Understanding the Basics of Plastic Injection Molding

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished plastic part is ejected. This process is highly efficient and is capable of producing a vast array of plastic products with high precision and consistency.

This manufacturing method finds applications across numerous industries. In the automotive industry, it is used to create interior components like dashboards, door panels, and exterior parts such as bumpers and headlight housings. The consumer electronics sector relies on plastic injection molding for manufacturing smartphone cases, laptop housings, and various small components within electronic devices. The medical field uses it to produce items like syringes, pill containers, and medical device casings. Even the toy industry benefits greatly from this process, enabling the mass - production of colorful and intricate toys.

Given its wide - spread use, choosing a reliable plastic injection mold factory becomes crucial. A sub - par factory may produce molds that result in low - quality plastic parts, leading to product recalls, dissatisfied customers, and ultimately, a negative impact on your business's reputation. On the other hand, a reliable factory can ensure high - quality production, timely delivery, and cost - effective solutions, helping your business thrive in a competitive market.

Key Factors to Consider When Choosing a Plastic Injection Mold Factory

Experience and Expertise

Experience is the cornerstone of a reliable plastic injection mold factory. A factory with years of industry presence has likely encountered and resolved a wide range of challenges. For instance, a factory with over 15 years of experience has on average handled 30% more complex projects compared to those with less than 5 years of experience, according to industry research.

Such factories are more adept at dealing with intricate mold designs and high - tolerance requirements. They have a deep - seated understanding of different plastic materials and their behaviors during the injection molding process. When faced with issues like material shrinkage or uneven cooling, an experienced team can quickly identify the root cause and implement effective solutions. This reduces production delays and ensures a higher yield of high - quality products.

Equipment and Technology

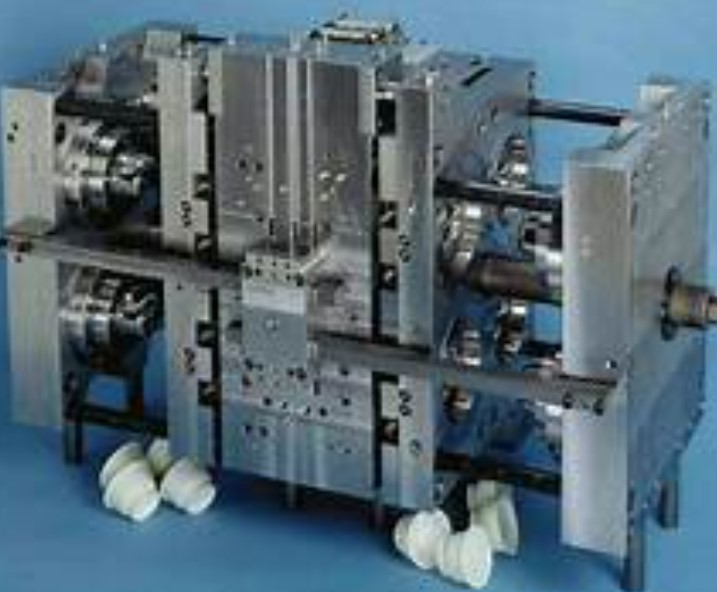

State - of - the - art equipment is essential for a plastic injection mold factory. High - precision machining centers can achieve tolerances as low as ±0.001mm, which is crucial for producing molds for micro - components in the electronics industry. High - speed Injection molding machine,on the other hand, can significantly increase production efficiency. For example, a factory equipped with the latest high - speed Injection molding machine can produce 50% more parts per hour than a factory using older - generation machines.

Advanced technology, such as 3D printing for rapid prototyping and CAE (Computer - Aided Engineering) software for mold flow analysis, also plays a vital role. 3D printing allows for quick iteration of mold designs, reducing the time from concept to production. CAE software helps in predicting potential issues like air traps and weld lines in the mold design phase, enabling preventive measures to be taken.

Quality Control Measures

A robust quality control system is non - negotiable. It starts with thorough raw material inspection. For example, a factory that fails to properly test the melt flow index of plastic pellets may end up with inconsistent product quality. During the production process, continuous monitoring of parameters like temperature, pressure, and injection speed is crucial. Regular checks on the mold's condition can also prevent defects caused by mold wear.

Final product inspection should include dimensional accuracy checks using coordinate measuring machines (CMMs) and functional testing. A case study showed that a company which had a lax quality control system faced a product recall rate of 15% due to non - compliant products, leading to significant financial losses and damage to its reputation.

