Introduction

In the vast landscape of modern manufacturing, plastic injection mold manufacturers play a pivotal role. They are the unsung heroes behind the production of a staggering array of plastic products that permeate every aspect of our lives, from the smallest components in our electronic devices to the large parts in automobiles. Without these manufacturers, the mass production of high - quality, precise, and cost - effective plastic items would be nearly impossible.

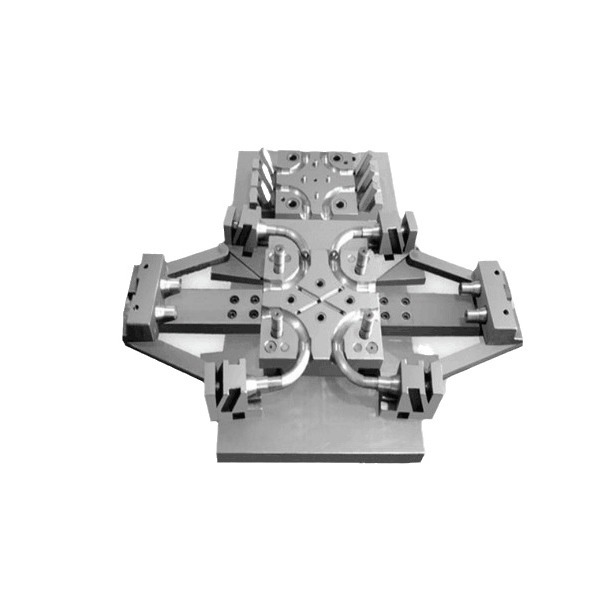

The manufacturing industry has evolved significantly over the years, and plastic injection molding has emerged as one of the most efficient and versatile production methods. This process involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. Plastic injection mold manufacturers are responsible for creating these molds, which are the key to the entire injection - molding process.

In this article, Yigu Technology will explore the numerous benefits of collaborating with plastic injection mold manufacturers. Whether you are a startup looking to bring a new plastic product to market or an established company aiming to optimize your production processes, understanding these advantages can help you make informed decisions and gain a competitive edge in the market.

Benefit 1: Expertise and Experience

In - depth Material Knowledge

Plastic injection mold manufacturers possess extensive knowledge about a wide range of plastic materials. This expertise is crucial as different materials have unique properties that make them suitable for specific applications. For Yigu Technology example, acrylonitrile butadiene styrene (ABS) is a popular choice for products that require a combination of strength, impact resistance, and good surface finish. It is commonly used in the production of electronic device housings, such as those for smartphones and laptops. Manufacturers know that ABS can withstand the rigors of daily use, including accidental drops, while maintaining its structural integrity.

Another material, polycarbonate (PC), is highly valued for its exceptional optical clarity, high heat resistance, and dimensional stability. It is often utilized in the manufacturing of automotive headlights, safety goggles, and food - storage containers. The manufacturers' understanding of PC allows them to create molds that can accurately shape the material, ensuring that the final products meet the strict quality standards required for these applications. They are aware of the optimal processing temperatures and pressures for PC, which helps in achieving consistent and high - quality results.

Complex Design Solutions

With years of experience in the field, plastic injection mold manufacturers are well - equipped to handle complex design challenges. They have encountered a diverse range of product designs throughout their careers and have developed innovative solutions to bring these designs to life.

Consider the production of a multi - component plastic toy with intricate internal mechanisms. This type of product requires a high - level of precision in mold design and manufacturing. The manufacturer needs to ensure that all the moving parts fit together perfectly, and that the mold can create the necessary cavities and channels for the toy's internal components. By leveraging their experience, they can use techniques such as insert molding, where pre - formed components are placed into the mold before injection, to achieve the desired result.

In the automotive industry, the production of interior components like dashboards also presents complex design problems. Dashboards often have irregular shapes, multiple functions (such as housing various controls and displays), and must meet strict safety and aesthetic standards. Plastic injection mold manufacturers have the skills to design molds that can produce dashboards with high - quality finishes, accurate dimensions, and integrated features. They can use advanced CAD/CAM (Computer - Aided Design/Computer - Aided Manufacturing) technologies to simulate the injection - molding process and optimize the mold design before production, reducing the risk of costly errors.

Benefit 2: Cost - effectiveness

Economies of Scale

One of the most significant cost - related advantages of working with plastic injection mold manufacturers is the ability to achieve economies of scale. When a company decides to produce plastic products on its own, the costs can be prohibitively high, especially for small - to - medium - sized enterprises.

For Yigu Technology example, consider a startup that wants to produce 10,000 plastic widgets. If they were to invest in their own injection - molding equipment, the initial capital expenditure for a basic injection - molding machine can range from \(50,000 to \)200,000, depending on the size and capabilities of the machine. Additionally, they would need to purchase or develop molds, which can cost anywhere from \(5,000 to \)50,000 per mold, again depending on the complexity of the design. There are also costs associated with hiring and training skilled operators, maintaining the equipment, and setting up a production facility.

