What is an Injection Mold?

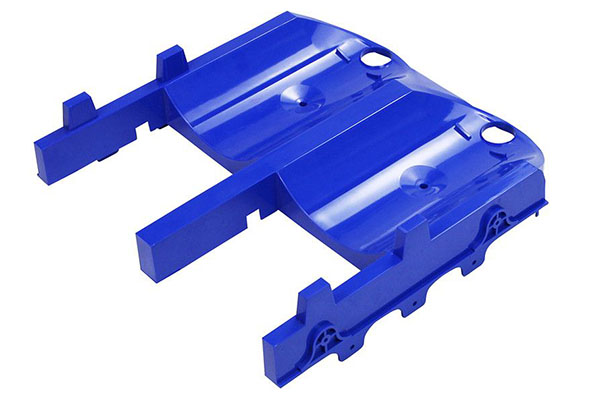

An injection mold is a specialized tool used in the injection molding process, which is a widely employed manufacturing method for producing plastic parts in high volumes. It serves as a hollow cavity that is precisely designed to shape molten plastic material into a specific form. Once the plastic cools and solidifies within the mold, it takes on the exact shape of the mold's interior, resulting in a finished product.

Think of an injection mold like a cookie cutter, but on a much more complex and industrial scale. Just as a cookie cutter imprints a specific shape onto dough, an injection mold imparts its shape onto molten plastic. However, injection molds can create far more intricate and detailed products compared to a simple cookie cutter.

For example, many of the plastic components in your everyday life, such as the housing of your smartphone, the keys on your keyboard, and the handles of your kitchen utensils, are likely produced using injection molds. These molds are engineered to replicate these complex shapes with high precision, ensuring that each product meets the required specifications.

Key Elements of an Injection Mold

Now that we have a basic understanding of what an injection mold is, let's delve into its key components. Each element plays a crucial role in the injection molding process, contributing to the overall quality and efficiency of the production.

Mold Cavity

The mold cavity is the space within the mold that determines the outer shape of the final product. It is like the negative impression of the product, where the molten plastic is injected and takes shape. There are two main types of mold cavities: integral cavities and combined cavities.

- Integral cavities are machined as a single, solid piece. They offer high rigidity and dimensional stability, making them suitable for high - pressure molding processes. For example, in the production of small, precision - engineered plastic components like electronic connectors, integral cavities can ensure the accurate replication of fine details. However, they can be more difficult and costly to manufacture, especially for complex shapes, as any modification to the cavity requires significant machining work on the entire solid block.

- Combined cavities, on the other hand, are made up of multiple parts that are assembled together. This design is more flexible and cost - effective for producing complex - shaped products. For instance, when manufacturing plastic toys with intricate geometries, combined cavities allow for easier manufacturing and repair. If one part of the cavity is damaged, only that specific component needs to be replaced, rather than the entire cavity.

Mold Core

The mold core is responsible for shaping the internal features of the product, such as holes, recesses, or hollow areas. Similar to the cavity, there are different types of cores:

- Integral cores are solid, one - piece structures that provide high - strength support for the internal structure of the part. They are commonly used when the internal feature is simple and requires high precision, like in the production of medical syringes, where the core creates the internal channel for the liquid to flow through.

- Combined cores are assembled from multiple components. They are ideal for creating complex internal shapes that would be difficult to achieve with a single - piece core. For example, in the production of automotive intake manifolds, which have complex internal passageways for air flow, combined cores can be used to accurately form these intricate channels.

- Movable cores are used to form undercuts or side holes in the part. These cores can be moved in and out of the mold during the molding process. For instance, when making plastic containers with snap - on lids that have internal hooks (undercuts), movable cores are retracted after the plastic has solidified to allow the removal of the finished product from the mold.

Runner System

The runner system is the network of channels that transports the molten plastic from the injection machine nozzle to the mold cavities. Its main function is to distribute the plastic evenly to all cavities in the mold. There are different types of runner shapes, each with its own advantages and disadvantages:

- Circular runners have a circular cross - section. They offer the lowest pressure drop, which means the molten plastic can flow through them with relatively little resistance. This makes them suitable for large - scale molds and high - volume production, as they can ensure efficient filling of all cavities. However, circular runners require more material to manufacture and may be more difficult to machine compared to other shapes.

- Trapezoidal runners have a trapezoidal cross - section. They are easier to machine and are widely used in common molds. They also offer a good balance between pressure drop and material usage. For small to medium - sized molds, trapezoidal runners can be a cost - effective choice, providing efficient plastic flow while minimizing material waste.

