Selecting the right injection molded plastic parts manufacturer is a critical decision that directly impacts your product's quality, cost, and time-to-market. It's more than just finding a supplier; it's about forming a strategic partnership. This guide breaks down the essential factors—from industry experience and quality certifications to production capabilities and cost-effectiveness—into a clear, actionable framework. We'll help you navigate the selection process with the confidence of an industry insider, ensuring you partner with a manufacturer that delivers precision, reliability, and true value.

1. Introduction

1.1 The Significance of Injection Molded Plastic Parts

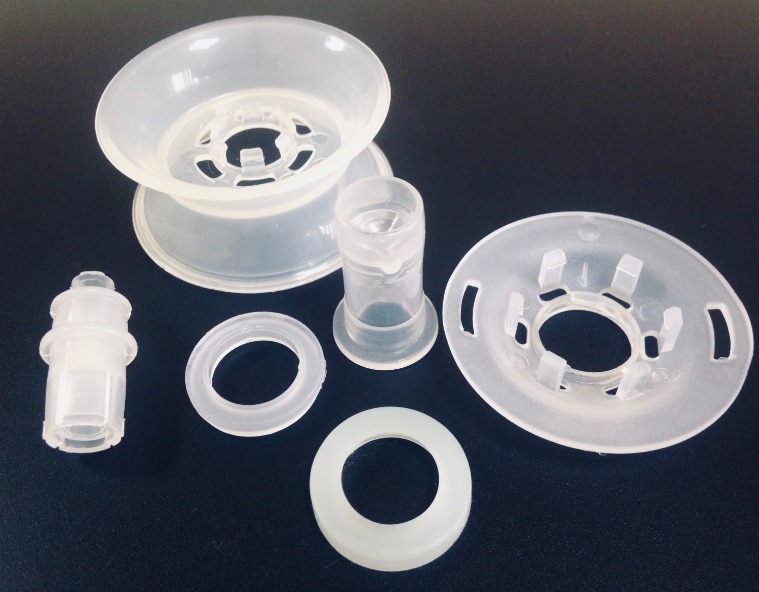

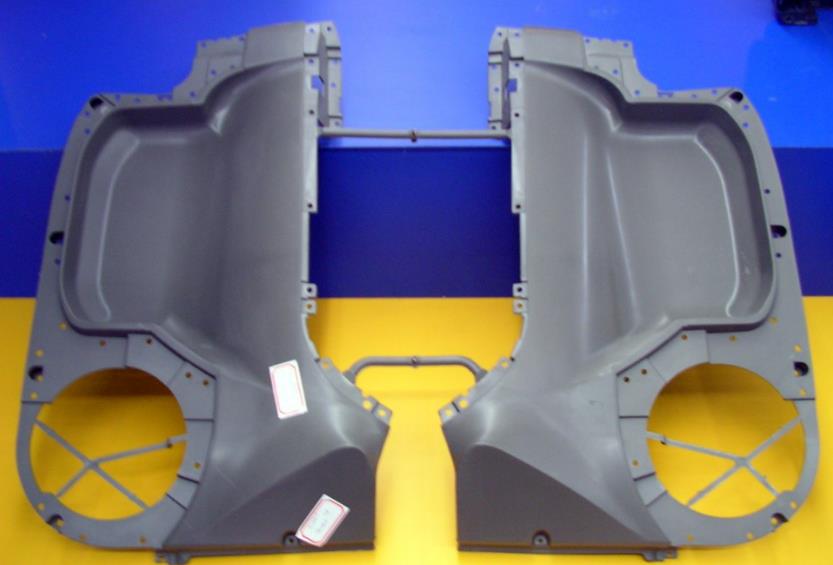

Why are injection molded plastic parts the backbone of so many products? From the tiny gear in your smartwatch to the durable housing of your car's dashboard, this manufacturing process offers unparalleled efficiency, repeatability, and design flexibility. The quality and performance of these plastic components are non-negotiable—they define your product's durability, safety, and user experience. Therefore, the manufacturer you choose becomes an extension of your own engineering and quality teams. A subpar part can lead to catastrophic failures, costly recalls, and irreparable brand damage. Understanding this significance is the first step toward making an informed, diligent selection.

