CNC processes are the backbone of modern precision manufacturing, leveraging computer numerical control (CNC) technology to automate and optimize a wide range of machining operations. From milling and turning to routing and grinding, these processes enable consistent, high-accuracy production of complex parts across industries such as aerospace, automotive, medical devices, and consumer electronics. This guide is designed for product engineers, manufacturing managers, design professionals, and industry enthusiasts seeking a deep understanding of CNC processes—covering core definitions, working principles, common types, step-by-step workflows, comparisons, and practical application insights. We integrate real-world case studies, actionable data, and expert analysis to help you select, implement, and optimize the right CNC processes for your specific project needs.

What Are CNC Processes? Working Principles & Core Concepts

At its essence, a CNC process is a computer-automated machining operation that uses pre-programmed G-code (or M-code) to control the movement of cutting tools and workpieces. Unlike manual machining, which relies on human operator skill for every movement, CNC processes translate digital design files into precise, repeatable physical parts. The core working principle revolves around three key components: a digital design (CAD model), a machine-readable program (CAM-generated code), and a CNC machine that executes the program with minimal human intervention.

Key foundational concepts of CNC processes include: Computer Numerical Control (CNC): The use of computers to control machining tools, replacing manual handwheels and levers. This automation eliminates human error and ensures consistent results across high-volume production runs. CAD/CAM Integration: Computer-Aided Design (CAD) software creates 2D or 3D models of the part, while Computer-Aided Manufacturing (CAM) software converts these models into G-code— the language that CNC machines understand. Axis Control: CNC machines operate along multiple axes (X, Y, Z for 3-axis; additional A, B, C axes for 4/5-axis machines) to access different part surfaces and create complex geometries. More axes enable more intricate designs but require more advanced programming. Feedback Loops: Advanced CNC processes incorporate sensors and closed-loop systems to monitor tool position and adjust in real time, ensuring tight tolerances even for long production runs.

Industry Insight: According to the Manufacturing Technology Association (MTA), CNC processes have increased production efficiency by an average of 40–60% compared to manual machining. Additionally, the global CNC machining market is projected to reach $180.5 billion by 2030 (CAGR of 6.8%), driven by the growing demand for precision parts in automotive and aerospace sectors.

NC vs CNC vs DNC: Key Differences in Automated Processes

To fully grasp CNC processes, it’s critical to distinguish them from related automated machining systems: NC (Numerical Control) and DNC (Direct Numerical Control). While all three use numerical code to control machines, their capabilities, flexibility, and use cases differ significantly. Below is a detailed comparison:

| Feature | NC (Numerical Control) | CNC (Computer Numerical Control) | DNC (Direct Numerical Control) |

|---|---|---|---|

| Program Storage | Stored on punched tapes or magnetic disks (fixed, non-editable) | Stored in on-board computer memory (editable, reusable) | Stored on a central computer, sent to machines in real time |

| Flexibility | Low—program changes require new tapes/disks | High—programs can be edited on the machine or via CAD/CAM | Very high—centralized control of multiple machines, easy program sharing |

| Machine Control | Single machine, no real-time adjustments | Single machine with real-time feedback and adjustments | Multiple machines controlled by a central system |

| Typical Use Cases | Legacy production lines, simple, high-volume parts (rare today) | Most modern precision manufacturing (prototyping, low-to-high volume) | Large-scale factories, synchronized production of complex part families |

| Cost | Low (but obsolete, high maintenance for tapes) | Moderate to high (depending on axes and capabilities) | High (centralized system + multiple machines) |

Key Takeaway: CNC processes have largely replaced NC due to their flexibility and real-time control, while DNC is reserved for large-scale manufacturing operations requiring centralized management of multiple CNC machines. For most modern applications—from prototyping to mid-volume production—CNC processes are the optimal choice.

