Introduction

Polylactic Acid (PLA) has become a star in the sustainable manufacturing world, but working with it in injection molding isn't without challenges. Manufacturers often struggle with its moisture sensitivity—even small amounts of moisture can ruin a batch. They also face issues like warpage due to PLA's unique cooling behavior and difficulty achieving consistent part quality. Selecting the right grade for specific applications and optimizing the molding process to prevent degradation are common headaches. This guide dives into every aspect of PLA injection molding to help you overcome these obstacles.

1. Material Properties of Polylactic Acid (PLA)

PLA stands out for its biodegradability and compostability; it breaks down in industrial composting facilities within 3-6 months, meeting standards like ASTM D6400. Derived from renewable resources such as corn starch and sugarcane, it has a low environmental impact compared to petroleum-based plastics.

In terms of mechanical properties, PLA offers good mechanical strength with a tensile strength ranging from 40 to 60 MPa—comparable to polystyrene. However, its elongation at break is relatively low, typically 3-5%, making it brittle compared to more flexible materials.

Thermal stability is a key consideration. PLA has a glass transition temperature around 55-60°C, meaning it softens significantly above this point. Its melting point is 150-170°C, which is lower than many traditional plastics.

One of PLA's biggest advantages is its optical clarity—it's nearly transparent, making it ideal for applications where visibility matters. It also boasts biocompatibility, with medical-grade PLA used in absorbable sutures and implants. But moisture sensitivity is a downside; it absorbs water quickly, leading to hydrolysis and degradation during processing.

2. Injection Molding Process for PLA

2.1 Critical Process Parameters

- Melt Temperature: PLA typically processes at 180-210°C. Going above 220°C increases the risk of thermal degradation, which reduces molecular weight and causes brittleness.

- Injection Speed and Pressure: A moderate injection speed (30-50 mm/s) works best. Higher speeds can cause shear heating and degradation. Injection pressure ranges from 500-900 bar, with thin-walled parts needing the higher end.

- Cooling Time and Cycle Time: Cooling time is 8-15 seconds for most parts, as PLA solidifies quickly. Total cycle times usually fall between 20-40 seconds, making it efficient for high-volume runs.

2.2 Material Handling Best Practices

Drying requirements are non-negotiable for PLA. It should be dried at 60-80°C for 4-6 hours in a dehumidifying dryer, reducing moisture content to below 0.02%. Even 0.05% moisture can cause voids and surface defects.

Humidity control is crucial in storage—keep PLA pellets in sealed bags or containers with desiccants, and store in a room with relative humidity below 40%. Never leave PLA exposed to ambient air for more than 30 minutes before processing.

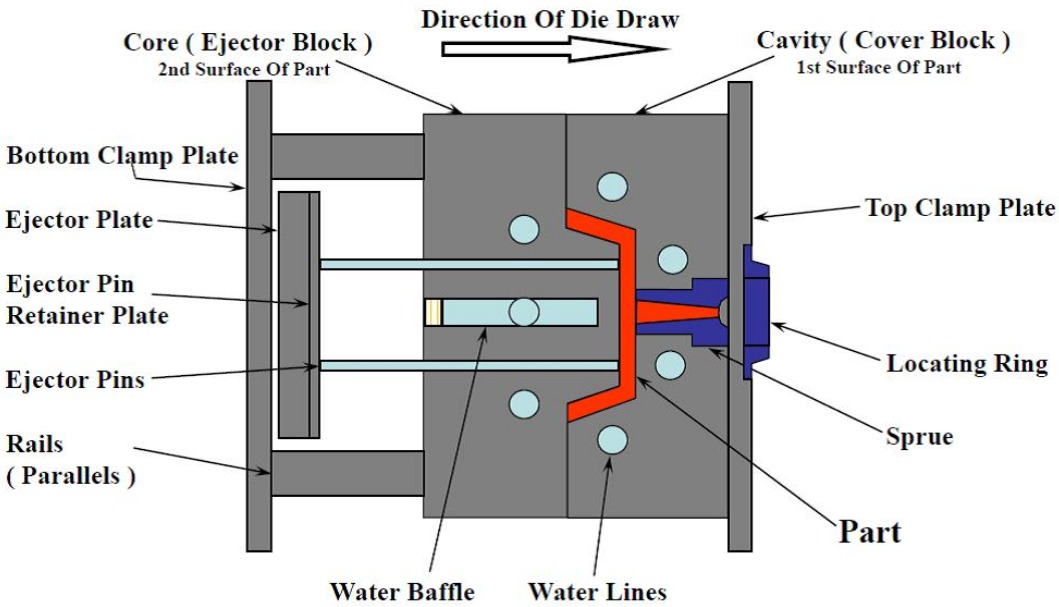

3. Mold Design for PLA Molding

3.1 Key Design Features

- Venting Requirements: PLA can trap air easily, so vents should be 0.01-0.02 mm deep and 8-10 mm wide, placed at the end of flow paths and around ribs. Inadequate venting causes burn marks and short shots.

