Introduction

Understanding the Significance of Plastic Molds Pricing

In the dynamic world of manufacturing, plastic molds play a pivotal role. They are the templates that give shape to countless plastic products we use in our daily lives, from the tiny components in our electronic devices to the large casings of household appliances. But for engineers, calculating the price of plastic molds is not just a matter of setting a number; it's a complex process that has far - reaching implications.

Accurate pricing of plastic molds is crucial for both the manufacturers and the clients. For manufacturers, it determines the profitability of a project. If the price is set too low, they may struggle to cover production costs, invest in research and development, and maintain high - quality standards. On the other hand, if the price is overestimated, it can lead to losing potential orders to competitors.

From the clients' perspective, the price of plastic molds affects their overall production budget. Whether they are a startup looking to launch a new plastic - based product or an established company planning to expand its product line, understanding the cost of plastic molds helps them make informed decisions about the feasibility of their projects. It also impacts the final price of the end - products in the market.

This article will delve deep into the various factors that engineers consider when calculating the price of plastic molds, aiming to demystify this important aspect of the plastic manufacturing industry.

Factors Influencing the Price of Plastic Molds

Material Selection

The choice of material for plastic molds is a fundamental factor in price determination. Steel is a commonly used material for plastic molds, especially in high - volume production scenarios. Different grades of steel, such as P20, 718, and H13, have distinct properties and cost levels. For example, P20 steel, with a price of around \(10 - 15 per kilogram, is suitable for general - purpose molds with a lifespan of approximately 300,000 shots. It offers good machinability and a balance between cost and performance. 718 steel, which is more expensive, at about \)20 - 30 per kilogram, has better polishing properties and dimensional stability, making it ideal for molds where surface finish and precision are crucial, and its lifespan can reach up to 500,000 shots. H13 steel, priced around $30 - 50 per kilogram, is highly valued for its excellent heat - resistance and toughness, often used in molds for high - temperature plastics or in applications that require long - term durability, with a lifespan of over 800,000 shots.

On the other hand, aluminum alloy is also an option, especially for small - batch production or prototypes. Aluminum molds are much lighter than steel molds, approximately 50% lighter, which can reduce handling and transportation costs. They are also easier to machine, with a machining speed about 40% faster than steel. However, their lower hardness means a shorter lifespan, usually suitable for producing up to 10,000 - 50,000 shots. The cost of aluminum alloy for molds is generally in the range of $15 - 25 per kilogram. In summary, the material selection directly impacts the price of plastic molds, with higher - performance materials leading to higher costs but also potentially better quality and longer - term value.

Complexity of Design

The complexity of a plastic mold's design has a significant bearing on its price. When it comes to the shape complexity, molds with intricate three - dimensional shapes, undercuts, or complex geometries are more expensive to produce. For instance, a mold for a simple rectangular plastic box will be far less costly than a mold for a medical device component with multiple curved surfaces and internal channels.

Precision requirements also play a crucial role. High - precision molds, where the tolerance might be within ±0.01mm or even less, demand more advanced manufacturing techniques and equipment. This often involves the use of high - end CNC (Computer Numerical Control) machines and highly skilled operators, driving up the cost.

