Introduction

Polyethylene (PE) is one of the most widely used plastics in injection molding, but working with Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) comes with distinct challenges. Manufacturers often struggle to choose between LDPE and HDPE for specific applications, optimize molding parameters for each type, and deal with issues like warping or poor dimensional stability. Whether you’re producing flexible packaging or rigid containers, understanding the differences between these polyethylene types and how to mold them effectively is crucial. This guide will explore everything from material properties to technical parameters, helping you achieve consistent, high-quality results.

Polyethylene Types

Key Varieties

- Low-Density Polyethylene (LDPE): Produced through high-pressure polymerization, LDPE has a branched polymer structure. This branching gives it low density (0.910–0.925 g/cm³) and high flexibility, making it ideal for products that need to bend or stretch.

- High-Density Polyethylene (HDPE): Made via low-pressure polymerization, HDPE has a linear polymer structure with little branching. This results in higher density (0.941–0.965 g/cm³) and greater rigidity compared to LDPE.

- Linear Low-Density Polyethylene (LLDPE): A hybrid of sorts, LLDPE has a linear structure with short branches, offering better impact resistance and puncture resistance than LDPE. It’s often used in stretch films and liners but is less common in injection molding than LDPE and HDPE.

- Polyethylene Resins: These are the raw materials used in injection molding, available in pellet form. Resins are formulated to meet specific property requirements, such as enhanced chemical resistance or improved flow.

Comparison of Structures and Properties

| Property | LDPE | HDPE | LLDPE |

| Polymer Structure | Highly branched | Linear, minimal branching | Linear with short branches |

| Density (g/cm³) | 0.910–0.925 | 0.941–0.965 | 0.915–0.925 |

| Flexibility | High | Low | Very High |

| Rigidity | Low | High | Medium |

Injection Molding Process for PE

Equipment and Cycle

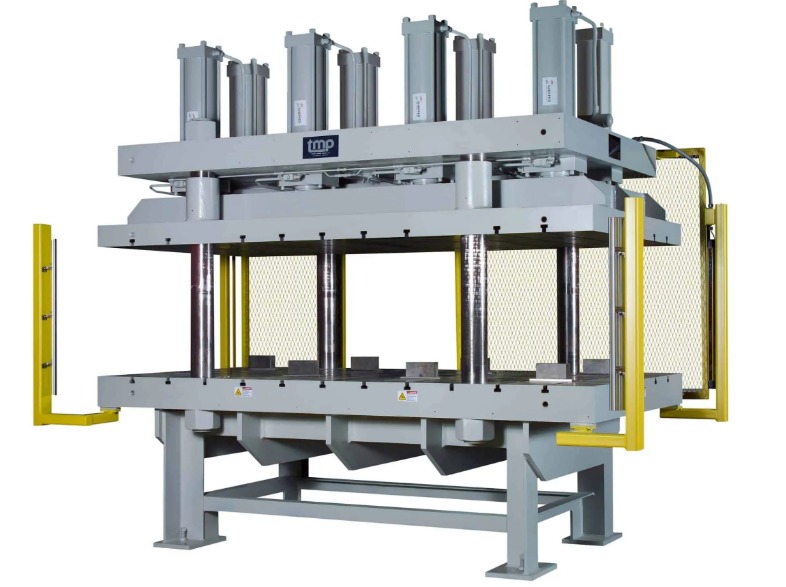

- Injection Molding Machine: Machines for PE should have a screw with a shallow flight depth to handle the low viscosity of molten PE. A screw diameter of 30–100 mm is typical, depending on part size.

- Molding Cycle: The cycle time for PE ranges from 10 to 60 seconds, with LDPE generally having shorter cycles due to its lower melting point. The cycle includes injection, holding, cooling, and ejection stages.

- Mold Design: Molds for PE need proper cooling channels to handle the material’s high thermal conductivity. For LDPE, which has higher shrinkage, molds should include shrinkage compensation. HDPE molds require precise venting to prevent air traps in rigid parts.

- Clamping Force: Clamping force depends on part size and type. For small parts, 50–100 tons may suffice, while large containers may need 200–500 tons. LDPE, with its lower viscosity, may require slightly lower clamping force than HDPE to avoid flash.

Critical Parameters

- Injection Pressure: LDPE typically requires 500–1000 bar, while HDPE needs 800–1500 bar due to its higher viscosity. Too much pressure can cause flash, especially with LDPE’s lower melt strength.

- Cooling Time: Cooling time is 10–30 seconds for thin-walled parts and 30–60 seconds for thick-walled ones. HDPE, with its higher crystallinity, takes longer to cool than LDPE.

Material Properties

Key Characteristics

- Density: As mentioned, LDPE has a lower density than HDPE, which affects both weight and performance. LDPE’s lower density makes it lighter, while HDPE’s higher density contributes to its strength.

- Tensile Strength: HDPE has higher tensile strength (22–38 MPa) compared to LDPE (7–15 MPa), making it better suited for load-bearing applications.