Common Types of CNC Processes

There are dozens of specialized CNC processes, each tailored to specific materials, part geometries, and production requirements. Below are the most widely used types, along with their core capabilities, typical applications, and key considerations:

1. CNC Milling

CNC milling is one of the most versatile CNC processes, using rotating cutting tools to remove material from a stationary workpiece. It operates along X, Y, and Z axes (3-axis milling) or additional axes (4/5-axis) for complex 3D geometries. The cutting tool can move in multiple directions, enabling operations like facing, drilling, boring, and contouring.

Key Details: Capabilities: Tolerances of ±0.001–±0.005 inches; handles metals (aluminum, steel, titanium), plastics, and wood.Applications: Aerospace components (engine brackets), automotive parts (transmission housings), consumer electronics (phone casings), and custom prototypes.Case Study: A leading aerospace manufacturer used 5-axis CNC milling to produce titanium engine blades. The process achieved tolerances of ±0.002 inches, reducing part weight by 15% compared to traditional 3-axis milling and improving fuel efficiency for the end product.

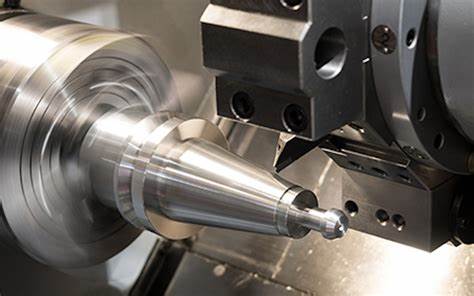

2. CNC Turning

CNC turning is a lathe-based CNC process where the workpiece rotates while a stationary cutting tool removes material. It’s ideal for cylindrical or conical parts and operates primarily along the X and Z axes. Advanced turning centers may include live tooling (Y-axis) for milling operations, eliminating the need for secondary machining.

Key Details: Capabilities: Tolerances of ±0.0005–±0.003 inches; excels at metals (steel, brass, aluminum) and plastics.Applications: Shafts, bolts, nuts, bearings, and hydraulic cylinders.Example: An automotive supplier uses CNC turning to produce 10,000 steel drive shafts per day. The process ensures consistent diameter and surface finish, reducing assembly defects by 35% compared to manual turning.

3. CNC Routing

CNC routing is a CNC process focused on cutting, carving, or engraving flat or slightly curved materials. It uses a rotating spindle with specialized bits and is commonly used for wood, plastics, composites, and soft metals (aluminum). CNC routers range from small benchtop models to large industrial machines for architectural components.

Key Details: Capabilities: Tolerances of ±0.001–±0.005 inches; handles large workpieces (up to 10x20 feet for industrial routers).Applications: Architectural cladding, custom signage, furniture components, and plastic enclosures.

4. CNC Grinding

CNC grinding is a precision CNC process that uses abrasive wheels to remove material and achieve ultra-smooth surface finishes. It’s used for parts requiring tight tolerances and fine surface roughness (Ra values as low as 0.025 μm). Common types include surface grinding (flat parts), cylindrical grinding (cylindrical parts), and centerless grinding (small shafts).

Key Details: Capabilities: Tolerances of ±0.0001–±0.001 inches; ideal for hard metals (tungsten carbide, hardened steel) and precision components.Applications: Medical implants (hip joints), bearing races, and tool and die components.

5. CNC EDM (Electrical Discharge Machining)

CNC EDM is a non-traditional CNC process that uses electrical discharges (sparks) to erode material, rather than physical cutting. It’s ideal for hard or brittle materials that are difficult to machine with conventional tools. Common types include wire EDM (for complex shapes) and sinker EDM (for cavities and molds).

Key Details: Capabilities: Tolerances of ±0.0001–±0.002 inches; handles hardened steel, titanium, and carbide.Applications: Mold and die making, aerospace components, and medical device parts with complex internal geometries.

6. CNC Plasma Cutting

CNC plasma cutting is a CNC process that uses a high-temperature plasma arc to cut through conductive materials (steel, aluminum, copper). It’s fast, cost-effective, and ideal for thick materials (up to 6 inches or more) and large workpieces. Plasma cutting is commonly used in the metal fabrication and construction industries.

