Introduction

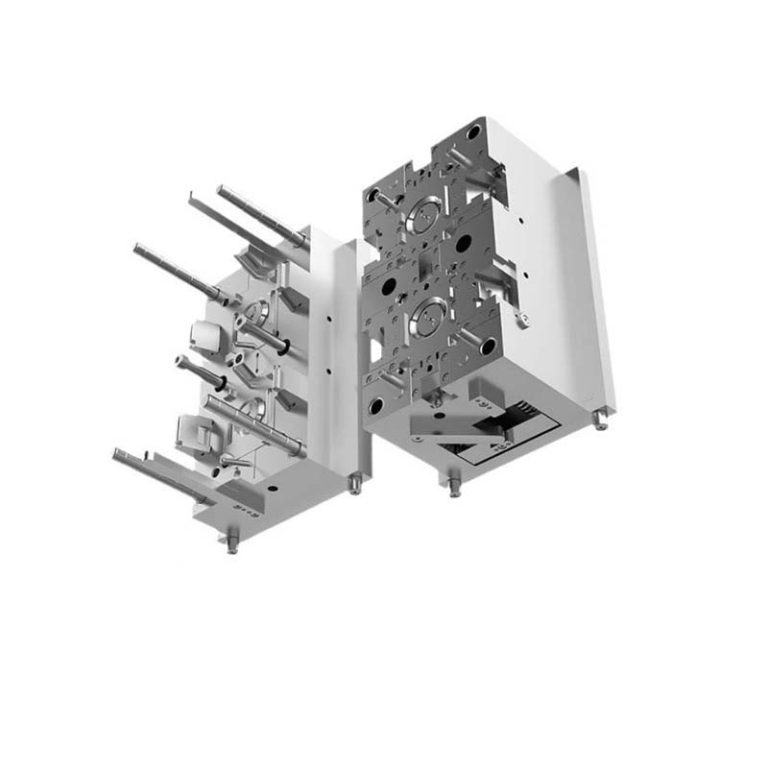

Injection molding manufacturing stands as a cornerstone in modern manufacturing, playing a pivotal role across diverse industries. From the smallest components in electronics to large - scale automotive parts, its applications are far - reaching. This manufacturing process involves injecting molten material, typically plastic, into a mold cavity where it cools and solidifies, taking on the shape of the mold.

The global injection molding market has been witnessing steady growth. According to market research, the market size was approximately \(1300 billion in 2020 and is projected to reach around \)1700 billion by 2025, with a compound annual growth rate (CAGR) of about 4%. This growth is propelled by the increasing demand for plastic products in various sectors such as automotive, consumer electronics, packaging, and medical.

Given its significance and the dynamic nature of the manufacturing landscape, exploring the trends and innovations in injection molding manufacturing becomes crucial. In the following sections, we will delve into the latest technological advancements, material innovations, and sustainable practices that are shaping the future of injection molding manufacturing.

Trend 1: Automation and Smart Manufacturing

Automated Production Lines

Automation has become a game - changer in injection molding manufacturing. Automated production lines are being increasingly adopted, with processes such as automatic material feeding and part demolding.

In a traditional injection molding setup, manual material feeding can be time - consuming and error - prone. Workers need to measure and load the plastic pellets into the injection molding machine, which not only requires significant labor but also has a risk of inconsistent material dosage. However, with automatic material - feeding systems, plastic pellets are automatically conveyed from storage silos to the injection molding machine. These systems can accurately control the amount of material fed, ensuring consistent product quality. For Yigu Technology example, a mid - sized injection molding factory that used to rely on manual material feeding for 8 hours a day with 3 workers has now switched to an automatic material - feeding system. This change has reduced the labor cost by approximately 60% in this process alone, and the production efficiency has increased by 30% due to the continuous and precise material supply.

Automatic demolding systems also play a crucial role. After the plastic parts are molded and cooled in the mold, they need to be removed. In the past, this was often done manually, which was slow and could potentially damage the parts. Now, automated demolding robots can quickly and precisely extract the parts from the mold. They can handle a high volume of parts per hour, further enhancing the overall production rate. Some advanced demolding robots can even perform quality inspections during the demolding process, such as checking for part defects like warping or missing features.

