Introduction

In the vast world of machinery, the choice of components can significantly impact performance, efficiency, and cost. Among these components, plastic spur gears have emerged as a revolutionary solution, offering a unique set of advantages over their traditional counterparts. This article delves deep into the realm of plastic spur gears, exploring their features, applications, and why they are becoming the go - to choice for many industries.

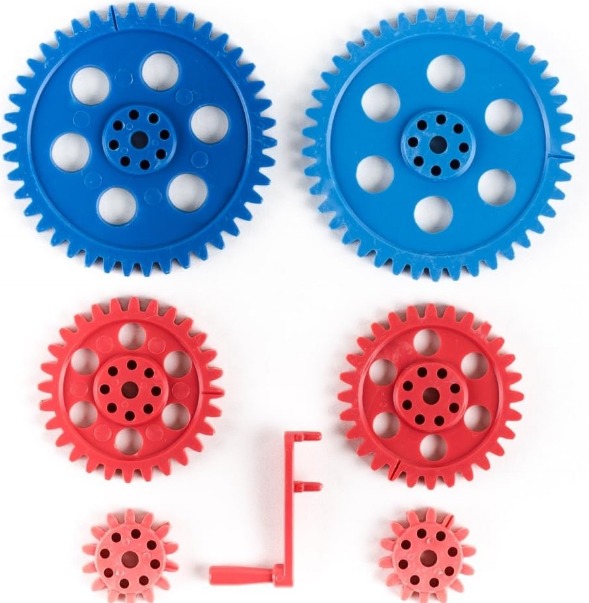

Understanding Plastic Spur Gears

Plastic spur gears are mechanical components with teeth evenly spaced around the circumference of a cylindrical shape. They are designed to transmit power and motion between parallel shafts by meshing with another gear. Unlike metal gears, which are commonly made of steel or brass, plastic spur gears are crafted from various types of engineering plastics such as acetal (POM), nylon (PA), and polypropylene (PP).

These plastics are carefully selected for their specific mechanical properties, chemical resistance, and cost - effectiveness. For example, acetal is known for its high stiffness, low friction, and excellent dimensional stability, making it an ideal material for precision - engineered plastic spur gears. Nylon, on the other hand, offers good impact resistance, self - lubrication, and high strength - to - weight ratio, which are beneficial in applications where gears need to withstand occasional shocks and vibrations while remaining lightweight.

Plastic spur gears play a crucial role in modern machinery. They are used in a wide range of applications, from small - scale consumer electronics to large - scale industrial equipment. In a nutshell, they are the unsung heroes that enable the smooth operation of countless mechanical systems, quietly revolutionizing the way motion is transferred and managed in machinery.

Types of Plastic Materials for Spur Gears

The performance of plastic spur gears is highly dependent on the type of plastic material used. Different plastics offer unique properties, making them suitable for various applications. Here are some of the most commonly used plastic materials for spur gears:

Nylon

Nylon, also known as polyamide (PA), is a popular choice for plastic spur gears due to its high strength - to - weight ratio. It has excellent wear resistance, which means it can withstand the constant friction that occurs during gear operation. For example, in industrial sewing machines, nylon spur gears are often used. These machines require gears that can handle high - speed rotation and frequent starts and stops. Nylon gears can endure this harsh operating condition, reducing the need for frequent replacements. In small motors, nylon gears also prove to be effective. They can transmit power smoothly while remaining lightweight, which is beneficial for applications where weight is a concern, such as in portable electronic devices that are powered by small motors. Additionally, nylon has self - lubricating properties, which helps to reduce friction and wear even further, leading to longer - lasting gears.

Acetal

Acetal, or polyoxymethylene (POM), is prized for its outstanding dimensional stability. This means that it maintains its shape accurately even under different environmental conditions and mechanical stresses. In applications with low - load and low - speed requirements, such as in electronic clocks, acetal spur gears are a great fit. Electronic clocks need gears that can rotate precisely to keep accurate time, and acetal's dimensional stability ensures that the gears mesh correctly over time. Small fans, like those used in computer cooling systems or small household appliances, also often use acetal gears. These fans operate at relatively low speeds and do not require high - strength gears. Acetal gears can provide the necessary precision and durability while being cost - effective. Moreover, acetal has a low coefficient of friction, which allows for smooth operation and reduces energy consumption.

