Introduction

Understanding Plastic Injection Molding

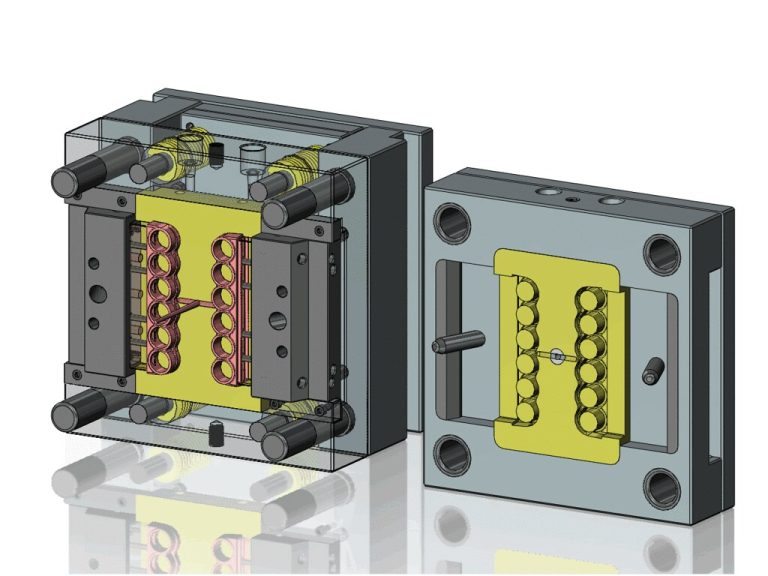

Plastic injection molding is a widely used manufacturing process that has revolutionized the production of plastic components across various industries. In this process, molten plastic material is injected under high pressure into a mold cavity. The mold, typically made of steel or aluminum, is precisely designed to create the desired shape of the final product. Once the plastic has filled the mold, it cools and solidifies, taking on the shape of the cavity. Finally, the mold is opened, and the finished plastic part is ejected.

The process begins with the selection of the appropriate plastic resin, which comes in the form of small pellets. These pellets are fed into the hopper of an injection molding machine. Inside the machine, a screw - like mechanism, known as the screw extruder, heats and melts the plastic pellets as it rotates. This ensures that the plastic is uniformly melted and ready for injection.

The injection stage is crucial, where the molten plastic is forced into the closed mold cavity at high pressure. This high - pressure injection allows the plastic to fill even the most intricate details of the mold. After injection, the plastic is held under pressure for a short period, known as the holding or packing phase, to compensate for any shrinkage as the plastic cools.

As the plastic cools and solidifies, the mold is opened, and the finished part is removed. In some cases, additional post - processing steps such as trimming, finishing, or assembly may be required.

This process has become the go - to method for manufacturing a vast array of products, from small and intricate electronic components to large automotive parts. But what exactly makes plastic injection molding so popular in the manufacturing world? In the following sections, we will explore the numerous advantages that have led to its widespread adoption.

High - Efficiency Production

Swift Production Cycles

One of the most significant advantages of plastic injection molding is its ability to achieve swift production cycles. The process is highly automated, allowing for rapid production of individual plastic parts.

Typically, the injection phase, where the molten plastic is forced into the mold cavity, can be completed in a matter of seconds. For Yigu Technology example, in the production of small plastic components like toy parts or simple consumer goods, the injection time might be as short as 1 - 3 seconds. After injection, the cooling stage follows. Modern mold designs often incorporate efficient cooling channels, which can significantly reduce the cooling time. Depending on the size and material of the part, the cooling time can range from 5 - 30 seconds. Once the plastic has solidified, the mold is opened, and the part is ejected, which usually takes less than 1 second.

In total, for many small to medium - sized plastic parts, the entire production cycle can be completed within 10 - 40 seconds. This rapid production rate makes plastic injection molding an ideal choice for manufacturers looking to produce large quantities of parts in a short period. For instance, a single injection molding machine can produce hundreds to thousands of parts per hour, depending on the complexity of the part and the cycle time.

Mass Production Feasibility

Plastic injection molding is uniquely suited for mass production. The process's high - speed production cycles, combined with the durability of the molds, make it an economically viable option for manufacturing large volumes of products.