2. Key Factors to Consider

2.1 Experience and Expertise

Don't just look for a manufacturer; look for a proven problem-solver. Deep industry knowledge and technical expertise are forged over years and across countless projects. They mean your partner has likely already navigated the specific challenges your project presents.

2.1.1 Years in the Industry

How many cycles has their machinery—and their team—been through? A company with 15+ years in plastic injection molding has weathered economic shifts, technological revolutions, and evolving material science. This longevity suggests stability, refined processes, and a wealth of tacit knowledge. For instance, a veteran engineer might spot a potential sink mark or warp issue in your design that simulation software could miss, saving weeks of troubleshooting.

2.1.2 Industry Specializations

Does your part serve the medical, automotive, or consumer electronics sector? Each has unique "rules of the game." A manufacturer specializing in medical-grade plastic parts will be intimately familiar with ISO 13485, biocompatibility protocols, and cleanroom molding requirements. They'll understand the critical importance of traceability for every component. Choosing a specialist over a generalist often translates to faster compliance, fewer errors, and a product that meets stringent industry-specific performance benchmarks from the first run.

2.2 Quality Assurance

Quality cannot be inspected into a part; it must be built into the process. A manufacturer's commitment to quality assurance is the bedrock of trust.

2.2.1 Certifications

Certifications are your first line of objective verification. Look for:

- ISO 9001: The baseline for a certified Quality Management System.

- IATF 16949: Essential for automotive supply, focusing on defect prevention and supply chain consistency.

- ISO 13485: Non-negotiable for medical device manufacturing.

- UL Recognition: Important for components requiring specific safety standards, like those in electrical applications.

These are not just plaques on the wall. They represent a framework for consistent, documented, and continually improving processes.

2.2.2 Quality Control Processes

What happens on the production floor? Elite manufacturers integrate Statistical Process Control (SPC) to monitor production in real-time, catching deviations before they become defects. They employ advanced metrology like Coordinate Measuring Machines (CMM) and optical scanners for first-article and in-process inspections. Ask for their Production Part Approval Process (PPAP) documentation. A robust PPAP packet—including design records, material certifications, and capability studies—provides transparent, data-driven proof that their process can produce your part to spec, consistently.

2.3 Production Capabilities

Can they not only make your part but also scale with your vision? Assessing production capabilities ensures they have the muscle for your project's lifecycle.

2.3.1 Equipment and Technology

The machine portfolio tells a story. A mix of all-electric, hybrid, and hydraulic presses indicates the ability to match the right machine to the part's requirements (precision, speed, clamping force). Look for ancillary technology: automated robotic part removal for consistency and reduced cycle times, hot runner systems for complex parts to reduce waste, and in-mold sensors for real-time quality feedback. For example, manufacturing a thin-wall, optical-grade lens requires a different setup than a large, structural bin.

2.3.2 Production Capacity

Capacity is about more than just press tonnage. It's a holistic view of their ability to deliver your volume on time.

| Capacity Factor | What to Ask | Why It Matters |

|---|---|---|

| Press Range | What is your clamp force range (e.g., 50 to 1000 tons)? | Ensures they can handle parts from tiny to large. |

| Mold Shop | Do you have in-house mold making and maintenance? | Controls lead times, quality, and cost for tooling. |

| Shift Schedule | How many shifts do you operate? Can you scale for surges? | Determines true output potential and flexibility. |

| Supply Chain | How do you secure raw material (pellets) for long runs? | Prevents production stoppages due to material shortages. |

2.4 Cost-effectiveness

The lowest quote can be the most expensive choice. True cost-effectiveness balances the initial price with the total cost of ownership over the part's production life.

2.4.1 Price Structure

Demand transparency. A detailed quote should break down:

- Non-recurring Engineering (NRE) Costs: Mold design, fabrication, and testing.

- Piece Price: The cost per part, detailing material, labor, and overhead.

- Minimum Order Quantities (MOQs): Can they accommodate both prototyping and full production runs?

Beware of quotes that seem too good to be true—they often hide costs in secondary operations, inferior materials, or lax tolerances that lead to assembly issues downstream.

