Introduction

The Magic of Mold in Plastic Transformation

Have you ever paused to consider the origins of the countless plastic items that surround us daily? From the sleek smartphone cases that safeguard our devices to the sturdy automotive parts that ensure a smooth ride, and the precise components within our electronic gadgets, all these plastics are the result of a remarkable process - plastic transformation through molds. Molds are the unsung heroes behind the creation of these plastic products, playing a pivotal role in determining their shape, size, and quality.

In the realm of plastic manufacturing, the mold serves as a crucial link between raw materials and the final product. It is a specialized tool, typically crafted from materials like steel or aluminum, designed to endure high pressures and temperatures during the plastic - molding process. The design of the mold is a meticulous and complex task, as it must precisely replicate the desired shape of the plastic product, down to the tiniest details, whether it's a minute electronic component or a large - scale automotive part.

Key Factors in Plastic Transformation with Molds

Material Selection

The choice of plastic material is the cornerstone of successful plastic transformation. Different plastic materials possess unique characteristics that significantly impact the molding process and the final product quality.

Polypropylene (PP): It has a relatively low melting point, typically around 160 - 170°C. PP offers good chemical resistance and is lightweight, with a density of about 0.9 - 0.91 g/cm³. Its excellent flowability makes it suitable for complex - shaped products, but it has a relatively high 成型收缩率 (1.0 - 2.5%), which requires careful consideration in mold design to prevent dimensional inaccuracies. For example, in the production of plastic storage boxes, PP's cost - effectiveness, chemical resistance, and ability to be easily molded into large - scale containers make it a popular choice.

Polycarbonate (PC): PC has a high melting point, usually starting to flow at around 225°C and with a processing range of 270 - 320°C. It is renowned for its high impact strength, heat resistance, and dimensional stability. With a density of approximately 1.2 g/cm³, PC is often used in applications where mechanical strength and heat resistance are crucial, such as in automotive headlights and electronic device housings. However, its high viscosity during processing means that it requires higher injection pressures and well - designed mold channels to ensure proper filling.

Acrylonitrile Butadiene Styrene (ABS): ABS has a melting range of 200 - 240°C. It combines good impact resistance, strength, and processability. With a density of 1.05 g/cm³, it is a versatile material used in a wide range of products, from toys to automotive interior components. ABS has a relatively balanced 流动性,which allows for the production of parts with detailed features. However, it is sensitive to heat degradation above 270°C, so temperature control during molding is critical.

Mold Design

A well - designed mold is essential for producing high - quality plastic products. The following aspects of mold design play crucial roles:

| Mold Component | Design Considerations | Impact on Product Quality |

| Cavity | Precise cavity design is crucial for replicating the product's shape accurately. The surface finish of the cavity affects the surface quality of the product. For example, a smooth - finished cavity will result in a smooth - surfaced plastic part. | A poorly designed cavity may lead to incomplete filling, resulting in products with missing features or uneven surfaces. |

| Core | The core determines the internal shape of the product. Its stability and alignment within the mold are vital. In the case of a hollow plastic product, the core must be properly supported to ensure uniform wall thickness. | If the core is not well - designed or supported, it can cause the product to have an uneven wall thickness, leading to structural weaknesses and potential deformation. |

| Ejection System | An efficient ejection system is necessary to remove the molded product from the mold without causing damage. The location and number of ejector pins should be carefully chosen. For example, in a thin - walled plastic product, evenly distributed ejector pins are needed to prevent the product from warping during ejection. | A faulty ejection system can cause the product to be damaged during removal, resulting in scrap parts. |

| Cooling System | The cooling system controls the temperature of the mold during the molding process. It should be designed to ensure uniform cooling of the plastic. Cooling channels that are too close or too far apart can lead to uneven cooling. | Uneven cooling can cause internal stresses in the product, resulting in warping, cracking, or dimensional inaccuracies. |

Temperature Control

Temperature has a profound impact on the plastic transformation process. Here is how temperature affects plastic 流动性 and 成型质量:

As the temperature increases, the viscosity of the plastic decreases, leading to improved 流动性. For example, for Polyethylene (PE), when the temperature is raised from 140°C to 180°C, its 流动性 significantly improves, making it easier to fill the mold cavities. However, if the temperature is too high, it can cause the plastic to degrade. Each plastic material has an optimal 成型温度范围. For instance, for Polyamide 6 (PA6), the suitable 成型温度 is around 215 - 221°C. Operating outside this range can result in problems such as poor product quality, with low temperatures leading to incomplete filling and high temperatures causing material degradation.

