Nothing frustrates manufacturers more than molds that wear out prematurely, corrode under chemical exposure, or fail to maintain precision in high-temperature operations. These issues aren’t just costly—they disrupt production schedules and compromise part quality. Enter 8407, a premium hot work tool steel that’s redefining durability and performance in mold making. Designed to excel in extreme conditions, 8407 combines exceptional toughness, wear resistance, and thermal stability, making it a top choice for everything from plastic injection molds to die casting tools. In this guide, we’ll explore how 8407 solves these critical pain points, its unique properties, and how to leverage its full potential in your manufacturing processes.

Material Properties of 8407

The material properties of 8407 are what make it a standout in the world of hot work tool steels, balancing strength and resilience to handle tough conditions:

- Hardness: After proper heat treatment, 8407 achieves a hardness of 44-48 HRC, striking the perfect balance between wear resistance and toughness. This hardness level ensures it maintains its shape even under the pressure of repeated molding cycles.

- Toughness: 8407’s fine-grained structure gives it exceptional toughness, allowing it to absorb impact without cracking. In Charpy impact tests, it delivers 20-30% higher energy absorption than H13, making it ideal for high-stress applications like die casting.

- Wear resistance: Thanks to its optimized chemical composition (1.0% carbon, 5.0% chromium, 1.5% molybdenum, and 1.0% vanadium), 8407 forms hard carbides that resist abrasion. It outperforms standard hot work steels by 25-30% in wear tests, extending mold life significantly.

- Corrosion resistance: While not a stainless steel, 8407 offers better corrosion resistance than many hot work steels, thanks to its chromium content. This makes it suitable for use with mold release agents and coolants that can degrade lesser materials.

- Grain structure: 8407 features a uniform, fine-grained structure (ASTM 8-10), which enhances its toughness and ensures consistent performance across the entire mold. This structure also improves machinability and reduces the risk of localized failure.

Mold Making Techniques with 8407

Working with 8407 requires precision, but its versatility makes it compatible with a range of mold making techniques:

- Precision machining: 8407 is readily machinable in its annealed state (200-220 HB). Using carbide tools with a cutting speed of 50-80 SFM yields the best results, with minimal tool wear. Its fine grain structure ensures smooth finishes, reducing the need for post-machining polishing.

- EDM (Electrical Discharge Machining): 8407 handles EDM well, producing clean, precise cuts even in complex geometries. The recast layer is thin (0.0001-0.0002 inches) and easy to remove, preventing cracking in high-stress areas.

- Grinding: To achieve tight tolerances (±0.0001 inches), grinding 8407 with a resin-bonded diamond wheel is recommended. Coolant must be applied continuously to avoid overheating, which can affect hardness.

- Milling: Vertical and horizontal milling operations work effectively with 8407. Using high-speed steel (HSS) or carbide end mills with a positive rake angle reduces cutting forces and improves surface finish.

- Surface finishing: 8407 polishes to a mirror finish (Ra 0.02-0.05 μm), making it ideal for plastic injection molds where surface quality directly impacts part aesthetics. Techniques like buffing with 1200-grit compound achieve the desired finish efficiently.

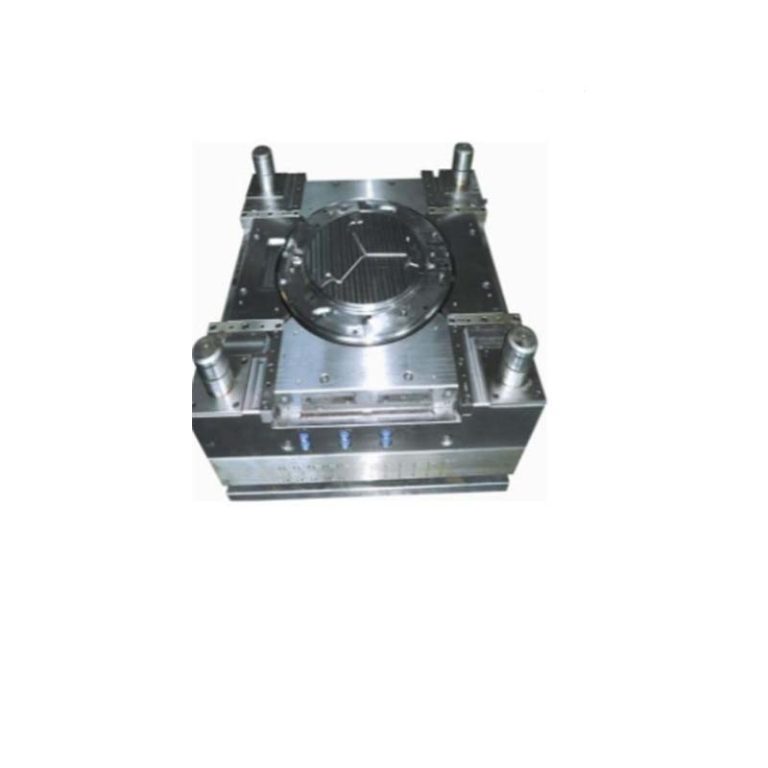

Applications of 8407 in Mold Making

8407’s unique blend of properties makes it suitable for a wide range of applications in mold making, particularly those involving high temperatures or abrasive materials:

- Plastic injection molds: For molding high-temperature plastics (like PEEK and nylon) or filled resins (glass or mineral-filled), 8407’s wear resistance and thermal stability shine. Molds made from 8407 last 50-70% longer than those made from standard steels, even with abrasive fillers.