Polyethylene

Polyethylene (PE) is characterized by its light weight and strong chemical resistance. When gears are used in environments where they come into contact with various chemical substances, such as in chemical pipeline valves, polyethylene spur gears are an ideal choice. Chemical pipelines may carry corrosive liquids or gases, and polyethylene's resistance to these chemicals ensures that the gears do not degrade easily, maintaining the proper functioning of the valves. In laboratory small stirrers, which are often used to mix chemical solutions, polyethylene gears can also perform well. The light - weight nature of polyethylene reduces the overall weight of the stirrer, making it easier to handle, and its chemical resistance protects the gears from the substances being stirred. Polyethylene comes in different densities, such as low - density polyethylene (LDPE) and high - density polyethylene (HDPE), each with slightly different properties that can be selected according to specific application needs.

Polycarbonate

Polycarbonate (PC) is well - known for its high impact strength. In equipment that is prone to impacts, such as the internal gears in the casing of power tools, polycarbonate spur gears are frequently employed. Power tools are often subject to sudden impacts during use, and polycarbonate gears can withstand these impacts without breaking or deforming significantly, ensuring the continued operation of the tool. In sports equipment internal transmission components, like those in some exercise machines, polycarbonate gears are also suitable. These components may experience impacts during the normal use of the sports equipment, and polycarbonate's impact - resistant property makes it a reliable material choice. Additionally, polycarbonate has good dimensional stability and can maintain its shape under different temperatures, which is important for the proper meshing of gears in various operating conditions.

Comparison with Metal Gears

Create a Comparison Table

While metal gears have long been the standard in the machinery industry, plastic spur gears are rapidly gaining ground due to their unique advantages. A comparison between the two can help in understanding when to choose plastic spur gears over metal ones. The following table outlines some key differences:

| Feature | Plastic Spur Gears | Metal Gears |

| Weight | Significantly lighter. For example, a plastic spur gear of a certain size might weigh only 10 - 20% of its metal counterpart with the same dimensions. This makes them ideal for applications where weight reduction is crucial, such as in portable devices or lightweight machinery. | Heavier, which can add unnecessary weight to the overall machinery, especially in large - scale applications where multiple gears are used. |

| Cost | Generally much lower. The raw materials for plastic gears are less expensive, and the manufacturing processes, such as injection molding, are often more cost - effective. In large - scale production, the cost savings can be substantial, sometimes up to 50 - 70% compared to metal gears. | Higher cost due to the expensive raw materials, especially for high - quality metals like stainless steel or brass, and more complex manufacturing processes like forging or machining. |

| Noise | Produce less noise during operation. Their soft material reduces the impact and vibration between meshing teeth. In applications like household appliances or office equipment, the quiet operation of plastic gears is highly desirable. | Tend to be noisier, especially in high - speed or high - load applications, as the hard metal teeth can cause more friction and impact when meshing. |

| Corrosion Resistance | Excellent corrosion resistance, especially in the presence of moisture, chemicals, or in humid environments. This makes them suitable for use in industries such as food processing, where contact with water or cleaning agents is common, or in chemical plants. | Prone to corrosion, especially in the presence of moisture and certain chemicals. Metal gears often require additional coatings or treatments to prevent corrosion, which adds to the cost and maintenance requirements. |

| Strength | Have lower tensile strength compared to metal gears, but can be engineered to have sufficient strength for many low - to - medium load applications. For instance, in small - scale electronics or toys, plastic gears can perform well under normal operating conditions. | Generally have higher tensile strength and can withstand higher loads and stresses, making them suitable for heavy - duty industrial applications such as in large - scale manufacturing equipment or automotive transmissions. |

| Lubrication Requirement | Some plastic materials, like nylon, have self - lubricating properties, reducing or eliminating the need for external lubrication. This simplifies maintenance and reduces the risk of oil leakage, which is important in applications where cleanliness is required. | Usually require regular lubrication to reduce friction and wear, which means more maintenance efforts and potential environmental concerns if the lubricant leaks. |

Choosing the Right Plastic Spur Gear

Selecting the appropriate plastic spur gear is crucial to ensure optimal performance and longevity of your machinery. Here are some key factors to consider:

Clarify Your Needs

Before choosing a plastic spur gear, it is essential to clearly define your application requirements and the operating environment. Consider factors such as load size, rotational speed, temperature, and humidity. For example, if the gear will be used in a high - load application, you need to ensure that the chosen gear can withstand the stress. In a high - speed application, the gear should be able to operate smoothly without excessive vibration or wear. Understanding these factors will help you narrow down your options and make a more informed decision.