Smart Monitoring and Control Systems

Smart monitoring and control systems are another key aspect of smart manufacturing in injection molding. These systems use sensors to collect real - time data on various parameters during the injection molding process, such as temperature, pressure, and injection speed.

For instance, temperature is a critical factor in injection molding. If the temperature in the mold or the barrel is too high or too low, it can lead to product defects like poor surface finish, shrinkage, or incomplete filling. Smart monitoring systems can continuously monitor the temperature at different points in the machine and the mold. When the temperature deviates from the optimal range, the system can automatically adjust the heating or cooling elements to bring it back to the desired level.

These systems also analyze the collected data to optimize the production process. By studying historical data on production runs, they can identify patterns and correlations between process parameters and product quality. For example, the system might find that a certain combination of injection pressure and speed results in a higher yield of defect - free products. Based on this analysis, it can adjust the process parameters in real - time to improve product quality and production efficiency.

Moreover, smart monitoring systems can predict potential equipment failures. By analyzing trends in sensor data, such as changes in vibration levels or motor current, the system can detect early signs of equipment wear or malfunction. This allows manufacturers to schedule maintenance proactively, reducing unplanned downtime. A study shows that factories using smart monitoring and control systems in injection molding have reduced unplanned downtime by up to 40%, leading to significant cost savings and increased productivity.

Trend 2: Material Innovations

High - Performance Plastics

High - performance plastics have emerged as a significant innovation in injection molding manufacturing. Materials like polyetheretherketone (PEEK) and polyimide (PI) are gaining traction due to their exceptional properties.

PEEK, for example, has a high melting point of around 343°C and can be used continuously at temperatures up to 260°C. This makes it an ideal choice for applications in the aerospace and automotive industries where parts are exposed to high - temperature environments. In aerospace, PEEK is used to manufacture components such as aircraft engine parts, where it can withstand the extreme heat generated during flight. Its high strength - to - weight ratio also contributes to reducing the overall weight of the aircraft, thereby improving fuel efficiency.

Polyimide (PI) is another high - performance plastic known for its high - temperature resistance, excellent mechanical properties, and chemical stability. It can endure temperatures up to 400°C in some cases. In the electronics industry, PI is often used in flexible printed circuit boards. These boards require a material that can withstand the heat generated during the soldering process and also maintain its flexibility over time. PI's ability to resist high temperatures without degrading ensures the long - term reliability of the electronic components.

The use of these high - performance plastics in injection molding manufacturing offers several advantages. They can replace traditional metals in many applications, leading to significant weight reduction. This is crucial in industries like aerospace and automotive, where lighter components can improve fuel efficiency and performance. Additionally, their high - temperature resistance and chemical stability extend the lifespan of the products, reducing the need for frequent replacements and maintenance.

Biodegradable Materials

The use of biodegradable materials in injection molding is a growing trend, driven by the increasing global focus on environmental protection. Biodegradable plastics, such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch - based polymers, are being increasingly used in injection molding processes.

PLA, derived from renewable resources like corn starch or sugarcane, is one of the most widely used biodegradable plastics. It has good mechanical properties and is suitable for a variety of applications. In the packaging industry, PLA is used to make disposable cutlery, food containers, and packaging films. These products can break down naturally in the environment, reducing the accumulation of plastic waste. For instance, a major fast - food chain has started using PLA - based disposable cutlery in some of its stores. These utensils can decompose within a few months in a composting environment, compared to traditional plastic cutlery that can take hundreds of years to degrade.

PHA is another biodegradable material with excellent biocompatibility. It is often used in the medical field for applications such as drug delivery systems and tissue engineering scaffolds. Since PHA can degrade inside the body without causing adverse reactions, it provides a sustainable solution for medical devices that are designed to be absorbed over time.

