What is the Injection Molding Cycle?

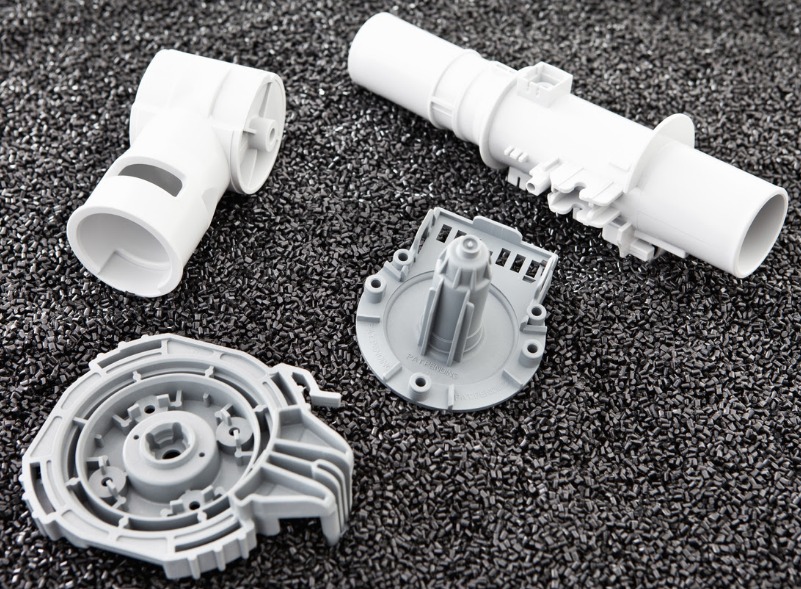

The injection molding cycle is the sequence of steps involved in the injection molding process, which is a widely used manufacturing method for producing plastic parts. This cycle is the heartbeat of injection molding production, dictating the efficiency, quality, and cost - effectiveness of the manufacturing process.

At its most basic, the injection molding cycle consists of several key stages: clamping, injection, packing, cooling, and ejection. Each stage is crucial and contributes to the overall success of creating a high - quality plastic part.

Clamping: The first step in the injection molding cycle. In this stage, the two halves of the mold are brought together and held tightly in place by the clamping unit of the injection molding machine. The clamping force needs to be sufficient to prevent the mold from opening during the injection and packing stages when high pressures are involved. For example, in the production of large - scale plastic automotive parts, a clamping force of several hundred tons might be required to keep the mold closed.

Injection: Once the mold is clamped, molten plastic is injected into the mold cavity through a nozzle. The plastic, which is typically in granular form initially, is heated and melted in a barrel. A reciprocating screw or a plunger is used to push the molten plastic at high speed into the mold. The injection speed and pressure are carefully controlled parameters. For small, intricate parts, a relatively high injection speed might be used to ensure that the plastic fills all the fine details of the mold cavity before it starts to cool.

Packing: After the mold cavity is filled with molten plastic, a packing pressure is applied. This pressure compensates for the shrinkage of the plastic as it cools and solidifies. By maintaining a certain pressure during the early stages of cooling, the final part will have the correct dimensions and density. If the packing pressure is too low, the part may have voids or sink marks; if it's too high, it can cause excessive stress in the part.

Cooling: This is one of the longest stages in the injection molding cycle. The molten plastic in the mold needs to cool down and solidify to the point where it can maintain its shape when ejected. Cooling channels are built into the mold, and a coolant (usually water) is circulated through these channels to speed up the cooling process. The cooling time depends on various factors such as the thickness of the part, the type of plastic used, and the mold design. Thicker parts will naturally require longer cooling times. For instance, a plastic part with a wall thickness of 3 - 5 mm might take 10 - 20 seconds to cool adequately, while a thinner part with a wall thickness of 1 - 2 mm could cool in 3 - 8 seconds.

Ejection: Once the plastic part has cooled and solidified, the mold is opened, and the part is ejected from the mold cavity. Ejector pins, which are small rods located within the mold, push the part out. The design of the ejection system is important to ensure that the part is ejected smoothly without being damaged.

Key Elements of the Injection Molding Cycle

1. Clamping Stage

The clamping stage is the starting point of the injection molding cycle. The clamping unit of the injection molding machine is responsible for closing and holding the mold halves together. Clamping force is a critical parameter. It must be sufficient to counteract the injection and packing pressures. Insufficient clamping force can lead to flash, where plastic leaks out between the mold halves, ruining the part and potentially damaging the mold. For example, in a standard household plastic product production, a clamping force of around 50 - 100 tons might be used.

The clamping speed also matters. A fast clamping speed can save time, but if it's too fast, it can cause the mold to slam shut, leading to premature wear and tear of the mold components. On the other hand, a slow clamping speed can increase the cycle time, reducing production efficiency.

The clamping stroke determines how far the mold halves move to close. Different molds have different requirements for the clamping stroke, which is usually set according to the mold's thickness and the size of the part to be produced. For small, simple molds, the clamping stroke might be only a few centimeters, while for large, complex molds used in industrial applications, the clamping stroke could be several tens of centimeters.

2. Injection Stage

During the injection stage, molten plastic is injected into the mold cavity. The injection volume is calculated based on the volume of the mold cavity and the desired part dimensions. Over - injection can cause the part to be over - sized or have excessive flash, while under - injection results in incomplete filling of the mold cavity, leading to a defective part.

Injection speed affects the quality of the part. A high injection speed is suitable for filling molds with complex geometries and fine details quickly, before the plastic cools too much. However, it can also cause problems such as air entrapment, which may lead to voids or bubbles in the part. In contrast, a low injection speed might result in incomplete filling or long flow marks on the part surface. For parts with a high aspect ratio (such as long, thin plastic tubes), a carefully controlled injection speed is crucial to ensure uniform filling.