On the other hand, when partnering with a plastic injection mold manufacturer, the cost per unit can be significantly lower for large production runs. Let's assume the same startup orders 10,000 plastic widgets from a manufacturer. The manufacturer, who has a large - scale operation and produces for multiple clients, can spread the fixed costs (such as the cost of the injection - molding machines, molds, and factory overhead) over a much larger number of units. As a result, the cost per widget might be \(2, including all production and material costs. In contrast, if the startup produced the widgets on its own, considering all the initial investments and ongoing operational costs, the cost per widget could be as high as \)10 or more.

This cost - per - unit reduction with increasing production volume is a fundamental principle of economies of scale. Plastic injection mold manufacturers are well - positioned to take advantage of this, as they can produce large quantities of products for various clients simultaneously, which leads to lower costs for each individual client.

Cost - saving in the Long Run

Long - term cooperation with plastic injection mold manufacturers also offers cost - saving benefits in areas such as mold maintenance and product improvement.

Mold maintenance is a crucial aspect of plastic injection molding. A well - maintained mold can produce high - quality products consistently and have a longer lifespan. Plastic injection mold manufacturers have in - house teams of experienced technicians who are dedicated to mold maintenance. They perform regular inspections, cleaning, and minor repairs to keep the molds in optimal condition. The cost of these maintenance services is spread across all the clients using the molds, making it more cost - effective for individual companies.

For example, if a company were to maintain its own mold, it would need to hire a specialized mold maintenance technician or outsource the service. A full - time mold maintenance technician can cost a company around \(50,000 - \)80,000 per year in salary and benefits. Additionally, the company would need to invest in maintenance tools and spare parts, which could amount to several thousand dollars annually. In contrast, when working with a plastic injection mold manufacturer, the company may only pay a small fraction of these costs as part of the overall production fee.

Moreover, over time, manufacturers can also contribute to product improvement. As they gain more experience with a particular product or industry, they can offer suggestions on design modifications or material substitutions that can enhance the product's performance while reducing costs. For instance, a manufacturer might recommend a different type of plastic material that has similar properties but is more cost - effective. By implementing such suggestions, companies can save on material costs in the long run without sacrificing product quality.

Benefit 3: High - quality Products

Precision in Manufacturing

Plastic injection mold manufacturers are renowned for their ability to achieve high precision in the manufacturing process. The precision of the molds they produce directly impacts the quality and functionality of the final plastic products.

In modern plastic injection molding, the dimensional accuracy of the molds can be extremely high. For example, in the production of micro - components for medical devices or electronics, some advanced manufacturers can achieve a dimensional accuracy of ±0.001mm to ±0.01mm. This level of precision ensures that the small plastic parts fit together perfectly, whether it's in a complex medical instrument where tiny components need to interact precisely or in a high - end smartphone with intricate internal plastic structures.

For larger - scale products, such as automotive interior parts, the precision requirements are also stringent. The mold manufacturing tolerance for these parts is often maintained within ±0.1mm to ±0.2mm. This allows for consistent production of parts that match the design specifications accurately, ensuring a proper fit within the vehicle and meeting the high - quality standards expected by automotive manufacturers.

The use of advanced manufacturing technologies, like five - axis CNC (Computer Numerical Control) machining, contributes significantly to this precision. Five - axis CNC machines can move the cutting tool and the workpiece in five different axes simultaneously, enabling the creation of complex shapes with high accuracy. They can produce molds with smooth surfaces and precise angles, reducing the need for additional finishing processes and ensuring that the final plastic products have a high - quality appearance and functionality.

Quality Control Systems

To ensure the production of high - quality products, plastic injection mold manufacturers implement strict quality control systems. These systems cover every stage of the production process, from the initial design and material selection to the final product inspection.

Raw Material Inspection: The process begins with a thorough inspection of the raw materials. Manufacturers carefully check the plastic pellets for their quality, ensuring that they meet the required specifications. This includes testing the material's physical properties, such as melt flow index, density, and tensile strength. For example, if a particular product requires a high - strength plastic, the manufacturer will verify that the chosen material has the appropriate tensile strength to withstand the intended use. They also check for any impurities or contaminants in the raw materials, as these can affect the quality of the final product.

In - process Quality Checks: During the injection - molding process, regular in - process quality checks are carried out. Operators monitor the key process parameters, such as injection pressure, temperature, and cooling time. These parameters are crucial for ensuring consistent product quality. For instance, if the injection pressure is too low, the plastic may not fill the mold cavity completely, resulting in incomplete products. On the other hand, if the temperature is too high, the plastic may degrade, affecting its mechanical properties. By closely monitoring these parameters and making adjustments as needed, manufacturers can prevent defects and ensure that each product meets the quality standards.