Key Details: Capabilities: Tolerances of ±0.01–±0.05 inches; cuts thick materials quickly.Applications: Structural steel components, shipbuilding, and custom metal art.

The 4 Main Steps of a Typical CNC Machining Process

Regardless of the specific type, most CNC processes follow a standardized 4-step workflow to convert a digital design into a physical part. Below is a detailed, actionable breakdown of each step, including best practices and common pitfalls to avoid:

Step 1: Prepare a CAD Model

The first step in any CNC process is creating a detailed 2D or 3D CAD (Computer-Aided Design) model of the part. This model serves as the blueprint for the entire machining operation.

Best Practices: Use industry-standard CAD software (e.g., SolidWorks, AutoCAD, Fusion 360) for compatibility with CAM systems.Include all critical features (holes, slots, contours) and specify tolerance requirements directly in the model.Avoid over-engineering: Design features that are compatible with the intended CNC process (e.g., avoid sharp internal corners for CNC milling, as they require specialized tools).Validate the model for errors (e.g., overlapping geometry, non-manifold surfaces) using CAD software’s built-in check tools.

Case Study: A product design firm was tasked with creating a custom aluminum bracket for a medical device. The team used SolidWorks to design a 3D CAD model, incorporating tolerance annotations for critical mating surfaces. By validating the model for manufacturability upfront, they avoided costly rework later in the CNC process.

Step 2: Convert to CNC-Compatible Format (CAM Programming)

Once the CAD model is complete, the next step is converting it into a machine-readable format using CAM (Computer-Aided Manufacturing) software. This software generates G-code—a set of numerical instructions that tell the CNC machine how to move the cutting tool and workpiece.

Key Actions: Import the CAD model into the CAM software (ensure file compatibility: STEP, IGES, or DWG/DXF formats are preferred).Select the appropriate CNC process (e.g., milling, turning) and machine type (e.g., 3-axis mill, 5-axis lathe).Define cutting parameters: Tool type, spindle speed (RPM), feed rate (IPM), depth of cut, and coolant usage—all tailored to the material (e.g., aluminum requires higher RPM than steel).Simulate the tool path to identify potential collisions (e.g., tool vs. workpiece, tool vs. fixture) and optimize the program for efficiency.Export the G-code to a USB drive, network, or directly to the CNC machine (for DNC systems).

Expert Tip: Invest time in tool path simulation—this step reduces the risk of machine damage and part scrappage. According to a study by the Association for Manufacturing Technology, CAM simulation reduces programming errors by up to 70% in CNC processes.

Step 3: Setup Execution (Machine and Fixture Preparation)

Setup execution is a critical phase of the CNC process that involves preparing the CNC machine, workpiece, and fixtures for machining. Proper setup ensures accuracy and consistency across all parts.

Step-by-Step Setup:Mount the appropriate cutting tools in the machine’s tool holder. Ensure tools are sharp and properly balanced to avoid vibration.Secure the workpiece to the machine’s worktable using fixtures (e.g., vices, clamps, vacuum tables). Fixtures must be rigid to prevent movement during machining.Set the machine’s work offset: This tells the CNC machine the location of the workpiece relative to the tool’s starting point. Use a touch probe or edge finder for precise offset calibration.Load the G-code program into the CNC machine and perform a dry run (no material cutting) to verify tool paths and machine movements.Adjust coolant systems (if applicable) to prevent tool overheating and improve surface finish.

Step 4: Machine the Part (Execution and Quality Control)

The final step in the CNC process is executing the machining operation and inspecting the finished part to ensure it meets design specifications.

Execution and Inspection Actions: Start the CNC machine and monitor the initial machining steps to ensure no errors (e.g., tool chatter, incorrect offsets) occur.Perform in-process inspections using precision measuring tools (e.g., calipers, micrometers, CMMs) to verify critical dimensions during machining. This helps catch issues early and avoid scrapping entire batches.Once machining is complete, remove the part from the fixture and perform a final inspection. Check for surface finish, dimensional accuracy, and any defects (e.g., burrs, tool marks).Deburr or finish the part (if needed) using secondary processes (e.g., sanding, polishing).Document inspection results for quality control purposes. This is especially important for industries with strict regulations (e.g., medical, aerospace).