[Insert a simple line graph here with temperature on the x - axis and plastic viscosity on the y - axis, showing a downward - sloping curve to represent the relationship between temperature and viscosity]

Pressure Management

Pressure is a critical factor in plastic molding processes such as 注塑 and 压缩成型.

In 注塑,the injection pressure is used to push the molten plastic into the mold cavity. Higher injection pressures are required for plastics with high viscosity or for complex - shaped molds. For example, when molding PC, which has a relatively high viscosity, a higher injection pressure is needed compared to molding PP. However, if the injection pressure is too high, it can cause problems like flash (excess plastic around the edges of the product), over - packing (resulting in high internal stresses), and damage to the mold.

In 压缩成型,pressure is applied to compress the plastic material in the mold. The pressure must be carefully controlled to ensure proper consolidation of the plastic and to achieve the desired product density and shape. The pressure parameters should be adjusted according to the plastic material and mold design. Softer plastics may require lower pressures, while more rigid plastics may need higher pressures to be properly formed.

Types of Molds for Plastic Transformation

Injection Molds

Injection molds are among the most widely used molds in plastic manufacturing. Structurally, an injection mold consists of two main parts: the fixed mold (also known as the stationary mold or the cavity half) and the moving mold (the ejector half). These two parts are precisely machined to form a cavity that replicates the shape of the desired plastic product.

The working principle of injection molds is as follows: First, plastic granules are fed into the injection molding machine's hopper. They then enter the heated barrel where they are melted by the heat generated from the heating elements and the mechanical action of the screw. Once the plastic is in a molten state, the screw rotates and pushes the molten plastic under high pressure through the nozzle and into the mold cavity. After the cavity is filled, the plastic is held under pressure (known as the holding pressure) for a short period to compensate for the shrinkage during cooling. As the plastic cools and solidifies, it takes on the shape of the mold cavity. Finally, the mold opens, and the ejector system, which typically includes ejector pins, pushes the molded plastic part out of the mold.

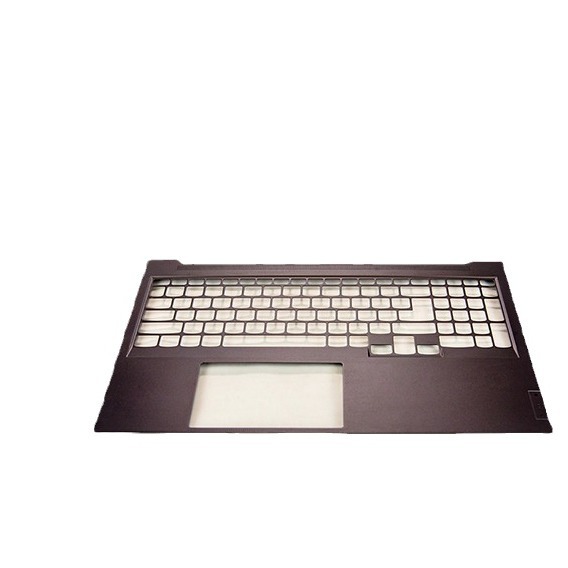

Injection molds are suitable for producing a wide range of products. For example, in the automotive industry, injection molds are used to manufacture various interior components such as dashboard parts, door panels, and center consoles. In the consumer electronics sector, they are employed to create smartphone cases, laptop housings, and remote - control casings. A case in point is the production of Apple's iPhone cases. High - precision injection molds are used to ensure that the cases fit the phone perfectly, with precise cut - outs for buttons, ports, and cameras. These molds allow for mass production, with a single mold often capable of producing hundreds or even thousands of cases in a day, depending on the complexity of the mold and the production capacity of the injection molding machine. The high - volume production made possible by injection molds significantly reduces the cost per unit, making it an ideal choice for products with high market demand.

Compression Molds

Compression molds operate in a different way compared to injection molds. In a compression molding process, the plastic material, which can be in the form of powder, pre - formed pellets, or a pre - heated sheet, is placed directly into the open mold cavity. The mold then closes, and pressure is applied to the plastic through a plunger or a male part of the mold. As the mold closes, the plastic is compressed and forced to fill the entire cavity. Heat is also applied during this process, either through electric heating elements embedded in the mold or by the heat generated from the compression itself. For thermosetting plastics, the heat causes a chemical reaction that cures the plastic, hardening it into the final shape. For thermoplastic materials, the heat softens the plastic, allowing it to flow and take the shape of the cavity, and then it cools and solidifies as the mold is opened.

