Leading CNC Machining Companies in Australia and Their Services

The CNC machining industry in Australia is thriving, supported by advancements in technology and growing demand across key sectors such as aerospace, automotive, defense, and healthcare. Australia's top CNC machining companies have established themselves as leaders in precision engineering, offering a wide range of services to meet the specific needs of industries requiring high-quality, precise manufacturing solutions. Companies like CNC Manufacturing Pty Ltd, Aria Manufacturing Limited, Berkeley Engineering, Southside Australia Pty Ltd, and Zeal 3D Printing stand out for their technological capabilities, commitment to quality, and innovative approaches. These companies provide a variety of CNC services, including milling, turning, rapid prototyping, and 5-axis machining, all designed to meet the demanding specifications of their clients.

Overview of the Australian CNC Machining Industry

The CNC machining industry in Australia has evolved substantially over the last few decades. As demand for high-precision components has grown, so has the capability of Australian CNC machining companies. CNC (Computer Numerical Control) technology is now at the heart of manufacturing processes across a wide range of industries, including aerospace, automotive, defense, and healthcare. The ability to manufacture parts with extremely tight tolerances and complex geometries makes CNC machining indispensable for modern manufacturing needs.

Technological Advancements and Industry Growth

The introduction of 5-axis CNC machines, automation, and the integration of Artificial Intelligence (AI) and Machine Learning (ML) into CNC systems have transformed the industry, enhancing both efficiency and accuracy. The growing adoption of Industry 4.0 principles—such as automation, data analytics, and predictive maintenance—has also contributed to improving productivity across the sector.

With increasing investment in research and development, the Australian CNC machining industry is poised for further growth, making it an attractive sector for both domestic and international business partners.

Growth and Demand in Key Sectors

The demand for CNC machining services is growing in various industries, each requiring specialized manufacturing capabilities. Key sectors driving this growth include:

Aerospace

In the aerospace sector, precision and reliability are critical. CNC machining is used to manufacture lightweight yet durable components, such as aircraft parts, engines, and space equipment, meeting the strict safety and performance standards required in aviation and space exploration.

Automotive

CNC machining plays a vital role in the automotive industry, particularly in creating prototype parts and mass-produced components. By ensuring precise fit and finish, CNC machining enhances vehicle performance, safety, and reliability.

Defense

The defense sector relies on CNC machining for creating custom-made components capable of withstanding extreme conditions. These specialized parts—ranging from military-grade hardware to precision components for weapon systems—are critical for national security.

Healthcare

In the healthcare sector, CNC machining is used to produce medical devices, implants, and surgical tools. These components must meet stringent biocompatibility and sterilization standards, making high-precision machining essential for patient safety and effective treatment.

Services Offered by Leading CNC Machining Companies in Australia

Australian CNC machining companies offer a wide array of services to meet the diverse needs of industries requiring high-quality, precision-engineered parts. These services include:

CNC Milling and Turning

- CNC Milling involves the use of rotating tools to cut away material from a workpiece, creating complex shapes and features.

- CNC Turning is used to create cylindrical parts by rotating the workpiece while a cutting tool shapes it. Both processes are vital for producing high-precision components with tight tolerances.

5-Axis CNC Machining

- 5-axis CNC machining allows for simultaneous movement along five axes, enabling the production of highly complex parts that require intricate geometries. This service is particularly valuable for industries like aerospace and defense, where parts with complex shapes and multiple angles need to be manufactured accurately in a single setup.

Rapid Prototyping and High-Volume Production

- Rapid Prototyping is an essential service for businesses looking to quickly bring their product designs to life. CNC machining allows companies to produce prototypes with high accuracy, enabling them to test and refine designs before mass production.

- Once the design is finalized, companies can scale up to high-volume production with CNC machines, maintaining quality and precision across large batches of parts.

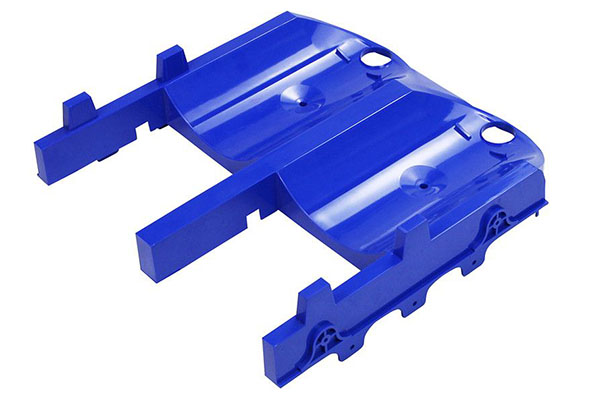

Custom Metal CNC Machining

- Many industries require custom CNC machining to produce bespoke components tailored to unique specifications. This service allows companies to create parts that cannot be produced with standard off-the-shelf solutions. Whether it’s for one-off prototypes or small-batch manufacturing, custom machining is key to creating innovative solutions for clients.

