Introduction

In the vast landscape of industrial manufacturing, aluminum molds have emerged as a cornerstone, playing a pivotal role in shaping a diverse range of products across multiple sectors. Their significance lies not only in their ability to produce high - quality components efficiently but also in their potential to drive innovation and open up new possibilities in design and production.

Aluminum molds are widely used in industries such as automotive, aerospace, electronics, and consumer goods. For example, in the automotive industry, they are used to create engine parts, body panels, and interior components. In aerospace, they help manufacture lightweight yet strong components that are crucial for aircraft performance. The electronics industry relies on aluminum molds for the production of sleek and durable device casings.

This article delves deep into how aluminum molds can forge creativity and unleash potential. We will explore their unique properties, design flexibility, cost - effectiveness, and the role of technological advancements in maximizing their capabilities. Whether you are a manufacturer looking to enhance production, a designer seeking more creative freedom, or an industry enthusiast, understanding the power of aluminum molds can provide valuable insights into the future of manufacturing.

1. The Advantages of Aluminum Molds

1.1 Lightweight yet Durable

Aluminum molds are renowned for their impressive combination of light weight and durability. When compared to steel molds, aluminum molds are approximately 50% lighter. For instance, a typical medium - sized steel mold might weigh around 500 kg, while its aluminum counterpart would weigh only about 250 kg. This significant weight reduction brings numerous benefits.

In terms of transportation, lighter molds are much easier and more cost - effective to move. They do not require expensive heavy - duty lifting equipment such as large cranes or specialized trucks, which can cut down transportation costs by up to 30 - 40%. Additionally, during the manufacturing process, the lighter weight of aluminum molds makes them easier to handle and install, reducing the risk of injuries to workers and improving overall operational efficiency.

Despite their light weight, aluminum molds are highly durable. They can withstand a large number of production cycles. Many aluminum molds can endure up to 10,000 - 50,000 production cycles depending on the application and the quality of the aluminum alloy used. This durability ensures that they are a reliable choice for long - term production needs, making them suitable for both small - scale and large - scale manufacturing operations.

1.2 Excellent Thermal Conductivity

One of the most remarkable properties of aluminum molds is their excellent thermal conductivity. As shown in the following table, the thermal conductivity of aluminum is much higher than that of many other common mold materials:

| Material | Thermal Conductivity (W/m·K) |

| Aluminum | 237 |

| Steel | 50 - 60 |

| Copper - alloy | 160 - 400 |

| Plastics | 0.1 - 0.5 |

In injection molding processes, for example, the high thermal conductivity of aluminum molds allows for rapid heat transfer. When molten plastic is injected into the mold, the aluminum mold can quickly dissipate heat, causing the plastic to cool down rapidly. This results in a significant reduction in the cooling time of the product. In a typical injection - molding production cycle, which might be 30 - 60 seconds for a steel - mold - based process, using an aluminum mold can shorten the cycle time to 15 - 30 seconds. This 50% reduction in cycle time can greatly increase production efficiency, allowing manufacturers to produce more products in the same amount of time and ultimately increasing their productivity and profitability.

1.3 High Precision and Surface Finish

Aluminum molds are capable of achieving extremely high precision and an outstanding surface finish. In industries like aerospace, where the tolerance requirements for components are incredibly strict, aluminum molds play a crucial role. For example, when manufacturing components for aircraft engines, the dimensional accuracy requirements can be within ±0.01 - 0.05 mm. Aluminum molds can meet these high - precision demands through advanced manufacturing techniques such as computer - numerical - control (CNC) machining.

