Introduction

What is Plastic Injection Molding?

Plastic injection molding is a fundamental manufacturing process that plays a pivotal role in the production of plastic components. In this process, plastic injection molding begins with plastic resin, typically in the form of small pellets. These pellets are fed into a heated barrel of an injection molding machine. Inside the barrel, the plastic is heated to a molten state through a combination of external heating elements and the mechanical action of a screw or plunger.

Once the plastic is fully molten, it is forced, under high pressure, into a carefully designed mold cavity. The mold cavity is precisely machined to the exact shape of the desired plastic part. After the mold cavity is filled with the molten plastic, it is allowed to cool and solidify. This cooling process is often facilitated by a cooling system within the mold, which helps to speed up the solidification process. Once the plastic has solidified, the mold opens, and the newly formed plastic part is ejected. This cycle of filling, cooling, and ejection is repeated continuously, allowing for the high - volume production of plastic parts.

The Process of Plastic Injection Molding

Step - by - Step Breakdown

- Material Preparation:The first step in plastic injection molding is material preparation. High - quality plastic pellets are carefully selected based on the requirements of the final product. These pellets can be made from various types of plastics, such as ABS (Acrylonitrile Butadiene Styrene), PP (Polypropylene), or PE (Polyethylene). Additives may be incorporated at this stage. For example, colorants can be added to achieve the desired color of the product. Flame retardants might be included if the end - product needs to have fire - resistant properties. Additionally, the plastic pellets are often dried to remove any moisture. Moisture in the plastic can cause defects like voids or surface imperfections in the final product. Specialized drying equipment, such as desiccant dryers, is commonly used to ensure the moisture content is reduced to an acceptable level, usually less than 0.05% for most plastics.

- Melting and Injection:Once the materials are prepared, they are fed into the barrel of the injection molding machine. The barrel is equipped with heating elements that raise the temperature of the plastic pellets. As the temperature increases, the plastic transitions from a solid to a molten state. A screw inside the barrel rotates, which not only helps in melting the plastic by generating frictional heat but also pushes the molten plastic forward. When the required amount of molten plastic has accumulated at the front of the screw, the screw moves forward rapidly, injecting the molten plastic into the mold cavity at high pressure. Injection pressures can range from 500 to 3000 bar, depending on factors like the type of plastic, the complexity of the mold, and the size of the product. For small, simple parts made of low - viscosity plastics, a lower injection pressure of around 500 - 1000 bar might be sufficient. In contrast, large, complex parts made of high - viscosity engineering plastics may require pressures closer to 3000 bar.

- Cooling and Solidification:After the mold cavity is filled with molten plastic, the cooling process begins. The mold is designed with a cooling system, typically consisting of channels through which a cooling medium, usually water or a water - glycol mixture, flows. The cooling medium absorbs the heat from the molten plastic, causing it to solidify. The cooling time is a crucial factor and can vary from a few seconds to several minutes. It depends on the thickness of the plastic part, the type of plastic, and the efficiency of the cooling system. For example, a thin - walled plastic cup may cool and solidify in just 5 - 10 seconds, while a thick - walled automotive component could take 30 seconds to a minute or more. During this cooling phase, the plastic shrinks as it solidifies, and proper design of the mold and cooling system is essential to ensure uniform shrinkage and prevent warping or dimensional inaccuracies.

- Mold Opening and Ejection:Once the plastic has solidified sufficiently, the mold opens. The two halves of the mold, the stationary half (also known as the cavity side) and the moving half (the core side), separate. Ejection pins, which are located in the core side of the mold, then push the newly formed plastic part out of the mold cavity. These ejection pins are strategically placed to ensure that the part is ejected smoothly without causing any damage. In some cases, especially for complex parts with undercuts or internal features, additional mechanisms like slides or lifters may be used to release the part from the mold before ejection.

- Post - Processing:After ejection, the plastic part may undergo post - processing steps. One common post - processing step is the removal of flash, which are thin, excess pieces of plastic that form around the edges of the part during the injection process. This can be done manually using tools like trimming knives or through mechanical processes such as tumbling. The part may also need to be trimmed to remove any remaining sprue (the channel through which the molten plastic entered the mold) and runners (the channels that distribute the molten plastic within the mold). Additionally, surface finishing operations like painting, plating, or texturing may be carried out to enhance the appearance or functionality of the product. For example, a plastic smartphone case may be painted to give it an attractive color and a smooth finish, or it may be textured to provide a better grip.

