular among collectors and museums.

The curing process of epoxy resins involves a chemical reaction between the epoxy resin and a curing agent. This reaction causes the resin to harden and form a solid, three - dimensional structure. The curing time and properties of the cured epoxy can be influenced by several factors. The type and amount of curing agent used play a crucial role. A faster - curing agent will result in a shorter curing time, but it may also affect the final mechanical and chemical properties of the epoxy. Temperature is another important factor. Higher temperatures generally accelerate the curing process, but if the temperature is too high, it can cause the epoxy to cure too quickly, leading to internal stresses and potential cracking. The presence of any impurities or contaminants in the resin or curing agent can also impact the curing process and the quality of the final product.

Comparison of Materials and Techniques

Understanding the differences between materials and techniques is crucial for making informed decisions in the manufacturing of plastic silicone molds. The following table provides a detailed comparison:

| Aspects | Injection Molding | Compression Molding | Transfer Molding | Silicone Rubber | Thermoplastic Elastomers (TPEs) | Epoxy Resins |

| Cost | High initial investment in equipment; lower per - unit cost for high - volume production | Lower equipment cost; higher labor cost for manual material loading, especially for large - scale products | Medium equipment cost; cost can be high for complex molds due to the need for precise runner systems | Relatively high material cost, but cost - effective in applications where its unique properties are required | Cost varies depending on the type of TPE; generally, more cost - effective than some high - performance elastomers | Medium to high material cost, especially for high - quality epoxy resins |

| Production Efficiency | High - speed process suitable for mass production. Can produce multiple parts in a single cycle | Slower process compared to injection molding, especially for complex shapes. Not ideal for high - volume, time - sensitive production | Faster than compression molding for some complex parts but slower than injection molding in general | Production speed depends on the curing process and the complexity of the mold. Can be relatively slow for large or complex molds | Production speed is similar to that of traditional plastics when using common processing methods like injection molding | Curing time can be relatively long, especially for large molds or when using slow - curing agents |

| Product Quality | High - precision parts with consistent dimensions. Can achieve smooth surface finishes and complex geometries | Good for products with simple geometries. May have some surface imperfections or unevenness in thick - walled parts if not properly processed | High - precision parts with excellent dimensional accuracy. Can produce parts with fine details and complex internal structures | Good flexibility and resilience, maintaining product shape and quality over time. Resistant to deformation under normal use | Good mechanical properties and dimensional stability. Can be tailored to have specific hardness and elasticity levels | High mechanical strength and dimensional stability. Can provide a smooth and durable surface finish |

| 适用范围 | Suitable for a wide range of products, including small to large - scale components, with high production volume requirements | Best for large - scale, thick - walled products and products with simple geometries, such as large storage tanks, industrial containers | Ideal for high - precision components, especially in the electrical and automotive industries, where tight tolerances and complex shapes are required | Suitable for applications where heat resistance, chemical resistance, and elasticity are important, such as in the food, medical, and electronics industries | Used in various industries for products that require a combination of plastic - like processing and rubber - like properties, such as soft - grip products, sealing applications, and automotive parts | Preferred for precision molds, artwork replication, and applications where high mechanical strength and adhesion are required |

Yigu Technology's Perspective

As a Supplier of non - standard plastic metal custom products, Yigu Technology deeply understands the significance of choosing the right materials and techniques for plastic silicone molds. Every customer's need is unique, and we emphasize the importance of a tailored approach.

Our vast experience in the field allows us to provide comprehensive and customized solutions. When dealing with materials, we carefully evaluate factors such as the product's end - use environment, performance requirements, and cost - effectiveness for our clients. For example, if a client needs molds for high - temperature - resistant products in the automotive engine area, we might recommend silicone rubber due to its excellent heat - resistance properties.

In terms of manufacturing techniques, we consider aspects like production volume, product complexity, and precision requirements. For high - volume production of small and precise parts, we often suggest injection molding. Our in - house team of experts is well - versed in all the techniques mentioned above and can guide customers through every step of the process, from design to production. We take pride in our ability to combine the best materials and techniques to create high - quality plastic silicone molds that meet and exceed our customers' expectations.

FAQs

What are the advantages of using silicone rubber for plastic molds?

Silicone rubber offers several advantages for plastic molds. Firstly, it has excellent high - temperature resistance, being able to withstand temperatures up to 200℃ or even higher in some cases. This makes it suitable for applications where heat exposure is common, like in bakeware production. Secondly, it shows outstanding chemical corrosion resistance, remaining stable when exposed to a wide variety of chemicals, including acids, alkalis, and solvents. Additionally, its high elasticity allows it to stretch and return to its original shape repeatedly without permanent deformation, which is beneficial for easily releasing the product from the mold.

Which manufacturing technique is best for high - volume production?

Injection molding is generally the best choice for high - volume production. It has a high - speed process that can produce multiple parts in a single cycle. The initial investment in equipment might be high, but the per - unit cost is significantly reduced for large - scale production. This technique can achieve high - precision parts with consistent dimensions and is suitable for a wide range of products, making it highly efficient for meeting the demands of high - volume manufacturing.

Can I use epoxy resin for food - contact applications?

Epoxy resin is generally not recommended for food - contact applications without proper treatment and certification. Although epoxy resins have good mechanical strength and adhesion properties, in their normal state, they may release harmful substances that could contaminate food. However, if an epoxy resin has been specifically formulated, processed, and certified to meet strict food - safety standards, it can be used in certain food - contact scenarios. For example, some food - grade epoxy coatings are used in food containers, but they must comply with regulations regarding migration limits of potentially harmful substances.