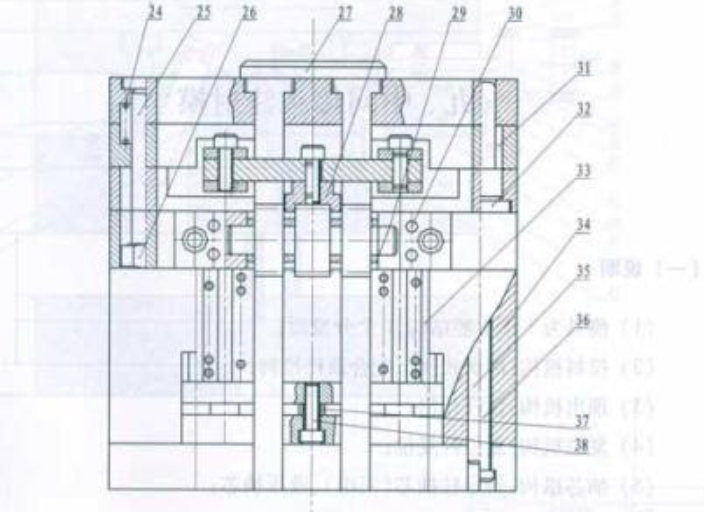

The (demolding method) is another aspect. Side - action molds, which require additional mechanisms like slides or lifters for demolding, are more complex and expensive compared to simple two - plate molds with straightforward ejection systems. In general, as the design complexity increases, so does the time, effort, and technology required for manufacturing, resulting in a higher price for the plastic mold.

Manufacturing Processes

Machining Operations

Different machining operations contribute differently to the cost of plastic molds. Milling is a common process, and its cost depends on factors such as the complexity of the milling path, the type of milling cutter used, and the machining time. For simple milling operations on flat surfaces, the cost is relatively low. However, when it comes to high - speed milling of complex 3D shapes, the cost can increase significantly. High - speed milling can achieve better surface finish and higher precision but requires more advanced and expensive milling machines, as well as skilled operators.

(Turning) is mainly used for creating rotational parts in the mold, such as cores or shafts. The cost of turning is influenced by the material being turned, the length and diameter of the part, and the required precision. Turning operations on hard materials or those with tight tolerances will be more costly.

(Electrical Discharge Machining, EDM) is often employed when the mold has intricate details, small holes, or sharp corners that are difficult to machine by traditional methods. EDM works by eroding the material using electrical discharges. It is a slow and energy - intensive process, which makes it relatively expensive. For example, machining a small, highly detailed cavity in a mold using EDM can take several hours and consume a significant amount of electricity, adding to the overall cost. In general, EDM is more costly per unit volume of material removed compared to milling or turning.

Surface Finishing

Surface finishing processes can greatly enhance the price of plastic molds. Polishing is a common surface - finishing technique. A high - gloss polish, such as a mirror - finish polish with a surface roughness of Ra 0.01μm or less, requires a great deal of manual labor and specialized polishing tools. Skilled polishers spend hours carefully buffing the mold surface to achieve the desired finish. This not only increases labor costs but also requires high - quality abrasives and polishing compounds, which contribute to the overall expense.

(Electroplating) is another surface - treatment option. Plating the mold with materials like chrome can improve its corrosion resistance, wear resistance, and surface hardness. The cost of electroplating depends on the type of plating material, the thickness of the plating layer, and the surface area to be plated. Chrome plating, for example, involves a multi - step process that includes cleaning, pre - treatment, plating, and post - treatment, all of which add to the cost.

(Nitriding) is a heat - treatment process that diffuses nitrogen into the surface of the mold steel to form a hard nitride layer. This can significantly improve the mold's wear resistance and fatigue strength. The cost of nitriding is related to the time of the nitriding process, the size of the mold, and the equipment used. Since nitriding requires specialized furnaces and precise control of temperature and gas flow, it adds to the overall manufacturing cost of the plastic mold.

Quantity and Production Volume

The quantity of plastic molds ordered and the production volume they are intended for have a direct impact on the unit cost. When the order quantity is small, the fixed costs associated with mold design, setup, and tooling are spread over a fewer number of molds. For example, if the setup cost for a mold is \(5,000 and only 10 molds are ordered, each mold will bear a significant portion of this setup cost, \)500 in this case.

However, as the order quantity increases, the unit cost decreases due to economies of scale. Suppose the order quantity is increased to 100 molds. The setup cost per mold then drops to $50. In large - scale production, manufacturers can also benefit from bulk purchasing of materials, which often comes with discounts. Additionally, the learning curve effect means that as workers produce more molds, they become more efficient, reducing the labor time per mold.

