Manufacturers producing high-precision, thin-walled plastic parts often grapple with a critical issue: even slight delays in cooling can cause warping, dimensional inconsistencies, or extended cycle times. While copper alloys are known for good thermal conductivity, many lack the strength to withstand high-pressure molding cycles, leading to premature wear or deformation. This is where MoldMAX HH (Cu-Ni-Sn) emerges as a game-changer. As a premium copper-nickel-tin alloy, MoldMAX HH delivers exceptional thermal conductivity—far higher than most copper alloys—paired with impressive strength and hardness, solving the dual challenges of rapid cooling and durability. In this guide, we’ll explore how MoldMAX HH transforms precision mold making, its standout properties, and how to maximize its performance in critical applications.

Introduction to MoldMAX HH (Cu-Ni-Sn)

MoldMAX HH (Cu-Ni-Sn) is a high-performance copper alloy engineered specifically for mold making applications demanding superior thermal management and strength:

- Definition: MoldMAX HH is a precipitation-hardened copper-nickel-tin alloy (also known as a “spinodal alloy”), designed to combine ultra-high thermal conductivity with robust mechanical properties. Its unique microstructure ensures consistent performance even in high-cycle, high-pressure environments.

- Standard specifications: MoldMAX HH meets industry standards for premium mold materials, with a tightly controlled chemical composition of 95.5% copper, 3% nickel, and 1.5% tin. This precise blend is key to its exceptional thermal and mechanical balance.

- Supplier brands: Brush Wellman (now part of Materion Corporation) is the primary manufacturer, renowned for developing specialized copper alloys for industrial applications. The alloy is available in rods, plates, and custom shapes optimized for mold components like cooling inserts and cores.

- Industry usage: MoldMAX HH is widely used in 15-20% of high-precision molds, particularly in automotive interior parts, consumer electronics, and medical devices. Its ability to reduce cooling times by 30-40% makes it a top choice for thin-walled parts (0.5-2mm thick) where precision is critical.

- Comparison with other copper alloys: Compared to Ampco 940, MoldMAX HH offers significantly higher thermal conductivity (331 W/m-K vs. 208 W/m-K) while maintaining comparable tensile strength (620 MPa vs. 689 MPa). It outperforms beryllium copper in heat transfer (331 W/m-K vs. 200-250 W/m-K) and is safer, with no beryllium. For applications where cooling speed is paramount, MoldMAX HH is unmatched.

Properties of MoldMAX HH (Cu-Ni-Sn)

The properties of MoldMAX HH (Cu-Ni-Sn) make it the gold standard for thermal management in precision molds:

- High thermal conductivity: At 331 W/m-K, MoldMAX HH conducts heat 6-8x faster than steel and 60% faster than Ampco 940. This rapid heat transfer reduces cooling times by 30-40% for thin-walled parts, cutting overall cycle times and increasing production throughput.

- High electrical conductivity: With 35% IACS conductivity, MoldMAX HH is suitable for molds integrating in-mold sensors or heating elements, such as those used in medical device manufacturing.

- High tensile strength: MoldMAX HH achieves a tensile strength of up to 620 MPa, making it strong enough to withstand injection pressures up to 20,000 psi. This strength ensures durability in high-volume production runs (100,000+ cycles).

- High hardness: With a hardness of 350-400 HB, MoldMAX HH resists wear from repeated contact with molten plastic, including engineering plastics with minor abrasive additives. This hardness outperforms standard copper alloys (100-200 HB) and matches many aluminum grades.

- Good corrosion resistance: MoldMAX HH resists corrosion from water-based coolants, humidity, and mild chemicals, ensuring long-term thermal performance. Its resistance to tarnishing means cooling channels remain unobstructed, maintaining consistent heat transfer.

- Thermal expansion coefficient: At 17.5 μm/m-°C, MoldMAX HH expands slightly more than steel but less than aluminum, allowing for compatibility with multi-material mold designs when proper clearances are incorporated.