Compression molds are well - suited for producing large - scale plastic products such as plastic pallets, large - sized storage tanks, and thick - walled industrial components. For instance, in the construction industry, compression molds are used to manufacture large plastic pipes and fittings. These products require a large amount of plastic material and need to have high structural integrity. Compression molding can handle the large volume of plastic well and can produce parts with a high degree of dimensional stability. Another example is the production of plastic manhole covers. The thick - walled and sturdy nature of manhole covers makes compression molding an appropriate choice, as it can ensure that the final product has the necessary strength to withstand heavy loads.

Blow Molds

Blow molds are specifically designed for creating hollow plastic products. The key feature of blow molds is their ability to inflate a pre - formed plastic parison (a tube - like piece of semi - molten plastic) inside the mold cavity to create a hollow shape.

The blow molding process typically begins with the extrusion or injection of a plastic parison. In extrusion blow molding, a continuous tube of molten plastic is extruded downward, and a mold then closes around the parison. Compressed air is then injected into the parison through a blow pin, causing the plastic to expand and fill the mold cavity, taking on the shape of the mold. In injection blow molding, a pre - molded plastic preform (a small, thick - walled container) is first created using an injection mold. This preform is then transferred to a blow mold, where it is reheated and inflated with compressed air to form the final product.

Blow molds are commonly used in the production of plastic bottles, such as those for beverages, detergents, and cosmetics. They are also used to make plastic toys, especially those with hollow parts like balls and action figures. For example, a typical 500 - ml PET (polyethylene terephthalate) water bottle is produced using blow molds. The pre - form, which is injection - molded, is heated and then blown into the final bottle shape in the blow mold. This process allows for the production of bottles with a smooth surface, precise dimensions, and uniform wall thickness, ensuring both the aesthetic appeal and the functional integrity of the product.

Successful Examples of Plastic Transformation with Molds

Automotive Industry

In the automotive industry, molds are indispensable for creating high - performance plastic components. One of the most prominent examples is the bumper. A modern car bumper is not just a simple protective structure; it is a complex plastic part designed to meet strict safety and aesthetic standards. Molds enable the production of bumpers with intricate shapes that integrate features such as air vents, sensor recesses, and stylish contours. For instance, the injection - molded bumpers of luxury cars often have a smooth and high - quality surface finish, which is achieved through precise mold design and advanced molding techniques. These molds are designed to handle large - scale production while maintaining consistent quality.

Interior components are another area where molds shine. Dashboard parts, door panels, and center consoles are all made using molds. Take the dashboard as an example. It contains multiple plastic parts with different functions, such as instrument clusters, air vents, and storage compartments. Molds allow for the precise integration of these features into a single, cohesive unit. The use of molds also ensures that the plastic parts have the necessary strength and durability to withstand the vibrations and temperature changes inside a vehicle. Additionally, molds enable the production of textured surfaces on interior components, which not only enhance the aesthetic appeal but also improve grip and reduce glare.

Consumer Goods

The consumer goods sector is filled with creative plastic products made possible by molds. Consider the world of kitchenware. Silicone baking molds have become increasingly popular due to their flexibility, heat resistance, and non - stick properties. These molds are designed to create various shapes of baked goods, from intricate muffin shapes to novelty - shaped cakes. Molds in this case are made from high - quality silicone materials, and their design takes into account factors such as easy release of the baked product and even heat distribution. They are produced in large quantities through injection molding processes, making them affordable for consumers.

In the toy industry, molds play a crucial role in bringing imaginative designs to life. Action figures, for example, are highly detailed plastic products. Molds are used to replicate every feature of the character, from the facial expressions to the clothing details. Manufacturers use molds to produce a large number of identical action figures, which are then painted and assembled. The use of molds in toy production ensures that the toys are consistent in quality and appearance, meeting the high standards of consumers. It also allows for cost - effective production, making toys more accessible to a wide range of customers. Whether it's a small, collectible toy or a large - scale playset, molds are the key to transforming plastic materials into engaging and market - competitive consumer goods.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology brings a wealth of experience and unique advantages to the table in the realm of mold - related plastic molding.

We possess advanced mold manufacturing technology. Our state - of - the - art equipment and highly skilled technicians enable us to create molds with exceptional precision. For example, we utilize high - speed CNC machining centers to ensure that every mold cavity and core is machined to the tightest tolerances, often within ±0.01mm. This level of precision is crucial for producing high - quality plastic products with consistent dimensions.

Customization is at the heart of our service. We understand that each client has unique requirements, and we work closely with them from the initial design concept to the final product. Whether it's a complex automotive component or a specialized consumer goods item, we can tailor the mold design and manufacturing process to meet specific needs. Our in - house design team uses the latest CAD/CAM software to develop innovative mold designs, ensuring that our clients' products stand out in the market. Additionally, we offer a wide range of plastic materials and finishing options, allowing for further customization of the final plastic products.