Introduction

The Significance of Mould Assembly Parts

In the manufacturing industry, mould assembly parts play a pivotal role. They are the building blocks that transform raw materials into the diverse products we encounter daily, from the smartphones in our pockets to the cars we drive.

Impact on Product Quality

The quality of mould assembly parts is directly proportional to the quality of the final product. High - precision parts ensure that the products have accurate dimensions, smooth surfaces, and consistent performance. For example, in the production of plastic injection - molded products, if the mould cavity and core (two important mould assembly parts) are not machined to the correct tolerances, the plastic parts may have defects such as warping, uneven wall thickness, or poor surface finish. A study by a leading manufacturing research institute found that over 70% of product quality issues in injection - molding processes can be traced back to problems with mould assembly parts.

Influence on Production Efficiency

Efficient production heavily relies on well - designed and high - quality mould assembly parts. When parts fit together precisely and function smoothly, the production cycle can be shortened. Consider a stamping die used in the automotive industry. If the punch and die (key mould assembly parts) are made of high - wear - resistant materials and are accurately assembled, the stamping process can operate at a higher speed, increasing the number of parts produced per hour. In contrast, if the parts are of poor quality or not properly assembled, frequent breakdowns, adjustments, and replacements will occur, leading to significant production downtime. According to industry statistics, companies that invest in high - quality mould assembly parts can reduce production downtime by up to 30% compared to those using sub - standard parts.

Key Components of Mould Assembly Parts

Types of Mould Assembly Parts

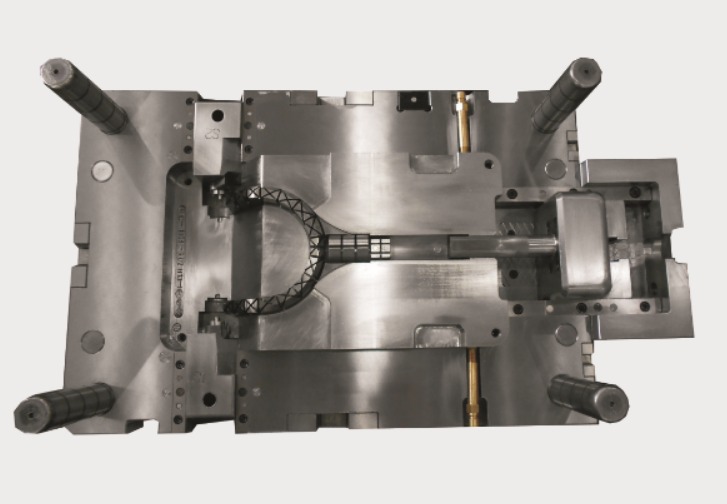

- Core

- Function: In a mould, the core is crucial for shaping the internal features of a product. For example, in the injection - molding of a plastic bottle, the core determines the inner diameter and the shape of the hollow part of the bottle. It is usually located opposite the cavity. The core is often designed with a top - out system. After the plastic material solidifies in the mould, the top - out system in the core ejects the finished product, ensuring that the product can be smoothly removed from the mould without damaging its internal structure.

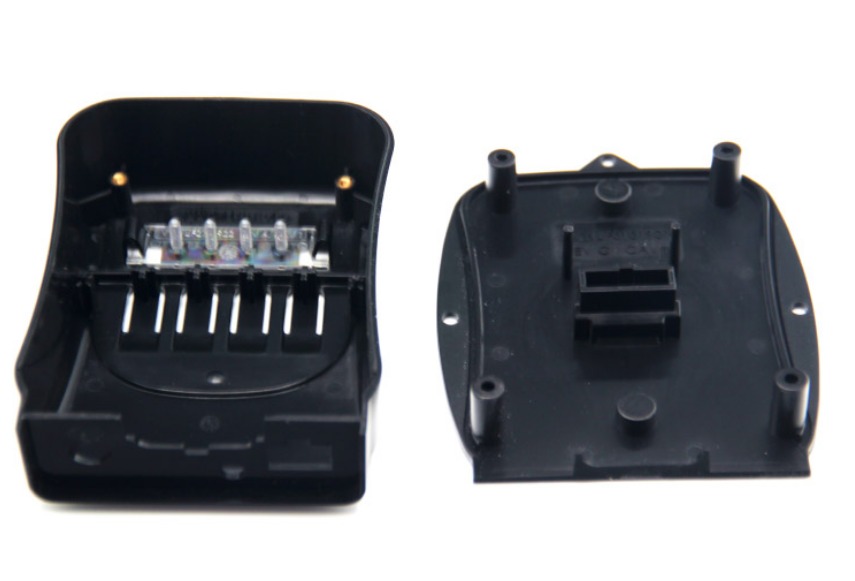

- Cavity

- Function: The cavity defines the outer shape of the molded product. In the production of a smartphone case, the cavity's shape and surface finish directly influence the outer appearance, dimensions, and texture of the case. High - precision cavities are required to produce products with smooth surfaces and accurate dimensions. Any defects or inaccuracies in the cavity can lead to flaws in the final product, such as rough surfaces or incorrect outer shapes.

