Introduction

The Significance of a Right Injection Tooling Supplier

In the complex and competitive landscape of manufacturing, the choice of an injection tooling supplier stands as a cornerstone for achieving manufacturing excellence. The injection tooling, often the unsung hero behind the production of countless plastic products, plays a pivotal role in determining the quality, cost - effectiveness, and timeliness of production.

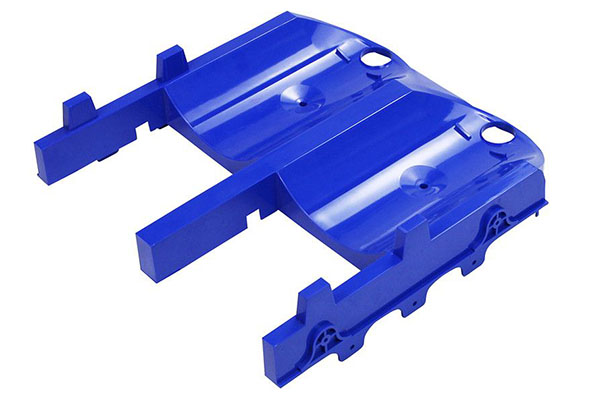

Quality Assurance: A reliable injection tooling supplier is synonymous with high - quality molds. High - precision molds are essential for producing plastic parts with tight tolerances. For example, in the production of medical devices, a deviation of even a fraction of a millimeter can render the product ineffective or even dangerous. A top - tier injection tooling supplier, with advanced machining capabilities and strict quality control measures, can ensure that the molds produce parts that meet or exceed the required quality standards. In contrast, a subpar supplier may produce molds that lead to products with defects such as warping, flash, or inconsistent wall thickness, which not only increases waste but also damages the reputation of the end - product manufacturer.

Cost - Efficiency: The right injection tooling supplier can significantly impact the overall cost of production. Firstly, well - designed and durable molds reduce the need for frequent replacements. A study by the Plastics Industry Association found that high - quality molds from reliable suppliers can last up to 50% longer than those from less - experienced suppliers. This longevity means lower replacement costs over time. Additionally, an experienced supplier can offer cost - saving suggestions during the mold - design phase, such as optimizing the gating system to reduce material waste or suggesting the use of more cost - effective yet suitable materials without sacrificing quality.

Timely Delivery: In today's fast - paced business world, time is of the essence. A dependable injection tooling supplier understands the importance of meeting deadlines. Whether it's for a new product launch or to restock inventory, on - time delivery of molds is crucial. Delays in receiving the molds can lead to production bottlenecks, missed market opportunities, and increased costs due to idle production lines. A supplier with efficient production processes, proper resource management, and a track record of on - time deliveries can help manufacturers keep their production schedules on track.

As we can see, choosing the right injection tooling supplier is not just a matter of finding a vendor; it's a strategic decision that can have far - reaching implications for a manufacturer's success. In the following sections, we will explore the key factors to consider when making this crucial choice.

Key Factors in Selecting an Injection Tooling Supplier

1. Experience and Expertise

Experience is the bedrock of a reliable injection tooling supplier. A supplier with a long - standing presence in the industry has likely encountered a diverse range of projects. For instance, if a supplier has been in business for over 15 years, it has had the opportunity to work on projects across multiple sectors, such as automotive, consumer electronics, and medical. This breadth of experience equips them with the knowledge to handle complex design requirements.

Industry - specific experience is equally crucial. A supplier that specializes in automotive injection tooling will be well - versed in the strict tolerances and material requirements of the automotive industry. They will understand the need for high - strength materials that can withstand the vibrations and heat generated in a vehicle engine compartment. Additionally, they will be familiar with the industry's regulatory standards, ensuring that the produced molds are compliant.

You can assess a supplier's expertise by asking for case studies of their past projects. A detailed case study should include information about the project challenges, the solutions they implemented, and the final results. For example, a case study of a project for manufacturing a complex plastic component for a smartphone should detail how the supplier overcame issues like thin - wall molding and achieving high - gloss surface finishes.

2. Quality Assurance

Quality assurance is non - negotiable when it comes to injection tooling. A reputable supplier will have a comprehensive quality control system in place. This starts with the selection of high - quality raw materials. For example, they will source top - grade mold steels like Swedish - made ASSAB 718 or German - made 2738, which are known for their excellent machinability, hardness, and wear resistance.

The supplier should also have in - house quality inspection processes at every stage of production. This includes inspections during mold design, machining, heat treatment, and assembly. They will use advanced measuring equipment such as coordinate measuring machines (CMMs) to ensure that the mold dimensions are within the specified tolerances. A CMM can measure the mold components with an accuracy of up to ±0.001mm, ensuring that the final product meets the highest quality standards.

Moreover, look for suppliers with quality certifications such as ISO 9001:2015. This certification indicates that the supplier follows international quality management standards, covering aspects like process control, customer satisfaction, and continuous improvement.

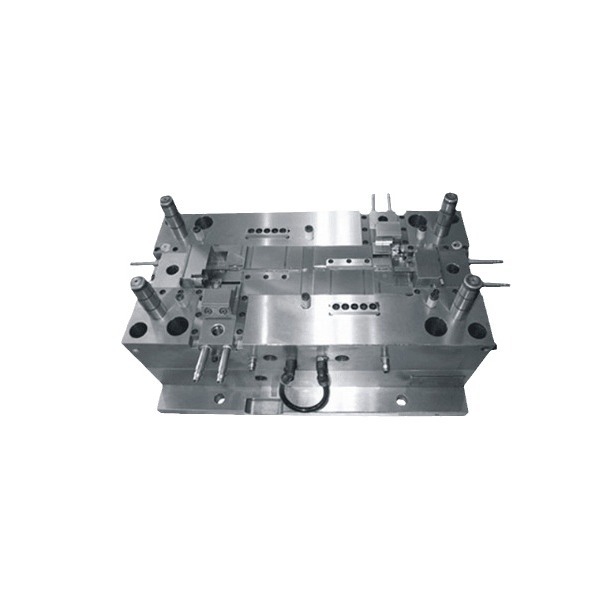

3. Production Capacity

Production capacity is a vital factor, especially if you have large - scale production requirements or tight deadlines. Consider the number and type of injection molding machines the supplier owns. A supplier with a fleet of modern, high - tonnage injection molding machines, such as those with clamping forces ranging from 500 to 3000 tons, can handle large - sized molds and high - volume production runs.