Applications of MoldMAX HH (Cu-Ni-Sn) in Mold Making

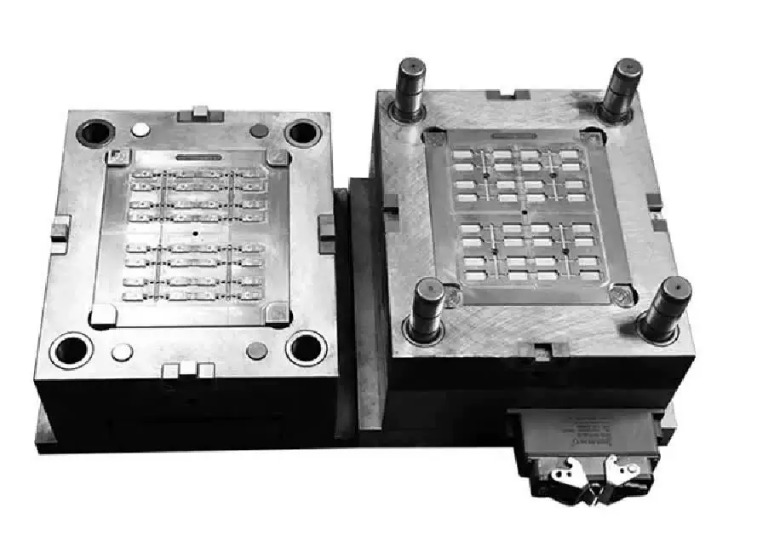

MoldMAX HH (Cu-Ni-Sn) excels in applications where rapid, uniform cooling is critical for part quality:

- Plastic injection molding for high-precision parts: MoldMAX HH is ideal for molds producing thin-walled components like smartphone cases, laptop bezels, and microelectronics housings. Its thermal conductivity ensures uniform cooling, preventing warping and maintaining tight tolerances (±0.0001 inches).

- Automotive molds: For automotive interior parts (e.g., dashboard trim, door panels) with complex geometries, MoldMAX HH’s heat transfer capabilities reduce cycle times by 30%, while its strength withstands high-volume production demands.

- Consumer electronics molds: Molds for 5G device components and wearable tech rely on MoldMAX HH to cool heat-sensitive parts quickly, ensuring dimensional stability in small, intricate designs.

- Medical device molds: Syringe barrels, catheter components, and other medical parts require precise cooling to maintain sterility and dimensional accuracy. MoldMAX HH’s corrosion resistance and rapid cooling make it a reliable choice for these applications.

- Prototype molds: For validating cooling strategies in new designs, MoldMAX HH allows engineers to test thermal performance quickly, ensuring production molds will meet cycle time targets.

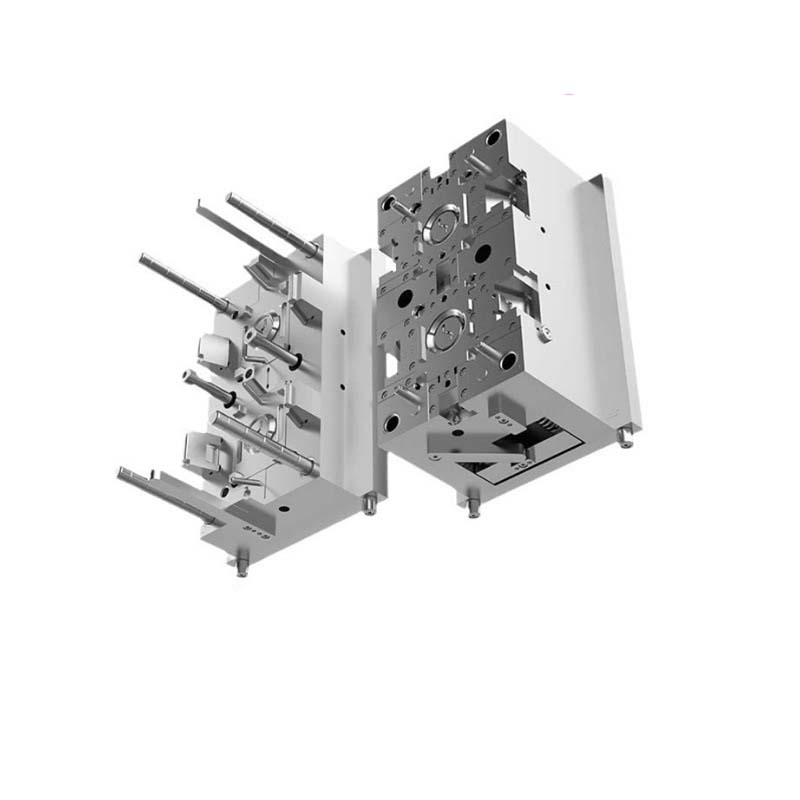

Machining and Fabrication of MoldMAX HH (Cu-Ni-Sn)

Machining and fabrication of MoldMAX HH require attention to its hardness and thermal properties, but yield excellent results with proper techniques:

- Precision machining: MoldMAX HH machines best with carbide tools due to its hardness. Use cutting speeds of 100-140 SFM and light feeds to minimize tool wear. Coolant is essential to dissipate heat and prevent chip welding, ensuring clean cuts and tight tolerances (±0.0002 inches).