2.4.2 Value for Money

Value is delivered through expertise that reduces your total cost. An experienced manufacturer might propose a design for manufacturability (DFM) change that consolidates two parts into one, eliminating assembly steps and reducing final part cost by 20%. They might recommend a slightly more expensive but faster-cycling material that lowers the per-part cost at high volumes. The goal is a partnership focused on optimizing the entire production ecosystem, not just winning a single purchase order.

2.5 Customer Service and Communication

Your project's success hinges on a seamless flow of information. Responsive communication and dedicated support are indicators of a true partner.

2.5.1 Responsiveness

Gauge this early. Are your initial inquiries met with timely, knowledgeable replies? Is a dedicated project manager assigned to your account? During the quoting phase, a manufacturer invested in understanding your needs will ask probing questions about end-use, testing requirements, and lifecycle expectations—not just request a CAD file. Their communication style should be proactive, clear, and technically detailed.

2.5.2 After-sales Support

The relationship doesn't end when the first shipment leaves the dock. What happens if there's a quality issue six months into production? Reliable manufacturers stand behind their work with clear warranty terms and a structured process for addressing concerns. They should also be a resource for future iterations, offering insights on material upgrades or process improvements. This long-term technical partnership is where the greatest value is often realized.

FAQ

What is the most important factor when choosing an injection molder?

While all factors are interconnected, proven expertise and a robust Quality Management System are paramount. A manufacturer with deep experience in your industry and certified processes (like IATF 16949 or ISO 13485) provides a foundation of reliability that mitigates the vast majority of risks related to quality, compliance, and performance.

How do I evaluate a manufacturer's quality if I can't visit in person?

Request detailed evidence. Ask for their quality manual, sample PPAP packets (with proprietary info redacted), and certification certificates. A virtual tour via video call of their production floor and quality lab can be very revealing. Also, insist on receiving first-article inspection reports and material certification documents with your initial production run.

What's the difference between a "cheap" quote and a "cost-effective" one?

A cheap quote often cuts corners on material grade, tool steel quality, or process control, leading to higher defect rates, shorter tool life, and field failures. A cost-effective quote provides a transparent breakdown, may include valuable DFM suggestions to lower long-term cost, and comes from a manufacturer whose processes are designed to produce consistent, high-quality parts with minimal waste and rework.

Is it better to choose a local or overseas manufacturer for plastic parts?

The decision balances cost, communication, and logistics. Overseas manufacturers may offer lower piece prices but come with challenges in time zones, language barriers, IP protection, and longer supply chains. Local or regional manufacturers (like in North America) typically offer better real-time communication, easier collaboration on DFM, faster turnaround on iterations, and reduced shipping complexity. For complex, high-precision, or rapidly evolving products, the value of close partnership often outweighs initial price differences.

What should a Design for Manufacturability (DFM) report include?

A comprehensive DFM report is a sign of an expert partner. It should analyze:

- Draft Angles & Wall Thickness: Recommendations for uniform walls and adequate draft for part ejection.

- Gate & Ejector Pin Locations: Proposed locations to minimize visibility and optimize fill.

- Material Selection: Analysis of your chosen resin for the application, with alternatives if needed.

- Tolerance Analysis: A realistic assessment of which critical dimensions are achievable.

- Mold Flow Analysis (if included): Simulations predicting fill patterns, potential weld lines, and sink marks.

Contact Yigu Technology for Custom Manufacturing

Ready to translate your design into high-precision, reliable injection molded plastic parts? At Yigu Technology, we combine decades of engineering expertise with state-of-the-art production facilities and an unwavering commitment to quality. We specialize in guiding projects from concept to mass production, providing actionable DFM feedback, transparent pricing, and dedicated project management.

Partner with us for:

- End-to-End Solutions: From mold design and fabrication to high-volume production and assembly.

- Industry-Specific Expertise: Serving demanding sectors including automotive, medical, and consumer electronics.

- Certified Quality: Our processes are built on robust, certified quality management systems.

- Transparent Collaboration: You’ll have a direct line to our engineering team throughout the process.

Contact us today for a confidential consultation and detailed quote. Let's discuss how we can optimize your design for manufacturability and deliver plastic components that meet your highest standards for performance, cost, and timely delivery.