Imagine a toolmaker trying to cut a 0.1 mm wide slot in a hardened steel die—traditional milling tools either break or leave 粗糙 edges. Or an aerospace engineer needing a complex turbine blade profile with tolerances of ±0.001 mm, impossible to achieve with conventional machining. These are the challenges that Wire Cut Electric Discharge Machining (WEDM) solves. By using a thin, electrically charged wire to erode material through controlled sparks, WEDM delivers precision that other processes can’t match. In this guide, we’ll explore how WEDM works, its applications, and how to overcome its unique challenges to achieve flawless results.

Wire Cut Electric Discharge Machining (WEDM) Basics: How It All Works

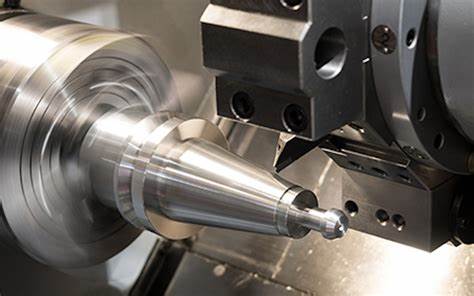

At its core, WEDM is a specialized form of Electric Discharge Machining that uses a continuously moving wire electrode to cut through conductive materials. Here’s the fundamental process:

- Spark Erosion: The wire (typically brass or copper, 0.02–0.3 mm in diameter) acts as one electrode, while the workpiece is the other. Submerged in dielectric fluid (usually deionized water), the wire is charged with pulsed current (5–300 A), creating sparks (10,000–30,000°C) that melt and vaporize tiny bits of the workpiece.

- Non-Contact Machining: The wire never touches the workpiece, eliminating mechanical stress. This makes WEDM ideal for fragile parts or pre-hardened materials (up to 65 HRC) that would crack under cutting forces.

- Wire Movement: The wire feeds continuously from a spool, ensuring a fresh electrode is always in contact with the workpiece. This reduces electrode wear compared to sinker EDM, where the electrode is stationary.

A key advantage is precision: WEDM can achieve tolerances as tight as ±0.0005 mm, with a recent study showing that 98% of medical device components machined with WEDM meet their dimensional specs on the first try.

WEDM Equipment and Setup: The Tools of the Trade

Successful WEDM relies on proper equipment and setup. Here’s what you need to know:

- WEDM Machine: Modern machines feature computerized controls, multi-axis movement (up to 5 axes), and automatic wire threading. A 5-axis WEDM can tilt the workpiece, enabling complex 3D cuts like the contours on aerospace turbine blades.

- Wire Tension System: Maintaining consistent tension (5–25 N) prevents wire vibration, which can cause inaccuracies. A machine with automatic tension adjustment reduces wire breakage by 40% compared to manual systems.

- Dielectric Fluid Supply: Deionized water (resistivity 50–100 kΩ·cm) cools the wire, flushes away debris, and insulates the spark gap. High-pressure pumps (10–30 bar) ensure the fluid reaches the cutting zone, critical for deep cuts.

- Electrode Wire: Brass wire is cost-effective for general use, while coated wires (e.g., zinc-coated brass) improve cutting speed by 20% and reduce wear. For micro-machining, 0.02 mm tungsten wire enables 0.03 mm wide slots.

- Workpiece Holder: Precision fixtures with clamping forces of 50–500 N secure the workpiece without distortion. A magnetic chuck is ideal for flat steel parts, while custom jigs work for irregular shapes.

A leading tool shop reports that investing in a high-end WEDM machine reduced setup time by 30% and improved accuracy by 50% compared to older models.

WEDM Process Parameters: Tuning for Success

The quality of a WEDM cut depends on optimizing key parameters:

- Pulse On-Time (Ton): The duration of each spark (0.1–100 μs). Short Ton (0.1–5 μs) produces fine surface finishes (Ra 0.2–0.8 μm) but slower cutting. Long Ton (50–100 μs) increases speed but roughens the surface (Ra 1.6–3.2 μm).

- Pulse Off-Time (Toff): The pause between sparks (1–200 μs). Toff must be long enough to flush debris—too short causes wire breakage. A good rule: Toff = 2–3 × Ton.

- Wire Feed Rate: How fast the wire moves (2–20 m/min). Higher rates (10–20 m/min) reduce wire wear but increase costs. For precision cuts, 2–5 m/min is better.

- Discharge Current: Determines material removal rate (1–300 A). High current (100–300 A) cuts faster but increases the Heat Affected Zone (HAZ). For medical parts, 5–20 A minimizes HAZ to 5–10 μm.

