Introduction to Mold Manufacturing in the Plastic Revolution

In the ever - evolving landscape of modern manufacturing, the plastic revolution has been nothing short of transformative. At the heart of this revolution lies mold manufacturing, a critical process that serves as the backbone for the production of a vast array of plastic products we encounter in our daily lives.

Plastics have infiltrated nearly every aspect of our existence, from the consumer goods we use at home, such as kitchenware, toys, and packaging materials, to the components in automobiles, electronics, and medical devices. The versatility, durability, and cost - effectiveness of plastics have made them the material of choice for countless applications. However, none of these plastic products could be produced on a large scale without the precision and efficiency offered by mold manufacturing.

Mold manufacturing can be likened to the art of creating a master template. A mold is a specialized tool that is used to shape liquid or semi - liquid materials, in this case, plastics, into a desired form. Once the mold is created, it can be used repeatedly to produce identical plastic parts with high precision and at a relatively low cost per unit. This mass - production capability has been a game - changer, enabling industries to meet the growing global demand for plastic products.

For Yigu Technology example, in the automotive industry, plastic components have become increasingly common. From interior dashboard panels to exterior body parts, plastics are used to reduce weight, improve fuel efficiency, and enhance design flexibility. A single car can contain hundreds of plastic parts, all of which are produced using molds. In the electronics sector, the miniaturization and complex designs of devices like smartphones and tablets would be impossible without the highly precise molds that can create intricate plastic casings and internal components.

The significance of mold manufacturing in the plastic revolution is further underscored by the fact that it has enabled the development of new and innovative plastic products. As mold - making technologies have advanced, manufacturers have been able to create more complex shapes, thinner walls, and higher - quality finishes, opening up new possibilities for product design and functionality.

In the following sections, Yigu Technology will delve deeper into the various aspects of mold manufacturing in the plastic revolution, including different types of molds, the manufacturing process, emerging trends, challenges, and future prospects.