- Cooling Channel Layout: To prevent warpage, cooling channels should be 8-10 mm from the cavity surface, with a diameter of 6-8 mm. Use a 2:1 ratio of channel length to diameter for efficient cooling.

- Draft Angles and Surface Finish: A minimum draft angle of 1° per side is needed for easy ejection, increasing to 2° for textured surfaces. A smooth surface finish (Ra 0.4-0.8 μm) improves part release and appearance.

3.2 Mold Materials and Systems

P20 steel is the standard for PLA molds, offering good machinability and durability. For high-volume production, H13 steel with a nitride coating (50-70 μm thick) reduces wear.

Hot runner systems can be used but require precise temperature control (180-200°C) to avoid PLA degradation. Insulate hot runners from the cold mold to prevent premature solidification.

4. Quality Control and Defects in PLA Molding

4.1 Common Defects and Solutions

| Defect | Cause | Solution |

| Warpage | Uneven cooling or mold temperature variation | Balance cooling channels; set mold temperature to 40-50°C |

| Voids | Moisture in material or insufficient packing | Improve drying; increase packing pressure by 10% |

| Flash | Excessive injection pressure or mold wear | Reduce pressure; check and repair mold seals |

| Surface Defects | Contaminated material or poor flow | Use clean resin; increase melt temperature slightly |

4.2 Quality Control Measures

Implement statistical process control to monitor melt temperature, injection pressure, and cooling time, with variations kept within ±2%. Conduct degradation testing by measuring the melt flow rate (MFR) of processed PLA—an increase of more than 20% indicates degradation.

Dimensional accuracy should be checked with CMMs, aiming for tolerances of ±0.1 mm for parts under 50 mm and ±0.2 mm for larger parts. Visual inspections every 30 minutes catch surface defects early.

5. Applications of PLA in Injection Molding

5.1 Key Application Areas

- Packaging Materials: PLA's optical clarity makes it ideal for food containers, clamshell packaging, and blister packs. It provides a clear view of products while offering sustainability.

- Single-use Products: Cutlery, straws, and disposable cups made from PLA are widely used, decomposing quickly in composting facilities.

- Medical Devices: Biocompatible PLA grades are used for surgical sutures, drug delivery devices, and temporary implants that dissolve in the body over time.

- Consumer Products: Toys, cosmetic containers, and electronic device casings benefit from PLA's combination of appearance and eco-friendliness.

6. Post-Processing and Finishing of PLA Parts

6.1 Effective Techniques

- Painting and Coating: Use acrylic or water-based paints, as solvent-based paints can craze PLA. Clean surfaces with isopropyl alcohol before painting for better adhesion.

- Ultrasonic Welding: Works well for PLA, using 20-30 kHz frequencies and weld times of 0.5-1.5 seconds. Ensure parts have a energy director for strong bonds.

- Machining and Trimming: PLA machines easily with high-speed steel tools. Use cutting speeds of 1000-1500 RPM to avoid melting, and keep tools sharp to prevent chipping.

Yigu Technology, a leading custom manufacturing supplier in China, specializes in PLA injection molding. We understand PLA's unique characteristics and optimize processes to deliver high-quality, sustainable parts. Our expertise in mold design and process control ensures consistent results, making us a trusted partner for businesses seeking eco-friendly manufacturing solutions.

FAQs

- Can PLA parts withstand high temperatures?

No, PLA softens above 60°C, so it's not suitable for hot applications. For higher temperature resistance, use PLA blends with heat stabilizers, which can withstand up to 80°C.

- How long can PLA parts be stored before degradation?

Properly stored (sealed, dry, cool conditions), PLA parts remain stable for 1-2 years. Exposure to heat, moisture, or UV light accelerates degradation.

- Is recycled PLA suitable for injection molding?

Yes, but recycled PLA should be blended with 50% or more virgin resin to maintain mechanical properties. It's best for non-critical applications like packaging.