Take the automotive industry as an example. Every year, millions of cars are produced worldwide, and each car contains numerous plastic components. From interior parts such as dashboards, door panels, and seat covers to exterior components like bumpers and body panels, plastic injection molding is used to manufacture these parts in large quantities. A single car model may require hundreds of different plastic injection - molded parts, and the production volume for each part can reach hundreds of thousands or even millions per year.

The electronics industry is another sector that heavily relies on plastic injection molding for mass production. The demand for smartphones, tablets, laptops, and other electronic devices is constantly growing. The outer shells, internal frames, and various small components of these devices are often made through plastic injection molding. For example, a popular smartphone model might sell tens of millions of units in a year, and each unit requires multiple plastic injection - molded parts, such as the phone's housing, button covers, and speaker grilles.

Precision and Complexity

Tight Tolerances

Plastic injection molding is renowned for its ability to achieve extremely tight tolerances, making it the go - to choice for industries where precision is paramount. In general, injection - molded parts can achieve a dimensional tolerance of ±0.05 - ±0.1mm for small - sized products, and for larger parts, the tolerance can be maintained within ±0.1 - ±0.2mm. For Yigu Technology example, in the production of small, intricate electronic components like connectors, the tolerance can be as low as ±0.02mm.

When compared to 3D printing, which is also a popular manufacturing method, injection molding has a clear edge in terms of tolerance control. 3D printing, especially in the case of fused deposition modeling (FDM) technology, typically has a tolerance range of ±0.2 - ±0.5mm. This is due to the nature of 3D printing, which builds parts layer by layer. Each layer has a certain thickness, and factors such as material shrinkage, nozzle diameter, and printer calibration can all contribute to larger tolerances.

Industries such as the medical, aerospace, and electronics sectors have high - precision requirements. In the medical industry, components like syringe barrels and implantable devices need to have extremely accurate dimensions. A deviation of even a fraction of a millimeter can have serious consequences for the functionality and safety of these devices. In the aerospace industry, parts used in aircraft engines and avionics systems must meet tight tolerance standards to ensure optimal performance and reliability. For instance, a small deviation in the dimensions of a turbine blade could lead to imbalances, reduced efficiency, and potential safety hazards.

Creation of Complex Geometries

Another remarkable advantage of plastic injection molding is its capability to create complex geometries. The process can produce parts with intricate details, undercuts, and hollow interiors that would be extremely challenging or even impossible to achieve with other manufacturing methods.

Undercuts, which are features that protrude in a direction perpendicular to the axis of mold opening, can be easily formed using side - action mechanisms in the mold design. These side - action mechanisms, such as slides or lifters, move horizontally or at an angle to create the undercut features during the injection molding process. For example, in the production of a plastic toy with a handle that has an undercut shape for a better grip, the mold can be designed with a slide mechanism. As the mold closes, the slide moves into position to create the undercut shape, and when the mold opens, the slide retracts, allowing the part to be ejected.

Hollow interiors are also achievable through plastic injection molding. One common method is gas - assisted injection molding. In this process, after the molten plastic is partially injected into the mold cavity, a high - pressure gas, usually nitrogen, is introduced. The gas pushes the molten plastic towards the walls of the mold cavity, creating a hollow interior. This technique is often used in the production of large - scale plastic products such as automotive bumpers and furniture components. It not only reduces the weight of the final product but also improves its strength - to - weight ratio.

The mold design plays a crucial role in enabling the creation of complex geometries. Modern computer - aided design (CAD) and computer - aided manufacturing (CAM) technologies allow designers to create highly detailed and sophisticated mold designs. These designs can be optimized for the flow of molten plastic, ensuring that every part of the complex mold cavity is filled evenly and accurately. Additionally, advanced machining techniques such as electrical discharge machining (EDM) can be used to create intricate mold cavities with high precision, further enhancing the ability to produce complex - shaped plastic parts.

Material Versatility

Diverse Plastic Resins

Plastic injection molding offers an extensive range of plastic resins to choose from, each with its unique set of properties, making it suitable for a wide variety of applications.