CNC Processes Comparison: How to Choose the Right One

Selecting the right CNC process depends on several factors, including material type, part geometry, tolerance requirements, production volume, and cost. Below is a comparative analysis of the most common CNC processes to help you make an informed decision:

| CNC Process | Best For | Tolerance Range | Material Compatibility | Production Volume | Cost (Relative) |

|---|---|---|---|---|---|

| CNC Milling | Complex 3D geometries, flat parts, holes, contours | ±0.001–±0.005 inches | Metals, plastics, wood, composites | Low to high | Moderate |

| CNC Turning | Cylindrical/conical parts, shafts, bolts | ±0.0005–±0.003 inches | Metals, plastics | Low to high | Moderate |

| CNC Routing | Flat/curved parts, engraving, large workpieces | ±0.001–±0.005 inches | Wood, plastics, composites, soft metals | Low to medium | Low to moderate |

| CNC Grinding | Precision parts, ultra-smooth surfaces | ±0.0001–±0.001 inches | Hard metals, ceramics | Low to medium | High |

| CNC EDM | Complex internal geometries, hard materials | ±0.0001–±0.002 inches | Hardened steel, titanium, carbide | Low to medium | High |

| CNC Plasma Cutting | Thick conductive materials, large parts | ±0.01–±0.05 inches | Steel, aluminum, copper | Medium to high | Low to moderate |

Decision-Making Framework: Start by defining your part’s core requirements (geometry, tolerance, material). Then, match these to the process capabilities above. For example: A complex 3D aluminum part with tight tolerances (±0.002 inches) → CNC Milling (5-axis).A cylindrical steel shaft for an automotive transmission → CNC Turning.A large architectural ACM panel → CNC Routing.A precision medical implant with an ultra-smooth surface → CNC Grinding.

Benefits of Implementing Advanced CNC Processes

Adopting modern CNC processes offers numerous advantages over traditional manual machining or legacy automated systems. These benefits directly impact production efficiency, part quality, and overall business profitability:

1. Enhanced Precision and Consistency

CNC processes eliminate human error, ensuring every part produced matches the exact specifications of the CAD model. This consistency is critical for industries like aerospace and medical, where even minor deviations can lead to safety risks. For example, CNC turning processes can achieve tolerances as tight as ±0.0005 inches, far beyond what manual turning can accomplish.

2. Increased Production Efficiency

CNC machines can operate 24/7 with minimal human intervention, reducing production time and increasing throughput. Additionally, advanced features like automatic tool changers and fast setup times (enabled by CAM software) minimize downtime between jobs. According to the MTA, CNC processes reduce cycle times by an average of 30–50% compared to manual machining.

3. Flexibility and Scalability

CNC processes can be quickly reprogrammed to produce new part designs, making them ideal for prototyping and low-volume, high-mix production. This flexibility allows manufacturers to respond rapidly to changing customer demands without significant retooling costs. For high-volume production, CNC machines can be scaled using DNC systems to control multiple machines from a central location.

4. Reduced Material Waste

CAM software optimizes tool paths and material usage, reducing waste by up to 30% compared to manual machining. For example, CNC milling processes use nesting software to arrange multiple parts on a single material sheet, minimizing scrap. This not only reduces material costs but also supports sustainability goals.

5. Improved Workplace Safety

CNC processes reduce the need for human operators to be in close proximity to rotating cutting tools, minimizing the risk of injuries. Advanced safety features like enclosed work areas, emergency stop buttons, and collision detection systems further enhance workplace safety.

FAQ About CNC Processes

Q1: What is the most common CNC process? A1: CNC milling and CNC turning are the most commonCNC processes. CNC milling is versatile and used for a wide range of part geometries, while CNC turning is ideal for cylindrical parts. Together, they account for over 70% of all CNC machining operations, according to industry reports.

