From the smartphone in your pocket to the jet engine soaring overhead, countless components that define our world start as raw material and are transformed into precise, functional parts through a fundamental manufacturing process: milling. This article serves as your comprehensive guide to milling parts, demystifying the process, materials, applications, and critical considerations for sourcing. Whether you're an engineer designing a new product, a procurement specialist seeking a reliable supplier, or simply curious about how complex metal and plastic parts are made, you'll find actionable insights and expert knowledge here to inform your decisions.

What Are Milling Parts?

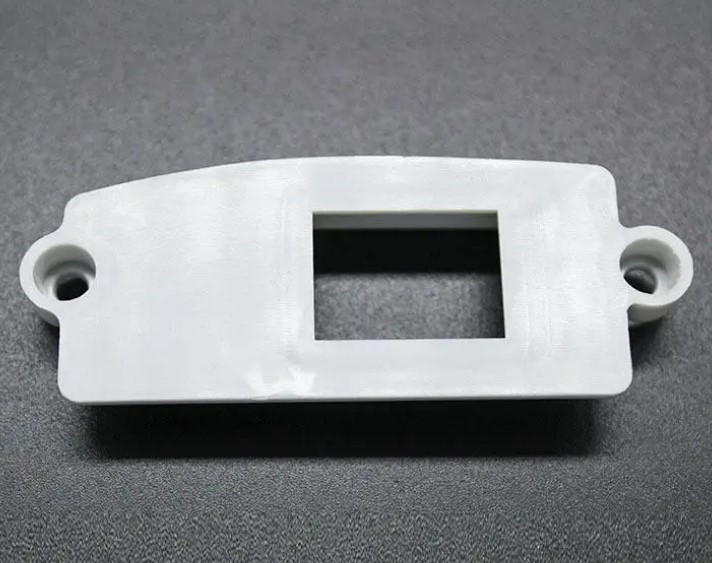

Milling parts are components manufactured using a milling machine, where a rotating cutting tool removes material from a solid workpiece. Unlike turning, where the workpiece rotates, in milling, the tool spins. This process is exceptionally versatile, capable of creating a vast array of shapes, features, and surface finishes. These components are characterized by their precision, dimensional accuracy, and the presence of features like flat surfaces, slots, grooves, pockets, threads, and complex contours.

The defining feature of a milled part is its genesis from a subtractive process. Think of it like sculpting from a block of marble, but with digital precision. A CNC (Computer Numerical Control) milling machine follows a programmed toolpath to carve the final geometry from a larger blank, such as a block of aluminum, a steel billet, or a plastic sheet. The resulting parts can range from simple brackets to intricate aerospace components with tight tolerances.

What Materials Are Best Suited for Milling Parts?

The choice of material is pivotal, impacting the part's cost, strength, weight, corrosion resistance, and machinability. Here’s a breakdown of the most common material families and their ideal applications:

| Material Family | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Metals & Alloys | Aluminum 6061, 7075 | Lightweight, good strength-to-weight ratio, excellent machinability, corrosion resistant. | Aerospace frames, automotive parts, electronic enclosures, robotics. |

| Stainless Steel (304, 316) | High strength, excellent corrosion and heat resistance, durable. | Medical instruments, food processing equipment, marine hardware. | |

| Steel (Mild, Alloy) | High strength and toughness, cost-effective. | Industrial machinery, automotive components, tooling fixtures. | |

| Titanium (Ti-6Al-4V) | Exceptional strength-to-weight ratio, biocompatible, corrosion resistant. | Aerospace fasteners, medical implants, high-performance automotive. | |

| Plastics & Composites | Delrin (POM) | High stiffness, low friction, excellent dimensional stability. | Gears, bearings, insulators. |

| Nylon (PA) | Good wear resistance, toughness, and fatigue resistance. | Bushings, spacers, wear pads. | |

| PTFE (Teflon) | Excellent chemical resistance, very low friction, high-temperature tolerance. | Seals, gaskets, insulating parts. | |

| Peek | Extremely high strength and temperature resistance, biocompatible. | Aerospace, medical, and semiconductor components. |

Expert Insight: For high-volume production, machinability is a critical economic factor. For instance, while both are aluminum alloys, 6061 is generally easier and faster to machine than 7075, though 7075 is stronger. A seasoned engineer will always balance material performance with manufacturability and total cost.

