Key Techniques and Challenges in Aerospace Machining

Aerospace machining is a specialized field requiring advanced technologies and high precision to create the complex components used in aircraft and spacecraft. This sector demands the highest standards for quality, strength, and reliability due to the critical nature of the parts involved. This article explores the key techniques used in aerospace machining—such as CNC machining, electrochemical machining (ECM), and laser beam machining—as well as the challenges that come with working with aerospace materials and maintaining tight tolerances.

Introduction to Aerospace Machining

Definition and Importance

Aerospace machining refers to the process of manufacturing parts and components specifically for the aerospace industry. These parts are used in a wide range of applications, from aircraft engines and airframes to spacecraft structures. Aerospace components must meet extremely stringent specifications related to precision, strength, lightweight properties, and reliability. The importance of aerospace machining is paramount, as the safety, performance, and efficiency of both air and space vehicles depend on the quality of these parts.

Historical Development

The origins of aerospace machining trace back to the early 20th century when the first powered flight was achieved. Initially, machining was rudimentary, with manual methods used for component manufacturing. However, as aircraft technology advanced, so did the techniques used to produce their components. The development of Computer Numerical Control (CNC) machining and additive manufacturing has significantly transformed aerospace machining, enabling the production of more complex and precise components. Today, aerospace machining incorporates cutting-edge materials, technology, and automation to meet the evolving demands of the industry.

Key Techniques in Aerospace Machining

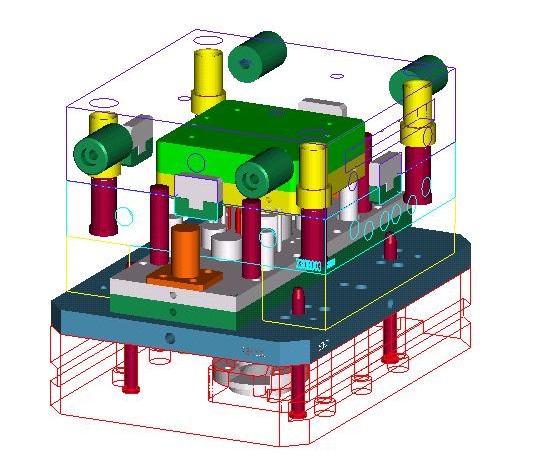

1. Computer Numerical Control (CNC) Machining

CNC machining is one of the most widely used techniques in aerospace machining. CNC machines operate based on computer-programmed instructions that dictate the movements of a tool, allowing for the precise cutting, shaping, and finishing of materials. This method offers several advantages:

- High Precision and Repeatability: CNC machining can create intricate and complex parts with tight tolerances repeatedly without variations.

- Versatility: CNC machines can work with a variety of materials, including metals, composites, and alloys commonly used in aerospace.

- Complex Geometries: CNC machining can produce highly complex geometries that would be difficult or impossible to achieve with manual methods, making it ideal for aerospace components.

2. Electrochemical Machining (ECM)

Electrochemical machining (ECM) is a non-traditional machining process that uses electrolysis to remove material from a workpiece. ECM involves passing an electric current through an electrolyte solution to remove material at the anode (workpiece) without physically contacting the part. This technique offers several benefits for aerospace machining:

- Machining Hard Materials: ECM is highly effective for machining hard and brittle materials, such as titanium and superalloys, which are commonly used in aerospace applications.

- Excellent Surface Finish: ECM produces a smooth surface finish without the thermal damage that other machining techniques may cause.

- No Mechanical Stresses: Because there’s no direct contact between the tool and the material, ECM avoids introducing mechanical stresses into the components, which is crucial for aerospace parts that must withstand extreme conditions.

3. Laser Beam Machining

Laser beam machining (LBM) uses focused laser light to cut, engrave, or etch materials with high precision. The focused laser beam generates enough energy to vaporize the material, creating clean cuts or fine details. Key advantages of laser machining include:

- High Precision: LBM can achieve incredibly precise cuts, making it ideal for intricate aerospace parts, such as those with fine details or small geometries.

- Minimal Heat-Affected Zones: Unlike conventional machining, laser beam machining generates a minimal heat-affected zone, which reduces the risk of thermal distortion in sensitive materials.

- Material Versatility: LBM can be used on a wide range of materials, including metals, composites, plastics, and ceramics.

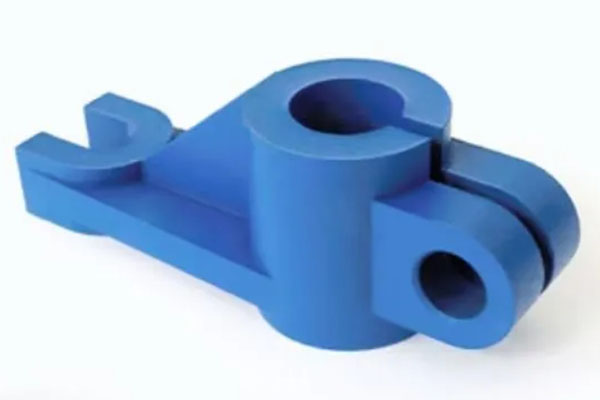

4. Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is revolutionizing aerospace machining by enabling the layer-by-layer construction of complex parts from digital models. Some of the key benefits of additive manufacturing in aerospace machining include:

- Complex Geometries: Additive manufacturing allows for the production of highly complex and optimized geometries, such as lightweight lattice structures or parts with internal channels.