Final Product Inspection: After the plastic products are 成型,they undergo a comprehensive final product inspection. This includes both visual and dimensional inspections. Visually, inspectors check for any surface defects, such as scratches, bubbles, or discoloration. For products with high - end aesthetics, like consumer electronics housings, even the slightest surface imperfection can be unacceptable. Dimensional inspections are also crucial, and they are often carried out using precision measuring instruments, such as coordinate measuring machines (CMMs). CMMs can accurately measure the dimensions of the product and compare them to the design specifications, ensuring that the product meets the required size tolerances. Additionally, for products with specific functional requirements, such as mechanical strength or electrical conductivity, further functional tests are performed to verify that the product functions as intended.

Yigu Technology's View

At Yigu Technology, we highly value the significance of collaborating with plastic injection mold manufacturers. When working with them, companies can obtain professional support in material selection. Our experiences have shown that manufacturers' in - depth material knowledge helps us choose the most suitable plastic materials for different products, ensuring optimal performance.

In terms of design, their expertise in handling complex designs has been a great advantage. We've witnessed how they turn our innovative ideas into practical products. For large - scale production, cost - effectiveness is a major plus. The economies of scale they offer significantly reduce our production costs, and their long - term cost - saving strategies, like efficient mold maintenance, are also beneficial.

Moreover, their strict quality control systems ensure that we receive high - quality products, and the fast production speed and timely delivery enable us to respond promptly to market demands. In a nutshell, partnering with plastic injection mold manufacturers is a smart choice for any business aiming for success in product development and production.

FAQ

1. How can I ensure the quality of products when working with plastic injection mold manufacturers?

Reputable plastic injection mold manufacturers implement several quality - control measures. Firstly, they conduct strict material testing. They verify the properties of the plastic materials, such as melt flow index, tensile strength, and heat resistance, to ensure they meet the product's requirements. For example, if a product needs to withstand high temperatures, the manufacturer will ensure the material has sufficient heat - resistance properties. During the production process, they closely monitor parameters like injection pressure, temperature, and cooling time. This helps to prevent defects like incomplete filling, warping, or surface imperfections. After production, a comprehensive final inspection is carried out. This includes dimensional checks using precision measuring tools like coordinate measuring machines (CMMs) to ensure the product meets the specified dimensions, and visual inspections to detect any surface flaws.

2. What if I have a small - quantity order? Can plastic injection mold manufacturers still help?

Yes, many plastic injection mold manufacturers can handle small - quantity orders. Some may have flexible production arrangements. They can adjust their production schedules to accommodate small - batch production without major disruptions. Additionally, some manufacturers offer the option of shared molds. In this case, multiple customers can use the same mold for their small - quantity production runs, which helps to reduce the per - unit cost of mold usage. For example, a startup with a small - quantity order of a plastic product can share a mold with other similar - sized businesses, making the production process more cost - effective for everyone involved. This way, even with a small - quantity order, you can still benefit from the expertise and resources of plastic injection mold manufacturers.

3. How do plastic injection mold manufacturers handle design changes during the production process?

When a design change occurs during production, plastic injection mold manufacturers follow a systematic process. First, they assess the impact of the design change on the mold and the overall production process. This includes evaluating how the change will affect the mold's structure, the injection - molding parameters, and the final product quality. If the change requires modifications to the mold, they use advanced CAD/CAM (Computer - Aided Design/Computer - Aided Manufacturing) technologies to design the necessary adjustments. The mold is then modified using precision machining techniques. After the mold is adjusted, the manufacturer conducts test runs to ensure that the new design works as expected. This may involve producing a small batch of sample products and subjecting them to various quality checks, such as dimensional inspections and functional tests, to confirm that the design change has been successfully implemented.

Conclusion

In conclusion, the benefits of working with plastic injection mold manufacturers are multi - faceted and far - reaching. Their expertise and experience in material knowledge and complex design solutions can turn your product ideas into reality with precision and innovation. The cost - effectiveness they offer, both in terms of economies of scale and long - term cost - saving measures, can significantly improve your bottom line. The high - quality products they produce, backed by precision manufacturing and strict quality control systems, ensure that your brand's reputation for quality is maintained. And their time - efficiency, with fast turnaround times and timely delivery, can keep your business operations running smoothly and help you stay ahead in the competitive market.

If you are looking to produce plastic products, whether it's a new product launch or an expansion of your existing product line, don't hesitate to partner with a professional plastic injection mold manufacturer. Their capabilities can add significant value to your business, helping you achieve success in product development, production, and ultimately, in the marketplace.