In the precise world of machining, creating a specific cavity or groove is a fundamental task. Whether it's for a keyway in a shaft, a guide rail in a machine bed, or a coolant channel in a mold, the ability to machine precise slots is crucial. This is where slot milling, a core milling operation, comes into play. This comprehensive guide dives deep into slot milling techniques, from the basic principles to advanced applications. We'll explore the tools for milling slots, suitable materials, and the key advantages this process offers to engineers, machinists, and manufacturing professionals. By the end, you'll have a thorough understanding of how to effectively apply slot milling strategies to your projects.

What Is Slot Milling?

Slot milling is a milling process specifically designed to cut narrow, elongated cavities—or slots—into a workpiece. These slots can be through (cutting completely through the material) or blind (ending at a certain depth within the material). The primary function is to create features that allow for the assembly of parts, provide pathways, or facilitate the movement of components. It is one of the most common and essential machining operations in workshops and production floors, forming the basis for more complex milling tasks.

How Does Slot Milling Work?

The process involves a rotating end mill tool whose axis of rotation is typically perpendicular to the workpiece surface. The cutting edges on the periphery and often the bottom (face) of the tool engage with the material, removing it in the form of chips to form the slot. Successful slot milling relies on several critical parameters:

- Width of Cut: This is determined by the diameter of the cutter. A slot milling cutter with a diameter matching the desired slot width can complete it in a single pass.

- Depth of Cut: The axial distance the tool plunges into the material. Deep slots may require multiple step-down passes to avoid tool overload.

- Feed Rate and Spindle Speed: These must be carefully calculated based on the tool material, workpiece material, and desired surface finish to ensure efficient material removal and tool life.

- Cutting Path: For slots wider than the available tool, strategies like side milling (creating the slot's walls) and plunge milling (for roughing out material) are used.

Case in Point: Imagine machining a T-slot into an aluminum machine table. The operator wouldn't use a T-shaped cutter immediately. First, a standard end mill would be used to mill the vertical, narrow channel (slot milling the basic groove). Then, a special T-slot cutter would be employed to undercut and form the wider base of the "T". This two-step process showcases how slot milling is often integrated with other milling operations.

Types of Slot Milling Operations

Not all slots are created equal, and neither are the methods to machine them. Here are the primary types of slot milling:

- Plain Slot Milling: The most basic form, using an end mill to cut a slot with straight, parallel sides and a flat bottom.

- Side Milling: The cutter machines the side of a workpiece to create a slot or a surface. It's effective for creating slots wider than the cutter by making multiple passes.

- Plunge Milling: Here, the feed is directed axially into the material. It's excellent for roughing out material in deep cavities or starting slots, acting as a precursor to side milling.

- Gang Milling: Multiple cutters are mounted on the same arbor to machine several surfaces or slots simultaneously, dramatically increasing productivity for repeat features.

- T-Slot & Dovetail Milling: These involve specialized cutters to create inverted-T or trapezoidal-shaped slots used for clamping and precise linear motion, respectively.

What Tools Are Needed?

Selecting the right tool is paramount for successful slot milling. The choice depends on slot dimensions, material, and precision requirements.

| Tool Type | Best For | Key Considerations |

|---|---|---|

| End Mill (2-flute) | Slotting in aluminum and other non-ferrous metals; provides good chip evacuation. | The flute count is critical. 2-flute tools offer more chip space for deep slot milling. |

| End Mill (3+ flute) | Slotting in steel and harder materials; provides a finer finish and more rigid cut. | Higher flute counts reduce chip space; shallower depths of cut are often necessary. |

| Slot Drill / Slot Mill | True slot milling operations where the tool can plunge directly into the material. | Typically has cutting edges that extend to the center, unlike some end mills. |

| Woodruff Keyseat Cutter | Specifically for cutting semicircular keyseats (Woodruff key slots). | A specialized form tool for a specific machining operation. |

| T-Slot & Dovetail Cutters | Creating the respective locking and sliding profiles. | Always require a pre-milled plain slot for the neck of the cutter to enter. |

Professional Insight: For high-performance slot milling in tough materials like titanium or hardened steels, modern solid carbide end mills with specialized coatings (like AlTiN) are essential. They allow for higher temperatures and pressures, enabling efficient material removal where HSS tools would fail.

Which Materials Are Suitable?

Slot milling is applicable to a vast range of materials. The process parameters and tooling change, but the fundamental operation remains.

- Metals: Extremely common. This includes aluminum (easy to machine, high speeds), steel (requires robust tools and lower speeds), stainless steel (tough, work-hardening, needs constant feed), and titanium (high strength, low thermal conductivity, demanding careful strategy).

- Plastics & Composites: Can be machined well but require sharp tools to prevent melting or delamination. Chip evacuation is still crucial.

- Wood: A traditional application for routing operations, which is a form of slot milling.