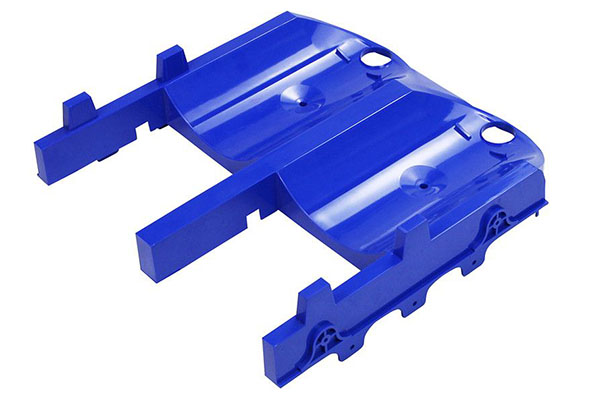

The surface finish of products produced by aluminum molds is also of high quality. Take the production of electronic device casings as an example. Aluminum - mold - produced casings have a smooth surface with a roughness value (Ra) that can be as low as 0.1 - 0.5 μm. This smooth surface not only enhances the aesthetic appearance of the product but also improves its functionality. For instance, a smooth - surfaced electronic device casing is more comfortable to hold and is less likely to accumulate dust or dirt. In the image below, we can clearly see the high - quality surface finish of an aluminum - mold - produced aerospace component, with no visible defects or roughness, demonstrating the superiority of aluminum molds in achieving high - precision and high - quality surface finishes.

[Insert a high - resolution image of an aerospace component produced by an aluminum mold here, showing its smooth surface and precise shape]

2. Aluminum Molds in Different Industries

2.1 Automotive Industry

In the automotive industry, aluminum molds are extensively used and play a vital role in the manufacturing process. For engine components, aluminum molds are crucial for producing engine cylinder blocks. Many modern car manufacturers, such as Ford and Toyota, have adopted aluminum - mold - cast engine cylinder blocks. These cylinder blocks are not only lighter in weight compared to traditional cast - iron ones but also have better heat dissipation performance. For instance, a typical cast - iron engine cylinder block might weigh around 50 - 80 kg, while an aluminum - mold - produced one can be 30 - 50% lighter, weighing only 30 - 40 kg. This significant weight reduction helps improve fuel efficiency, as the engine has to work less to move the lighter component.

When it comes to wheel hub manufacturing, aluminum molds are also the go - to choice. Brands like Audi often use aluminum - alloy wheel hubs made with the help of aluminum molds. These wheel hubs not only enhance the vehicle's aesthetics but also contribute to better handling and fuel economy. Aluminum - mold - produced wheel hubs are generally 20 - 30% lighter than steel wheel hubs. A steel wheel hub for a mid - sized car might weigh around 10 - 12 kg, while an aluminum one weighs approximately 7 - 9 kg. This weight reduction leads to lower unsprung mass, which in turn improves the vehicle's acceleration, braking, and overall driving dynamics.

Moreover, the use of aluminum molds in the automotive industry helps reduce production costs in the long run. Although the initial investment in aluminum molds might be slightly higher than some other mold materials, their long - term durability and the ability to produce components with high precision and fewer defects result in cost savings. For example, the high - precision nature of aluminum - mold - produced parts reduces the need for extensive post - production machining and finishing, cutting down on labor and material costs associated with rework.

2.2 Aerospace Industry

In the aerospace industry, every gram of weight reduction matters significantly, and aluminum molds are essential for achieving this goal. They are used to manufacture a wide range of aircraft components, with wings and fuselage parts being prime examples. For aircraft wings, aluminum - mold - made components contribute to the overall lightweight design of the wing structure. According to industry data, for every 100 kg reduction in an aircraft's weight, fuel consumption can be reduced by approximately 3 - 5% during a typical flight. Since a significant portion of an aircraft's weight comes from its wings, the use of aluminum - mold - produced wing components is crucial.

Aluminum molds are also used in the production of fuselage parts. These parts need to be lightweight yet strong enough to withstand the various forces during flight. Aluminum - alloy components made from aluminum molds meet these requirements. For example, a large commercial aircraft like the Boeing 737 uses a substantial amount of aluminum - alloy parts in its fuselage, which are produced using aluminum molds. These parts not only reduce the overall weight of the aircraft but also offer excellent corrosion resistance, ensuring the aircraft's long - term durability.

In addition, the high - precision capabilities of aluminum molds are vital in the aerospace industry. Components such as engine parts and landing gear components require extremely tight tolerances. Aluminum molds can achieve the necessary precision, ensuring that these critical components fit together perfectly and function optimally. Any deviation in the dimensions of these parts could lead to serious safety issues and reduced aircraft performance.

2.3 Consumer Goods Industry

In the consumer goods industry, aluminum molds find applications in various product categories. In the electronics sector, they are commonly used for manufacturing the casings of smartphones, tablets, and laptops. For example, Apple's MacBook series often features sleek and durable aluminum - alloy casings that are produced using aluminum molds. These casings not only provide a premium look and feel but also offer good heat dissipation for the internal components.