Injection pressure is closely related to the injection speed. It needs to be high enough to push the molten plastic through the narrow channels of the runner system and into the mold cavity. The pressure requirements can vary greatly depending on the type of plastic, the complexity of the mold, and the size of the part. For example, high - viscosity plastics like some engineering plastics require higher injection pressures compared to low - viscosity commodity plastics.

Holding time, also known as packing time, is the period during which pressure is maintained after the mold is filled. This helps to compensate for the shrinkage of the plastic as it cools. If the holding time is too short, the part may have sink marks or low density areas. A proper holding time ensures that the part has the correct shape and dimensions.

3. Cooling Stage

The cooling stage is one of the most time - consuming parts of the injection molding cycle, but it's essential for the quality and efficiency of the production. Cooling time is mainly determined by the thickness of the plastic part, the type of plastic, and the mold's cooling system. Thicker parts take longer to cool because heat has to dissipate from a larger volume of material. For example, a 5 - mm - thick plastic part might require 20 - 30 seconds of cooling time, while a 1 - mm - thick part could cool in 5 - 10 seconds.

Mold temperature control is another crucial factor. The temperature of the mold affects how quickly the plastic cools and solidifies. A well - designed cooling system with efficient coolant circulation can maintain a consistent mold temperature, which in turn ensures uniform cooling of the part. If the mold temperature is too high, the cooling time will be extended, reducing production efficiency. If it's too low, the plastic may cool too quickly, causing internal stresses in the part, which can lead to warping, cracking, or other defects.

4. Ejection Stage

In the ejection stage, the cooled and solidified plastic part is removed from the mold cavity. Ejection pressure must be carefully adjusted. If it's too low, the part may not be ejected properly and could remain stuck in the mold. If it's too high, it can damage the part, especially if the part has thin walls or delicate features.

Ejection speed also needs to be controlled. A high - speed ejection might be suitable for simple, robust parts, but for more complex or fragile parts, a slower ejection speed is required to prevent damage.

The ejection stroke is the distance that the ejector pins move to push the part out of the mold. This needs to be set correctly to ensure that the part is fully ejected without being damaged. A short ejection stroke may leave the part partially in the mold, while an overly long ejection stroke can waste time and potentially damage the ejection mechanism.

Factors Affecting the Injection Molding Cycle

1. Material Properties

The properties of the plastic material used play a significant role in the injection molding cycle. Melting point is a crucial property. For example, materials like polyethylene (PE) have a relatively low melting point, typically around 120 - 130°C for high - density polyethylene (HDPE). This allows for quicker heating and melting during the injection process, potentially shortening the overall cycle time. In contrast, engineering plastics such as polyetheretherketone (PEEK) have a much higher melting point, around 343°C. Heating PEEK to its melting point requires more energy and time, thus increasing the injection molding cycle time.

Liquidity is another important factor. High - flow plastics can fill the mold cavity more rapidly. For instance, some grades of polystyrene (PS) have excellent flow properties. This means that during the injection stage, they can be injected into the mold at a faster rate, reducing the injection time. On the other hand, plastics with low 流动性,like certain filled - glass fiber reinforced plastics, require more pressure and time to fill the mold cavity, which can extend the injection and overall cycle time.

Shrinkage rate also affects the cycle. Plastics with high 收缩率,such as polypropylene (PP), which has a relatively high linear 收缩率 of about 1 - 2.5%, need more careful packing and cooling to ensure the final part has the correct dimensions. A longer packing time may be required to compensate for the shrinkage during cooling. If not properly managed, the part may have sink marks or incorrect dimensions, and additional post - processing may be needed, which effectively increases the overall production time.

2. Mold Design

The design of the mold is a key determinant of the injection molding cycle. Flow channel system design is crucial. A well - designed runner system can reduce the pressure drop and the time it takes for the molten plastic to reach the mold cavity. For example, a balanced runner system, where the length and diameter of each runner branch are equal, ensures that the plastic reaches all parts of the mold cavity simultaneously. This reduces the injection time and ensures uniform filling. In contrast, an unbalanced runner system may cause some areas of the mold to fill later than others, leading to longer injection times and potential quality issues.

Cooling channel are essential for the cooling stage. The layout and efficiency of the cooling channels can significantly impact the cooling time. If the cooling channels are too far apart or have a small cross - sectional area, heat transfer from the plastic to the coolant will be slow, prolonging the cooling time. For example, in a mold for a large plastic part, having closely spaced cooling channels with a sufficient diameter can ensure that the plastic cools evenly and quickly. Some advanced mold designs use conformal cooling channels, which are designed to follow the shape of the part. This can provide more efficient cooling and potentially reduce the cooling time by up to 30 - 50% compared to traditional straight - line cooling channels.

Demolding mechanism also affects the cycle. A well - designed ejection system can quickly and smoothly remove the part from the mold. If the ejection mechanism is not properly designed, the part may get stuck in the mold, requiring additional time to remove it. For example, using the right number and size of ejector pins in the appropriate locations can ensure that the part is ejected without damage. If the ejector pins are too small or too few, they may not be able to provide enough force to eject the part, or they may cause the part to warp or break during ejection.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology understands the significance of the injection molding cycle deeply. Our professional technical team is proficient in optimizing every stage of the injection molding cycle. We know that a well - controlled injection molding cycle is the key to producing high - quality non - standard products.

For different customized products, we carefully adjust machine settings according to material properties and mold designs. Our customized services ensure that each product meets the unique requirements of customers. By continuously improving our technology and process, we can reduce the injection molding cycle time while maintaining product quality, thereby improving production efficiency and reducing costs for customers. We believe that professional technology and customized services are the core competitiveness in the field of non - standard plastic metal products manufacturing.