Imagine investing in a set of molds that promise durability, only to have them crack after a few thousand cycles. Or dealing with constant rework because your tools can’t maintain precision in high-volume production. These are the headaches that plague manufacturers using subpar materials. Enter Mold Making DC53—a Japanese cold work steel that’s redefining what’s possible in precision tooling. Designed to overcome the limitations of traditional steels, DC53 offers a rare blend of hardness, toughness, and wear resistance. In this guide, we’ll explore how DC53 solves common manufacturing pain points and why it’s becoming the go-to choice for demanding mold applications.

Material Overview of DC53

DC53 tool steel is a product of advanced Japanese metallurgy, developed as an upgrade to the popular SKD11. Here’s what makes its material overview stand out:

- Japanese standard: DC53 adheres to strict Japanese industrial standards, ensuring consistent quality and performance. It’s part of the JIS (Japanese Industrial Standards) family, known for precision in alloy composition.

- Cold work steel: Classified as a cold work steel, DC53 is engineered for applications where metal is shaped at or near room temperature—think stamping, extrusion, and cold forging.

- Chemical composition: DC53’s magic lies in its balanced alloys: 12% chromium (for wear resistance), 0.9% molybdenum (for toughness), 1.1% vanadium (for grain refinement), and 1.0% carbon (for hardness). This mix avoids the brittleness of higher-carbon steels while maintaining strength.

- High-speed steel alternative: While not a high-speed steel, DC53 performs admirably in high-velocity applications like rapid stamping, often matching or exceeding the performance of some high-speed grades at a lower cost.

- Grade specifications: DC53 is typically supplied in the annealed condition (255 HB max) for easy machining, with strict controls on impurities that can weaken the steel.

Properties and Characteristics of DC53

DC53’s properties and characteristics set it apart from other cold work steels, making it a versatile solution for tough applications:

- High hardness: After heat treatment, DC53 reaches a hardness range of 58-62 HRC—ideal for maintaining sharp edges in high-wear tasks like stamping.

- Excellent wear resistance: Thanks to its high chromium content, DC53 forms hard carbides that resist abrasion. In testing, it outperforms D2 by 15-20% in wear resistance during continuous stamping.

- Good toughness: Unlike brittle high-hardness steels, DC53 offers impressive toughness. It can absorb 30% more impact energy than SKD11 before cracking, reducing the risk of sudden tool failure.

- High thermal stability: DC53 retains its hardness at temperatures up to 450°F (232°C), making it suitable for applications where friction generates moderate heat.

- Dimensional stability: During heat treatment, DC53 experiences minimal distortion—less than 0.0002 inches per inch. This is critical for high-precision molds where tight tolerances are non-negotiable.

- Edge retention: In cold extrusion applications, DC53 maintains its cutting edge 25% longer than D2, reducing downtime for sharpening.

Heat Treatment and Processing of DC53

To unlock DC53’s full potential, heat treatment and processing must be precise. Here’s how to get the best results:

- Annealing process: DC53 is annealed at 1500-1550°F (815-845°C) for 2-4 hours, then cooled slowly to 1000°F (538°C) at 50°F per hour. This softens the steel for machining while reducing internal stresses.

- Hardening temperatures: Heat to 1800-1850°F (980-1010°C) and hold for 30-60 minutes. This temperature range ensures carbides dissolve evenly, promoting uniform hardness.

- Quenching methods: Oil quenching is standard, cooling the steel rapidly to form a hard martensitic structure. For complex molds, vacuum quenching minimizes oxidation, reducing post-processing time by 20%.

- Tempering cycles: Temper at 300-400°F (150-204°C) for 2 hours, then air cool. A second tempering cycle ensures maximum toughness—critical for impact-resistant tools.

- Surface treatments: Nitriding boosts surface hardness to 65-70 HRC, enhancing wear resistance by 40%. PVD coatings like TiAlN reduce friction, making it ideal for plastic injection molds.

- Machinability: Annealed DC53 is easily machinable with carbide tools. Cutting speeds of 50-80 SFM work best, with coolant to prevent overheating.

- EDM performance: DC53 handles Electrical Discharge Machining (EDM) well, with a thin recast layer (0.0001 inches) that’s easy to remove, reducing the risk of cracking.

Applications in Mold Making: Where DC53 Shines

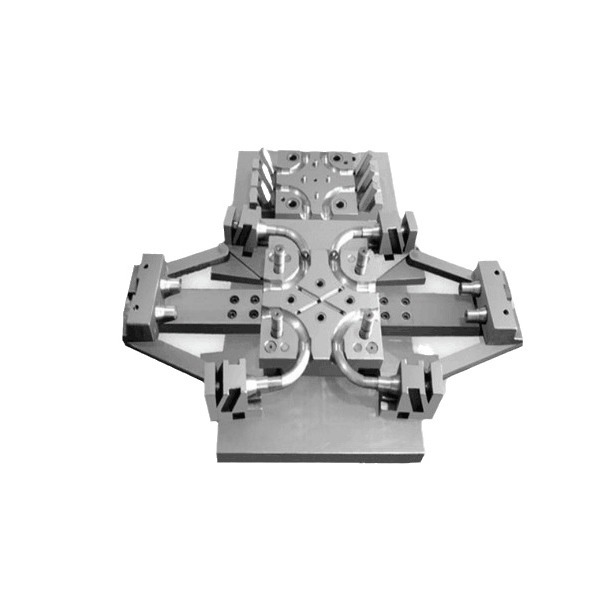

DC53 excels in a wide range of applications in mold making, thanks to its balanced properties:

- Cold work tooling: From blanking dies to forming tools, DC53’s toughness and wear resistance make it a workhorse for high-volume cold work.

