Introduction

The Significance of Plastic Moulds

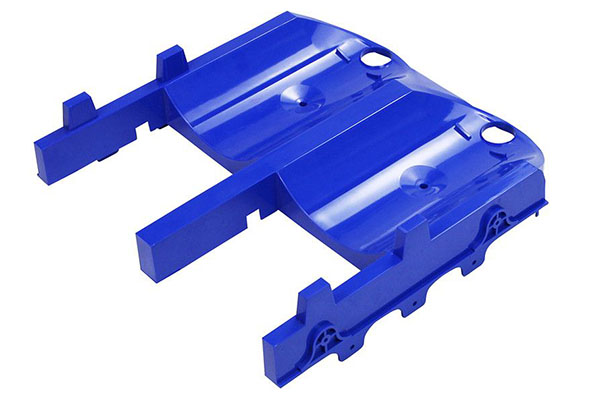

In the modern manufacturing landscape, plastic moulds stand as the cornerstone of countless industries. Their importance cannot be overstated, as they are the key elements in the production of a vast array of plastic products that we encounter in our daily lives.

Plastic moulds are extensively used in the automotive industry. They are responsible for manufacturing interior components like dashboards, door panels, and seat covers, as well as exterior parts such as bumpers and body panels. These mould - made plastic parts not only reduce the overall weight of vehicles, thereby improving fuel efficiency, but also offer design flexibility, allowing for aerodynamic and aesthetically pleasing shapes. According to a report by the Society of Plastics Engineers, around 50% of a vehicle's volume is composed of plastics, and plastic moulds play a crucial role in shaping these components.

In the electronics sector, plastic moulds are indispensable. From the sleek casings of smartphones and tablets to the intricate parts inside laptops and gaming consoles, plastic moulds enable the mass production of high - precision components with consistent quality. For instance, the tiny connectors and brackets in electronic devices are often made using plastic injection moulding with custom - designed moulds. The global electronics market's continuous growth, which is projected to reach $2.7 trillion by 2027 according to market research firm Statista, is closely tied to the capabilities of plastic mould - making technology.

The medical field also heavily relies on plastic moulds. Medical devices such as syringes, catheters, and diagnostic equipment components are made using plastic moulds that meet strict quality and hygiene standards. These moulds ensure the production of sterile, reliable, and cost - effective medical products. With the increasing demand for medical devices, especially in emerging economies, the role of plastic moulds in the medical industry is becoming even more significant.

Given their far - reaching applications across diverse industries, understanding how to make high - quality plastic moulds is essential. This article, "Crafting for Success: Making Moulds for Plastic", aims to provide in - depth knowledge about the process, materials, and techniques involved in plastic mould - making, equipping you with the information needed to succeed in this field.

Types of Plastic Moulding Processes

Injection Moulding

Injection moulding is one of the most widely used plastic moulding processes. The principle is straightforward yet highly effective. Plastic granules are first fed into a heated barrel, where they are melted into a viscous state. Then, a high - pressure screw or plunger injects this molten plastic into a closed mould cavity. The mould cavity is designed to the exact shape of the final product. Once the cavity is filled, the plastic is cooled and solidified within the mould. Finally, the mould opens, and the finished plastic part is ejected.

The process can be broken down into several key steps:

- Feeding: Plastic raw materials in granule form are loaded into the hopper of the injection - moulding machine.

- Melting: The granules are heated in the barrel, usually by electrical heaters around the barrel, and are melted by the rotation of the screw.

- Injection: The molten plastic is forced into the closed mould cavity at high pressure.

- Cooling: The plastic inside the mould is cooled, either by natural heat dissipation or by a cooling system in the mould, until it solidifies.

- Ejection: The mould opens, and the ejector pins push the solid plastic part out of the mould.

This process is suitable for a vast range of products. In the automotive industry, it is used to make components like dashboard components, which require high precision and complex shapes to fit perfectly into the vehicle's interior design, and engine covers, which need to have specific heat - resistant and mechanical properties. In the electronics sector, injection - moulded parts include smartphone cases, which must be lightweight, durable, and have a smooth surface finish for an appealing look, and computer keyboard keys, which require precise sizing for proper functionality.

In terms of market share, injection moulding is dominant. According to market research, in the global plastic moulding market, injection moulding accounts for approximately 40% of the total market share. This high percentage is due to its ability to produce high - volume, high - precision parts efficiently.