ABS (Acrylonitrile Butadiene Styrene): This is a popular thermoplastic polymer. ABS combines the strength and rigidity of acrylonitrile, the toughness and impact - resistance of butadiene, and the ease of processing and high surface gloss of styrene. It has excellent mechanical properties, with high tensile strength, good impact resistance, and dimensional stability. ABS is widely used in the automotive industry for interior components like dashboards and door panels. In the electronics field, it is commonly used for the casings of appliances such as televisions, computers, and game consoles due to its good heat resistance and ability to be easily molded into complex shapes.

Nylon (Polyamide - PA): Nylon is known for its high strength, durability, and excellent abrasion resistance. It has a relatively high melting point and can withstand high temperatures without significant deformation. Nylon also has good chemical resistance and is self - lubricating, which makes it ideal for applications where friction needs to be minimized. In the industrial sector, it is used to manufacture gears, bearings, and conveyor belts. In the textile industry, nylon fibers are used to make high - performance fabrics for sportswear and outdoor gear due to their strength and moisture - wicking properties.

PET (Polyethylene Terephthalate): PET is a strong and lightweight plastic with excellent dimensional stability. It has high transparency, good chemical resistance, and is widely used in the packaging industry. For Yigu Technology example, it is the primary material for plastic beverage bottles, as it can provide a good barrier against oxygen and carbon dioxide, helping to preserve the quality of the contents. In the electronics industry, PET is used in the production of flexible printed circuit boards and LCD screens due to its electrical insulation properties and ability to be formed into thin films.

Polypropylene (PP): PP is a semi - crystalline thermoplastic with a low density, making it lightweight. It has good chemical resistance, especially to acids and alkalis, and is also heat - resistant up to a certain temperature. PP is widely used in the production of food containers, as it is non - toxic and can withstand hot - fill processes. It is also used in automotive parts such as bumpers and interior trim due to its cost - effectiveness, light weight, and good impact resistance.

Customizable Material Properties

One of the remarkable aspects of plastic injection molding is the ability to customize the properties of plastic materials to meet specific product requirements. This is achieved through the addition of various additives such as fillers, reinforcements, and modifiers.

Fillers: Fillers are substances added to the plastic resin to modify its properties and reduce costs. For example, calcium carbonate is a common filler used in plastics. When added to polypropylene, it can increase the stiffness and dimensional stability of the final product. Talc is another filler that can improve the heat resistance and stiffness of plastics. It is often used in automotive parts where these properties are crucial. Fillers can also reduce the cost of the plastic material, as they are generally less expensive than the base resin.

Reinforcements: Fiberglass and carbon fiber are two common types of reinforcements. Fiberglass - reinforced plastics (FRP) are widely used in industries such as aerospace, automotive, and construction. When fiberglass is added to a plastic resin, it significantly increases the tensile strength, flexural strength, and impact resistance of the material. For instance, in the manufacturing of aircraft components, fiberglass - reinforced plastics are used to reduce weight while maintaining high strength. Carbon fiber - reinforced plastics (CFRP) offer even higher strength - to - weight ratios. They are used in high - performance applications such as racing cars, where the reduction in weight can improve speed and fuel efficiency, and in high - end sports equipment like tennis rackets and golf clubs.

Modifiers: Plasticizers are a type of modifier used to increase the flexibility and toughness of plastics. In the production of PVC (Polyvinyl Chloride) products such as vinyl flooring and flexible hoses, plasticizers are added to make the PVC more pliable. Flame retardants are another important type of modifier. They are added to plastics to enhance their fire - resistance properties. In the electronics industry, where fire safety is a major concern, flame - retardant - modified plastics are used for the casings of electrical devices to prevent the spread of fire in case of an electrical malfunction.

Cost - Effectiveness in the Long Run

Initial Investment vs. Long - Term Savings

Plastic injection molding does require a relatively high initial investment, mainly due to the cost of mold fabrication. The cost of a mold can vary significantly based on factors such as its complexity, the materials used (usually steel or aluminum), and the precision required. For simple molds, the cost might start from a few thousand dollars, while complex, high - precision molds for large - scale production can cost upwards of \(100,000. For example, a mold for producing small plastic toy parts might cost around \)5,000 - \(10,000, considering its relatively simple design. On the other hand, a mold for manufacturing automotive bumpers, which are large and have complex shapes, could cost \)50,000 - $100,000.