- Plastic injection molds: For molds producing glass-filled plastics, DC53’s wear resistance prevents premature degradation. It’s also polished to a mirror finish, ideal for cosmetic parts.

- Stamping dies: In automotive stamping, DC53 dies last 300,000-800,000 cycles—50% longer than SKD11 in identical conditions.

- Punches and shears: DC53 punches stay sharp 40% longer than D2 in 16-gauge steel cutting, reducing downtime for sharpening.

- High-precision molds: Medical device and electronics molds benefit from DC53’s dimensional stability, maintaining tolerances as tight as ±0.0001 inches.

- Progressive dies: These complex tools require both toughness and precision—DC53 delivers, handling multiple operations without cracking or wearing unevenly.

Performance and Advantages of DC53

When it comes to performance and advantages, DC53 outperforms many traditional steels:

- Longer mold life: In cold forging applications, DC53 molds last 40-60% longer than D2, thanks to its superior toughness and wear resistance.

- Reduced maintenance: With better edge retention, DC53 tools require sharpening 30% less frequently than SKD11, cutting downtime.

- Improved dimensional accuracy: DC53’s dimensional stability ensures parts stay within tolerance, reducing scrap rates by up to 25% in precision applications.

- Cost-effectiveness: While DC53 costs 10-15% more than SKD11 upfront, its longer life and lower maintenance make it 20-30% cheaper over the tool’s lifespan.

- Better toughness compared to D2: DC53’s unique alloy mix gives it 20-30% better impact resistance than D2, making it less prone to chipping in high-stress applications.

Comparison with Other Steels

How does DC53 stack up against alternatives? Here’s a clear breakdown:

| Steel Grade | Hardness (HRC) | Wear Resistance | Toughness | Cost (Relative) | Best For |

| DC53 | 58-62 | Very Good | Very Good | Medium-High | Balanced performance (stamping, precision molds) |

| D2 | 57-62 | Very Good | Good | Medium-High | High-wear, low-impact |

| SKD11 | 57-61 | Good | Good | Medium | General cold work |

| AISI D3 | 58-64 | Excellent | Low | Medium | Ultra-high wear, no impact |

| Cr12MoV | 57-62 | Good | Good | Medium | Budget-conscious applications |

- DC53 vs. D2: DC53 offers similar wear resistance but 20% better toughness, making it better for applications with moderate impact.

- DC53 vs. SKD11: DC53 is a direct upgrade, with 30% better toughness and 15% better wear resistance than SKD11, justifying its slightly higher cost.

- Cost comparison: DC53 costs less than powder metallurgy steels (e.g., ASP-60) but more than SKD11. Its performance-to-cost ratio makes it ideal for mid-to-high volume production.

Maintenance and Service of DC53 Tools

Proper maintenance and service can extend DC53’s life even further:

- Tool sharpening: Use diamond wheels to sharpen DC53, maintaining a cool cutting zone to avoid tempering. Sharpen when edge wear reaches 0.001 inches for best results.

- Reconditioning: DC53 tools can be reconditioned 3-4 times by grinding and re-tempering, extending their life by 2-3x.

- Crack repair: Small cracks can be welded with matching filler, but post-weld heat treatment is essential to restore toughness.

- Preventive maintenance: Clean tools after use and apply rust inhibitors during storage. Regular inspections catch wear early, preventing catastrophic failure.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends DC53 for clients needing both durability and precision. We’ve seen it outperform D2 and SKD11 in high-stress applications, reducing tooling costs by 25% on average. Our team optimizes DC53’s heat treatment for each project—whether it’s a medical device mold requiring tight tolerances or an automotive stamping die needing maximum wear resistance. For manufacturers looking to upgrade their tooling, DC53 offers a clear path to better performance and lower long-term costs.

FAQs

- Is DC53 suitable for high-impact applications?

Yes—DC53’s superior toughness makes it ideal for low-to-moderate impact applications like cold forging. It outperforms D2 and SKD11 in impact resistance by 20-30%.

- How does DC53 compare to powder metallurgy steels?

DC53 offers 80-90% of the wear resistance of powder metallurgy steels (e.g., ASP-60) at 50% of the cost, making it a better value for most applications.

- Can DC53 be used for plastic injection molds?

Absolutely—DC53’s excellent polishability and wear resistance make it perfect for plastic molds, especially those producing abrasive materials like glass-filled plastics.