Blow Moulding

Blow moulding is another important plastic moulding process, especially for the production of hollow plastic products. The basic steps are as follows:

- Pre - form creation: First, a parison (a tube - like piece of molten plastic) is formed. This can be done through extrusion (extrusion blow moulding) or injection (injection blow moulding). In extrusion blow moulding, the plastic is melted and extruded through a die to form a parison. In injection blow moulding, a pre - form is injection - moulded first.

- Mould clamping: The parison is then placed inside a blow mould, and the mould closes around it, gripping the parison at the ends.

- Blowing: Compressed air is injected into the parison, causing it to expand and take the shape of the mould cavity.

- Cooling and solidification: The blown - up plastic is cooled, either by air or water, until it solidifies into the final product shape.

- Mould opening and product removal: The mould opens, and the finished hollow product, such as a plastic bottle, is removed.

When comparing blow moulding with injection moulding:

| Comparison Aspect | Injection Moulding | Blow Moulding |

| Cost | Higher initial tooling cost, but lower per - unit cost for high - volume production. | Lower tooling cost, but higher per - unit cost for small - volume production. |

| Production Efficiency | High production speed, suitable for mass production. | Relatively slower production speed compared to injection moulding. |

| Product Thickness | Can achieve more uniform wall thickness in complex - shaped products. | Wall thickness may vary, especially in large - scale hollow products. |

| Product Complexity | Can produce highly complex shapes with intricate details. | Limited to hollow, relatively simple - shaped products. |

Compression Moulding

Compression moulding involves the following process: A pre - measured amount of plastic material, either in the form of granules, pellets, or a pre - formed shape (a pre - form), is placed into an open mould cavity. The mould is then closed, applying heat and pressure simultaneously. The heat softens the plastic, and the pressure forces it to fill the entire mould cavity. As the plastic cools and solidifies within the mould, it takes on the shape of the cavity. Once fully solidified, the mould is opened, and the finished product is removed.

This method has its own set of advantages and disadvantages. One of the main advantages is that it can be used for a wide range of plastic materials, including thermosetting plastics that cannot be processed by other methods easily. It also allows for the production of large - sized parts with thick walls. However, the process is relatively slow compared to injection moulding, and it may not be suitable for producing parts with very complex geometries.

Compression moulding is commonly used in manufacturing products such as electrical appliance housings, which need to be sturdy and heat - resistant to protect the internal components, and plastic tableware, where the process can create smooth surfaces and simple shapes efficiently.

Rotational Moulding

Rotational moulding, also known as rotomoulding, has a unique principle. In this process, a measured amount of powdered or liquid plastic is placed into a hollow mould. The mould is then placed into an oven and rotated slowly on two axes simultaneously. As the mould rotates, the heat from the oven causes the plastic to melt and spread evenly along the inner surface of the mould due to centrifugal force. Once the plastic has completely coated the inner surface of the mould, the mould is removed from the oven and cooled, usually by air or water. As it cools, the plastic solidifies, taking the shape of the mould cavity, and a hollow, seamless product is formed.

This process is particularly suitable for producing large - scale, hollow products. For example, large water storage tanks, which require a large - scale, seamless structure to hold a significant amount of liquid without leakage, and large - sized toys like inflatable playground equipment, which need to be durable and have a smooth outer surface for safety reasons, are often made using rotational moulding. The reason it is ideal for such products is that it can create large, uniform - wall - thickness hollow items without the need for complex joining or assembly processes.

Materials Used in Making Plastic Moulds

Steel

Steel is a popular choice for making plastic moulds due to its numerous advantages. One of the key strengths of steel is its high strength. It can withstand the high pressures and forces exerted during the plastic moulding process without deforming easily. For example, in injection moulding, where molten plastic is injected into the mould cavity at high pressure, a steel mould can maintain its shape and integrity over a large number of production cycles.

Steel also offers excellent wear resistance. The continuous friction between the molten plastic and the mould surface during the injection and ejection processes can cause wear on the mould. Steel's high - hardness properties make it highly resistant to this wear, ensuring a long - lasting mould. Different types of steel are used in plastic mould - making, each with its own set of properties.

For instance, P20 steel is a pre - hardened plastic mould steel. It has good machinability and is suitable for making large - scale and complex - shaped plastic moulds. P20 steel is often used in the production of automotive interior parts moulds, such as dashboard moulds. These moulds require complex geometries to match the interior design of vehicles, and P20 steel can be easily machined to achieve the required shapes.