How Does the Milling Process Work?

Modern milling is a symphony of digital design and mechanical precision. The process typically follows these steps:

- Design & Programming: It begins with a 3D CAD (Computer-Aided Design) model. Using CAM (Computer-Aided Manufacturing) software, a programmer defines the toolpaths, selecting cutting tools, spindle speeds, feed rates, and depth of cuts. This generates the G-code that instructs the CNC machine.

- Setup: The chosen material blank is securely clamped to the machine's worktable. The correct cutting tools are loaded into the machine's automatic tool changer (ATC).

- Machining Operations: The CNC mill executes the program. Common operations include:

- Face Milling: Creating a flat surface.

- Peripheral Milling: Cutting the outer contours of a part.

- Pocketing: Clearing out material to form enclosed cavities.

- Drilling & Boring: Creating holes.

- Thread Milling: Producing threads.

- Finishing: After rough machining removes bulk material, finishing passes with sharper tools and higher speeds achieve the final dimensions and surface quality. Additional post-processing like deburring, anodizing, or plating may follow.

Case in Point: Consider a drone's central frame. The process starts with a solid block of aluminum 7075. The CNC mill first faces all sides for flatness, then precisely machines out lightening pockets to reduce weight while maintaining rigidity, drills mounting holes for motors and electronics with tight positional accuracy, and finally creates cable routing channels. The entire complex geometry is produced in one setup, ensuring perfect alignment of all features.

What Are the Key Applications of Milled Components?

Milled parts are the backbone of precision engineering across industries. Their application is dictated by the need for strength, custom geometry, and reliable tolerances.

- Aerospace & Defense: This sector demands the utmost in reliability and performance. Milled components like turbine blades, structural airframe elements, landing gear parts, and radar housings are common. Materials like titanium and high-strength aluminum are machined to withstand extreme stresses and temperatures.

- Automotive & Motorsports: From engine blocks and transmission housings to custom suspension brackets and lightweight chassis components, milling enables both high-volume production and low-volume, high-performance prototyping. The shift to electric vehicles has created demand for precisely milled battery enclosures and motor housings.

- Medical Technology: Surgical instruments, implants (knee joints, spinal cages), and diagnostic equipment require biocompatible materials (like titanium and Peek), exceptional surface finishes, and sterile-cleannable geometries, all achievable through precision milling.

- Industrial Machinery: Milling produces robust gears, shafts, housings, and custom jigs and fixtures that keep production lines running. The ability to create one-off replacement parts quickly is a key advantage.

- Electronics & Telecom: Heat sinks for CPUs, waveguide components for radar, and robust enclosures for servers are all precision-milled to manage thermal dynamics and protect sensitive electronics.

What Tolerances Can Be Achieved in Milling Parts?

Tolerance defines the permissible limit of variation in a physical dimension. Achieving tight tolerances is a hallmark of advanced milling capabilities and directly impacts cost and performance.

- Standard Tolerances: For many commercial applications, a tolerance of ±0.005 inches (±0.127 mm) is standard and cost-effective.

- Precision Tolerances: With modern CNC mills, skilled operators, and controlled environments, tolerances of ±0.001 inches (±0.0254 mm) or even ±0.0005 inches (±0.0127 mm) are achievable for critical features.

- High-Precision / Micromachining: In specialized industries like medical or optics, tolerances within ±0.0001 inches (±0.00254 mm) are possible using specialized machine tools.

Critical Factors Influencing Tolerance:

- Machine Tool Calibration & Rigidity: A worn or less rigid machine cannot hold tight tolerances.