Aluminum molds also play a role in the production of everyday consumer goods. For instance, in the production of high - end kitchen utensils like pots and pans, aluminum molds are used to create intricate designs and ensure uniform wall thickness. This results in better heat distribution during cooking, improving the performance of the utensils.

The ability of aluminum molds to enable quick design changes is a significant advantage in the consumer goods industry. Market trends in this industry change rapidly, and companies need to update their product designs frequently to stay competitive. Aluminum molds can be modified relatively easily compared to some other mold materials. According to market research, companies that use aluminum molds can reduce the time to market for new product designs by up to 30 - 40%. This means that they can respond more quickly to changing consumer preferences and introduce new and improved products to the market faster, gaining a competitive edge.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the power of aluminum molds in forging creativity and unleashing potential. Over the years, we have been leveraging aluminum molds to provide innovative solutions for our clients.

We have successfully customized unique aluminum - mold products for many clients to meet their special requirements. For example, for a client in the high - end electronics industry, we designed and produced aluminum molds with intricate internal structures for their new - generation device casings. These molds not only enabled the production of parts with high precision but also allowed for creative design elements that enhanced the product's aesthetics and functionality.

Aluminum molds have also helped our clients gain a competitive edge in the market. The high - efficiency production enabled by aluminum molds, along with their ability to achieve high - quality surface finishes, has allowed our clients to produce products faster and with better quality. This has led to increased customer satisfaction and market share for our clients. We believe that continuous innovation in aluminum - mold technology and application is the key to driving the development of the manufacturing industry forward, and we are committed to exploring more possibilities in this field.

FAQ

1. Are aluminum molds suitable for high - volume production?

Yes, aluminum molds are highly suitable for high - volume production. Their lightweight nature makes them easier to handle during the production process, reducing the physical strain on workers and potentially speeding up the production cycle. For example, in an automotive parts manufacturing plant that produces thousands of engine components daily, the light weight of aluminum molds allows for quicker mold changes between production runs.

Moreover, aluminum molds have excellent thermal conductivity. In injection molding, this property enables rapid cooling of the injected material, significantly reducing the cycle time. A typical injection - molding cycle with a steel mold might take 45 seconds, while an aluminum mold can complete the same process in 25 seconds, increasing the number of parts produced per hour. However, one potential issue is wear and tear over time. To address this, proper mold coatings and regular maintenance can be implemented to extend the mold's lifespan during high - volume production.

2. How long does an aluminum mold typically last?

The lifespan of an aluminum mold can vary widely depending on several factors. Under normal operating conditions in a moderately demanding production environment, an aluminum mold can last for 10,000 - 50,000 production cycles. In a consumer goods factory producing plastic containers, an aluminum mold might endure around 30,000 cycles before significant wear occurs.

Factors that affect its lifespan include the type of aluminum alloy used, the production process (such as the temperature and pressure involved), and the quality of maintenance. Higher - grade aluminum alloys with better mechanical properties tend to last longer. For instance, an aluminum - silicon alloy mold may have a longer lifespan compared to a pure aluminum mold in a die - casting process due to its enhanced hardness and wear resistance.

To extend the mold's life, regular maintenance is crucial. This includes cleaning the mold after each production cycle to remove any residual material, applying appropriate lubricants to reduce friction during the molding process, and inspecting the mold for any signs of wear or damage regularly.

3. Can aluminum molds be used for complex - shaped products?

Absolutely, aluminum molds are well - suited for manufacturing complex - shaped products. Advanced manufacturing techniques like computer - numerical - control (CNC) machining enable precise shaping of aluminum molds. In the aerospace industry, for example, when producing turbine blades with intricate airfoil shapes and internal cooling channels, aluminum molds can be accurately machined to replicate these complex geometries.

The process involves using 3D design software to create a virtual model of the desired product. This model is then translated into a set of instructions for the CNC machine, which precisely carves the aluminum block into the mold cavity with the exact shape of the product. Additionally, the relatively soft nature of aluminum compared to some other metals makes it easier to machine complex features, and the high - precision capabilities of modern machining equipment ensure that the final mold can produce parts with tight tolerances, even for the most complex shapes.