Let's take a real - world example. A company that produces plastic toy parts orders 50 plastic molds. The total cost of manufacturing these molds, including design, materials, and machining, is \(50,000, resulting in a unit cost of \)1,000 per mold. If they increase the order to 500 molds, the total cost might increase to \(200,000, but the unit cost drops to \)400. This clearly shows how quantity and production volume can influence the price of plastic molds.

Pricing Models and Formulas

Cost - Plus Pricing

Cost - plus pricing is a straightforward and commonly used method in the plastic mold industry. First, the direct costs need to be determined. Direct material costs are relatively easy to calculate. For example, if a plastic mold requires 50 kilograms of P20 steel, and P20 steel costs \(12 per kilogram, then the direct material cost for steel is \)12×50 = $600.

Direct labor costs are calculated based on the time spent by workers on the mold production. Suppose a highly skilled mold - maker is paid \(30 per hour and spends 20 hours on the design and machining of a mold, then the direct labor cost is \)30×20 = $600.

Next are the indirect costs. Equipment depreciation is an important part of indirect costs. For instance, a high - end CNC milling machine costs \(100,000 and has an expected service life of 10 years with 2,000 working hours per year. The hourly depreciation cost of this machine is \)100,000÷(10×2,000) = \(5. If the mold production uses this CNC machine for 10 hours, the equipment depreciation cost allocated to this mold is \)5×10 = $50.

Overhead expenses such as rent, utilities, and management salaries also need to be allocated to the mold. Let's assume the total monthly overhead of a mold - making factory is \(50,000, and the factory produces 100 molds in a month. Then the overhead cost allocated to each mold is \)50,000÷100 = $500.

After calculating the total cost (direct costs + indirect costs), a profit margin is added. If the manufacturer aims for a 20% profit margin on the total cost, and the total cost of a mold is \(2,000, the profit amount is \)2,000×20% = \(400. So the final price of the mold using cost - plus pricing is \)2,000 + \(400=\)2,400.

Value - Based Pricing

Value - based pricing focuses on the value that the plastic mold brings to the customer rather than just the production cost. For example, if a mold is used to produce a revolutionary medical device that can save countless lives and has the potential to generate high - profit margins for the medical device manufacturer, the mold - maker can charge a premium price. Even if the production cost of the mold is relatively low, say \(5,000, but the value it creates for the customer in terms of potential revenue and market share is estimated to be in the millions, the mold - maker might price the mold at \)20,000 or more. This is because the customer is willing to pay a higher price based on the significant value the mold enables in their business. Another scenario could be a mold for a limited - edition, high - end consumer product. The brand value and exclusivity associated with the end - product mean that the mold can be priced higher, as it contributes to the overall brand image and profit - making potential of the product.

Competitive Pricing

Competitive pricing involves closely observing the prices set by competitors in the market. If most mold - making companies are offering a certain type of plastic mold at around \(1,500, a new entrant or an existing company might price their similar mold in the range of \)1,400 - $1,600 to be competitive. However, simply matching the price is not enough. To stand out, a company can offer additional value. This could include faster turnaround times. For example, while competitors might take 30 days to deliver a mold, a company could promise to deliver it in 20 days. Another advantage could be better after - sales service, such as providing free maintenance for the first six months, or offering technical support for mold operation and troubleshooting. By highlighting these unique selling points, a company can justify its price within the competitive pricing framework and attract more customers, even if the price is not the absolute lowest in the market.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of accurate plastic mold pricing. We always strive to strike a balance between cost - control and quality assurance. When calculating the price of plastic molds, we first have in - depth communication with clients to fully understand their product requirements, production volumes, and quality expectations. This helps us select the most suitable materials and manufacturing processes, ensuring that the price we quote is both reasonable and competitive.

We also take into account the long - term value that the mold brings to the client. For high - value projects, we may offer more customized solutions, even if it means a slightly higher upfront cost, because we believe that the long - term benefits in terms of product quality and production efficiency will outweigh the initial investment. Moreover, we continuously optimize our internal processes to reduce unnecessary costs without sacrificing quality, so as to provide clients with cost - effective plastic mold solutions.