- Tooling Quality & Wear: Sharp, high-quality tools are essential.

- Material Stability: Some materials warp or move more during machining.

- Thermal Management: Heat generated during cutting can expand the part and machine, so temperature control is crucial.

- Operator Expertise: Experience in setup and toolpath optimization is irreplaceable.

Data Point: A study by the National Institute of Standards and Technology (NIST) highlights that effective thermal compensation in CNC machines can improve dimensional accuracy by over 50% for tight-tolerance work.

How Do You Choose the Right Milling Parts Supplier?

Selecting a partner for your milled components is a strategic decision. Look beyond just price per piece and evaluate these key aspects:

- Technical Capability & Equipment: Do they have the right CNC machines (3-axis, 4-axis, 5-axis) and measurement equipment (CMMs, optical comparators) for your part's complexity and tolerance requirements?

- Engineering Support: A great supplier acts as a manufacturing partner. They should offer Design for Manufacturability (DFM) feedback to optimize your part for cost-effective production without compromising function.

- Material & Quality Certifications: Verify they source materials from reputable mills and have quality management systems (like ISO 9001) in place. For regulated industries (e.g., medical, aerospace), look for relevant certifications (AS9100, ISO 13485).

- Prototyping vs. Production Volume: Some shops excel at quick-turn prototypes, while others are optimized for high-volume production. Ensure their business model aligns with your needs.

- Transparent Communication & Proven Track Record: Request case studies or samples similar to your project. Clear communication about timelines, costs, and potential challenges is a must.

Ask This Question: "Can you walk me through your process for ensuring tolerance stability on a high-volume run of parts requiring ±0.001" on critical bore diameters?" The answer will reveal their process control depth.

Conclusion

Milling parts are more than just manufactured items; they are the physical manifestations of design intent, enabling innovation across every technical field. Understanding the process, from material science and machining principles to tolerance economics and supplier partnerships, empowers you to make better decisions—whether you're designing a groundbreaking product or sourcing a critical component. By leveraging the versatility and precision of modern milling, you can turn complex ideas into reliable, high-performance reality.

FAQ on Milling Parts

What is the difference between milling and turning?

Milling uses a rotating cutting tool against a stationary (or moving in multiple axes) workpiece to create complex features like flats, pockets, and slots. Turning (on a lathe) rotates the workpiece against a stationary cutting tool, primarily producing cylindrical or conical shapes like shafts and rings.

How do I reduce the cost of custom milling parts?

Key strategies include: simplifying the design to reduce machining time, specifying standard tool sizes for holes and radii, choosing a readily available and easily machinable material, relaxing non-critical tolerances, and considering the manufacturability of features like deep pockets or thin walls during the design phase.

What are the main advantages of CNC milling over manual milling?

CNC milling offers superior repeatability, accuracy, and complexity handling. Once programmed, a CNC machine can produce identical parts indefinitely. It can execute complex 3D contours impossible to do manually and operates with minimal human intervention, increasing consistency and productivity.

What file formats are needed to get a quote for milling parts?

Suppliers typically require a 3D model in a neutral format like STEP (.stp/.step) or IGES (.igs), along with a 2D drawing in PDF format. The drawing should clearly specify critical dimensions, tolerances, materials, and surface finish requirements.

Can milling be used for both prototyping and full production?

Absolutely. CNC milling is ideal for both. For prototyping, it allows for rapid iteration with real materials. For production, it can be scaled efficiently, especially for low to medium volumes, or used to create molds for high-volume casting or injection molding processes.

Contact Yigu for Custom Manufacturing.

Are you ready to bring your precision milling parts to life? At Yigu, we combine state-of-the-art CNC machining technology with deep engineering expertise to deliver components that meet your exact specifications, from prototype to production run. Our team is dedicated to providing DFM feedback, competitive pricing, and reliable timelines.

Let's discuss your project. Submit your CAD files and requirements today for a comprehensive quote and expert manufacturing guidance.