Gate

The gate is the connection point between the runner system and the mold cavity. It controls the flow rate and direction of the molten plastic into the cavity. There are several common types of gates:

- Side gates are located on the side of the cavity and are commonly used for parts with simple shapes. They are easy to manufacture and can be easily removed from the finished product. For example, in the production of plastic plates, side gates can be used to inject the plastic into the cavity.

- Submarine gates (also known as tunnel gates) are hidden within the mold and can automatically cut off the runner from the part during ejection. This results in a clean - cut separation between the product and the runner, reducing the need for post - processing to remove the gate residue. They are often used for products where a visible gate mark is not acceptable, such as in the production of cosmetic containers.

- Pin - point gates are very small in diameter and are suitable for high - precision and small - sized parts. They provide precise control over the plastic flow, allowing for the production of parts with tight tolerances. For example, in the manufacturing of micro - electronic components, pin - point gates can ensure accurate filling of the small cavities.

Ejector System

The ejector system is crucial for removing the finished product from the mold after the plastic has cooled and solidified. It consists of components such as ejector pins, ejector plates, and return pins. Ejector pins are small rods that are positioned in the mold cavity and are used to push the product out of the mold when the mold opens. The ejector plates are used to coordinate the movement of the ejector pins, ensuring that they all move simultaneously to evenly eject the product. Return pins are used to reset the ejector system to its original position when the mold closes again for the next molding cycle. Without a properly functioning ejector system, the molded products could become stuck in the mold, leading to production delays and potential damage to the mold and the products.

Injection Molding Process with an Injection Mold

Now that we understand the components of an injection mold, let's explore the injection molding process step - by - step. This process is what brings the mold to life and transforms raw plastic material into finished products.

Step 1: Mold Design

Mold design is the foundation of the injection molding process. A well - designed mold ensures the production of high - quality parts with consistent dimensions and excellent surface finish. When designing a mold, several factors need to be considered:

- Product Geometry: The shape and complexity of the final product play a crucial role in mold design. Complex geometries may require more intricate mold designs, such as the use of movable cores or slides to create undercuts and internal features. For example, if you are designing a mold for a plastic toy with a hollow interior and multiple small holes, the mold design needs to account for these details. Specialized software like CAD (Computer - Aided Design) and Moldflow analysis are often used to optimize the mold design based on the product geometry. CAD allows designers to create 3D models of the mold, making it easier to visualize and modify the design. Moldflow analysis helps in predicting the flow of the molten plastic within the mold, identifying potential issues like flow imbalance or air traps.

- Material Selection: Different plastic materials have varying properties, such as melt flow index, shrinkage rate, and heat resistance. The choice of material affects the mold design. For instance, materials with a high shrinkage rate may require larger mold cavities to compensate for the dimensional changes during cooling. If you are using a material like polypropylene (PP), which has a relatively high shrinkage rate compared to some other plastics, the mold design needs to be adjusted accordingly.

- Mold Cavity Layout: Deciding on the number of cavities in the mold is an important aspect of design. Multiple - cavity molds can increase production efficiency but also require careful consideration of the runner system to ensure even distribution of the molten plastic to each cavity. For high - volume production of small parts like plastic buttons, a multi - cavity mold with, say, 32 or 64 cavities might be used. However, for large and complex parts, a single - cavity mold may be more appropriate to ensure quality control.

Step 2: Mold Manufacturing

Once the mold design is finalized, the manufacturing process begins. Mold manufacturing is a complex and precise process that typically involves the following steps:

- Machining: High - precision machining techniques are used to create the mold components. CNC (Computer Numerical Control) machining is commonly employed to cut the mold cavity and core from blocks of steel or other suitable materials. The machining process requires skilled operators and advanced equipment to achieve the tight tolerances required for injection molds. For example, the cavity and core of a mold for producing optical lenses need to be machined with extremely high precision to ensure the clarity and quality of the final lenses.

- Electrode Machining: In some cases, especially for complex geometries that are difficult to machine directly, electrode machining is used. Electrodes are created, usually from copper or graphite, and then used in electrical discharge machining (EDM) to create the desired shape in the mold. This process is capable of producing intricate details and sharp corners. For molds with fine internal features like the small channels in a medical device mold, EDM using carefully crafted electrodes can accurately create these features.

- Heat Treatment: After machining, the mold components may undergo heat treatment to improve their hardness, wear resistance, and durability. Heat treatment processes such as quenching and tempering can enhance the mechanical properties of the mold steel, ensuring that the mold can withstand the high pressures and temperatures during the injection molding process. A mold used for high - volume production of automotive parts, which experiences significant stress during each molding cycle, will benefit greatly from proper heat treatment.

- Assembly: The individual mold components, including the cavity, core, runner system, and ejector system, are assembled together. Precision alignment is crucial during assembly to ensure that the mold functions correctly. The assembly process often involves the use of dowel pins and screws to hold the components in place. Each component must fit together precisely to prevent issues like misalignment, which could lead to defects in the molded products.