In plastic injection molding, the ability to produce parts with a high level of finish directly from the mold reduces both the time and cost associated with post - processing, contributing to the overall cost - effectiveness of the manufacturing process.

Surface Finish and Aesthetics

High - Quality Surface Finishes

Plastic injection molding offers a remarkable range of surface finishes, allowing manufacturers to achieve the desired aesthetic and functional properties for their products. One of the most common finishes is the smooth, high - gloss surface. This finish gives products a sleek and modern appearance, making it highly desirable for consumer electronics, such as the glossy exteriors of smartphones and tablets. The high - gloss finish not only enhances the visual appeal but also provides a smooth texture that is pleasant to the touch.

On the other hand, matte finishes are also popular, especially in applications where reducing glare and fingerprints is important. For example, the casings of laptops often feature a matte finish. This finish not only gives the product a more professional and understated look but also helps to hide fingerprints and smudges, which can be a common issue with high - gloss surfaces.

In addition to smooth finishes, plastic injection molding can also create textured surfaces. Textures can be used for both aesthetic and functional purposes. For instance, a textured surface can mimic the look and feel of natural materials like wood or leather. In the automotive interior, plastic parts with a simulated leather texture are used to create a more luxurious and comfortable environment. These textured surfaces can also improve grip, which is beneficial for products like tool handles or sports equipment. For example, the handles of power tools often have a textured surface to ensure a secure and comfortable grip during use.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the advantages of plastic injection molding. In our day - to - day production, we leverage these benefits to meet the diverse needs of our clients and deliver high - quality products.

The high - efficiency production of plastic injection molding allows us to handle large - scale orders with tight deadlines. For example, when a client requires a large quantity of customized plastic parts for a new product launch, we can rely on the swift production cycles to ensure timely delivery. The ability to achieve tight tolerances is crucial for us, especially when manufacturing parts for industries with strict quality standards, such as the medical and aerospace sectors. We can guarantee that our products meet the precise specifications demanded by these industries.

Material versatility is another aspect that we find extremely valuable. With a wide range of plastic resins available, we can select the most suitable material for each project based on the specific requirements of our clients. Whether it's high - strength materials for industrial applications or lightweight and aesthetically pleasing plastics for consumer products, we have the flexibility to choose the right material.

In summary, plastic injection molding's advantages enable Yigu Technology to offer customized solutions, high - quality products, and efficient service to our clients, helping us to build long - term and successful partnerships in the manufacturing industry.

FAQ

What types of plastics are most commonly used in plastic injection molding?

The most commonly used plastics in plastic injection molding include ABS, which offers a combination of strength, toughness, and good surface finish, making it ideal for electronics casings and automotive interior parts. Nylon is known for its high strength, abrasion resistance, and heat resistance, often used in industrial components like gears. PET is popular for packaging due to its transparency and chemical resistance, especially in beverage bottles. Polypropylene is lightweight, has good chemical resistance, and is cost - effective, used in food containers and automotive parts. Each of these plastics has unique properties that make them suitable for different applications in the injection - molding process.

How does plastic injection molding compare to 3D printing in terms of cost?

For low - volume production (usually less than a few hundred parts), 3D printing can be more cost - effective. It has a lower upfront cost as there is no need for expensive mold fabrication. However, as the production volume increases, plastic injection molding becomes much more affordable. The high initial cost of mold making in injection molding is spread over a large number of parts, reducing the per - unit cost significantly. For example, for a production run of 10,000 parts, injection molding will likely have a much lower unit cost compared to 3D printing, making it more suitable for mass production.

Can plastic injection molding be used for small - scale production?

Plastic injection molding can be used for small - scale production, but it may not be the most cost - efficient option. The high cost of mold fabrication can make the per - unit cost quite high when producing only a small number of parts. For example, if you only need to produce 100 parts, the cost of the mold, which could be several thousand dollars, will be a significant portion of the total cost. Additionally, setting up the injection molding machine for a small - scale run may be time - consuming. However, if the parts require high precision and consistent quality, injection molding can still be a viable choice despite the cost challenges in small - scale production.