Another type, S136 steel, is known for its high corrosion resistance. This makes it ideal for applications where the mould will be exposed to corrosive substances or environments. In the medical industry, for example, when making moulds for medical devices like syringes or catheters, S136 steel is a great choice. The medical devices often come into contact with various chemicals and body fluids, and the corrosion - resistant S136 steel ensures that the moulds do not corrode, which could otherwise affect the quality and safety of the medical products.

The table below shows a comparison of some common steel types used in plastic mould - making:

| Steel Type | Strength | Wear Resistance | Corrosion Resistance | Machinability | Cost | Suitable Applications |

| P20 | High | Good | Moderate | Excellent | Moderate | Large - scale, complex - shaped moulds (e.g., automotive interior parts) |

| S136 | High | Good | High | Good | High | Moulds for products in corrosive environments (e.g., medical devices) |

| 718 | High | Excellent | Good | Good | High | High - precision moulds for products with high surface finish requirements (e.g., luxury consumer goods) |

Aluminum

Aluminum is also widely used in plastic mould - making, especially when certain specific properties are required. One of the main advantages of aluminum is its low density, which results in lightweight moulds. This makes it easier to handle and install the moulds, reducing the overall weight of the mould - making equipment. For example, in small - scale production setups where the moulds need to be frequently changed or moved, the lightweight nature of aluminum moulds can significantly improve the efficiency of the production process.

Aluminum has excellent thermal conductivity. It can dissipate heat quickly, which is beneficial during the plastic moulding process. In injection moulding, for instance, rapid cooling of the molten plastic in the mould cavity is crucial to shorten the production cycle. Aluminum's high thermal conductivity allows for faster heat transfer from the plastic to the surrounding environment or cooling medium, reducing the cooling time and increasing the production speed.

Aluminum - based moulds are commonly used in the production of consumer electronics products. For example, the moulds for making smartphone cases are often made of aluminum. The lightweight and good - heat - dissipating properties of aluminum ensure that the moulds can be easily handled during the manufacturing process, and the fast cooling helps in quickly producing high - quality smartphone cases with a smooth surface finish. They are also used in the production of small - scale plastic toys, where the relatively low cost and easy - to - machine nature of aluminum make it an attractive option for creating moulds with various shapes and sizes.

However, aluminum also has some limitations. Its hardness is lower compared to steel, which means it may not be as suitable for applications where the mould needs to withstand extremely high pressures or abrasive plastics.

Other Materials

In addition to steel and aluminum, other materials are also used in plastic mould - making, each with its own niche applications.

Thermoplastic plastics can be used to make moulds, especially for low - volume production or prototyping. Materials like acrylonitrile - butadiene - styrene (ABS) and polycarbonate (PC) are sometimes used. ABS has good impact resistance and is relatively easy to machine, making it suitable for creating simple moulds for small - scale production or for testing product designs. PC, on the other hand, has high strength and heat resistance, which can be useful in certain mould - making applications where these properties are required.

Composites, such as fiber - reinforced plastics, are also emerging as materials for plastic moulds. These composites often combine the strength of fibers (such as carbon fiber or glass fiber) with the moldability of plastics. They can offer a good balance of strength, lightweight properties, and corrosion resistance. For example, carbon - fiber - reinforced plastics can be used to make moulds for high - performance automotive parts or aerospace components. These moulds need to be strong, lightweight, and able to withstand high temperatures and pressures, and the properties of carbon - fiber - reinforced composites make them suitable for such demanding applications.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology has in - depth insights into making plastic moulds.

When it comes to material selection, we consider not only the basic properties of materials like steel and aluminum but also the specific requirements of the products. For example, for high - precision and high - volume production moulds, we might opt for high - quality steel grades with excellent wear resistance to ensure long - term stable production.

In terms of process control, we have a strict quality management system. Each step of the mould - making process, from machining to surface treatment, is carefully monitored. We use advanced equipment and techniques to ensure that the moulds meet the highest standards of precision and quality.

For mould design optimization, our experienced design team utilizes the latest CAD/CAM software. They take into account all aspects such as part geometry, shrinkage, and ejection systems. By simulating the moulding process in the design phase, we can identify and solve potential problems in advance, reducing the time and cost of trial - and - error during actual production. Our focus on these key aspects allows us to provide high - quality plastic moulds that meet and exceed our customers' expectations.