- Die casting molds: In aluminum and magnesium die casting, 8407 resists the cyclic heat (600-1200°F) and chemical attack from molten metals. It typically lasts 100,000-200,000 cycles, 30-40% longer than H13 in the same application.

- Hot forming molds: For automotive hot stamping (where boron steel is heated to 900°C and formed), 8407 maintains dimensional stability, ensuring consistent part quality. Its toughness prevents cracking during the rapid cooling cycles.

- Aerospace molds: The high precision and reliability of 8407 make it ideal for aerospace components, where tight tolerances and material integrity are critical. It’s commonly used for molding turbine parts and structural components.

- Consumer electronics molds: 8407’s ability to achieve a mirror finish makes it perfect for molds producing smartphone casings, laptop parts, and other consumer electronics with strict aesthetic requirements.

Heat Treatment of 8407

Proper heat treatment of 8407 is essential to unlock its full potential—small mistakes can drastically reduce performance:

- Annealing: Heat to 1500-1550°F (815-845°C), hold for 2-3 hours, then cool slowly (≤50°F/hour) to 1000°F (538°C). This softens the steel for machining and relieves internal stresses, resulting in a hardness of 200-220 HB.

- Hardening: Heat to 1850-1900°F (1010-1038°C), hold for 30-45 minutes (depending on section size), then quench in oil or under vacuum. Vacuum quenching is preferred for complex molds, as it ensures uniform cooling and reduces oxidation.

- Tempering: Temper at 1000-1100°F (538-593°C) for 2-4 hours, repeating the cycle once. This results in a final hardness of 44-48 HRC, balancing strength and toughness. For maximum toughness, temper at 1100°F; for better wear resistance, temper at 1000°F.

- Case hardening: For applications needing extra surface wear resistance, case hardening (like nitriding) can be applied. This creates a hard surface layer (65-70 HRC) while keeping the core tough, extending mold life by 40-50% in abrasive environments.

- Heat treatment equipment: Using controlled-atmosphere furnaces with precise temperature control (±5°F) is critical. This ensures uniform heating and prevents decarburization, which weakens the steel’s surface.

Maintenance and Machining of 8407 Molds

Proper maintenance and machining of 8407 molds can extend their service life by 2-3 times, maximizing your investment:

- Tool wear management: Monitor cutting tools during machining—8407’s carbide content can wear tools faster than softer steels. Replace inserts when wear reaches 0.005 inches to maintain precision.

- Surface treatment: Regular cleaning with mild solvents removes mold release agents and debris, preventing buildup that causes uneven wear. Applying a protective coating during storage prevents corrosion.

- Repair techniques: Small cracks or worn areas can be repaired via welding with 8407 filler rod. Post-weld heat treatment (tempering at 1050°F) restores toughness, ensuring the repair lasts as long as the original mold.

- Cooling systems: Ensuring proper mold cooling reduces thermal stress, extending life. 8407’s good thermal conductivity means efficient cooling channels can be machined to dissipate heat quickly.

- Quality control: Regular inspections (using ultrasonic testing or dye penetrant) catch cracks early. Measuring dimensional stability after each 10,000 cycles ensures the mold remains within tolerance.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology has seen 8407 transform our clients’ production efficiency. Its superior toughness and wear resistance make it a standout for high-volume die casting and plastic injection applicaie casting and plastic injection applications. We recommend 8407 for clients facing frequent mold failures due to thermal fatigue or abrasion—switching from H13 typically increases mold life by 40-60%. Our in-house heat treatment experts optimize 8407’s properties for each application, ensuring the perfect balance of hardness and toughness. For precision-critical molds, 8407’s machinability and surface finish capabilities deliver parts that meet the strictest quality standards.

FAQs

- How does 8407 compare to H13 in terms of performance?

8407 offers 20-30% better toughness and wear resistance than H13, making it ideal for high-stress applications. It also has better corrosion resistance, extending life in environments with coolants or mold release agents.

- Can 8407 be used for cold work applications?

While 8407 can handle cold work, its hardness (44-48 HRC) is lower than cold work steels like D2 (57-62 HRC), making it less cost-effective for low-temperature, high-wear tasks.

- What’s the best way to extend the life of an 8407 mold?

Regular cleaning, proper cooling system maintenance, and timely repairs are key. Applying a nitrided surface treatment can also improve wear resistance, extending life by 40-50% in abrasive applications.