- Slider

- Function: Sliders are used when the product has features that cannot be directly ejected from the mould in a simple up - and - down motion. For instance, if a plastic part has a side hole or a protrusion on the side, a slider is employed. During the mould - opening process, the slider moves horizontally or at an angle to create space for the ejection of the product. There are different types of sliders, such as straight - line sliders, curve sliders, and inclined sliders, each suitable for different product geometries.

- Ejector Pin

- Function: Ejector pins are responsible for pushing the finished product out of the mould after the molding process is complete. They are placed at strategic positions within the mould, typically in areas where the product is likely to stick to the mould cavity or core. For small plastic parts, multiple ejector pins may be used to evenly distribute the ejection force and prevent the product from deforming during ejection.

- Guide Pin and Guide Bush

- Function: Guide pins and guide bushes work together to ensure the accurate alignment of the moving parts of the mould during the opening and closing processes. The guide pin is usually installed on one part of the mould (such as the moving half), and the guide bush is installed on the corresponding part (the fixed half). They reduce friction and prevent misalignment, which is essential for maintaining the precision of the mould and ensuring that the product is molded with consistent quality.

Material Selection for Parts

When choosing materials for mould assembly parts, several factors need to be considered:

- Strength

- Importance: Parts like cores and cavities need to withstand high pressures during the molding process. For example, in die - casting, where molten metal is injected into the mould at high pressures, the materials of the core and cavity must have sufficient strength to prevent deformation or breakage. High - strength steels, such as alloy tool steels, are often used in these applications. They can endure the mechanical stresses exerted during the molding operation.

- Wear Resistance

- Importance: In moulds that are used for high - volume production, wear resistance is a critical factor. Ejector pins, for instance, come into contact with the molded product during the ejection process, and repeated friction can cause wear. Materials with high wear - resistance, such as tungsten - carbide - coated steels, are suitable for ejector pins. These materials can significantly extend the service life of the parts, reducing the frequency of replacement and thus increasing production efficiency.

- Cost

- Importance: Cost is always a consideration in manufacturing. While high - performance materials offer excellent properties, they may be expensive. For some low - volume production or less - demanding applications, more cost - effective materials can be chosen. For example, in the production of simple plastic products with short production runs, ordinary carbon steels can be used for some mould parts instead of more expensive alloy steels. However, it's important to balance cost with the required performance to avoid sacrificing product quality.

- Thermal Conductivity

- Importance: In injection - molding and other heat - involved processes, parts need to dissipate heat efficiently to ensure proper cooling of the molded product. Cores made of materials with high thermal conductivity, such as beryllium copper, can help in rapid heat transfer, reducing the cooling time of the product and increasing the production cycle speed.

| Material | Advantages | Disadvantages |

| Alloy Tool Steel | High strength, good wear - resistance, can be heat - treated to achieve different hardness levels | Relatively high cost, may require complex heat - treatment processes |

| Tungsten - Carbide - Coated Steel | Exceptional wear - resistance, high hardness | High cost, difficult to machine, brittle if not properly applied |

| Beryllium Copper | High thermal conductivity, good corrosion resistance, excellent formability | Expensive, beryllium is toxic and requires special handling during manufacturing |

| Ordinary Carbon Steel | Low cost, easy to machine | Low strength and wear - resistance compared to alloy steels, not suitable for high - pressure or high - volume production |

Design Considerations

Design Principles for Mould Assembly

When designing mould assembly parts, several fundamental principles must be adhered to:

- Precision: Precision is the cornerstone of mould design. All parts should be designed with tight tolerances. For example, the core and cavity in a high - precision plastic injection mould may have a tolerance of ±0.01mm. This ensures that the molded products have accurate dimensions, which is crucial for products that require a high degree of fit, such as medical device components or aerospace parts.

- Ease of Assembly and Disassembly: The design should facilitate the assembly and disassembly of parts. Components should be designed with clear alignment features, such as guide pins and 定位 holes. For instance, in a multi - component mould, each part should be designed in a way that it can be easily installed and removed during maintenance or replacement. This reduces the time and effort required for mould setup and repair, improving production efficiency.

- Function Optimization: Each part should be designed to optimize its specific function. For example, ejector pins should be placed in positions that ensure the smooth ejection of the product without causing deformation. In a complex mould for a large - scale automotive interior part, the ejector pins may need to be strategically distributed to evenly push the product out of the mould.