- Reduced Waste: Unlike subtractive methods, additive manufacturing only uses the material needed for the part, reducing material waste and making it more sustainable.

- Faster Prototyping: Components can be produced quickly for rapid prototyping, allowing aerospace engineers to test and refine designs faster than with traditional methods.

Materials Used in Aerospace Machining

1. Aluminum Alloys

Aluminum alloys are among the most commonly used materials in aerospace machining due to their favorable strength-to-weight ratio, corrosion resistance, and ease of machinability. Aluminum alloys like 6061, 7075, and 2024 are commonly used for aerospace components, from aircraft fuselages to aircraft wings and engine components.

2. Titanium Alloys

Titanium alloys are favored in aerospace for their high strength, low density, and exceptional resistance to heat and corrosion. Although they are more challenging to machine due to their hardness and tendency to generate high temperatures during cutting, titanium alloys are indispensable for critical aerospace applications, such as engine components and airframe structures. Common titanium alloys used include Ti-6Al-4V.

3. Composite Materials

Composite materials, such as carbon fiber-reinforced polymers (CFRP) and glass fiber-reinforced polymers (GFRP), are increasingly being used in aerospace machining because of their lightweight, high-strength properties, and tailored performance characteristics. However, machining composites poses unique challenges, such as:

- Delamination: The layers of composite materials may separate during machining, compromising the integrity of the part.

- Tool Wear: The abrasiveness of materials like carbon fiber can cause excessive wear on machining tools, requiring specialized tools and techniques like diamond-coated tools.

Challenges in Aerospace Machining

1. Material Complexity

Aerospace components are often made from highly specialized materials that are difficult to machine. For example, titanium alloys and composites have unique properties that require specialized machining techniques, tools, and expertise. Additionally, materials must be carefully chosen to balance strength, weight, and durability—a critical aspect of aerospace design.

2. Tight Tolerances

Aerospace components must adhere to extremely tight tolerances due to their critical role in the performance and safety of air and space vehicles. Achieving these tolerances often requires sophisticated machining equipment, precise setups, and highly skilled operators. Even slight deviations can result in components that fail to meet specifications, potentially leading to safety issues.

3. Lightweight yet Strong Components

Aerospace manufacturers must produce components that are both lightweight and strong to maximize performance and fuel efficiency. This requires the use of advanced materials, such as titanium alloys, composites, and superalloys, which combine low density with high strength. Balancing these factors while maintaining manufacturability can be a significant challenge in aerospace machining.

4. Surface Finish and Quality

Surface finish is critical in aerospace machining, particularly for components exposed to extreme conditions such as high temperatures, pressure, and wear. Techniques like electrochemical machining (ECM), laser machining, and precision grinding are often used to achieve the necessary surface finishes that can reduce friction, improve aerodynamics, and prevent corrosion.

Future Trends in Aerospace Machining

1. Automation and Robotics

Automation is becoming increasingly important in aerospace machining. Robotic systems and automated machining centers can improve efficiency, reduce human error, and achieve more consistent results across large production runs. Robotics also allows for greater precision in handling complex components and performing tasks that might be too dangerous for humans.

2. Sustainable Manufacturing Practices

As environmental concerns grow, aerospace manufacturers are exploring ways to make the machining process more sustainable. This includes reducing material waste, lowering energy consumption, and recycling scrap materials. Techniques such as water-based cutting and the use of environmentally friendly lubricants are gaining popularity.

3. Advancements in Materials Science

The development of new materials is driving innovation in aerospace machining. For example, researchers are exploring graphene, nanomaterials, and high-performance polymers that offer improved strength-to-weight ratios, better heat resistance, and greater durability. These materials could significantly enhance the performance of aerospace components.

Conclusion

Aerospace machining is a highly specialized field that demands advanced techniques, precision, and the ability to work with complex materials. Key techniques like CNC machining, electrochemical machining, laser beam machining, and additive manufacturing are critical to producing the components required for modern air and space vehicles. Despite the challenges, including material complexity, tight tolerances, and the need for lightweight yet strong components, the aerospace industry continues to evolve with technological innovations in machining, materials, and manufacturing processes. As the industry moves forward, trends like automation, sustainable practices, and material science advancements will continue to shape the future of aerospace machining.

FAQs

What is the most common material used in aerospace machining?

A: Aluminum alloys, especially 6061, 7075, and 2024, are the most commonly used materials in aerospace machining due to their excellent strength-to-weight ratio and corrosion resistance. Titanium alloys and composite materials like CFRP are also widely used for critical applications.

How does CNC machining benefit aerospace component manufacturing?

A: CNC machining offers high precision, repeatability, and complex geometry capabilities, which are crucial in the aerospace industry. It allows manufacturers to produce intricate components with tight tolerances, ensuring that aerospace parts meet rigorous standards for quality, performance, and safety.

What are the main challenges in aerospace machining?

A: Major challenges include material complexity, the need for tight tolerances, and the requirement for components to be both lightweight and strong. Additionally, ensuring surface finish quality and dealing with the wear and tear of specialized tools when machining hard materials like titanium and composites also present significant obstacles.