The market potential for biodegradable materials in injection molding is substantial. According to market research, the global biodegradable plastics market was valued at around \(3.5 billion in 2020 and is projected to reach approximately \)7.3 billion by 2025, with a CAGR of about 16%. This growth is mainly driven by the implementation of strict environmental regulations in many countries, such as plastic - bag bans and restrictions on single - use plastics. Consumers are also becoming more environmentally conscious and are increasingly demanding products made from sustainable materials. As a result, manufacturers are under pressure to adopt biodegradable materials in their injection - molding processes to meet market demands and regulatory requirements.

Trend 3: Precision and Micro - Molding

Precision Molding Techniques

Precision molding techniques have revolutionized the injection molding manufacturing process, enabling the production of high - accuracy and complex - shaped products. These techniques involve the use of advanced molds and precise control of the injection molding parameters.

The molds used in precision molding are often made from high - quality steel or other specialized materials, and they are manufactured with extremely tight tolerances. For Yigu Technology example, the tolerance of the mold cavities can be controlled within ±0.01 mm or even less. This high - precision mold manufacturing ensures that the final products have consistent dimensions and excellent surface finish.

In the injection molding process, parameters such as injection pressure, temperature, and cooling rate are precisely controlled. Advanced injection molding machines are equipped with sophisticated control systems that can adjust these parameters in real - time. For instance, the injection pressure can be adjusted with an accuracy of ±0.1 MPa. This precise control of process parameters is crucial for achieving high - quality products with complex shapes.

Precision molding has found extensive applications in the electronics and medical fields. In the electronics industry, it is used to produce components such as connectors, sensors, and micro - switches. These components require high precision to ensure proper functionality. For example, a micro - switch used in a smartphone needs to have precise dimensions to ensure reliable operation. If the switch is not molded accurately, it may lead to malfunctions such as false triggering or poor contact.

In the medical field, precision - molded products are used in various applications, including surgical instruments, implantable devices, and diagnostic equipment. A surgical instrument, like a micro - forceps used in minimally invasive surgery, must be precisely molded to ensure delicate and accurate handling during procedures. Implantable devices, such as pacemaker casings, also require high - precision molding to ensure biocompatibility and proper fit within the body.

Micro - Molding for Miniature Components

Micro - molding is a specialized form of injection molding that focuses on the production of miniature components. These components typically have dimensions in the millimeter or even sub - millimeter range, and they require extremely tight tolerance control and the ability to replicate fine structures.

One of the key features of micro - molding is its ability to achieve very small tolerances. Tolerances in micro - molding can be as low as ±0.001 mm or even lower in some cases. This high - level of precision is essential for ensuring the proper functionality of miniature components. For example, in the production of micro - gears used in micro - electromechanical systems (MEMS), the teeth of the gears need to be precisely formed with tight tolerances to ensure smooth operation and accurate transmission of motion.

Micro - molding also excels in replicating fine structures. Molds for micro - molding are often fabricated using advanced techniques such as lithography and micro - electro - discharge machining (EDM). These techniques allow for the creation of molds with intricate features, such as micro - channels, holes, and grooves. For instance, in the production of micro - fluidic chips, which are used in chemical and biological analysis, micro - molding can accurately replicate the complex network of micro - channels within the chip. These micro - channels are typically only a few micrometers in diameter and require precise replication to ensure proper fluid flow and analysis.

The applications of micro - molding are diverse, spanning from MEMS devices to optical components. In MEMS, micro - molded components are used in accelerometers, gyroscopes, and pressure sensors. These components play a crucial role in applications such as automotive airbag deployment systems, smartphone motion sensing, and industrial process control. In the optical field, micro - molding is used to produce lenses, prisms, and optical waveguides. These micro - optical components are essential for applications such as optical communication, microscopy, and laser systems.

Trend 4: Multi - Component and Overmolding

Two - Shot and Multi - Shot Molding

Two - shot and multi - shot molding are advanced techniques in injection molding manufacturing that enable the production of products with multiple materials or colors. In two - shot molding, two different materials or colors are injected into the mold in two separate injection steps. This is achieved using a specialized injection molding machine with two injection units.

The process starts with the first material being injected into the mold cavity to form the base or a part of the product. After the first material has cooled and solidified to a certain extent, the mold rotates or moves to position the partially - formed product in front of the second injection unit. Then, the second material is injected, which bonds with the first material, creating a single, integrated product with two distinct materials or colors.