Key Types of Mold Manufacturing in Plastic Production

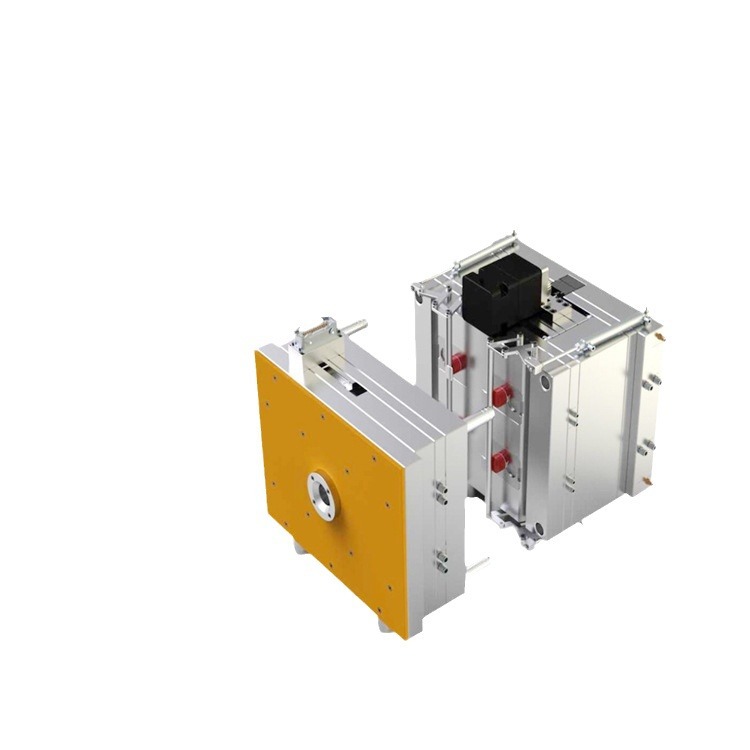

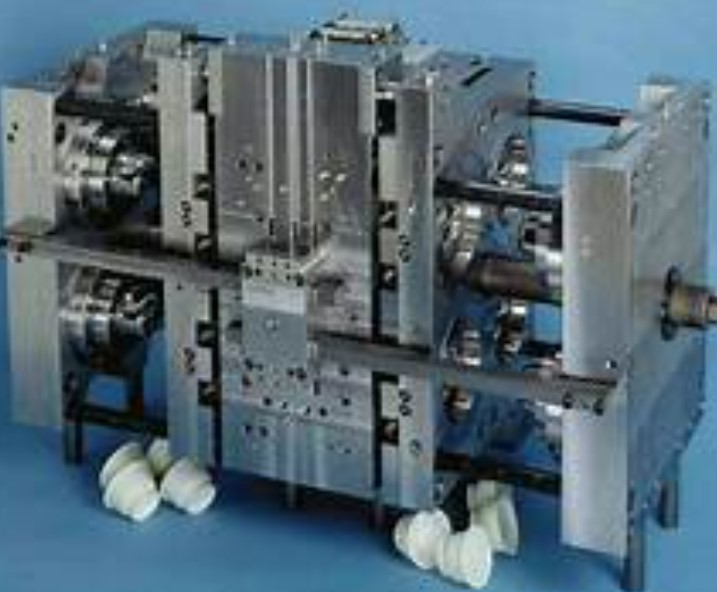

Injection Molding

Injection molding is one of the most widely used methods in plastic mold manufacturing. The principle behind injection molding is relatively straightforward yet highly effective. It begins with plastic pellets being fed into a heated barrel. Inside the barrel, a screw rotates, melting the plastic pellets through a combination of heat and shear forces. Once the plastic reaches a molten, viscous state, the screw exerts pressure to inject this molten plastic into a closed mold cavity.

The process cycle of injection molding typically consists of several key steps:

- Clamping: The mold halves are brought together with high force to ensure a tight seal during the injection process. This clamping force prevents the molten plastic from escaping and is crucial for maintaining the integrity of the mold cavity.

- Injection: As mentioned earlier, the molten plastic is forced into the mold cavity at high pressure. The speed and pressure of injection are carefully controlled parameters, as they can significantly impact the quality of the final product. For Yigu Technology example, too high an injection pressure can cause flash (excess plastic seeping out of the mold), while too low a pressure may result in incomplete filling of the mold.

- Holding Pressure and Cooling: After the mold is filled, a holding pressure is applied to compensate for the shrinkage of the plastic as it cools. During this stage, the plastic gradually solidifies within the mold cavity, taking on the shape of the mold. Cooling channels within the mold help to accelerate this cooling process, and the temperature of the cooling medium (usually water) is also a critical factor in determining the cooling time and the quality of the final part.

- Ejection: Once the plastic has solidified sufficiently, the mold opens, and a system of ejector pins pushes the finished plastic part out of the mold.

Injection molding finds applications in a vast number of industries. In the automotive industry, it is used to produce a wide range of components such as dashboards, bumpers, and interior trims. For instance, a modern car's dashboard is a complex assembly of various plastic parts, all of which are likely produced through injection molding. These parts not only need to have precise dimensions for a perfect fit but also need to meet high - quality standards in terms of aesthetics and durability.

In the electronics industry, injection molding is the go - to process for manufacturing device housings. Smartphones, tablets, and laptops all have plastic casings that are injection - molded. These casings need to be lightweight yet strong enough to protect the delicate internal components. Additionally, they often require a high - quality finish to appeal to consumers.

When it comes to cost, injection molding can be a cost - effective solution, especially for high - volume production. However, the initial investment in equipment and mold manufacturing can be substantial. A small - scale injection molding factory with a few basic injection molding machines and limited mold - making capabilities might have an initial investment of around \(100,000 - \)500,000. This includes the cost of the injection molding machines, molds, and basic auxiliary equipment. For a medium - sized factory with more advanced equipment and a larger production capacity, the investment could range from \(500,000 - \)2 million. Larger, high - volume production facilities might invest upwards of \(2 million, with the cost of a single high - precision mold for a complex part potentially costing hundreds of thousands of dollars. But as the production volume increases, the cost per unit can drop significantly. For example, for a simple plastic part, if produced in small quantities (say, 1000 units), the cost per unit might be \)5 - \(10. However, when the production volume reaches 100,000 units or more, the cost per unit could drop to \)1 - $3.

Blow Molding

Blow molding is another important technique in the realm of plastic mold manufacturing, particularly well - suited for creating hollow plastic products. The fundamental working principle of blow molding involves heating a plastic parison (a tube - like piece of semi - molten plastic). Once the parison is heated to the appropriate temperature, it is placed inside a two - part mold. Compressed air is then introduced into the parison, causing it to expand and take on the shape of the mold cavity.