- Dielectric Fluid Pressure: Affects flushing efficiency (10–30 bar). Higher pressure (20–30 bar) is needed for thick workpieces (50+ mm) to prevent debris buildup.

A case study: A mold maker adjusted Ton from 10 μs to 2 μs and current from 50 A to 10 A, improving surface finish from Ra 1.6 μm to Ra 0.4 μm, eliminating the need for post-polishing.

Applications of WEDM: Where Precision Reigns

WEDM’s ability to cut hard materials and complex shapes makes it indispensable across industries:

- Tool and Die Making: Cutting punches, dies, and mold inserts from hardened steel. A die shop used WEDM to create a 0.5 mm wide slot in a 50 mm thick D2 steel die, a task impossible with milling.

- Aerospace Components: Machining turbine blades, fuel nozzles, and structural parts from Inconel and titanium. WEDM’s precision ensures airfoil shapes meet aerodynamic specs with ±0.001 mm tolerance.

- Medical Devices: Creating micro-components like surgical scissors (0.1 mm sharp edges) and implant features (0.05 mm channels). WEDM’s non-contact process avoids damaging delicate parts.

- Micro Machining: Producing electronics components, such as 0.03 mm diameter holes in sensor probes. A electronics manufacturer used 0.02 mm wire to cut 1,000+ micro-slots in a 10 mm × 10 mm chip carrier.

Advantages and Challenges of WEDM: Weighing the Pros and Cons

WEDM offers unique benefits but comes with trade-offs:

| Advantages | Challenges |

| High Precision: Tolerances as tight as ±0.0005 mm | Wire Breakage: Occurs 1–5% of the time, especially with thin wires or high current |

| Complex Shapes: Cuts undercuts, sharp corners, and 3D profiles | Surface Recast Layer: A 5–20 μm layer requiring post-processing for critical parts |

| No Mechanical Stress: Safe for fragile or pre-hardened materials | Slow Speed: 10–50 mm²/min, 5–10 times slower than CNC milling for large areas |

| Low Cutting Forces: No workpiece distortion | Environmental Concerns: Dielectric fluid disposal requires filtration systems |

For example, while WEDM excels at cutting a 0.05 mm tolerance gear in hardened steel, it would take 2 hours to cut a 100 mm diameter gear—making it impractical for high-volume production.

Quality Control and Surface Finish in WEDM: Ensuring Excellence

Achieving top quality in WEDM requires attention to surface finish and integrity:

- Surface Roughness: Measured in Ra (μm). Fine cuts (short Ton) achieve Ra 0.2–0.8 μm, suitable for sealing surfaces. A automotive parts maker specifies Ra 0.4 μm for hydraulic valve spools to prevent leaks.

- Heat Affected Zone (HAZ): The area around the cut where material properties change. HAZ depth (5–50 μm) increases with current and Ton. Post-processing like grinding removes HAZ in critical parts.

- Inspection Techniques: CMMs verify dimensions, while optical profilers check surface finish. A medical device manufacturer uses confocal microscopy to ensure Ra < 0.3 μm on implant surfaces.

- Recast Layer Removal: Chemical etching or electropolishing removes the 5–20 μm recast layer, improving fatigue strength. A study found that removing the recast layer increased part lifespan by 300% in high-stress applications.

Yigu Technology’s Perspective: Mastering WEDM for Precision Parts

At Yigu Technology, WEDM is a cornerstone of our precision machining capabilities. Our advanced 5-axis WEDM machines, paired with coated brass and tungsten wires, handle everything from 0.02 mm micro-slots to 200 mm thick steel plates. We optimize process parameters—tuning Ton, current, and wire tension—for each project, ensuring tight tolerances (±0.001 mm) and fine surface finishes (Ra 0.4 μm). Whether it’s a complex mold for electronics or a micro-component for medical devices, our expertise in WEDM delivers parts that meet the most demanding standards, on time and within budget.

FAQs

- What materials can be cut with WEDM?

WEDM works with all conductive materials, including hardened steel, titanium, Inconel, copper, and aluminum. Non-conductive materials like ceramics can’t be cut with standard WEDM.

- How thick of a workpiece can WEDM handle?

Most WEDM machines cut up to 300 mm thick, though some industrial models handle 500+ mm. Thicker parts require higher dielectric pressure (20–30 bar) and slower cutting speeds (5–10 mm²/min).

- How much does WEDM cost compared to other machining processes?

WEDM has higher hourly rates (\(80–\)150) than CNC milling (\(50–\)100) but lower tooling costs for complex parts. For simple shapes, CNC is cheaper; for complex, tight-tolerance parts, WEDM often saves money by eliminating rework.