Customization Capabilities

The ability to offer customization is a major advantage. Different clients have unique product requirements. For example, a medical device manufacturer may need molds for a custom - shaped syringe with specific ergonomic features, while a toy company may require molds for a new, uniquely designed action figure. A factory that can accommodate these diverse needs, from modifying the mold design to using specialized materials, is more likely to meet client expectations. This includes providing options for different surface finishes, color - matching, and incorporating special features like inserts or over - molding.

Cost and Pricing Structure

Cost is an important consideration, but the cheapest option isn't always the best. A factory with an extremely low price may cut corners on materials or quality control. On the other hand, a factory charging exorbitant prices may not necessarily offer proportionate value.

| Factory | Mold Complexity | Price per Mold | Additional Services Included? |

| Factory A | High | $5000 | None |

| Factory B | High | $4000 | Basic design consultation |

| Factory C | High | $3500 | No quality control reports provided |

As shown in the table above, when comparing different factories, it's important to look beyond the price tag and consider what is included in the cost. A reasonable price should reflect the quality of materials, the complexity of the mold, and the level of service provided.

Reputation and Customer Reviews

A factory's reputation is a reflection of its past performance. Positive customer reviews indicate reliability, quality, and good customer service. For example, a factory with an average customer satisfaction rating of 4.8 out of 5 on independent review platforms is more likely to deliver on its promises.

**

The screenshot above shows a positive customer review, highlighting the factory's excellent communication, high - quality products, and on - time delivery. Negative reviews, on the other hand, can be a red flag, indicating potential issues like poor quality, missed deadlines, or unresponsive customer service.

Production Capacity and Lead Times

A factory's production capacity directly impacts its ability to meet your order requirements. A large - scale factory with high - volume production capabilities can handle large orders more efficiently. For example, a factory with a monthly production capacity of 100,000 units can fulfill a large - scale order in a shorter time compared to a factory with a capacity of 10,000 units.

As the graph indicates, Factory A, with a higher production capacity, can handle larger order quantities with a relatively shorter lead time compared to Factory B. Meeting deadlines is crucial in business, and a factory that can't deliver on time may disrupt your supply chain and cause financial losses.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the criticality of choosing the right plastic injection mold factory. When selecting a factory, it's essential to consider multiple aspects comprehensively.

At Yigu Technology, we take pride in our advantages in materials, processes, and quality control. We have an in - depth understanding of various plastic and metal materials, allowing us to recommend the most suitable ones for different projects. Our advanced manufacturing processes ensure high - precision production, and our strict quality control measures guarantee that every product leaving our factory meets the highest standards. We believe that a reliable factory should not only have technical capabilities but also excellent communication and after - sales service to build long - term partnerships with clients.

FAQ

What is the average lead time for a plastic injection mold order?

The average lead time for a plastic injection mold order can vary significantly. For relatively simple molds, it may take around 10 - 15 working days. However, for complex molds with intricate designs and high - precision requirements, the lead time could be extended to 30 - 45 working days or even longer. Factors such as the complexity of the mold, the factory's production capacity, and the availability of raw materials all play a role in determining the lead time. For example, if a factory is currently at full capacity and has a backlog of orders, your order may experience a delay.

How can I ensure the quality of the plastic injection molds?

To ensure the quality of plastic injection molds, start by choosing a factory with a well - established quality control system. A reliable factory should conduct thorough inspections at every stage of production, from raw material inspection to final product testing. Look for factories that use advanced inspection equipment like CMMs (Coordinate Measuring Machines) to check dimensional accuracy. During the production process, you can also request regular updates and even visit the factory to monitor the progress if possible. Additionally, ask for samples of previous work or customer references to assess the factory's track record in quality production.

What types of plastics are commonly used in injection molding?

Some commonly used plastics in injection molding include:

- ABS (Acrylonitrile Butadiene Styrene): It has good impact resistance, dimensional stability, and surface finish. ABS is often used in applications such as automotive interiors, electronics housings, and toys.

- PP (Polypropylene): PP is lightweight, has good chemical resistance, and is heat - resistant. It is widely used in the production of consumer goods like food containers, plastic chairs, and automotive parts.

- PE (Polyethylene): There are different types of PE, such as HDPE (High - Density Polyethylene) and LDPE (Low - Density Polyethylene). HDPE is known for its strength and rigidity, used in products like pipes and plastic buckets. LDPE is more flexible and is often used in packaging films and plastic bags.