3D Printing and Additive Manufacturing

- Some leading CNC machining companies in Australia also offer 3D printing services, such as Zeal 3D Printing, combining traditional CNC machining with additive manufacturing. This hybrid approach can reduce material waste, speed up production, and enable even more complex shapes to be created.

Key Regions and Industry Hubs for CNC Machining in Australia

Certain regions in Australia have become hubs for CNC machining due to their industrial bases, skilled workforce, and proximity to key markets. These hubs provide a conducive environment for CNC machining companies to thrive.

Sydney

- Sydney is home to a wide variety of CNC machining companies specializing in aerospace, defense, and medical technologies. The city’s proximity to research institutions, ports, and key infrastructure makes it an attractive location for CNC machining services.

Perth

- Perth is a major center for the mining and resources sectors, with CNC machining companies supporting these industries by providing precision-engineered parts for heavy machinery, drilling equipment, and other mining operations.

Adelaide

- Adelaide is known for its focus on advanced manufacturing and innovation, especially in aerospace and defense. The city is home to high-tech research centers and R&D-driven CNC machining companies that leverage cutting-edge technology to meet the growing needs of the sector.

Melbourne

- Melbourne is a key manufacturing hub, particularly for aerospace and automotive industries. The city's strong industrial base and highly skilled workforce have made it an ideal location for CNC machining activities.

Brisbane

- Brisbane offers CNC machining services to a variety of industries, including construction, marine, and automotive. The city’s proximity to Queensland’s industrial sectors makes it a prime location for companies offering custom machining and rapid prototyping.

Impact of Tariffs and Trade Agreements on the CNC Industry

Global trade policies and tariffs can influence the CNC machining industry in Australia, impacting costs, market access, and competitiveness.

Global Trade Policies and Australian CNC Market

- Free trade agreements (FTAs) between Australia and countries such as China, Japan, and South Korea have opened up opportunities for CNC machining companies to expand their reach and tap into international markets. These agreements reduce trade barriers and provide access to a broader customer base.

Tariffs and Free Trade Agreements: Benefits and Challenges

- Tariffs can protect domestic manufacturers from foreign competition, but they can also lead to increased costs for raw materials, making them a challenge for CNC machining companies. Conversely, free trade agreements reduce tariffs and offer access to cheaper materials, though they may increase competition in the market.

FAQs

Q1: What are the primary benefits of using CNC machining for manufacturing components?

A1: CNC machining offers several advantages, including high precision, repeatability, and efficiency. It allows for the creation of complex geometries with tight tolerances, reducing human error and increasing the speed of production. Additionally, CNC machining offers scalability, making it ideal for both low-volume prototyping and high-volume production.

Q2: How do technological advancements impact the CNC machining industry?

A2: Technological advancements, such as 5-axis CNC machining, AI, and ML, have significantly enhanced the capabilities of CNC machines. These innovations allow for greater accuracy, faster production cycles, and the ability to handle more complex geometries. As a result, CNC machining companies can improve their efficiency, reduce downtime, and offer more precise and customizable solutions to clients.

Q3: What are some common challenges faced by CNC machining companies in Australia?

A3: CNC machining companies in Australia face several challenges, including:

- Rapid technological changes: Keeping up with the latest technological advancements can be costly.

- Global competition: Companies must remain competitive in both pricing and innovation in an increasingly globalized market.

- Skilled labor shortages: Finding skilled machinists and engineers can be difficult, especially as demand for CNC services grows.

- Supply chain disruptions: Global events can cause delays in the supply of raw materials, impacting production schedules.

Conclusion

The CNC machining industry in Australia is integral to the country’s manufacturing landscape, serving vital sectors like aerospace, automotive, defense, and healthcare. Leading companies in the sector, such as CNC Manufacturing Pty Ltd, Aria Manufacturing, and Berkeley Engineering, offer an impressive range of services, from precision machining to rapid prototyping and 5-axis CNC capabilities. With the ongoing advancements in technology and the strategic positioning of CNC hubs across the country, Australian CNC machining companies are well-equipped to meet the growing demands of both domestic and international markets.