For example, in the production of a toothbrush, the handle part may be made of a hard plastic like polypropylene (PP) in the first shot for strength and durability. In the second shot, a soft thermoplastic elastomer (TPE) is injected around the handle to provide a comfortable grip. This combination of hard and soft materials not only enhances the functionality of the toothbrush but also improves the user experience.

Multi - shot molding extends this concept further, allowing for the injection of three or more materials or colors. This is especially useful for manufacturing complex products that require a combination of different properties. In the automotive industry, some interior components such as dashboard panels may be produced using multi - shot molding. Different materials can be used to create areas with different textures, colors, and mechanical properties. A rigid plastic can be used for the structural part, a soft - touch material for the areas where the driver may touch, and a colored material for decorative elements, all in one integrated component.

The advantages of two - shot and multi - shot molding are significant. They eliminate the need for post - assembly operations, which reduces production time and cost. The seamless integration of different materials also improves the product's aesthetic appeal and functionality. Moreover, it allows for greater design flexibility, enabling manufacturers to create innovative products that meet the diverse needs of consumers.

Overmolding Technology

Overmolding is a technique that involves molding one material over another pre - formed component, known as the insert. This process combines the properties of different materials to create a single, unified product with enhanced functionality.

The overmolding process typically starts with the insert, which can be a plastic, metal, or even a previously molded plastic part. The insert is placed into the mold cavity, and then the overmolding material, usually a softer or more flexible material, is injected around it. The overmolding material bonds with the insert, creating a strong and durable connection.

In the electronics industry, overmolding is commonly used to protect sensitive electronic components. For example, a printed circuit board (PCB) may have electronic components soldered onto it. To protect these components from environmental factors such as moisture, dust, and mechanical stress, an overmolding material like silicone rubber is used. The silicone rubber is molded over the PCB and the components, providing a protective seal. This not only extends the lifespan of the electronic components but also improves the reliability of the overall device.

In the automotive industry, overmolding is used in the production of various parts. Door handles are often overmolded with a soft - touch material to improve grip and comfort. The inner part of the door handle is usually made of a strong and rigid plastic or metal for structural integrity, while the outer layer is overmolded with a thermoplastic elastomer (TPE) or rubber - like material. This combination of materials ensures that the door handle is easy to grasp and operate, even in wet or cold conditions.

Another example is the production of automotive airbag covers. The cover is typically made of a rigid plastic base that is overmolded with a thin layer of a specialized material. This overmolded layer is designed to tear or break in a controlled manner when the airbag deploys, ensuring the safe and proper inflation of the airbag.

Yigu Technology's Perspective

As a non - standard plastic and metal products custom supplier, Yigu Technology closely follows the trends in injection molding manufacturing. We have substantial technical accumulations and practical experience in automation, material innovation, and precision manufacturing.

In terms of automation, we have introduced advanced automated production lines. Our automatic material - feeding and part - demolding systems ensure high - efficiency production with reduced labor costs and enhanced product quality consistency. For example, our automatic material - feeding system can precisely control the amount of plastic pellets fed into the injection molding machine, eliminating the risk of inconsistent material dosage caused by manual operation.

Regarding material innovation, we are actively exploring the application of high - performance and biodegradable materials. We have successfully used high - performance plastics like PEEK in some high - end product manufacturing, taking advantage of its excellent high - temperature resistance and mechanical properties. Also, we are increasingly applying biodegradable materials such as PLA in our products, meeting the growing market demand for environmental protection.

In precision manufacturing, our precision molding and micro - molding techniques enable us to produce products with high accuracy and complex shapes. Our molds are manufactured with extremely tight tolerances, and we precisely control injection molding parameters. We can produce micro - components with dimensions in the sub - millimeter range for applications in MEMS devices.

We are committed to providing customized solutions for our customers. By understanding their unique requirements, we can combine the latest injection molding manufacturing trends and our technical strengths to create products that meet their specific needs, whether it's a complex multi - component product or a high - precision micro - part.