- CNC milling: 3-axis and 5-axis CNC milling are effective for complex geometries, with rigid setups to avoid tool deflection. High-speed machining strategies reduce cycle times while maintaining precision in intricate features like cooling channels.

- EDM (Electrical Discharge Machining): EDM works well for detailed features, though MoldMAX HH’s high conductivity requires adjusted parameters (lower current) to prevent excessive electrode wear. The process produces smooth, burr-free surfaces ideal for high-precision molds.

- Grinding: Silicon carbide wheels are recommended for grinding MoldMAX HH, with a 400-grit wheel achieving Ra 0.05 μm surface finish. Light pressure prevents wheel clogging and ensures consistent results.

- Surface finishing: MoldMAX HH polishes to a smooth finish (Ra 0.02-0.05 μm) with 600-grit sandpaper and a buffing wheel. No additional plating is needed for most applications, though nickel plating can enhance wear resistance in extreme conditions.

- Machining challenges: MoldMAX HH’s ductility can lead to stringy chips, so chip breakers and high-pressure coolant systems are recommended. Sharp tools are critical to avoid work hardening, which can compromise surface finish.

Maintenance and Repair of MoldMAX HH (Cu-Ni-Sn) Molds

Proper maintenance and repair ensure MoldMAX HH molds retain their thermal efficiency and precision:

- Mold cleaning: Clean MoldMAX HH surfaces with mild detergents and soft brushes to remove plastic residue. Avoid abrasive cleaners, which can scratch the surface and reduce thermal conductivity.

- Surface treatment: A thin layer of anti-tarnish coating (e.g., clear lacquer) can protect MoldMAX HH in humid environments, though it’s often unnecessary due to the alloy’s natural corrosion resistance.

- Repair welding: MoldMAX HH can be TIG welded with matching copper-nickel-tin filler wire. Post-weld annealing restores hardness and thermal conductivity, ensuring repaired areas perform like the original material.

- Preventive maintenance: Inspect cooling channels monthly for blockages, as even minor debris can reduce heat transfer. Polishing worn surfaces restores their thermal performance and prevents part defects.

- Inspection: Use ultrasonic testing to detect internal cracks, which can compromise strength and heat transfer. Visual checks for corrosion or wear in high-pressure areas (e.g., gate inserts) ensure mold reliability.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends MoldMAX HH for clients prioritizing rapid cooling in high-precision molds. Its 331 W/m-K thermal conductivity reduces cycle times by 30-40% for thin-walled parts, a critical advantage in electronics and medical manufacturing. While it costs more than standard copper alloys, its 620 MPa tensile strength and 350-400 HB hardness ensure long life in high-volume runs. Our team uses carbide tools and EDM to achieve tight tolerances, integrating MoldMAX HH inserts seamlessly with steel molds. For applications where cooling speed directly impacts part quality, MoldMAX HH delivers unmatched value.

FAQs

- How does MoldMAX HH compare to pure copper in terms of performance?

MoldMAX HH offers 82% of pure copper’s thermal conductivity (331 W/m-K vs. 401 W/m-K) but with 3x higher tensile strength (620 MPa vs. 200 MPa). This makes it far more durable than pure copper in high-pressure molding applications.

- Can MoldMAX HH be used with abrasive plastics like glass-filled nylon?

MoldMAX HH handles 5-10% glass-filled plastics for 50,000-80,000 cycles. For higher filler content, consider nickel plating to enhance wear resistance, though steel inserts may be more cost-effective for extreme abrasion.

- Is MoldMAX HH suitable for food-grade or medical mold applications?

Yes—MoldMAX HH’s composition (copper, nickel, tin) meets FDA standards for indirect food contact and biocompatibility requirements for medical devices. Its corrosion resistance ensures safe, reliable performance in these critical applications.