- Impact Resistance: LDPE offers excellent impact resistance at low temperatures, while HDPE remains tough even at higher temperatures. LLDPE outperforms both in impact resistance but is less used in injection molding.

- Flexibility: LDPE is highly flexible and can be folded or twisted repeatedly without breaking, making it ideal for squeeze bottles and flexible lids. HDPE is rigid and less flexible, suitable for rigid containers and structural parts.

- Chemical Resistance: Both LDPE and HDPE are resistant to most acids, alkalis, and organic solvents, which is why they’re used in chemical storage containers and lab equipment.

- Thermal Properties: LDPE has a melting point of 105–115°C, while HDPE melts at 120–130°C. HDPE can withstand higher temperatures, making it suitable for products that may be exposed to boiling water, such as detergent bottles.

Applications and Uses

Common Products

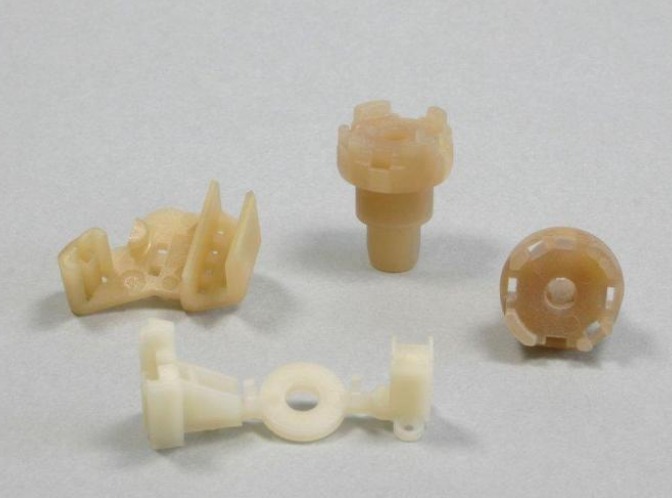

- Packaging: LDPE is used for flexible packaging like plastic bags, shrink wraps, and squeeze bottles. HDPE is used for rigid packaging such as cereal box liners and detergent containers.

- Containers and Bottles: HDPE is the go-to material for milk jugs, water bottles, and food containers due to its rigidity and chemical resistance. LDPE is used for squeeze bottles (e.g., honey, mustard) because of its flexibility.

- Automotive Parts: HDPE is used in automotive fuel tanks, battery cases, and interior trim due to its strength and chemical resistance. LDPE finds use in gaskets and seals.

- Consumer Goods: LDPE is used in toys, shower curtains, and squeeze toys. HDPE is used in cutting boards, trash cans, and storage bins.

- Industrial Components: HDPE is used for pipes, fittings, and chemical storage tanks. LDPE is used in liners and protective covers.

Technical Parameters

Molding Specifications

- Melting Temperature: LDPE melts at 105–115°C, while HDPE melts at 120–130°C. It’s important to set the melt temperature correctly to ensure proper flow without thermal degradation.

- Flow Rate: LDPE has a higher flow rate than HDPE, making it easier to fill complex molds. HDPE’s lower flow rate requires higher injection pressure to fill thin-walled sections.

- Shrinkage Rate: LDPE has a higher shrinkage rate (1.5–3.0%) than HDPE (1.0–2.5%). This must be accounted for in mold design to ensure dimensional accuracy.

- Surface Finish: Both LDPE and HDPE can achieve a smooth surface finish, but HDPE is more prone to surface defects like sink marks if the molding process isn’t optimized.

- Dimensional Stability: HDPE has better dimensional stability than LDPE due to its lower shrinkage and higher crystallinity, making it suitable for parts with tight tolerances.

- Post-Processing: PE parts can be welded, glued, or printed on, but surface treatment (e.g., corona discharge) may be needed to improve adhesion for printing or bonding.

Yigu Technology's View

As a parts custom manufacturing supplier, Yigu Technology has extensive experience in injection molding both LDPE and HDPE. We understand the nuances of each material, from optimizing injection pressure for HDPE’s rigidity to ensuring proper cooling for LDPE’s flexibility. Our expertise in mold design for polyethylene ensures dimensional accuracy and reduces defects. Whether you need flexible packaging or rigid containers, we deliver high-quality PE parts tailored to your needs, leveraging our knowledge of material properties and process parameters.

FAQs

- Can LDPE and HDPE be recycled together?

No, LDPE and HDPE are recycled separately. LDPE is marked with resin code 4, while HDPE uses code 2. Mixing them can reduce the quality of the recycled material.

- Which is more cost-effective, LDPE or HDPE?

LDPE is generally slightly more expensive than HDPE due to the high-pressure polymerization process. However, the cost difference is minimal, and the choice should be based on performance requirements rather than cost alone.

- Can PE parts be used in food contact applications?

Yes, both LDPE and HDPE are FDA-approved for food contact. They are non-toxic and resistant to food acids and oils, making them safe for food packaging and containers.