Material Selection

As mentioned earlier, different plastic materials have different properties. For high - load applications, nylon might be a better choice due to its high strength - to - weight ratio and wear resistance. In applications with low - load and low - speed requirements, acetal can be a cost - effective option because of its dimensional stability and low coefficient of friction. If the gear will be exposed to chemicals, polyethylene's chemical resistance makes it a suitable candidate. Polycarbonate is ideal for applications where the gear may be subject to impacts. So, carefully assess the demands of your application to select the most suitable plastic material for your spur gear.

Design Optimization

The design of the plastic spur gear can significantly impact its performance and efficiency. Some key design considerations include tooth shape, module, number of teeth, and tooth width. The tooth shape affects how the gears mesh with each other. A proper tooth shape can reduce noise, vibration, and wear. The module is a measure of the size of the gear teeth, and it influences the gear's strength and the amount of power it can transmit. The number of teeth determines the gear ratio, which is crucial for controlling the speed and torque of the machinery. The tooth width also plays a role in the gear's load - bearing capacity. By optimizing these design parameters, you can ensure that the plastic spur gear performs at its best in your specific application.

Supplier and After - sales Service

Choosing a reliable supplier is as important as selecting the right gear. A good supplier should have the necessary qualifications and a good reputation in the industry. They should be able to provide high - quality products that meet your specifications. Additionally, excellent after - sales service is essential. This includes providing technical support, handling warranty claims promptly, and offering replacement parts when needed. You can check online reviews, ask for references from other customers, or evaluate the supplier's response to your initial inquiries to gauge their service quality. A reliable supplier will not only provide you with a great product but also support you throughout the lifespan of the plastic spur gear, ensuring that your machinery operates smoothly.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the potential of plastic spur gears. In the process of custom - making products, we have found that plastic spur gears are extremely versatile. Their unique properties allow us to meet the special needs of various clients. For example, when clients require components for applications in corrosive environments, we can use plastic materials with high chemical resistance to manufacture spur gears.

We also provide professional advice to our clients. Based on our in - depth understanding of different plastic materials and gear design, we help clients select the most suitable plastic spur gears for their specific applications. This ensures that the final product not only meets the performance requirements but also has a long service life.

Quality is our top priority. Yigu Technology has strict quality control measures in place to guarantee that each plastic spur gear we produce meets high - quality standards. We use advanced manufacturing techniques and conduct thorough inspections at every production stage, from raw material procurement to the final product delivery, to ensure that our clients receive reliable and durable plastic spur gears.

FAQ

Are plastic spur gears suitable for high - load applications?

Plastic spur gears generally have lower tensile strength compared to metal gears, so they are not typically the first choice for high - load applications. However, some high - performance plastics like nylon can be engineered to handle medium - load applications quite well. For example, in some small - scale industrial equipment with loads up to 50 - 100 Nm (Newton - meters), nylon plastic spur gears can function properly. But for applications with extremely high loads, say above 500 Nm, metal gears are usually more suitable. In cases where plastic gears are used in high - load situations, they may need to be designed with larger tooth widths or additional reinforcement structures to improve their load - bearing capacity.

How do I determine the right size of plastic spur gear for my application?

To determine the right size of a plastic spur gear, several factors need to be considered. First, calculate the required gear ratio based on the speed and torque requirements of your machinery. For example, if you need to increase the torque output, you may need a larger - sized driven gear compared to the driving gear. Consider the available space for installation. Measure the dimensions of the area where the gear will be placed to ensure that the chosen gear size fits properly. The load and rotational speed also play a role. Higher - load or higher - speed applications may require larger - sized gears to handle the stress and prevent premature wear. Additionally, refer to gear design standards and consult with gear manufacturers or suppliers who can provide expert advice based on your specific application details.

Can plastic spur gears be used in high - temperature environments?

The suitability of plastic spur gears in high - temperature environments depends on the type of plastic material. Nylon can generally withstand temperatures up to around 80°C, acetal has a working temperature range of up to about 100°C, polyethylene can handle temperatures up to 100 - 140°C depending on its density, and polycarbonate can operate in environments up to around 130 - 140°C under normal conditions. In high - temperature environments approaching or exceeding these limits, the plastic may soften, lose its mechanical properties, and cause the gear to fail. If you need to use plastic spur gears in high - temperature applications, consider using heat - resistant plastics or adding heat - dissipating mechanisms to keep the gear temperature within the acceptable range.