Key Components in Plastic Injection Molding

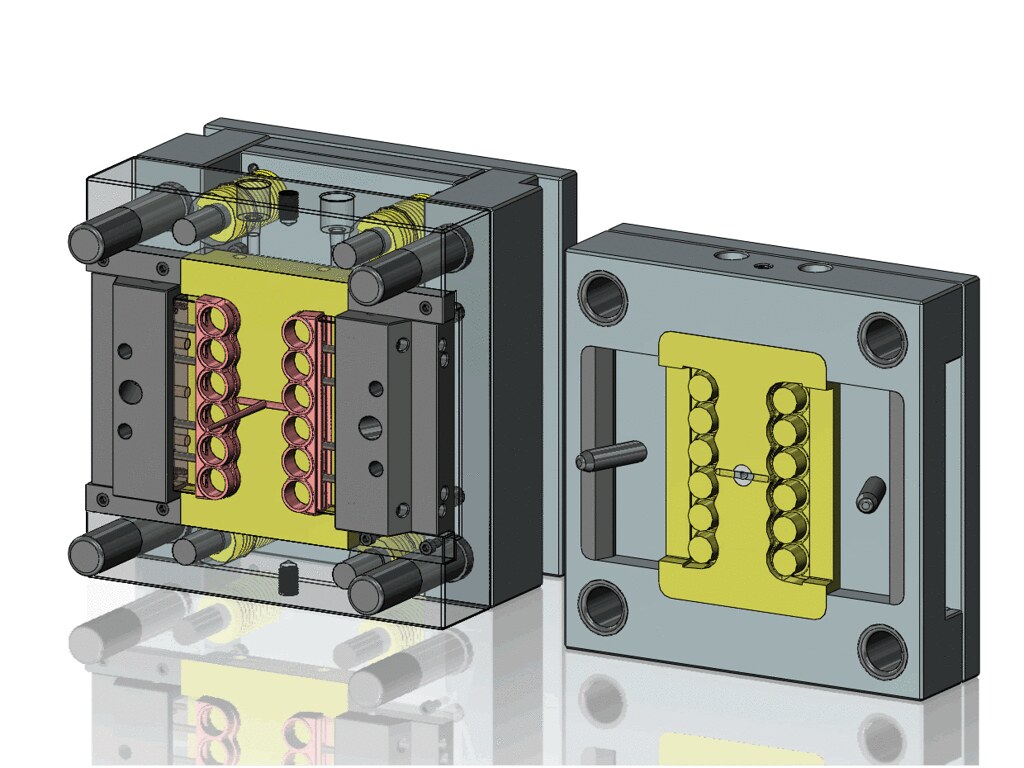

Molds

- Fixed Mold Base Plate:The fixed mold base plate is the stationary part of the mold structure. It is firmly attached to the stationary platen of the injection molding machine. Its primary function is to provide a stable foundation for the fixed mold components. It holds the fixed mold plate in place, which in turn houses the cavity. For example, in a mold for producing plastic cups, the fixed mold base plate ensures that the cavity, which gives the cup its outer shape, remains in a fixed position during the injection molding process. This stability is crucial for achieving consistent and accurate molding results.

- Movable Mold Base Plate:During the molding process, the movable mold base plate moves along with the moving platen of the injection molding machine. It is responsible for the movement that allows the mold to open and close. When the mold is closed, it aligns precisely with the fixed mold base plate, creating a sealed cavity for the molten plastic. Once the plastic has solidified, the movable mold base plate moves away from the fixed one, enabling the ejection of the finished plastic part. In the case of a mold for manufacturing plastic toys with complex shapes, the movement of the movable mold base plate allows for the easy removal of the toy after the molding process is complete.

- Fixed Mold Plate and Movable Mold Plate:The fixed mold plate is where the cavity is machined. The cavity determines the outer shape of the plastic part. For instance, if the product is a plastic container, the cavity in the fixed mold plate will have the exact shape of the outer surface of the container. On the other hand, the movable mold plate typically holds the core. The core forms the internal features of the plastic part. In the case of the plastic container, the core in the movable mold plate would create any internal dividers or hollow spaces within the container. The precise alignment and cooperation between the fixed and movable mold plates are essential for the successful formation of the plastic part.

Guiding component

- Guide Pillar and Guide Bush:Guide pillars and guide bushes play a crucial role in ensuring the accurate alignment of the fixed and movable molds. The guide pillars are typically cylindrical rods that are firmly attached to one half of the mold, usually the fixed mold. The guide bushes, which are sleeves, are installed in the other half of the mold, the movable mold. During the opening and closing of the mold, the guide bushes slide smoothly along the guide pillars. This smooth movement ensures that the two halves of the mold come together precisely, preventing any misalignment that could lead to defects in the plastic part. For example, in a high - precision mold for producing small electronic components, the guide pillars and guide bushes ensure that the cavity and core align perfectly, resulting in components with tight tolerances.

- Return Pin Guide Bush and Ejector Plate Guide Pillar (and Bush):The return pin guide bush provides a stable guiding path for the return pin. The return pin is used to bring the ejector plate back to its original position after the plastic part has been ejected. The return pin guide bush ensures that the return pin moves in a straight line, preventing any jamming or misalignment. The ejector plate guide pillar (and bush) is responsible for keeping the ejector plate moving in a straight line during the ejection process. In a mold for manufacturing plastic bottle caps, the ejector plate guide pillar and bush ensure that the ejection pins push the caps out of the mold evenly, without causing any damage to the caps.