- Limitations: Very soft, gummy materials (like certain pure coppers or soft plastics) can be challenging due to chip adhesion. Brittle materials like ceramics typically require grinding rather than milling operations.

What Are the Key Applications?

The applications of slot milling are ubiquitous across industries. It is a foundational machining process for creating functional part features.

- Aerospace: Machining lightening slots, guide rails, and cooling channels in engine components and airframe structures.

- Automotive: Creating keyways for gears on transmission shafts, milling slots for piston rings, and machining features in engine blocks.

- Mold & Die: Producing intricate slots and channels for ejector pins, cooling lines, and vents in injection molds and stamping dies.

- General Machinery: Manufacturing keyseats for shaft-hub connections, T-slots for machine tool beds, and guideways for linear motion systems.

- Consumer Electronics: Precise slot milling for heat sinks, connector slots, and internal guides in device housings.

Advantages and Limitations

Understanding the pros and cons helps in selecting slot milling over other processes.

Advantages:

- Versatility: Can produce a wide variety of slot profiles (plain, T, dovetail) with standard and specialized tooling.

- High Efficiency: Modern CNC machines and tools allow for very fast material removal rates, especially in softer materials.

- Excellent Precision and Finish: Capable of holding tight tolerances (often within ±0.025 mm or better) and producing fine surface finishes suitable for bearing surfaces.

- Flexibility: Easily integrated into complex machining sequences on CNC machining centers.

Limitations:

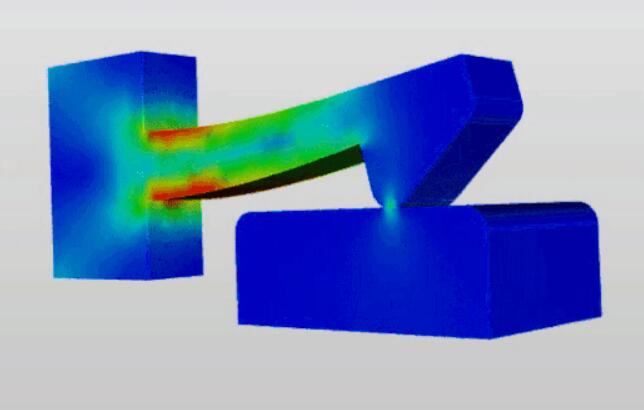

- Tool Deflection and Breakage: In deep slot milling, long tools can deflect, causing taper and risking breakage. This requires careful toolpath strategies (e.g., trochoidal milling).

- Chip Evacuation Challenges: Removing chips from deep, narrow slots is difficult and can lead to recutting, poor surface finish, and tool damage.

- Heat Generation: Concentrated cutting in a confined area generates significant heat, which can affect tool life and part geometry, necessitating effective cooling.

- Not Ideal for All Profiles: Extremely intricate internal profiles might be better suited for EDM (Electrical Discharge Machining).

Conclusion

Slot milling is far more than just making a groove; it is a fundamental, versatile, and powerful milling process critical to modern manufacturing. From the simple keyway to the complex T-slotted table, mastering slot milling techniques—including the right choice of tools for milling slots, parameters, and strategies—is essential for any machinist or engineer. By understanding its principles, applications, and nuances, you can leverage this operation to produce high-quality, functional parts efficiently and reliably, forming the backbone of countless mechanical assemblies.

FAQ

What is the difference between slot milling and side milling?

Slot milling typically refers to cutting an enclosed, narrow cavity where the tool's diameter defines the slot width. Side milling is a broader term for machining the side surface of a workpiece, which can be used to create a slot by making successive passes but is not limited to slot creation.

How do I prevent tool breakage in deep slot milling?

Use tools with a shorter flute length than the slot depth whenever possible. Employ trochoidal milling or plunge milling strategies to reduce radial engagement and heat buildup. Ensure robust chip evacuation using compressed air or high-pressure coolant.

Can I use a 4-flute end mill for slotting?

Yes, especially in harder materials like steel, as it provides a more rigid cut. However, for deep slot milling or in gummy materials like aluminum, a 2 or 3-flute end mill is preferable due to its larger chip gullet, which improves chip removal and prevents clogging.

What is the best speed and feed for slot milling?

There is no single answer, as it depends on the tool material, workpiece material, tool diameter, and machine rigidity. Always start with the tool manufacturer's recommended parameters and adjust based on cutting sound, chip formation, and tool wear. For example, slotting in aluminum with a 10mm carbide end mill might start at 1200 SFM and 0.08 mm per tooth, while the same tool in mild steel might run at 300 SFM and 0.05 mm per tooth.

Contact Yigu for Custom Manufacturing.

Do you have a project requiring precision slot milling or complex machining operations? At Yigu, we combine expert engineering with advanced CNC technology to deliver high-quality, custom-manufactured components. From prototype to production, our team ensures every slot, groove, and feature meets your exact specifications. Reach out today for a consultation and quote.