There are different types of blow molding processes, with the two most common being extrusion blow molding and injection blow molding. In extrusion blow molding, the parison is extruded continuously from an extruder. This method is often used for producing larger hollow products such as industrial drums, water tanks, and large - scale containers. For example, the large plastic water tanks used in many households and industrial settings are typically made through extrusion blow molding. The process allows for the production of these tanks in various sizes and shapes, with relatively thick walls to ensure durability.

Injection blow molding, on the other hand, starts with an injection - molded preform. This preform is then transferred to a blow - molding station where it is reheated and blown into the final product shape. This method is commonly used for producing smaller, more precise hollow products like plastic bottles for beverages, cosmetics, and pharmaceuticals. For instance, the small, sleek bottles used for high - end perfumes or expensive skincare products are often made through injection blow molding. The process enables the production of bottles with very thin walls while maintaining high dimensional accuracy and a smooth surface finish.

The cost and efficiency of blow molding can vary depending on factors such as the thickness of the 塑料制品. Consider the production of plastic bottles. For a bottle with a relatively thin wall (say, 0.5 - 1 mm), the production cost per unit might be lower due to less material usage. If the production volume is high (e.g., 100,000 bottles), the cost per bottle could be around \(0.1 - \)0.3. The production efficiency is also high, with modern blow - molding machines capable of producing a large number of bottles per hour. However, when producing thicker - walled plastic products, such as industrial drums with walls 3 - 5 mm thick, the material cost increases significantly. The cost per unit for a large industrial drum in high - volume production might be \(10 - \)30. The production process also takes longer due to the need for more time to heat and cool the thicker plastic, resulting in a lower overall production efficiency compared to thinner - walled products.

The following Yigu Technology table provides a more detailed comparison:

| Product Thickness | Cost per Unit (High - volume Production) | Production Efficiency (Products per Hour) |

| Thin - walled (0.5 - 1 mm, e.g., small plastic bottles) | \(0.1 - \)0.3 | 500 - 1000 |

| Medium - walled (1 - 3 mm, e.g., some household containers) | \(0.5 - \)1 | 200 - 500 |

| Thick - walled (3 - 5 mm, e.g., industrial drums) | \(10 - \)30 | 50 - 100 |

Compression Molding

Compression molding is a process that is particularly useful for certain types of plastics, especially thermosetting plastics and some rubber materials. The operation of compression molding involves several distinct steps. First, a pre - measured amount of raw material, which can be in the form of a powder, pellet, or pre - formed shape (such as a pre - press), is placed into the lower half of a heated mold.

The mold is then closed, and pressure is applied. This pressure forces the material to flow and fill the entire mold cavity. As the material is compressed, heat is also applied. In the case of thermosetting plastics, the heat causes a chemical reaction to occur, known as curing. This curing process transforms the plastic from a malleable state into a hardened, rigid form that retains the shape of the mold.

Rubber products are often made using compression molding. For Yigu Technology example, rubber gaskets, which are used in a wide range of applications from automotive engines to plumbing fixtures, are commonly produced through this method. The process allows for the creation of gaskets with precise dimensions and the ability to withstand high pressures and temperatures.

Thermosetting plastic products such as electrical insulators and some types of kitchenware handles are also made using compression molding. These products require the high - temperature resistance and dimensional stability that thermosetting plastics offer, and compression molding is an ideal process to achieve these properties.

When it comes to the choice of mold materials for compression molding, different materials have different characteristics in terms of cost and lifespan. Steel molds are known for their high strength and durability. A steel mold for compression molding can have a lifespan of up to 500,000 - 1,000,000 cycles, depending on the complexity of the mold and the operating conditions. However, steel molds are relatively expensive to manufacture, with the cost of a medium - sized steel mold for compression molding ranging from \(10,000 - \)50,000. Aluminum molds, on the other hand, are lighter and less expensive to produce. The cost of an aluminum mold for a similar application might be \(5,000 - \)20,000. But aluminum molds have a shorter lifespan, typically around 100,000 - 300,000 cycles, as they are more prone to wear and tear under the high - pressure and high - temperature conditions of compression molding.