Positioning component

- Locating Ring:The locating ring is used to accurately position the mold on the injection molding machine. It fits precisely into a corresponding recess on the injection molding machine's fixed platen. This ensures that the center of the mold aligns with the center of the injection nozzle. For example, in a large - scale production of plastic automotive parts, the locating ring ensures that the mold is positioned correctly on the injection molding machine, allowing for the efficient injection of molten plastic into the mold cavity. It is an essential component for maintaining the accuracy and consistency of the injection molding process.

- Tapered Surface Positioning and Key Positioning:Tapered surface positioning offers high - precision alignment between the mold components. The tapered surfaces on the mold parts fit together snugly, providing a more accurate alignment compared to some other methods. This is particularly useful in molds where tight tolerances are required, such as in the production of medical devices. Key positioning, on the other hand, is used to prevent relative rotation between the mold plates. A key, which is a small, shaped protrusion, fits into a corresponding keyway on the other mold plate. This ensures that the mold plates maintain their proper orientation during the molding process, which is important for the correct formation of the plastic part.

Pouring system

- Sprue, Sprue Bushing, and Nozzle Bushing:The sprue is the main passage through which the molten plastic enters the mold from the injection nozzle. It is usually a vertical channel at the beginning of the plastic's journey into the mold. The sprue bushing, made of wear - resistant material, lines the sprue. It withstands the high - speed flow of the molten plastic and helps to maintain the integrity of the sprue. The nozzle bushing connects the injection nozzle to the sprue, ensuring a smooth transition of the plastic from the nozzle into the mold. In a mold for making plastic utensils, the sprue, sprue bushing, and nozzle bushing work together to direct the molten plastic into the mold cavity accurately.

- Runner (Circular and Trapezoidal) and Gate (Side, Submarine, Pin - point, Fan):The runner distributes the molten plastic evenly to each cavity in the mold. Circular runners have a low pressure - drop, making them suitable for large - scale molds where efficient plastic distribution over long distances is required. Trapezoidal runners, on the other hand, are easy to machine and are widely used in common molds. Gates are crucial as they control the flow rate and direction of the molten plastic into the cavity. Side gates are commonly used for parts with simple shapes. Submarine gates can automatically cut off the runner from the part during ejection, which is useful for parts where a clean separation of the runner from the product is necessary. Pin - point gates are suitable for high - precision and small - sized parts, allowing for precise control of the plastic flow. Fan gates are used when a wide and thin flow of plastic is required, such as in the production of flat, thin - walled plastic products.

- Cold Slug Well:At the beginning of the injection process, the cold slug well traps the cold plastic that is present at the front of the molten plastic stream. This cold plastic, which may have cooled slightly in the nozzle or runner, can cause defects in the plastic part if it enters the cavity. By capturing this cold plastic, the cold slug well ensures that only the properly molten plastic enters the cavity, resulting in a higher - quality plastic part. For example, in the production of plastic pipes, the cold slug well prevents the cold plastic from entering the mold cavity, which could lead to weak spots or inconsistent wall thickness in the pipes.

Forming component

- Cavity (Integral and Combined) and Core (Integral, Combined, Movable):The cavity determines the outer shape of the molded part. An integral cavity, which is a single, continuous structure, is more rigid and suitable for high - pressure molding. It is often used for parts with simple shapes where high - strength and precision are required. A combined cavity, made up of multiple parts, is easier to manufacture and repair for complex - shaped parts. For example, in the production of a plastic figurine with intricate details, a combined cavity can be used to create the detailed outer shape. The core forms the internal features of the molded part. An integral core provides high - strength support for the internal structure of the part. A combined core is used to create complex internal shapes, such as in the case of a plastic container with internal ribs. A movable core is used to form undercuts or side holes in the part. In a plastic toy with a detachable handle, a movable core can be used to create the hole for the handle attachment.

- Insert:Inserts are used to create complex details or to replace parts of the mold that are prone to wear. For example, if a plastic part has a very small, detailed feature like a tiny logo or a fine texture, an insert can be used to create that feature. Inserts can also be used in areas of the mold that experience high stress or wear, such as the areas where the molten plastic enters the cavity. By using inserts, these worn - out parts can be easily replaced without having to replace the entire mold, saving time and cost. In the production of plastic phone cases with a raised brand logo, an insert can be used to create the logo on the case surface.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology has a deep - seated understanding of the importance of plastic injection molding technology. Our expertise lies in the ability to apply this technology in innovative ways to meet the unique demands of our clients.

We have a state - of - the - art manufacturing facility equipped with advanced injection molding machines. These machines are capable of handling a wide range of plastic materials, allowing us to produce high - quality non - standard products with precision. Our team of experienced engineers and technicians is well - versed in every aspect of the plastic injection molding process, from mold design to product post - processing.

One of our core strengths is our ability to customize molds according to our clients' specific requirements. We use advanced CAD/CAM technology to design and manufacture molds that can produce complex plastic - metal components. This not only enables us to meet the diverse needs of different industries but also ensures high production efficiency and product quality. For example, in the production of custom - designed plastic - metal connectors for the electronics industry, our team can optimize the mold design to achieve precise dimensional accuracy and excellent surface finish.