- Durability: Considering the harsh working conditions of moulds, parts should be designed to be durable. This may involve using appropriate materials and design features to withstand high pressures, temperatures, and repeated mechanical stresses. For example, moulds used in die - casting processes, which are subject to high - pressure molten metal injection, need to have parts with robust designs to ensure a long service life.

Importance of Precision in Design

Precision in the design of mould assembly parts is of utmost importance. A slight deviation in the design can lead to significant issues in the production process and the quality of the final product.

- Impact on Product Quality: Inaccurate design can result in products with dimensional inaccuracies, surface defects, or functional failures. For example, if the design of a mould cavity for a smartphone screen protector is not precise, the screen protector may not fit the screen properly, have uneven edges, or affect the touch - screen sensitivity. Research shows that about 50% of product rejects in injection - molding can be attributed to design - related precision issues.

- Influence on Production Efficiency: Imprecise designs can cause frequent mould adjustments, breakdowns, and longer production cycles. For instance, if the guide pins and bushes in a mould are not designed to the correct tolerances, the mould may experience misalignment during operation. This can lead to parts getting stuck in the mould, requiring the production line to be halted for re - alignment and repair. According to industry data, companies can experience a 20 - 30% increase in production costs due to inefficiencies caused by imprecise mould designs.

- Cost Implications: Design precision directly affects the cost of production. Reworking or scrapping products due to design - related precision problems increases material, labor, and time costs. Additionally, frequent mould maintenance and replacement due to design flaws can also add to the overall manufacturing cost. Therefore, investing in precise design from the beginning can save significant costs in the long run.

Assembly and Installation

Best Practices for Assembly

- Follow the Assembly Sequence: A proper assembly sequence is crucial. For example, in a plastic injection mould, the core should be installed into the cavity - half of the mould first. Then, the ejector pins and other moving parts are installed. This ensures that each part is in the correct position and can function properly. A study of mould assembly in a large - scale manufacturing plant showed that following the correct assembly sequence reduced the defect rate of assembled moulds by 40%.

- Use Appropriate Assembly Tools: The right tools are essential for a successful assembly. For instance, torque - controlled wrenches should be used when tightening screws in a mould. This ensures that the screws are tightened to the correct torque value. Using a torque - controlled wrench can prevent over - tightening, which may damage the parts, or under - tightening, which can lead to loose connections. In high - precision moulds, the torque tolerance for screws may be within ±5 N·m.

- Clean and Lubricate Parts: Before assembly, all parts should be thoroughly cleaned to remove any dirt, debris, or machining chips. For example, the guide pins and guide bushes should be cleaned with a suitable solvent to ensure smooth movement. After cleaning, parts that require lubrication, such as the moving parts like sliders and ejector pins, should be lubricated with a high - quality lubricant. This reduces friction and wear during the mould's operation. A lubricated slider can move more smoothly, increasing the efficiency of the mould and reducing the risk of mechanical failure.

Installation Considerations

- Accurate Installation Location: The mould must be installed in the correct position on the machine. In injection - moulding machines, the mould should be centered precisely on the platen. Any misalignment can cause uneven pressure distribution during the moulding process, resulting in products with inconsistent quality. For example, if a mould for manufacturing plastic pipes is not centered correctly on the injection - moulding machine, the pipes may have uneven wall thicknesses.

- Reliable Fixing Methods: Securely fixing the mould is of utmost importance. Bolts and nuts are commonly used to fix the mould to the machine. The size and strength of the bolts should be appropriate for the size and weight of the mould. In a large - scale die - casting mould, high - strength bolts with a diameter of 20 - 30 mm may be used to ensure that the mould remains firmly in place during the high - pressure die - casting process. Additionally, anti - vibration pads can be used to reduce the impact of vibrations on the mould during operation.

- Check for Levelness: The mould should be installed in a level position. A non - level mould can cause problems such as uneven filling of the mould cavity and difficulties in product ejection. Using a spirit level, the mould's levelness should be checked both horizontally and vertically. In a mould for manufacturing flat - panel products, a deviation of more than 0.5 mm from the horizontal or vertical plane can lead to significant product quality issues.

Yigu Technology's Perspective

Yigu Technology, as a non - standard plastic metal products custom Supplier, has a deep - seated understanding of mould assembly parts. Our team of experts emphasizes the importance of customization in meeting the unique needs of different manufacturers. We believe that a one - size - fits - all approach does not work when it comes to mould assembly parts. Each project may require specific design modifications, material selections, and manufacturing processes.

In terms of quality control, Yigu Technology has a rigorous system in place. From the initial material inspection to the final product delivery, every step is closely monitored. We use advanced inspection equipment to ensure that the parts meet the highest precision and quality standards. Our commitment to quality has enabled us to build long - term partnerships with numerous clients in various industries. Additionally, we provide comprehensive after - sales service, offering technical support and quick solutions to any issues that may arise during the use of our mould assembly parts.