Understanding the Significance of a Right Choice

Selecting the appropriate Plastic Injection Molding Factory is a pivotal decision that can significantly influence the success of your project. This choice is not merely about finding a service provider but rather a strategic partner who can align with your project's goals and requirements.

Cost - Efficiency

The cost of plastic injection molding services can vary widely among different factories. A factory with efficient operations, advanced equipment, and optimized production processes can offer competitive pricing. For example, a factory that has invested in high - speed injection machines can produce more units in less time, reducing the per - unit production cost. On the contrary, an inefficient factory may have high overhead costs, which could be passed on to you in the form of higher prices. These costs can include excessive energy consumption, frequent equipment breakdowns leading to downtime, and poor inventory management. According to industry reports, choosing the wrong factory could potentially increase your production costs by 20 - 30%, which can have a substantial impact on the overall profitability of your project.

Quality Assurance

Quality is non - negotiable when it comes to plastic injection molding. A reliable factory will have strict quality control measures in place, from the selection of raw materials to the final inspection of the molded products. They will use high - grade plastics that meet industry standards and have advanced testing equipment to ensure product integrity. For instance, in the medical device industry, where precision and biocompatibility are crucial, a top - notch plastic injection molding factory will use specialized materials and carry out rigorous quality checks, such as dimensional accuracy testing with a tolerance of ±0.01mm. Products from a low - quality factory may have issues like warping, poor surface finish, or inconsistent wall thickness, which can lead to product failures, recalls, and damage to your brand reputation.

Production Cycle

The production cycle, which includes mold design, production, and delivery, is another critical aspect. A factory with a streamlined workflow and experienced staff can complete your project in a timely manner. For example, a factory that uses computer - aided design (CAD) and computer - aided manufacturing (CAM) technologies can significantly reduce the mold design time. In a fast - paced market, time - to - market can be a decisive factor. Delays in production can cause missed market opportunities, increased inventory holding costs, and potential loss of customers. Research shows that for every week of delay in product launch, a company can lose up to 10% of its potential market share.

Key Factors to Consider

When evaluating a Plastic Injection Molding Factory, several key factors need to be taken into account. Each factor plays a crucial role in determining whether the factory can meet your project's requirements.

Experience and Expertise

Experience is the cornerstone of a reliable plastic injection molding factory. Factories with a long - standing presence in the industry have encountered a wide range of projects, from simple to highly complex. For example, a factory with over 10 years of experience is likely to have dealt with intricate mold designs, such as those for multi - component or thin - walled plastic parts.

- Novice Factories: Newly established factories may offer lower prices, but they often lack the in - depth knowledge to handle complex projects. They may struggle with issues like mold flow analysis, which is essential for ensuring uniform plastic distribution in the mold. This can lead to products with defects such as air bubbles, sink marks, or inconsistent wall thickness.

- Experienced Factories: On the other hand, experienced factories have a wealth of knowledge in materials, mold design, and processing techniques. They can provide valuable insights during the product development phase, suggesting design modifications to improve manufacturability and reduce costs. For instance, they might recommend changing the draft angles of a part to facilitate easier demolding or suggest alternative materials that are more cost - effective without sacrificing quality.

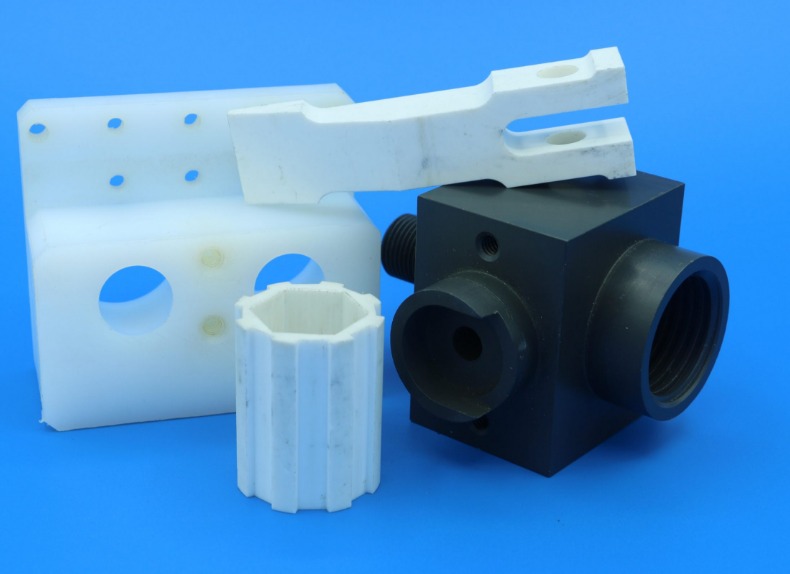

Equipment and Technology

The equipment and technology used by a plastic injection molding factory have a direct impact on the quality and efficiency of the production process.

- Outdated Equipment: Factories relying on old - fashioned injection molding machines may face limitations in terms of precision and production speed. Older machines may have a larger tolerance range, resulting in products with less accurate dimensions. They also tend to have longer cycle times, which can slow down the overall production rate. For example, an older machine might take 30 seconds to complete one injection cycle, while a modern machine can do the same in 15 seconds.