Rotational Molding

Rotational molding, also known as rotomolding, is a unique and specialized form of plastic mold manufacturing. The process involves placing a measured amount of powdered or liquid plastic material into a hollow mold. The mold is then placed into an oven and rotated simultaneously on two axes.

As the mold rotates, the plastic material inside gradually melts and coats the inner surface of the mold due to the action of gravity and centrifugal force. The even distribution of the plastic around the mold walls is a key advantage of rotational molding. Once the plastic has fully melted and adhered to the mold, the mold is removed from the oven and cooled, usually by air or water spraying. As it cools, the plastic solidifies, taking on the shape of the mold cavity.

One of the significant applications of rotational molding is in the production of large - scale products such as water storage tanks, chemical storage tanks, and large - sized containers. These large - scale water tanks can range in size from a few hundred liters to several thousand liters and are used in both domestic and industrial settings for storing water, chemicals, and other liquids.

Rotational molding is also commonly used in the production of children's 游乐设施,such as playground equipment like swings, slides, and climbing frames. The process allows for the creation of these products with smooth surfaces, rounded edges, and complex shapes, ensuring the safety and durability of the equipment.

The production cycle of rotational molding can vary depending on the size of the product. For a small - sized rotomolded product, such as a 50 - liter water tank, the production cycle might be around 30 - 60 minutes. This includes the time for heating the mold and melting the plastic, rotating the mold to distribute the plastic evenly, cooling the mold to solidify the plastic, and removing the finished product from the mold. For a large - scale product, like a 5000 - liter industrial storage tank, the production cycle can be several hours, typically 3 - 6 hours, due to the larger amount of plastic material involved and the longer time required for heating, cooling, and ensuring proper curing of the plastic. The following Yigu Technology table shows the approximate production cycle times for different - sized rotomolded products:

| Product Size | Production Cycle Time |

| Small (50 - 100 liters, e.g., small water tanks) | 30 - 60 minutes |

| Medium (100 - 1000 liters, e.g., medium - sized storage containers) | 1 - 3 hours |

| Large (1000 - 5000 liters, e.g., large industrial storage tanks) | 3 - 6 hours |

Conclusion

In the grand scheme of the plastic revolution, mold manufacturing stands as an indispensable pillar. It has not only enabled the mass - production of plastic products that have become an integral part of our lives but has also spurred innovation in product design and functionality.

The different types of mold manufacturing, including injection molding, blow molding, compression molding, and rotational molding, each offer unique advantages and are tailored to specific product requirements. For example, injection molding is ideal for high - volume production of complex - shaped parts, while blow molding is the go - to for hollow products. Compression molding is well - suited for thermosetting plastics and rubber, and rotational molding excels in creating large - scale, one - piece products.

When considering a plastic product development project, Yigu Technology choosing the right mold manufacturing method is of utmost importance. It can significantly impact the cost, quality, and production efficiency of the final product. Factors such as the type of plastic material, the complexity of the product design, the required production volume, and the desired product quality all need to be carefully evaluated.

As the plastic industry continues to evolve, driven by advancements in technology, changes in consumer demands, and environmental considerations, mold manufacturing will also need to adapt and innovate. New materials, more efficient manufacturing processes, and the integration of digital technologies such as 3D printing and AI - driven design optimization are likely to shape the future of mold manufacturing in the plastic revolution. By staying informed about these trends and making informed decisions regarding mold manufacturing methods, manufacturers can position themselves for success in this dynamic and ever - changing industry.

FAQ

1. What is the most cost - effective mold manufacturing method for high - volume production?

Injection molding is often the most cost - effective for high - volume production. Although the initial investment in equipment and molds is high, as the production volume increases, the cost per unit drops significantly due to its high - speed production capabilities.

2. Can the same mold be used for different types of plastics?

In most cases, different plastics have different melting points, viscosities, and shrinkage rates. So, a mold designed for one type of plastic may not be suitable for another without significant modifications. However, some molds can be adjusted to work with plastics that have similar properties.

3. How long does it typically take to develop a new mold?

The time to develop a new mold can vary greatly depending on its complexity. A simple mold might take a few weeks, while a highly complex mold for a precision - engineered product could take several months. Factors such as design complexity, material selection, and the manufacturing process used for the mold all influence the development time.