Q2: How accurate are CNC processes? A2: Accuracy varies by process, but most modern CNC processes achieve tolerances between ±0.0001 and ±0.005 inches. CNC grinding and EDM offer the tightest tolerances (±0.0001 inches), while plasma cutting has looser tolerances (±0.01–±0.05 inches). The exact accuracy depends on the machine’s capabilities, tool quality, and material type.

Q3: Can CNC processes handle all materials? A3: No, but CNC processes can handle most common manufacturing materials, including metals (aluminum, steel, titanium), plastics (ABS, Delrin, HDPE), wood, composites, and ceramics. Each process has material limitations: for example, CNC routing is not suitable for hard metals like tungsten carbide, while CNC EDM excels at hard materials but cannot process non-conductive materials (e.g., glass).

Q4: How long does it take to program a CNC process? A4: Programming time depends on part complexity and the programmer’s experience. Simple parts (e.g., a basic milled bracket) can be programmed in 30–60 minutes using CAM software. Complex parts (e.g., 5-axis aerospace components) may take 4–8 hours. Many CNC service providers offer template libraries to reduce programming time for common part geometries.

Q5: What is the difference between 3-axis and 5-axis CNC processes? A5: 3-axis CNC processes operate along X, Y, and Z axes, limiting tool access to the top and sides of the workpiece. 5-axis processes add two rotational axes (A and B or C), allowing the tool to access all sides of the workpiece without repositioning. 5-axis processes are ideal for complex 3D geometries but are more expensive and require more advanced programming than 3-axis processes.

Q6: Are CNC processes cost-effective for small-batch production? A6: Yes. While CNC machines have higher upfront costs than manual tools, their fast setup times and low per-part costs make them cost-effective for small-batch production (10–100 parts). For very small batches (1–5 parts), some manufacturers may use manual machining, but CNC processes offer better consistency and quality, which often justifies the cost.

Q7: What skills are needed to operate CNC processes? A7: Operating CNC processes requires skills in CAD/CAM programming, machine setup, tool selection, and quality control. Operators should be familiar with G-code, have a basic understanding of material science, and be able to use precision measuring tools (e.g., CMMs, micrometers). Many technical schools and community colleges offer certification programs in CNC machining.

Discuss Your Projects Needs with Yigu

At Yigu Technology, we specialize in delivering tailored CNC processes solutions for clients across aerospace, automotive, medical, and consumer electronics industries. With over a decade of expertise in precision manufacturing, our team of skilled engineers and CNC programmers works closely with you to select, optimize, and implement the right CNC processes for your specific project requirements—whether it’s 5-axis CNC milling for complex aerospace components, CNC turning for high-volume automotive parts, or CNC routing for custom architectural elements.

Our comprehensive services include: End-to-end CNC processes management: From CAD design and CAM programming to machine setup, execution, and quality control.Access to advanced CNC equipment: 3-axis, 4-axis, and 5-axis mills and lathes, CNC grinders, EDM machines, and plasma cutters. Material expertise: Capability to process a wide range of materials, including aluminum, steel, titanium, plastics, composites, and wood. Prototyping and production: Support for low-volume prototyping (1–100 parts) and high-volume production (1,000+ parts) with consistent quality. Quality assurance: Rigorous in-process and final inspection using CMMs, micrometers, and surface roughness testers, ensuring compliance with industry standards (ISO 9001, AS9100 for aerospace).Custom solutions: Tailored CNC processes for complex geometries, tight tolerances, and specialized material requirements.

We understand that every project has unique challenges—whether it’s achieving ultra-tight tolerances for a medical implant, reducing production time for a new automotive component, or optimizing material usage for cost savings. Our team leverages the latest CAD/CAM software and CNC technology to deliver solutions that balance quality, efficiency, and cost-effectiveness. We prioritize transparency and communication, keeping you informed at every step of the process from initial quote to final delivery.

Contact us today to discuss your CNC processes project needs. Let our expertise help you streamline your manufacturing workflow, improve part quality, and achieve your production goals.