- Advanced Equipment: Modern injection molding factories are equipped with state - of - the - art machines that offer high - precision control. These machines can achieve tight tolerances, sometimes as low as ±0.001mm, making them suitable for producing parts for industries like aerospace and medical devices. Additionally, advanced factories often use computer - aided design (CAD) and computer - aided manufacturing (CAM) software. CAD allows for detailed 3D modeling of the product and mold, while CAM enables precise control of the manufacturing process, reducing human error and improving overall efficiency.

Quality Assurance

A robust quality assurance system is non - negotiable when choosing a plastic injection molding factory.

- Quality Control Process: A reliable factory will have a comprehensive quality control process that starts from the incoming inspection of raw materials. They will test the plastics for properties such as melt flow index, tensile strength, and heat resistance to ensure they meet the required standards. During the production process, in - line inspections are carried out at regular intervals to monitor parameters like injection pressure, temperature, and cycle time. For example, a factory might check the product dimensions every 100 shots to detect any deviations early.

- Testing Standards: The factory should also adhere to international or industry - specific testing standards. For example, if you are producing products for the automotive industry, the factory should comply with standards such as ISO/TS 16949, which focuses on quality management systems for automotive production and relevant service part organizations. Factories with ISO 9001 certification have demonstrated their commitment to maintaining a high - quality management system, covering aspects from production processes to customer service.

Cost - effectiveness

While cost is an important consideration, it should not be the sole determining factor when choosing a plastic injection molding factory.

- Low - Cost Factories: Factories offering extremely low prices may cut corners on quality. They might use sub - standard raw materials or have inefficient production processes that lead to a high rate of defective products. Although the initial production cost may seem attractive, the cost of rework, scrap, and potential product recalls can far outweigh the savings. For example, a low - cost factory might use a cheaper grade of plastic that is more prone to cracking under stress, resulting in a high percentage of rejected products.

- High - Cost Factories: On the other hand, factories with high - end pricing may offer top - notch quality and service, but they may not always be the best fit for projects with budget constraints. It's important to find a balance. When evaluating costs, consider not only the per - unit production cost but also factors like tooling costs, minimum order quantities, and any additional charges for services such as design assistance or secondary operations.

Production Capacity

The production capacity of a plastic injection molding factory must align with your project's requirements.

- Small - Scale Factories: Small - scale factories with a limited number of injection molding machines are better suited for low - volume production runs. They may be more flexible in handling small orders and custom projects. For example, if you need to produce a few hundred prototype parts, a small - scale factory can often accommodate your needs quickly without the need for large - scale production setups.

- Large - Scale Factories: Large - scale factories, equipped with a fleet of high - capacity injection molding machines, are ideal for high - volume production. They can produce thousands or even millions of parts in a short period. For instance, if you are planning to launch a mass - market consumer product, a large - scale factory can ensure that you have a sufficient supply of products to meet market demand.

Communication and Customer Service

Good communication and customer service are often overlooked but are crucial for the success of any project.

- Poor Communication: A factory with poor communication channels can lead to misunderstandings, delays, and costly mistakes. For example, if there are issues with the mold design and the factory fails to communicate them clearly, it can result in extended production timelines or products that do not meet the desired specifications.

- Good Communication and Service: A factory that values communication will keep you informed at every stage of the project, from the initial design review to the final product delivery. They will respond promptly to your inquiries, provide regular updates on production progress, and be willing to work with you to resolve any issues that arise. A factory with excellent customer service will also offer after - sales support, such as handling product returns or providing technical assistance for any problems with the molded products.

Yigu Technology's Insights

At Yigu Technology, we believe that when choosing a plastic injection molding factory, technical innovation should be at the forefront. We continuously invest in R&D to explore new molding techniques, such as multi - material injection and micro - injection molding, which can meet the ever - evolving needs of our clients. Our focus on customization ensures that every project, whether it's a small - batch production for a startup or a large - scale order for an established brand, is tailored to perfection. We understand that each product has unique requirements, and our team of experts is dedicated to providing personalized solutions. This includes close collaboration with clients during the design phase to optimize product functionality and manufacturability.

FAQ

Q1: How can I assess a factory's experience?

You can assess a factory's experience by looking at its years in operation. A factory with over 5 - 10 years of experience is likely to have more in - depth knowledge. Review their project portfolio to see the types of products they have produced. For example, if they have successfully completed projects similar to yours, it's a good sign. Additionally, check the list of their previous clients. Big - name clients often choose factories with a proven track record, so if a factory has served well - known companies, it indicates their reliability.

Q2: What are the common quality issues in plastic injection molding?

Common quality issues include flash (excess plastic around the edges of the product), which can be caused by high injection pressure or a poor - fitting mold. Bubbles inside the product may occur due to improper venting during the molding process or trapped air in the plastic material. Sink marks, appearing as small depressions on the surface, are usually the result of uneven cooling or insufficient packing pressure. To solve flash, adjust the injection pressure and ensure the mold is properly maintained. For bubbles, improve the venting system of the mold. To address sink marks, optimize the cooling channels and packing parameters.

Q3: How to negotiate a reasonable price with the factory?

First, research the market to understand the average price range for plastic injection molding services. This will give you a benchmark for your negotiation. If possible, get quotes from multiple factories to compare. When negotiating, mention the volume of your order. Factories are often more willing to offer discounts for large - scale production. You can also ask about any hidden costs upfront, such as tooling fees, setup charges, or fees for secondary operations. Try to build a long - term relationship with the factory, as they may be more inclined to offer better pricing for repeat business.