Step 3: Injection

The injection stage is where the molten plastic is introduced into the mold cavity. Here's how it works:

- Plastic Melting: The plastic raw material, usually in the form of pellets, is fed into the hopper of the injection molding machine. From the hopper, the pellets enter the heated barrel of the machine. Inside the barrel, a rotating screw or a reciprocating plunger heats and melts the plastic. The temperature of the barrel is carefully controlled to ensure that the plastic reaches its melting point without overheating or degrading. For example, if the plastic is acrylonitrile butadiene styrene (ABS), the barrel temperature may be set between 200 - 250°C, depending on the specific grade of ABS and the requirements of the molding process.

- Injection into the Mold: Once the plastic is fully melted and homogenized, it is forced through the nozzle of the injection molding machine and into the runner system of the mold. High - pressure hydraulic cylinders or electric motors power the movement of the screw or plunger, which injects the molten plastic into the mold cavity at a specific pressure and speed. The injection pressure can range from 500 to 2000 bar, depending on factors such as the complexity of the mold, the viscosity of the plastic, and the size of the part. For a small and simple plastic part, a relatively lower injection pressure of around 800 bar might be sufficient. However, for a large and complex automotive component with thin walls, a higher injection pressure of 1500 - 2000 bar may be required to ensure complete filling of the mold cavity. The injection speed also plays a crucial role. A too - slow injection speed can result in incomplete filling or poor surface finish, while a too - fast injection speed can cause air entrapment, flash (excess plastic seeping out of the mold), or even damage to the mold.

Step 4: Cooling

After the mold cavity is filled with molten plastic, the cooling stage begins. Cooling is a critical step as it determines the final shape, dimensional stability, and quality of the product:

- Heat Transfer: The heat from the molten plastic is transferred to the mold walls. To facilitate this heat transfer, cooling channels are incorporated into the mold design. These channels are typically filled with a coolant, usually water or a water - glycol mixture. The coolant circulates through the channels, absorbing the heat from the plastic and dissipating it into the surrounding environment. The efficiency of the cooling system depends on factors such as the layout of the cooling channels, the flow rate of the coolant, and the temperature difference between the plastic and the coolant. For example, in a mold for producing plastic beverage bottles, the cooling channels are strategically placed close to the walls of the bottle - shaped cavity to ensure rapid and uniform cooling.

- Cooling Time: The cooling time is the period required for the plastic to solidify to a point where it can be safely ejected from the mold without deforming. The cooling time is influenced by several factors, including the thickness of the part, the type of plastic material, and the cooling efficiency of the mold. Thicker parts generally require longer cooling times. For instance, a plastic part with a wall thickness of 5 mm may need a cooling time of 30 - 60 seconds, while a thinner part with a wall thickness of 1 mm may cool in 10 - 20 seconds. If the cooling time is too short, the plastic may not be fully solidified, resulting in a deformed or defective product. On the other hand, if the cooling time is too long, it can reduce the production efficiency and increase the overall cost of production.

Step 5: Ejection

Once the plastic has cooled and solidified, it's time to eject the finished product from the mold:

- Mold Opening: The injection molding machine opens the mold, separating the two halves (the cavity half and the core half). As the mold opens, the ejector system comes into action.

- Ejector Operation: The ejector system, consisting of ejector pins, ejector plates, and return pins, pushes the product out of the mold cavity. Ejector pins are small rods that are placed in strategic locations within the mold cavity. When the mold opens, the ejector plates move forward, causing the ejector pins to push against the product. The force exerted by the ejector pins must be evenly distributed to prevent the product from being damaged or deformed during ejection. For example, in a mold for producing a plastic toy with a complex shape, the ejector pins are carefully positioned to ensure that the toy is ejected smoothly without breaking any of its delicate parts.

- Product Removal: After the product is ejected from the mold, it can be collected. In automated production lines, robots or conveyor belts are often used to pick up the ejected products and transport them to the next stage of processing, such as quality inspection or post - processing operations like trimming, painting, or assembly.

Yigu Technology's Viewpoint

As a non - standard plastic metal products custom Supplier, Yigu Technology understands the critical importance of injection molds in manufacturing. We believe that precise injection mold design and manufacturing require a deep understanding of the customer's product requirements. By leveraging advanced technologies and our rich experience, we ensure that each mold we produce meets the highest quality standards. Whether it's for the automotive, electronics, or consumer goods industry, our molds are tailored to meet the complex needs of different products. We also focus on providing excellent after - sales service, from mold maintenance to troubleshooting, to help our customers achieve seamless production processes and successful product launches.