The supplier's production efficiency is also important. A well - organized production line with optimized processes can significantly reduce production lead times. For example, a supplier that uses lean manufacturing principles can eliminate waste, streamline production flows, and increase output. They may also have advanced production planning and scheduling software that enables them to manage multiple projects simultaneously and ensure on - time deliveries.

In addition, inquire about the supplier's ability to scale production during peak seasons or in response to sudden increases in demand. A flexible supplier will have strategies in place, such as overtime work, subcontracting to reliable partners, or investing in additional equipment, to meet your production needs.

4. Cost - Effectiveness

While cost is an important consideration, it should not be the sole determining factor. A lower - priced injection tooling supplier may seem attractive initially, but if the quality of their molds is subpar, it can lead to higher long - term costs. For example, low - quality molds may result in a high rate of defective products, increasing material waste and rework costs.

Instead, focus on the overall cost - effectiveness. A supplier that offers value - added services, such as design optimization, can help you save costs in the long run. By optimizing the mold design, they can reduce the amount of material used, shorten the production cycle, and improve the overall quality of the final product.

Compare the total cost of ownership, which includes not only the initial purchase price of the molds but also factors like maintenance costs, the cost of spare parts, and the expected lifespan of the molds. A study by a leading manufacturing research firm found that molds from high - quality suppliers, although more expensive upfront, can have a total cost of ownership that is 30 - 40% lower over a five - year period compared to cheaper, low - quality molds.

5. Technological Capabilities

In today's rapidly evolving manufacturing landscape, a supplier's technological capabilities can give you a competitive edge. Advanced mold design software, such as CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing) systems, allows for more accurate and efficient mold design. With CAD/CAM, designers can create 3D models of the molds, simulate the injection molding process, and identify potential issues like air traps or uneven material flow before production begins.

The supplier should also have state - of - the - art manufacturing equipment. This may include high - speed machining centers, five - axis milling machines, and electric - driven injection molding machines. Five - axis milling machines can produce complex mold geometries with high precision, reducing the need for secondary operations and improving the overall quality of the mold.

Furthermore, keep an eye on suppliers that are investing in emerging technologies like 3D printing for mold manufacturing. 3D printing can enable the production of molds with complex internal structures, such as conformal cooling channels, which can significantly improve the cooling efficiency during the injection molding process and reduce cycle times.

6. Customer Service and Communication

Good customer service and communication are often overlooked but are essential for a successful partnership. A responsive supplier will be readily available to answer your questions, provide updates on the progress of your project, and address any concerns promptly. They should have a dedicated customer service team that can be reached via phone, email, or instant messaging.

During the design phase, the supplier should be able to communicate effectively with your engineering team. They should be able to understand your design requirements, offer suggestions for improvement, and provide detailed cost estimates and lead - time projections.

After - sales service is also crucial. A reliable supplier will offer support in case of mold failures or performance issues. They should provide warranty services, maintenance advice, and access to replacement parts. For example, if a mold experiences a minor defect within the warranty period, the supplier should be able to quickly diagnose the problem, provide a solution, and either repair or replace the affected parts at no additional cost.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology deeply understands the significance of choosing the right injection tooling supplier. In our experience, communication is the key to a successful partnership. When collaborating with injection tooling suppliers, clear and timely communication ensures that both parties understand the project requirements, design concepts, and any potential challenges. For example, during a complex project involving the production of plastic components with unique geometric features, continuous communication with the injection tooling supplier allowed us to jointly optimize the mold design, resulting in a more efficient production process.

We also highly value the shared pursuit of quality. Yigu Technology believes that a reliable injection tooling supplier should have the same commitment to delivering high - quality products as we do. This means using top - notch materials, implementing strict quality control measures, and being dedicated to continuous improvement. A supplier who shares our quality - first mindset can help us meet and exceed our customers' expectations, ultimately strengthening our market position.

FAQ

Q1: How can I tell if an injection tooling supplier has enough experience?

You can tell by checking their project history. A supplier with a diverse portfolio of projects across different industries and product types is likely to be experienced. Also, the number of years they have been in business matters. Generally, a supplier with over 10 years of operation has had more time to accumulate knowledge and skills. Additionally, asking for references from their past clients can provide insights into their experience level.

Q2: What are the common quality control methods in injection tooling manufacturing?

Common quality control methods include sampling inspection, where a certain percentage of molds are randomly selected for inspection. Mold testing is another crucial method. This involves running test injection molding cycles to check for issues like part dimensions, surface finish, and any defects. Using advanced inspection equipment such as CMMs (Coordinate Measuring Machines) to measure the mold components accurately also helps in ensuring high - quality molds.

Q3: Is the cheapest injection tooling supplier always the best choice?

No, the cheapest supplier is not always the best choice. While cost is important, quality and service should also be considered. A low - cost supplier may use inferior materials or have substandard manufacturing processes, leading to molds with a shorter lifespan, higher defect rates, and more frequent maintenance needs. In the long run, this can result in higher costs due to rework, production delays, and the need to replace molds more often. It's better to look for a supplier that offers a balance between cost, quality, and service.